Abstract

Flexible bioelectronics encompass a new generation of sensing devices, in which controlled interactions with tissue enhance understanding of biological processes in vivo. However, the fabrication of such thin film electronics with photolithographic processes remains a challenge for many biocompatible polymers. Recently, two shape memory polymer (SMP) systems, based on acrylate and thiol-ene/acrylate networks, were designed as substrates for softening neural interfaces with glass transitions above body temperature (37 °C) such that the materials are stiff for insertion into soft tissue and soften through low moisture absorption in physiological conditions. These two substrates, acrylate and thiol-ene/acrylate SMPs, are compared to polyethylene naphthalate, polycarbonate, polyimide, and polydimethylsiloxane, which have been widely used in flexible electronics research and industry. These six substrates are compared via dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), and swelling studies. The integrity of gold and chromium/gold thin films on SMP substrates are evaluated with optical profilometry and electrical measurements as a function of processing temperature above, below and through the glass transition temperature. The effects of crosslink density, adhesion and cure stress are shown to play a critical role in the stability of these thin film materials, and a guide for the future design of responsive polymeric materials suitable for neural interfaces is proposed. Finally, neural interfaces fabricated on thiol-ene/acrylate substrates demonstrate long-term fidelity through both in vitro impedance spectroscopy and the recording of driven local field potentials for 8 weeks in the auditory cortex of laboratory rats.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

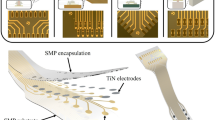

Interest in flexible electronics has enabled the development of advanced organic and inorganic thin film materials for large-area sensors and advanced devices for biological investigations (Li et al. 2007; Someya et al. 2004; Urban et al. 1992). Critically important to the implementation of these devices in translational research is the ability of the device to be fabricated with materials that enhance both device lifetime and biocompatibility (Williams 2008). However, the majority of thin film device development has been limited either to silicon or commercially available polymer substrates such as polycarbonate (PC), polyethylene naphthalate (PEN), polyimide (PI), and polydimethylsiloxane (PDMS) (Fig. 1) (Berggren and Richter–Dahlfors 2007; Grayson et al. 2004; MacDonald et al. 2007; Rogers and Nuzzo 2005; Viventi et al. 2011; Willner and Willner 2001). When using commercially available materials, tailoring the chemical and mechanical properties of the device to enhance biocompatibility for a particular biosensing application, such as neural interfaces, can be a major challenge (Grill et al. 2009). By fabricating thin film devices with photolithographic processes on stimuli responsive polymer substrates device lifetime of neural interfaces could be enhanced (Lendlein and Kelch 2002; Subbaroyan et al. 2005).

The chemical structure is shown for the three engineering thermoplastics (PC, PEN, PI) and one elastomer (PDMS) and compared to the starting chemicals of the acrylate (SMP1) and thiol-ene/acrylate (SMP2). The modulus (tensile) of materials used for sensing in biomedical applications compared to bone and soft tissue: (1) silicon = 190 GPa (Pearson et al. 1957); (2) bone = 17.1 GPa (Reilly et al. 1974); (3) neural tissue = 10 kPa (Metz et al. 1970); (4) polycarbonate = 1.9 GPa (Mercier et al. 1965); (5) polyethylene naphthalate = 4.3 GPa (Cakmak et al. 1990); (6) polyimide = 3 GPa (Isoda et al. 1982); and (7) polydimethylsiloxane = 1.5 MPa (Mata et al. 2005). The SMP substrates exhibit softening behavior in shear modulus from 700 MPa (≈ 2GPa tensile modulus) in the glassy state (8) to 300 kPa (≈ 1 MPa tensile modulus) for the acrylate SMP (Ware et al. 2012a, b) and (9) to 3 MPa (≈ 9 MPa tensile modulus) for the thiol-ene/acrylate SMP substrate in the rubbery state (Ware et al. 2013)

