The feasibility of applying thermal analysis to study of oil–containing rocks and organic matter is reviewed. Using heavy crudes from the Ashal’cha and Mordovo-Karmal fields, the potential for analysis of the effectiveness of iron-containing precursors of aquathermolysis catalysts is demonstrated with use of data derived from thermal analysis. The thermal effects detected in the presence of the catalyst precursor, as compared with the original sample, reflect decomposition of the catalyst precursor and degradation processes for the components of the crude oil activated by the catalyst. It is shown that use of thermal analysis is feasible for preliminary selection or optimization of catalyst compositions for in-situ upgrading of crude oils, taking into account the activity of the catalyst relative to certain components of the crude in a specific temperature range.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Exploitation of reserves of heavy high-viscosity crudes and natural bitumens is an important stage of stabilization of oil recovery in both Russia, and also Tatarstan [1–4]. Characteristics of the composition of heavy crudes, which determine their high viscosity, require use of recovery technologies that differ from those employed for light crudes, including technologies based on intra-pool steam-heat treatment – aquathermolysis [5]. The term “aquathermolysis” had been introduced in 1982 by J. B. Hyne et al. [6]. Oil- and water-soluble, as well as ultra-disperse catalysts, which can be introduced to the pool by pressure injection of steam, make it possible to improve the effectiveness of the steam-heat methods employed [5].

During aquathermolysis, the effect on the stratal oil is accompanied not only by a change in viscosity, but also in the element, group, and fractional compositions. In developing recovery procedures for heavy crudes, therefore, the existence of analytical methods permitting reliable evaluation of the influence exerted by catalysts and other factors on variation in the properties of the fluid being recovered is no less important.

Determination of content and fractional composition of organic matter

Pyrolytic methods directed toward deep investigation of the composition and properties of organic matter in rock allow for acquisition of the data required for solution of theoretical and applied problems of oil-gas prospecting and the oil-gas branch of geochemistry [7–15]. As compared with others, this method is more effective for determination of the content of organic matter (OM) in rock. The Rock-Eval method, which combines thermal analysis and chromatography, has been widely employed since the 1980s to assess the capacity of rocks to generate hydrocarbons in practical geochemical investigations [14]. In the pyrolysis process, a flame-ionization detector records three peaks The first peak S 0 reflects the content of free (sorbed) gas-forming and low-boiling liquid hydrocarbons (C1– C7). The moderate thermal effect (~300°C) on a sample will cause low-boiling hydrocarbons (C8–C33) to be released from rock (S 1). In the thermal-decomposition interval of kerogen (300 – 600°C), a third peak S 2 is observed [15].

In addition to the Rock-Eval method, differential thermal analysis (DTA), which combines differential thermal gravimetric analysis (DTG) with differential scanning calorimetry (DSC), have come into widespread use for analysis of oil-containing rocks and petroleum fluids [16]. A change in the enthalpy ΔH occurs as a result of the majority of physico-chemical processes and chemical reactions [17]; theoretically, therefore, the DTA method can be applied to a large number of systems [16–38] containing both inorganic, and also organic substances. Exothermal effects are manifested on the DTA curves as a result of the following processes: conversion from of an amorphous to crystalline state, conversion from a polymorphic state of an unstable modification to a stable state, oxidation or reduction of components of the material, and, burn-off of carbonaceous deposits on catalysts, sorbents, etc. Endothermic effects appear during decomposition of the contact mass with and without separation of the gaseous phase (removal of adsorption and crystallization water, and water of constitution, and separation of NOx and CO2), as well as during liquefaction of the material, etc.

Thermal analysis is widely employed to evaluate the mineral composition of bitumen-saturated rocks, and their potential OM content, and its thermal stability [18]. The presence of crystalline phases of solid waxes with respect to endothermic fusion peaks is observed in crudes by the method of thermal analysis. It is also possible to assess their content and composition. It is proposed in [19] that the original parameters of complex thermal analysis, which Yusupova et al. [20] have used for identification of crudes, be employed for analysis of the composition of paraffins in bitumen-tar-paraffin deposits.

