Abstract

To establish a reliable, reproducible and accurate release of the drug in the gastrointestinal tract, a novel release mechanism for a controllable drug-delivery system has been investigated. The release mechanism, consisting of a one-way valve for drug release, a drug chamber, two axially magnetized cylindrical permanent magnets and a multi-layer solenoid coil, is hosted in the capsule-shaped shell with diameter 11 mm and length 30 mm. To actuate the coil piston, the two static magnetic fields produced by the two magnets are aligned along the same axis, having the same magnitude, but opposite directions. Based on the principle of the electromagnetic force and the Bernoulli equation, the actuating force can be expressed as a function of the coil stroke and the excitation current, which was modeled and experimentally verified. Thus the actuating force can be controlled by adjusting the activated period and intensity of the coil, resulting in the reproducible release with different doses and mean rates. Then, a prototype of the drug-delivery system has been developed, which consists of a drug-delivery capsule, a radio frequency transmission module, an interface circuit, and an instruction setting and triggering platform. All the drug release parameters, including the release mode, times, dose and mean flow rate, can be set by the platform. The experiment verifies that the drug-delivery capsule can deliver a predetermined dose with different flow rates and dip angles of the capsule. The relative error of the releasing dose becomes larger with increasing releasing rate and decreasing releasing dose.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

There is the clinical need to target and treat specific pathologies, such as Crohn’s disease, obscure gastrointestinal bleeding, and small intestinal tumors (Rasouli et al. 2016). Controllable drug-delivery systems (Goffredo et al. 2015; Mapara and Patravale 2017) aim to deliver a specific amount of a given drug at an exact place of the gastrointestinal (GI) tract through the progressive release of medication. Recently, the systems have been developed for therapeutic treatment of diseases in the GI tract as well as for drug absorption studies (Becker et al. 2014).

Some attempts have been made to establish a reliable and accurate release mechanism. The Enterion™ capsule (Parasrampuria et al. 2015) is already commercially available, which can deliver solutions, suspensions, or powders to specific sites within the GI tract, with the location of the capsule determined using gamma scintigraphy. However, it can not implement an intelligent release of a specific amount.

The electromagnetic actuation mechanism, consisting of two ring-type soft magnets and a simple plastic hinge, is developed (Le et al. 2016). First, the drug is encapsulated by the attracting force between the two axially magnetized soft-magnets. At the target lesion, the two soft-magnetic rings are demagnetized and then radially magnetized. A strong pulsating magnetic field in a radial direction is applied, and the encapsulated drug can be released. The proposed release mechanism can be activated without any battery power, yet it is difficult in controlling the release dose and release rate. Similarly, two magnetic parts of the capsule serving as the passive release mechanism is developed (Dietzel et al. 2012). These two parts were magnetically attracted to each other to keep the capsule closed. Once the capsule reached the target position, an external magnetic field was used to open the capsule and release drug. The type of release mechanism only exposes the drug to the opened environment and relies on the fluid availability, or environmental conditions present at the target location to void the drug reservoir.

Polyelectrolyte multilayer capsules are used to fabricate micron- and submicron-sized delivery systems triggered in response to certain conditions of the environment, such as the temperature and pH (Antipina and Sukhorukov 2011). In these systems, the manipulation of physicochemical property of compounds is performed to increase intestinal concentration of drugs (Filipsky et al. 2013).

Several researches (Murad et al. 2013; Yim et al. 2013; van der Schaar et al. 2013; Woods and Constandinou 2013; Lai et al. 2014; Munoz et al. 2014, 2016; Beccani et al. 2015, 2016) have reported different techniques to expel the drug out of the reservoir once its release mechanism is remotely activated. This eliminates the dependency of the diffusion rate of the drug in the environment. The release mechanism proposed in (Murad et al. 2013) is based on thermally actuated shape memory alloys. Some of these approaches are more efficient in optimizing the volume of the capsule. A few disadvantages of this release mechanism include its poor reproducible release of the drug and the fact that only one dose can be released at a time for practical purposes. The controllability of the number of doses and release rate were enhanced in (Yim et al. 2013), through the usage of magnetic interactions between internal on-board permanent magnets and an external permanent magnet.