Neural interfaces are devices comprised of both conducting and insulating materials that can be inserted into soft, nervous system tissue (modulus ≈ 10 kPa) to record electrical activity (Hatsopoulos and Donoghue 2009; Metz et al. 1970). However, after the initial damage caused upon insertion, rigid neural interfaces can inhibit the natural wound healing response and decrease recording fidelity (Saxena et al. 2013). The field of neurophysiology has benefited from novel neural interfaces fabricated on glassy (at body temperature) polymer substrates such as polyimides, epoxy-based photoresists, and Parylene-C (Altuna et al. 2012; Rodger et al. 2008; Stieglitz et al. 2011). Neural interfaces on these substrates have provided penetrating intracortical electrode arrays with a reduced modulus (on the order of 1 GPa) compared to silicon-based electrodes (190 GPa) (Halary et al. 2011; Pearson et al. 1957). Additionally, compatibility with standard photolithographic processes has enabled the high-density electrode count necessary for the spatial and temporal resolution of neural processes (Kipke et al. 2008). However, these substrates are inherently limited in chemical and mechanical tailorability, since they have been adapted from the microelectronics industry whose materials selection parameters were based on quite different metrics (Cheung 2010).

Subsequently, work has focused on developing thin film electrodes on polymeric substrates that are stiff prior to insertion and soften in physiological conditions to improve the tissue-electrode interface by reducing the modulus of the electrode in vivo (Harris et al. 2011b). One such polymer system utilized poly(vinyl acetate) loaded with cellulose nanowhiskers to achieve sufficient stiffness to penetrate cortical tissue, then softened two orders of magnitude through the large uptake of fluid in physiological conditions. Results from immunohistochemistry studies with this dynamically softening substrate in comparison to rigid microwires suggested that softening probes can reduce the inflammatory response of surrounding neural tissue and that chronic recording may be mediated by softening neural interfaces (Harris et al. 2011a). But, rapid fluid uptake is a major challenge when fabricating high-density electrodes with photolithography and can affect the stability of thin film electrode materials used for recording neural activity (Liang et al. 2001). Thus, a central challenge remained: the design of a polymer substrate, stiff enough for insertion into cortical tissue with the ability to soften in vivo and fully compatible with photolithographically defined electrodes.

Shape memory polymers (SMPs) are a class of polymers that have been extensively studied for biomedical applications due to their unique, modular chemical and mechanical properties (Gall et al. 2005; Lendlein and Langer 2002; Safranski and Gall 2008). Recently, a method for combining photolithographically defined electrodes with SMPs was developed as an approach to fabricate softening neural interfaces. The first SMP substrate that incorporated thin film electrodes with a SMP substrate was a copolymer of methyl acrylate, isobornyl acrylate, and poly(ethylene glycol) diacrylate with varying amounts of acrylic acid (Fig. 1, SMP1) (Ware et al. 2012a). This device was fabricated using a transfer-by-polymerization process to combine pre-patterned electrodes with a low crosslink density polymer that was stiff during insertion and would soften post-insertion in response to physiological conditions. The main advantage of this process was the ability to tune the thermomechanical properties of substrate, such as (Tg) and rubbery modulus, independently of photolithographic processes. However, the inherent high cure stresses formed upon free-radical polymerization of the acrylate substrate diminishes dimensional stability, which can cause failure of thin film electrodes during subsequent processing steps (Lee et al. 2007). Ware et al. also showed that the other advantage of the transfer-by-polymerization process is the improvement in adhesion between thin film metals and the adaptive polymer substrate. But improved adhesion alone may not be sufficient to support thin film metals on softening neural interfaces, which can suffer from micro-cracks in the thin film conductors and loss of electrical continuity (Graudejus et al. 2010).

A second SMP substrate for softening neural interfaces, a thiol-ene/acrylate network, is made from the stoichiometric reaction of a tri-thiol and a tri-ene, with 31 mol% addition of a diacrylate (Fig. 1, SMP2) (Ware et al. 2012b, 2013). This reaction is often referred to as “click” chemistry due to its ability to form high yield products with simple reaction conditions. While both polymer networks are formed in bulk, compared to the acrylate system, the thiol-ene/acrylate reaction is uninhibited by oxygen and forms highly regular networks (Hoyle et al. 2010). The step growth polymerization between thiol and -ene groups does not reach gelation until high conversion, which reduces the cure stress in the polymer film and enhances dimensional stability (Lu et al. 2005). The addition of multifunctional acrylates provides a method to increase the glass transition of the network, but also raises the rubbery modulus by increasing crosslink density (Senyurt et al. 2007). Additionally, the strong interaction between thiols and noble metals, such as gold and platinum, can provide a mechanism for improved adhesion between the polymer substrate and thin film metal (Nuzzo et al. 1987). It is hypothesized that by controlling the crosslink density, adhesion and cure stress of a polymeric substrate, the stability and adhesion of thin film conductors can be controlled.