Destruction of alkanes of normal and isoprenoidal structure occurs most rapidly and readily under conditions of thermoloysis. The greater part of the structural characteristics of the initial compositions is retained during thermolysis [21]. Breaking of aliphatic chains from the cyclical structures, which takes place without pronounced selectivity, is the basic direction taken by the thermal destruction process.

Uisipova et al. [22] propose a procedure for determination of the content of OM locked in the pores and its fractional composition with use of complex thermal analysis. Preliminary tests were conducted for optimal experimental conditions. Open platinum crucibles were used, and the weight of the specimens of oil-containing rocks was 600–700 mg. and the heating rate 10 deg/min. The atmosphere in the furnace was maintained constant. Aluminum oxide was employed as an inert medium. Using the method of thermal analysis, it is possible to determine the content of organic matter in rocks formed from deposits of various ages: Permian Lower-Carboniferous, and Upper- and Middle-Devonian, and rocks of a crystalline foundation [23–26]. These data are used to interpret results of tests simulating transformation of organic matter during hydrothermal processes that occur under natural conditions, and during oil recovery by thermal methods.

An important advantage of the synchronous DTA-TG-DTG technology, as compared with other physical and chemical methods of analysis, is the possibility of acquiring complete information on the thermal transformations that take place in the specimen under investigation. It is possible to determine and study not only concentrated OM, but also dissipated OM with a concentration of less than 0.25%. Thermal analysis makes it possible to study the thermal decomposition of OM, and determine qualitative and quantitative characteristics that vary during its transformation [27].

A small endothermic peak in the 100-110°C interval on the DTA curves for specimens of oil-containing rock (Fig. 1) refers to release of adsorbed water [22]. Thermal oxidative destruction of OM in rock is initiated in the 130-200°.C temperature interval, and is completed at 600-700°C. The weight losses sustained in the 130-700°C interval correspond to the total OM content. Two basic stages of thermal oxidative destruction of OM may differ noticeable on the DTA and DTG curve. They are associated with evaporation and thermooxidation of the light and medium fractions (130-400°C), and with thermooxidative destruction of the high-molecular fractions (400-700°C). The ratio of the weight loss m 2 in the first stage of destruction to the weight loss m3 in the second stage characterizes the fractional composition of the OM. Repyakh et al. [27] have called this ratio the F index of the fractional composition of OM. It should be pointed out that the release of structural water from clays is superposed on the thermooxidative destruction of the heavy OM fractions within the range from 500 to 700°C for rock specimens containing clayey minerals as impurities. If the specimen is representative of carbonates, their content may be determined from characteristic effects in the temperature region from 600 to 1000°C. Let us also note the need for investigation of rock specimens after OM extraction by organic solvents for more accurate interpretation of data derived from thermal analysis.

Curves of thermal analysis of specimens of oil-containing rock [22].

Thermal analysis by a similar procedure was used in [27] to assess the effectiveness of ultrasonic treatment of oil-bitumen rocks. The content of adsorbed water, bitumen, and its fractional-composition index, as well as the carbonate content were determined in the rocks. Based on data derived from thermal analysis, the fractional composition index and indicator P characterizing the mass fraction of peripheral substituents in the condensed aromatic structures of a medium molecule [28], or the presence of high-molecular paraffins were determined from samples extracted from the rock.

A comparative estimate of two specimens of bitumen-containing rocks distinguished by bitumen content and mineral composition was conducted in [29] by the method of thermal analysis. In specimen 1 (Fig. 2, a), the bitumen content is ~ 35%, and clayey and carbonate minerals are present in the rock. Weight losses in the 720-820°C interval (decomposition of carbonates with liberation of CO2) suggest the presence of carbonates. In specimen 2, the content of bitumen is ~ 18%. Essentially the same values of the fractional-composition index for both bitumens (F = 0.8) suggest their similar composition. The value of index P for bitumen 1 is nearly twice that of bitumen 2, and most likely suggests a large fraction of high-molecular paraffins. In confirming this supposition, the endotherm of the meltingof the crystalline phase of the solid paraffins is observed on the DSC curve of bitumen 1 in the temperature interval from 35 to 60°C.