In the paper, a novel release mechanism for a drug-delivery system has been investigated, which aims to remote control the quantity of drug to be released, the flow rate and the releasement times. To experimentally verify the feasibility of the release mechanism to deliver a predetermined quantity of drug, a prototype of the drug-delivery system has been developed.

2 System overview

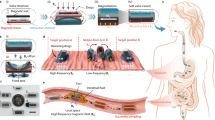

As shown in Fig. 1, the drug-delivery system consists of a drug-delivery capsule, a radio frequency transmission module, an interface circuit, and an instruction setting and triggering platform.

The drug-delivery capsule in the GI tract is composed of a shell, a release mechanism with one solenoid coil and two permanent magnets, a controlling module and batteries. The controlling module mainly includes a detection circuit of six-axis attitude angle, a pressure measurement module, an excitation time and intensity regulating circuit, an instruction wireless transmission circuit, a microcontroller unit (MCU), and a power management circuit.

For each application, drug release rate and dosage can be set up on the platform. Then, all instructions are transferred to the radio frequency transmission module by the interface circuit. While the triggering instruction is received, the drug-delivery capsule measures the current attitude angle. Then, the excitation time and intensity regulating circuit is controlled by the MCU to produce the proper actuating force. The system offers a complete solution to achieve an intelligent release of drug liquid.

3 Design of the drug-delivery system

3.1 Operation principle of the release mechanism

Referring to Fig. 2, the release mechanism with one solenoid coil and two permanent magnets is hosted in the capsule-shaped shell with diameter 11 mm and length 30 mm. It consists of a one-way valve for drug release, a drug chamber, two axially magnetized cylindrical permanent magnets, and a multi-layer solenoid coil.

The drug chamber (d = 11 mm, l = 8 mm, volume = 0.76 ml) is hosted in a cylindrical enclosure together with the multi-layer solenoid coil acting as a piston. Both the distal collar edge of the chamber and the center of the magnet close to the chamber have circular holes with a radius of 2 mm from where the drug is released outside. At normal atmosphere, the one-way valve with the predefined threshold pressure 602 Pa results in capability to be opened by the release mechanism and no leakage of the drug (Lu et al. 2018).

To actuate the coil piston, the two magnets are mounted at both sides of the drug chamber. Then the two static magnetic fields produced by the two magnets are aligned along the same axis, having the same magnitude, but opposite directions. The controlling module and batteries occupies the 10 mm length such that the length of the two magnets and the coil is 12 mm.

When the coil is excited, the electromagnetic force acting on the coil piston can extrude the drug chamber and open the one-way valve, then the drug can be released outside. By adjusting the intensity and the period of excitation current, the dosage and the average rate of drug release can be controlled. The operation principle of the release mechanism is derived as follows.

In a space of a magnetic field, the electromagnetic force acting on a unit of a current-carrying conductor is as follows:

where J is conductivity current density and B is magnetic flux density in the space of the current-carrying conductor.

The total magnetic force acting on the coil piston is

where V is the volume of the current-carrying conductor.

Since J is proportional to the current I, the coil dimensions, and the number of turns, all the three quantities need to be optimized to achieve enough force to push the coil along the chamber against the drug. Assuming the voltage keeps a constant as 3 V, the optimized parameters are listed as follows. The coil length is 5.78 mm, the wire diameter of the coil is 0.17 mm, and the inner diameter of the coil frame is zero (Lu et al. 2018).

Since the contribution of gravitational force of the coil piston is not negligible compared to the magnetic force acting on the coil piston, the release mechanism is unable to withstand it regardless of the capsule dip in release.

As shown in Fig. 3, cross-section 1 denotes the contact surface of the drug chamber and the coil piston. Cross-section 2 denotes the exit of the one-way valve. The flow rate of the medical liquid is denoted by v.