Curves of thermal analysis of specimens of oil-bitumen rock in Imankara field [29]: a) specimen 1; b) specimen 2.

Shishkin et al. [30] investigated thermal analysis in conjunction with the photometric method of mirror reflection to determine the recrystallization and melting points of individual paraffins and their mixtures Platforms on the mirror-reflection curve – steps – are observed in the region of phase transitions on the heating curves of the individual paraffins. In the case of paraffin blends, there are no platforms on the heating curves, while the steps are retained on the mirror-reflection curves.

The content of insoluble OM that remains in the rock after extraction by organic solvents can be determined by the method of thermal analysis.

The OM extracted from the rock is characterized qualitatively by the TG curve of weight losses in different stages of oxidative destruction:

-

stage I (170-410°C) – region of low-temperature oxidation in which decomposition reactions take place primarily in the aliphatic portion of the OM molecules, including the portion with broken C – O, C – N, and C – S bonds, i.e., primarily with detached alkyl substituents; and,

-

stage II (410-700°C) – high-temperature oxidation with decomposition of heavy condensed components.

The ratio of weight loss of a specimen in stages I and II was used by Kayukova et al. [31] for a comparative characteristic of high-viscosity oils and natural bitumens (maltha, asphalts, and asphaltites). The decrease in this ratio suggests a reduction in the aliphatic nature of the OM, owing to which it is enriched with heavy condensation structures. Moreover, the method in question permits indirect evaluation of the content of compounds with different thermal stability, and, consequently, tracing of their fractional participation in the genesis of the organic matter [32].

A method of defining the stages of the thermal destruction of substances and materials is known [33]. Here, the temperature, mass, and derivative of the mass with respect to time or temperature are measured during the heating process, and acoustic-emission signals that accompany accumulation of structural defects under the temperature effect are simultaneously received.

In [34], the influence exerted on the combustion process of heavy crudes by the heating rate and content of various clays in the reaction system is studied by the TGA-DTGA method. A significant change in the thermal and kinetic properties of the crude was observed when clays were added to the porous matrix (crude + limestone). It is noted that the heating rate affects the intervals of the reactions, peaks, and combustion temperatures. Two basic regions of reactions were observed for all combinations of crude + limestone, and, to wit, low-and high-temperature combustion. The significant effect of particle size of the limestone matrix on the combustion parameters of the heavy crude is also established from the TGA-DTGA data. [35].

Thermal analysis is widely used for investigation of heterogeneous entities. A method [36] for determination of the content of filler in a polymeric composite, the essence of which consists in heating a specimen of a material consisting of several components and having a heterogeneous structure with a phase interface up to the decomposition temperature of the polymeric component, has been patented. A method for determination of the relationship between the components in two-component poly-mineral clayey mixtures, which consists in heating of specimens under investigation at a rate of 10 deg/min, and use of initial poly-mineral clays that enter into the composition of the mixture under consideration as standards, is proposed in [37].

Use of thermal analysis for catalyst selection

The thermal analysis outlined in [38] is utilized to determine the temperature domain of stable performance of zeolite catalysts. Programmed heating of a catalyst specimen is carried out in a reaction chamber, and the lower temperature boundary is defined by the deviation of the path of the thermogram from the zero line.