Using the Bernoulli equation, the following expression can be derived:

where ρ is the density of medical liquid. g is gravitational acceleration. p1, v1 and z1 denote pressure, flow rate, altitude at cross-section 1, respectively. p2, v2 and z2 denote pressure, flow rate, altitude at cross-section 2, respectively. p2 is equal to the threshold pressure of the one-way valve. hj denotes local resistance loss of the sudden contraction pipe.

Referring to local head loss, the following equation can be obtained.

where \( \zeta =0.5\left(1-\frac{A_2}{A_1}\right) \). The value of ζ is equal to 0.48.

Setting cross-section 1 as a reference surface, z1 is equal to zero. Then, the height of cross-section 2 is expressed by

where L0 is the length from the contact surface of the drug chamber and the coil to the exit of the one-way valve. θ denotes the angle between the central axis of the drug chamber and the vertical plane (0° < θ < 180°).

Giving continuity equation, the volume flow Q is as follows:

where A1, A2 is the area of cross-section 1, cross-section 2, respectively.

The resultant force F1 acting on the drug chamber should be satisfied as follows:

Therefore, the actuating force F(I, d) produced by the two magnets on the coil piston can be derived as:

where G1,G2 is the gravitational force of the medical liquid and the coil, respectively. As shown in Fig. 3, θ denotes the angle between the flow direction of the medical liquid and the opposite direction of gravity (0° < θ < 180°).

The actuating force F(I, d) can be expressed as a function of the coil stroke d and the excitation current I of the coil. The trend of F(I, d) was modeled with curve fitting and experimentally verified as discussed in Section 4.

Giving the quantity of drug released M and the mean release rate v2, the activated period of the coil can be obtained:

Based on above expressions, the intensity and the time of excitation are relative to the dosage and the average rate of drug release. Drug can be released repeatedly by controlling the two parameters.

3.2 Hardware architecture of the drug-delivery capsule

3.2.1 Detection circuit of six-axis attitude angle

Combining the principle of a 3-axis gyroscope and a 3-axis accelerometer, a six-axis motion track chip (MPU6050, InvenSense, USA) is mounted in the capsule to measure the attitude angle, whose z-axis is parallel to the rotational center axis of the capsule.

As the posture of the capsule changes, the MPU6050 sensor outputs the angular velocity and acceleration of the X, Y and Z axes. Together with an onboard Digital Motion Processor, the device processes these data with complex 6-axis motion fusion algorithms. A quaternion is outputted and then converted to Euler angle. Define α, β, γ as the Yaw, Pitch, Roll in the Euler angle, respectively. Based on three sine theorem, θ can be expressed as

The MCU is based on a STM32 (STM32F407, ST Microelectronics, SUI), which can initialize the sensor module and gather a full set of sensor data through an auxiliary master I2C bus.

3.2.2 Excitation time and intensity regulating circuit

As for excitation time and intensity regulating circuit, a fast-transient, low-dropout voltage regulator (TPS7A7100, ST Microelectronics, SUI) is selected as the driver for the coil actuation circuitry. The coil is connected to the output of the regulator. The TPS7A7100 is driven by the MCU digital output and offers a fully user-configurable output voltage setting method. Its output voltage can be programmed to any target value from 0.9 V to 3.5 V with 50-mV steps.

The MCU switches the enable and disable states of the TPS7A7100 through the EN pin. A logic high input at the EN pin enables the device; a logic low input disables the device. The timer in the MCU can control the excitation period of the coil by switching the TPS7A7100.

3.3 Operation interface design

The drug-delivery capsule can be controlled manually in real-time through the instruction setting and triggering platform. The operation interface is programmed by VC++ language in VS2013, as shown in Fig. 4.

The platform consists of four function modules: an instruction communication module, a patient information management module, a parameter setting module for drug release and a triggering and responding module.