Programmed heating and cooling of the specimen then proceed in an oscillatory regime that ensures passage through the maximum on the cooling curve. The maximum temperature of the last cycle is adopted as the upper temperature boundary. Using thermal analysis, Rahman and Venkataraman [39] investigated thermal effects of the decomposition of ferrous-gluconate dihydrate FeC12H22O14·2H2O. A broad endothermic peak (~108°C) corresponding to losses of two molecules is observed on the DTA curve (Fig. 3). The TG curve also indicates water losses in the 40-140°C interval. Oxidative decomposition of the FeC12H22O14 complex is accompanied by the presence of four exothermic peaks at 220, 293, 350, and 421°C on the DTA curve. It is established that the first exothermic peak corresponds to formation of a mixture of FeO and water-free gluconate. Formation of a mixture of FeO and Fe3O4 occurs at 280°C. At 350°C, the exothermic peak reflects formation of mixed phases Fe3O4 and Fe2O3, while pure iron oxide Fe2O3- is formed at 421°C. No similar broad peaks are observed to form on the DTG curves at these same temperatures (see Fig. 3). The TG curve indicates, however, two stages of weight loss, and the continuous weight loss from 140 to 478° corresponds to formation of Fe2O3.

Curves derived from thermal analysis of FeC12H22O14·2H2O in air atmosphere [39].

Based on analysis of literature information relative to thermal methods of investigation, interest has been focused on use of the method of thermal analysis as a rapid test method for catalyst precursors in developing procedures for intra-pool refinement of heavy crudes. For example, the procedure in question may be useful in the stage of preliminary selection of catalyst precursors, or investigation of the composition of catalysts for determination of its optimal formulation.

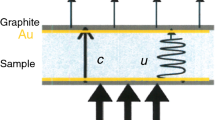

Catalytic aquathermology has been experimentally simulated on model systems with use of a synthesized oil- and water-soluble catalyst precursor based on iron (III). The model system consisted of an inert medium (aluminum oxide) and a heavy-crude specimen in a 9:1 ratio. The catalyst precursor was added to the crude in the amount of 10 wt. %. Thermal analysis was performed on an NETZSCH STA 499F3 instrument at a heating rate of 10 deg/min within the temperature interval from 30 to 700°C in a stationary air medium; the weight of a micro-batch of the modeled mixtures was 50 ± 10 mg.

Heavy crudes from the Ashal’cha and Mordovo-Karmal fields in the Tatarstan Republic served as subjects of investigation. The crudes investigated are distinguished by group composition and density (see Table 1). The crude from the Ashl’cha field is heavier: it contains less hydrocarbons and more tars and asphaltenes. Based on data derived from gas–liquid chromatography (GLC), the crudes investigated are referred to the same B2 chemical type [40], of which the presence of isoprenoidal alkanes C14– C20 is characteristic in the clear absence of n-alkanes.

On the DSC curve (Fig. 4), two broad exothermic peaks at 341°C and 460-465°C are apparent in the compositions of these crudes. prior to introduction of the catalyst precursor The crudes are distinguished by the intensity of the indicated peaks, suggesting their different stability under the thermal effect.

Introduction of the catalyst precursor to the model system gives rise to certain changes in the DSC curves and exothermic effects. Changes during catalytic oxidation of the Ashal’cha crude are most pronounced. The maximum temperature of appearance of the first exothermic peak is not significantly different from that peak for the initial crude, although its minor shift from 341 to 337°C in the low-temperature region can be noted. The width of this peak is appreciably expanded as a result of the appearance on the DSC curve of a new exothermic peak on the shoulder of the first one at 390°C. A noticeable drop in the height of the second exothermic peak and its shift into the higher-temperature region from 465 to 498°C is observed. Since low-temperature oxidation primarily with detached alkyl substituents occurs in the first stage of thermal oxidative destruction in the 170-410°C temperature region as a result of rupture of the least thermally stable C – O, C – N, and C – S bonds, and high-temperature oxidation reactions with decomposition of the heavy condensed components takes place in the 410-470° C interval in the second stage [16], the data derived from thermal analysis suggests the effect of the catalyst under investigation on the destruction primarily of the high-molecule components of the heavy oil with formation of hydrocarbons with a lower boiling point.

In contrast to the Ashal’cha crude, only an insignificant shift in the maximum temperature of the second exothermic peak into the higher-temperature region is observed on the DSC curve of the Mordovo-Karmal field: from 360°C to 475°C. An increase in the intensity of the peak at 340°C, which corresponds to low-temperature oxidation with detached alkyl substitutes, is more clearly expressed for this crude. As in the case of the Ashal’cha crude, an exothermic peak is manifested at 390°C in the first stage of oxidative destruction. The phenomena observed is more than likely caused by thermal destruction of the high-molecule components of the crude, which may be initiated by the catalyst [39].

Our attention is turned to pronounced reduction in the intensity of the thermal effect of oxidation on the Mordovo-Karmal crude in th presence of the catalyst within the high-temperature region from 500 to 600°C and a certain difference in the TG curves of the crudes investigated. Thus, the weight loss of the Ashal’cha crude is initiated at lower temperatures in the presence of the catalyst. In the case of the Mordovo-Karmal crude, rapid weight loss occurs only in the high-temperature region (above 300°C). This suggests less resistance to breaking of bonds in the structures of the high-molecule components of the Ashal’cha crude in the presence of the catalyst as compared with the Mordovo-Karmal crude.

Differences in the component and hydrocarbon compositions of these crudes are manifested under conditions of differentially thermal analysis both prior to, and after introduction of the catalyst precursor to the model system. It is possible to judge the decomposition of the catalyst precursors, the interaction between the catalyst and components of the crude, and destruction of the components of the crude from the change in the height of the peaks or the shift in the thermal effects on the DSC curves. The effectiveness of the different catalytic systems proposed for intensification of steam-heating methods in the recovery of heavy crudes is possible by the proposed method.

References

R. Kh. Muslimov, G. V. Romanov, G. P. Kayukova et al., Neft. Gaz. Novatsii, No. 2, 21–29 (2012).

R. S. Khisamov, N. S. Gatiyatullin, I. E. Shargorodskii et al., Geology and Exploitation of Natural-Bitumen Reservoirs in the Tatarstan Republic [in Russian], Fen, Kazan’ (2007).

A. K. Kurochkin and S. P. Toptygin, Sfera Neftegaz, No. 1, 92–96 (2010).

B. P. Tumanyan, G. V. Romanov, D. K. Nurgaliev et al., Khim. Tekhnol. Topl. Masel, No. 3, 6–8 (2014).

S. K. Maity, J. Ancheyata, and G. Marroquin, Energy & Fuels, 24, 2809–2816 (2010).

J. B. Hyne, J. W. Greidanus, J. D. Tyrer et al., In: Second International Conference “The Future of Heavy Crude and Tar Sands,” Caracas, Venezuela, 7–17 February 1982, McGraw Hill, New York (1984), pp. 404–411.

B. Tisso and D. Velte, Formation and Propagation of Crude Oil [Russian translation], Mir, Moscow (1981).

V. N. Melenevskii, Methodological Recommendations for Use of the Pyrolytic Method in Organic Geochemistry [in Russian], SNIIGTiMS, Novosibirsk (1985).

A. É. Kontorovich, V. N. Melenevskii, A. S. Fomichev et al., Geol. Neft. Gaza, No. 12, 36–41 (1986).

K. E. Peters, AAPG Bull., 70, 318–329 (1986).

N. V. Lopatin and T. P. Emets, Pyrolysis in Oil-Gas Geochemistry [in Russian], Nauka, Moscow (1987).

N. V. Lopatin and T. P. Emets, Geokhim., No. 12, 1751–1762 (1988).

K. E. Peters, C. C. Walters, and J. M. Moldowan, The Biomarker Guide, Cambridge University Press, New York (2005).

J. Espitalie, F. Marquis, and J. Barsony, Geochemical Logging by the Oil Show Analyzer, Butterworth, London (1984).

E. A. Glebovskaya, Modeling of Catagenesis Processes of Organic Matter and Oil and Gas Formation [in Russian], Nedra, Leningrad (1984).

N. A. Nechitailo, Khim. Tekhnol. Topl. Masel, No. 4, 40–43 (1988).

E. AS. Boiko, Complex Thermal Analysis of Solid Organic Fuels [in Russian], Krasnoyarsk (2006).

N. A. Savitskaya, Thermal Methods of Investigating Oil- and Gas-Generation Characteristics of Organic Matter in Rock [in Russian], VNIGRI, Leningrad (1988)..