The release mode, times, dose and mean flow rate can be set by the parameter setting module for drug release. The release mode can be mainly categorized into two types: immediate release and time-controlled release. In the immediate release mode, the release mechanism works once the triggering instruction is received. In the time-controlled release mode, the release mechanism works after the preset interval varying from 1 to 1440 min. Furthermore, the release dose is proportional to the mean release rate. The release times can be set from 1 to 3 times and drugs of different doses can be released in each time.

Through the triggering and responding module, the instructions are transferred from the platform to the MCU module through the interface circuit. Then, the MCU module communicates via Serial Peripheral Interface with the 433 MHz transceiver of the radio frequency transmission module. The handshake mean is employed to avoid the bit error and packet loss. The communication protocol is listed in Table 1.

4 System experimental assessments

4.1 Validation of the interaction force between the coil and the magnets

In order to verify the interaction force between the coil and the two magnets, the experimental setup is presented in Fig. 5. It is mainly composed by the release mechanism with one solenoid coil and two permanent magnets, a position sensor and a force sensor.

Considering the interacting force F as a function of the coil position d into the drug chamber and the excitation current I, the interaction force has been experimentally modeled using curve fitting. That is

where p, q is the highest power of i and d, respectively.

In the experiment, the position of the coil is set from 0 to 8 mm with the interval value 1 mm. And the excitation current of the coil is varied from 0.1 A to 0.4 A with the interval value 0.05 A. Meanwhile, the actuating force on the coil has been measured by the force sensor.

Coded with MATLAB, the coefficient matrix A of fitting curve can be calculated. And the function, with respect to the actuating force F, the coil position d and the excitation current I, has been modeled. The fitting precisions of the functions using different values of p, q are analyzed. When p = 7 and q = 9, the relative errors between the measured value and the fitting value of the actuating force are counted. From the experiment, the average relative error of the actuating force is 1.52% with the value of p, q set as 7, 9. Besides, the maximum of the relative errors is below 2.50%. Therefore, the value of p, q are optimized as 7, 9, respectively. As for different excitation currents 0.15 A, 0.20 A, 0.25 A, 0.30 A, the figure shown in Fig. 6 changes with different coil strokes.

The fitting curve is shown in Fig. 7. We can know that the actuating force increases with the increasing excitation current, when the coil stroke is kept a constant. As the stroke of the coil increases, the actuating force firstly decreases and then increases at the same excitation current.

4.2 Validation of the drug delivery

To experimentally verify the feasibility of the drug-delivery system to release a predetermined quantity of drug, the experimental setups were designed as shown in Fig. 8. They are composed of an azimuth adjustment and measurement device, the instruction setting and triggering platform, the release mechanism with one solenoid coil and two permanent magnets, the controlling module of the drug capsule, the radio frequency transmission module and the interface circuit. Using the azimuth adjustment and measurement device, the angle θ between the flow direction of the medical liquid and the opposite direction of gravity can be adjusted from 0 to 180 degrees.

All the drug release parameters, including release mode, times, dose, mean rate, can be set by the instruction setting and triggering platform. Once the capsule is triggered, the MCU in the capsule works according to the predetermined release parameters. A micro-burette with range 1 mL and scale division 0.01 mL has been used to assess the error between the release dose and the setting dose.

When θ is kept as 90 degrees, the relative errors of the dose have been counted at different levels of the mean release rate. In Fig. 9, different types of bars denote the relative errors of different doses, as the mean release rate is set as 0.020 mL/ms, 0.025 mL/ms, 0.030 mL/ms and 0.038 mL/ms, respectively. The relative errors for the quantity of released drug are 3.12% ± 0.93% for 0.76 mL release dose, 7.43% ± 2.50% for 0.51 mL release dose, and 8.73% ± 2.84% for 0.25 mL release dose, respectively. From the figures, we can know that the relative error becomes larger with the decreasing dose as the release rate is kept constant. Similarly, the relative error increases with increasing rate as the release dose is kept constant. Both the increasing release rate and the decreasing release dose lead to increasing error of excitation time and current. Besides, the assumptions in the formula derivation, such as the neglecting friction, laminar flow in drug release, bring about the errors.