T. N. Yuspova, L. M. Petrova, Yu. M. Ganeeva et al., Neftekhim., No. 4, 254–259 (1999).

T. N. Yusupova, Yu. M. Ganeeva, D. A. Khalikova et al., Neftekhim., 52, No. 1, 17–24 (2012).

G. N. Gordadze, Thermolysis of Organic Matter in Oil- and Gas-Prospecting Geochemistry [in Russian], Izdatel’stvo IGi RGI, Moscow (2002).

T. N. Usupova, L. M. Petrova, R. Z. Mukhametshin et al., J. Term. Anal. Calorim., 55, 99–107 (1999).

A. M. Kiyamova, G. P. Kayukova, G. V. Romanov et al., In: Materials Presented at the International Scientific-Practical Conference “Oil Refining “2008” [in Russian], TUP INKhP PB, Ufa (2008), pp. 32–35.

A. M. Kiyamova, G. P. Kayukova, V. I. Morozov et al., Tekhnol. Neft. Gaza, No. 1, 40–47 (2007).

A. M. Kiyamova, G. P. Kayukova, Yu. M. Ganeeva et al., In: Materials Presented at the International Scientific Practical Conference “Critical Problems of the Latter Stage of Exploitation of Oil and Gas Producing Regions [in Russian], FEN, Kazan’ (2006), pp. 236–241.

G. P. Kayukova, A. M. Kiyamova, I. P. Kosachev et al., In: Collection of Materials Presented at the Conference “Non-Traditional Hydrocarbon Reserves: Propagation, Genesis, Predictions, Prospects for Development [in Russian], GEOS, Moscow (2013), pp. 91–94.

N. A. Repyakh, Yu. M. Ganeeva, T. N. Yusupova et al., Vestn. Kazan. Tekhnol. Univ., 15, No. 6, 170–173 (2012).

T. N. Yusupova, L. M. Petrova, Yu. M. Ganeeva et al., Neftekhimiya, No. 4, 254–259 (1999).

D. A. Khalikova, A. Z. Tukhvatullina, Yu. M. Ganeeva et al., Vestn. Kazan. Tekhnol. Univ., No. 5, 349–357 (2009).

Yu. L. Shishkin, I. V. Yazynina, and E. V. Ovchar, Khim. Tekhnol. Topl. Masel, No. 1, 47–50 (2008).

G. P. Kayukova, G. P. Kurbskii, R. K. Gabitova et al., Geokhimiya, No. 12, 1748–1756 (1993).

N. A. Savitskaya, Investigation of Oil- and Gas-Generated Characteristics of Organic Matter in Rock by Thermal Methods [in Russian], VNIGRI, Leningrad (1988), p.103.

Russian Federation Patent No. 2324923.

M. V. Kock, Fuel Proc. Tekhnol., 96, 134–139 (2012).

M. V. Kock, Energy Sources, Part A, 36, 923–928 (2014).

Russian Federation Patent No. 2488101.

Russian Federation Patent No. 2284516.

Russian Federation Patent No. 1718074.

M. M. Rahman and A. Venkataraman, J. Therm. Anal. Calorim., 68, 91–101 (2002).

A. A. Petrov, Petroleum Hydrocarbons [in Russian], Nauka, Moscow (1984).

This study was performed through facilities of a subsidiary independent of the Kazan’ Federal University for fulfillment of a government assignment within the sphere of scientific activity.

It was carried out through facilities of a subsidiary isolated within the framework of government support for the Kazan’ Federal University for purposes of improving its competitiveness among the world’s leading scientific and educational centers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 6, pp. 75 – 80, November – December, 2014.

Rights and permissions

About this article

Cite this article

Vakhin, A.V., Morozov, V.P., Sitnov, S.A. et al. Application of Thermal Investigation Methods in Developing Heavy-Oil Production Technologies. Chem Technol Fuels Oils 50, 569–578 (2015). https://doi.org/10.1007/s10553-015-0565-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-015-0565-1