In order to validate the effect of gravity on the release mechanism, the trials were performed with the capsule assuming different orientations. Figure 10 shows the relative errors of the release dose with different dip angles θ and average values of release rate, as the release dose is 0.38 mL.

From the experiment, the relative errors of the release dose vary with different dip angles θ. The mean value of the relative errors is no more than 14%. The detection circuit of six-axis attitude angle brings about the error. As for the same dip angle, the relative error becomes larger with increasing release rate. It is because shorter control periods for the MCU lead to greater control errors. And with increasing release rate, the motion inertia of the coil also brings about bigger errors.

In order to verify the feasibility of in vivo application, we performed ex vivo experiments using a porcine intestine, a flat plate, a precision balance and the azimuth adjustment and measurement device. A flat plate (50 cm length × 40 cm width) with fixed points for attaching the intestine was constructed. The angle β between the flat plate and the horizontal plane can be adjusted by using the azimuth adjustment and measurement device. A fresh porcine intestine firstly was cleaned using Tyrode’s solution and then was attached to the flat plate. One entry point of the porcine intestine is mounted with a plastic tube, which provides an easy access for the prototype of the drug-delivery capsule. In order to evaluate the accuracy of the release dosage, a precision balance with the accuracy 0.001 g was used. The release mechanism was weighed before releasement and weighed again after releasement. The difference between the two values is the weight of the drug released. Then the volume of the released drug liquid can be calculated according to the weight.

In the experiment, the angle β was set as 0°, 30°, 60° and 90°, respectively, which aimed to create different dip angles of the prototype, mimicking the complex orientation present in the GI tract. When the angle β was kept as a constant, the release dose was set as 0.25 mL, 0.51 mL and 0.76 mL. As for the same release dose, the prototype was inserted into the intestine 5 times with the value of the mean release rate set as 0.020 mL/ms, 0.025 mL/ms, 0.030 mL/ms and 0.038 mL/ms, respectively.

In the case, seven failures occurred in total 240 times of application. The failures present the case in which the close contact between the exit of the one-way valve and body tissue leads to blockage. Table 2 shows the relative errors of the release dose with different values of dip angle β and release dose, as the mean release rate is set as 0.020 mL/ms, 0.025 mL/ms, 0.030 mL/ms and 0.038 mL/ms, respectively.

To take the complexity of in vivo application into consideration, a semi-liquid colloidal suspension was injected into the porcine intestine to mimic the GI contents and experiments were performed accordingly. In the case, 78% releasement failed and the failure rate further increased with increasing the quantity of the semi-liquid colloidal suspension. It is because the exit of the one-way valve tends to be blocked by the suspension. Thus, the GI preparation is required for in vivo use, such as cleaning of all fecal material in the intestine and fasting for hours before in vivo application.

5 Conclusions and future works

The release mechanism with one solenoid coil and two permanent magnets for a drug-delivery capsule has been presented and experimentally investigated. And the corresponding controlling module for the release mechanism is designed to control the dose, the rate and the mode of drug delivery. The controlling module mainly consists of the detection circuit of six-axis attitude angle, the excitation time and intensity regulating circuit, the instruction wireless transmission circuit, the microcontroller unit (MCU), and the power management circuit. Besides, the operation principle of the release mechanism is derived and the function with respect to the actuating force, the coil position and the excitation current is modeled. The operation interface on the instruction setting and triggering platform is programmed by VC++ language in VS2013. The prototype of the controllable drug-delivery capsule has been developed, which can be controlled manually in real-time through the platform.

The actuating force between the coil and the two magnets is experimentally verified. Considering the actuating force is a function of the coil position and the excitation current, the function has been experimentally modeled using curve fitting. The fitting precision of the functions using different curves are analyzed. The average relative error of the actuating force is 1.52% and the maximum is below 2.50%. According to the function, the actuating force can be controlled by adjusting the excitation current based on the coil position. Then, the feasibility of the drug-delivery system to release a predetermined quantity of drug has been experimentally verified. All the drug release parameters, including release mode, times, dose, mean rate, can be set by the instruction setting and triggering platform. The relative error of the release dose becomes larger with increasing release rate and decreasing release dose because of the control error from the MCU.

Before practical applications in ingestible medical devices, future works will focus on compact design of the electronic modules, packaging, and mechanical structures of the in-vivo device, leaving space for adding other functional modules, such as real-time localization (Guo et al. 2018) and/or locomotion control (Kim et al. 2006, 2010; Quirini et al. 2008; Hosokawa and Ishikawa 2009; Simi et al. 2010; Lien et al. 2012; De Falco et al. 2014; Cheong et al. 2015). Together with the locomotive controlling module showing advanced features of positioning controllability, drug-delivery systems can deliver a therapeutic drug to a specific target region in the GI tract. In addition, the delivery precision of the drug quantity needs to be improved in particular application.

References

M.N. Antipina, G.B. Sukhorukov, Remote control over guidance and release properties of composite polyelectrolyte based capsules. Adv. Drug Deliv. Rev. 63, 716–729 (2011)

M. Beccani, C.D. Natali, G. Aiello, C. Benjamin, E. Susilo, P. Valdastri, A magnetic drug delivery capsule based on a coil actuation mechanism. Procedia Eng. 120, 53–56 (2015)

M. Beccani, G. Aiello, N. Gkotsis, et al., Component based design of a drug delivery capsule robot. Sensors Actuators A Phys. 245, 180–188 (2016)

D. Becker, J. Zhang, T. Heimbach, et al., Novel orally swallowable IntelliCap® device to quantify regional drug absorption in human GI tract using diltiazem as model drug. AAPS PharmSciTech 15, 1490–1497 (2014)

L. Cheong, C. Hyunchul, G. Gwangjun, et al., Active locomotive intestinal capsule endoscope (ALICE) system: A prospective feasibility study, mechatronics. IEEE/ASME Trans. Mechatron. 20, 2067–2074 (2015)

I. De Falco, G. Tortora, P. Dario, et al., An integrated system for wireless capsule endoscopy in a liquid-distended stomach. IEEE Trans. Biomed. Eng. 61, 794–804 (2014)

T. Dietzel, H. Richert, S. Albert, U. Merkel, M. Hippius, A. Stallmach, Magnetic active agent release system (MAARS): Evaluation of a new way for a reproducible, externally controlled drug release into the small intestine. J. Control. Release 161, 722–727 (2012)

K.J. Filipsky, M.V. Varma, A.F. El-Kattan, C.M. Ambler, R.B. Ruggeri, T.C. Goosen, K.O. Cameron, Intestinal targeting of drugs: Rational design approaches and challenges. Curr. Top. Med. Chem. 13, 776–802 (2013)

R. Goffredo, D. Accoto, E. Guglielmelli, Swallowable smart pills for local drug delivery: Present status and future perspectives. Expert Rev. Med. Devices 12, 585–599 (2015)

X. Guo, Z. Lu, H. Cui, et al., Modelling and solving the position tracking problem of remote-controlled gastrointestinal drug-delivery capsules. Biomed. Signal Process. Control 39, 213–218 (2018)

D. Hosokawa, T. Ishikawa, Development of a biologically inspired locomotion system for a capsule endoscope. Int. J. Med. Robot. Comput. 5, 471–478 (2009)

B. Kim, M.G. Lee, Y.P. Lee, et al., An earthworm-like micro robot using shape memory alloy actuator. Sensors Actuators A Phys. 125, 429–437 (2006)

H.M. Kim, S. Yang, J. Kim, et al., Active locomotion of a paddling-based capsule endoscope in an in vitro and in vivo experiment (with videos). Gastointest. Endosc. 72, 381–387 (2010)

J.Y. Lai, N.C. Tsai, H.L. Chiu, Theoretical analysis and simulations of micro-dosing locomotive robot with drug-release mechanism. Robot. Auton. Syst. 62, 177–187 (2014)

V.H. Le, H.L. Rodriguez, C. Lee, G. Go, et al., A soft-magnet-based drug-delivery module for active locomotive intestinal capsule endoscopy using an electromagnetic actuation system. Sensors Actuators A Phys 243, 81–89 (2016)

G.S. Lien, C.W. Liu, J.A. Jiang, et al., Magnetic control system targeted for capsule endoscopic operations in the stomach–design, fabrication, and in vitro and ex vivo evaluations. IEEE Trans. Biomed. Eng. 59, 2068–2079 (2012)

Z. Lu, X. Guo, T. Xu, et al., Optimum design of remote delivery capsule’s driving mechanism based on electromagnetic-permanent magnet. J. Syst. Simul. 30, 747–752 (2018)

S.S. Mapara, V.B. Patravale, Medical capsule robots: A renaissance for diagnostics, drug delivery and surgical treatment. J. Control. Release 261, 337–351 (2017)

F. Munoz, G. Alici, W. Li, Design optimization of a magnetomechanical system for drug delivery in wireless capsule endoscopy. IEEE/ASME Int. Conf. Adv. Intell. Mech. (2014) pp. 1097–1102

F. Munoz, G. Alici, H. Zhou et al., Analysis of the magnetic torque on a tilted permanent magnet for drug delivery in capsule robots. IEEE/ASME Int. Conf. Adv. Intell. Mech. (2016) pp. 1386–1391

S. Murad, J. Murad, H. Khan, A smarter SMA technology for the realization of drug delivering endoscopic capsule. Rawal Med. J. 38, 66–74 (2013)

D.A. Parasrampuria, T. Kanamaru, A. Connor, et al., Evaluation of regional gastrointestinal absorption of edoxaban using the Enterion capsule. J. Clin. Pharmacol. 55, 1286–1292 (2015)

M. Quirini, A. Menciassi, S. Scapellato, et al., Feasibility proof of a legged locomotion capsule for the GI tract. Gastointest. Endosc. 67, 1153–1158 (2008)

M. Rasouli, L. Lin, A.P. Kencana, et al., Therapeutic capsule endoscopy: Opportunities and challenges. J. Healthc. Eng. 2, 459–471 (2016)

M. Simi, P. Valdastri, C. Quaglia, et al., Design, fabrication, and testing of a capsule with hybrid locomotion for gastrointestinal tract exploration. IEEE/ASME Trans. Mechatron. 15, 170–180 (2010)

P.J. van der Schaar, J.F. Dijksman, H. Broekhuizen-de Gast, J. Shimizu, N. van Lelyveld, H. Zou, V. Lordanov, C. Wanke, P.D. Siersema, A novel ingestible electronic drug delivery and monitoring device. Gastrointest. Endosc. 78, 520–528 (2013)

S.P. Woods, T.G. Constandinou, Wireless capsule endoscope for targeted drug delivery: Mechanics and design considerations. IEEE Trans. Biomed. Eng. 60, 945–953 (2013)

S. Yim, K. Goyal, M. Sitti, Magnetically actuated soft capsule with themultimodal drug release function. IEEE/ASME Trans. Mechatron. 18, 1413–1418 (2013)

Acknowledgments

This work was supported by Natural Science Foundation of Shanghai [grant number 15ZR1428200]; and the National Natural Science Foundation of China [grant number 61001164].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, X., Luo, Z., Cui, H. et al. A novel and reproducible release mechanism for a drug-delivery system in the gastrointestinal tract. Biomed Microdevices 21, 25 (2019). https://doi.org/10.1007/s10544-019-0383-z

Published:

DOI: https://doi.org/10.1007/s10544-019-0383-z