The goal of this work is to understand the stability of thin film electrodes on flexible SMP substrates for the fabrication of reliable neural interfaces. The thermomechanical properties, thermal stability, optical properties, and moisture absorption of PEN, PC, PI and PDMS are compared to the two SMP substrates since these properties benchmark the performance of flexible electronics substrates (MacDonald et al. 2007). Optical profilometry and electrical measurements are then used to compare the integrity of gold (Au) and chromium/gold (Cr/Au) thin films on SMP substrates to evaluate the fabrication of high-density electrodes using standard photolithographic processes. Then, to elucidate mechanisms behind the behavior of these SMP materials, three additional thermoset polymers were synthesized and evaluated as potential substrates: a high crosslink density acrylate, an epoxy/thiol and an epoxy/amine. This set of polymeric substrates will help provide a fundamental understanding of the stability and adhesion of Au and Cr/Au films on substrates with varying crosslink density, adhesion, and cure stress during photolithographic processing. The thiol-ene/acrylate network was chosen to fabricate implantable electrodes, and in vitro impedance spectroscopy measured the change in electrochemical properties in simulated physiological conditions. Finally, the softening thiol-ene/acrylate substrate will demonstrate the potential for a reliable, chronic neural interface: full photolithography intracortical probes are fabricated using this polymer system and implanted into the auditory cortex of laboratory rats. Over an 8-week time period, these devices are able to record driven local field potentials (LFPs).

2 Materials and methods

Methyl acrylate (MA), isobornyl acrylate (IBoA), poly(ethylene glycol)diacrylate (PEGDA, Mn~575), bisphenol A ethoxylate diacrylate (BPAEDA, Mn~512), tricyclo[5.2.1.02,6]decanedimethanol diacrylate (TCMDA), 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione (TATATO), bisphenol A diglycidyl ether (BPADGE), poly(propylene glycol) bis(2-aminopropyl ether) (Mn = 230 g/mol) (PPGBAPE), pentaerythritol tetrakis(3-mercaptopropionate) (PETMP), triethylamine, phosphate buffered saline (PBS) and 2,2-dimethoxy-2-phenyl acetophenone (DMPA) were purchased from Sigma Aldrich. Tris[2-(3-mercaptopropionyloxy)ethyl] isocyanurate (TMICN) was purchased from Wako Chemicals. All chemicals were used as received without further purification. Polycarbonate (PC, Lexan) and polyimide (PI, Kapton) were obtained from Grainger in 0.125 mm films. Biaxially oriented polyethylene naphthalate (PEN, Teonex) was obtained from DuPont in 0.125 mm films. Sylgard 184 silicone elastomer kit was obtained from Dow Corning to make polydimethylsiloxane (PDMS) in 0.125 mm films.

Polymer synthesis

Detailed synthesis of the SMP substrates has been previously reported (Ware et al. 2012a, b). Briefly, the low crosslink density acrylate SMP (SMP1) substrate was prepared by mixing a solution of 25 wt.% MA and 75 wt.% IBoA to which was added 1 wt.% PEGDA. The higher crosslink density acrylate was prepared by mixing a solution of 50 wt.% BPAEDA, 12.5 % MA and 37.5 % IBoA. The thiol-ene/acrylate (SMP2) substrate was prepared by mixing a solution of a stoichiometric ratio of TATATO and TMICN to which was added 31 mol% TCMDA. A photo initiator concentration of 0.1 wt.% DMPA was used for each. Both monomer solutions were placed in a parallel plate glass mold with a thickness of 0.035, 0.125 or 1.2 mm and photoinitiated in a crosslinking chamber with 365 nm UV light (Cole Parmer, UVP CL-1000 Ultraviolet Crosslinker). The epoxide/amine copolymer was synthesized in bulk using standard methods. Briefly, a 2:1 molar ratio of BPADGE and PPGBAPE was thoroughly mixed at 60 °C. The monomer solution was then cast in a parallel plate glass mold with a thickness of 0.035 mm or 1.2 mm. The mold was then placed in an oven at 120 °C for 1 h to allow for polymerization. The film was then post-cured for 24 h at 120 °C after removal from the mold. The epoxide/thiol copolymer was synthesized in bulk. Briefly, a 2:1 molar ratio of BPADGE and PETMP was thoroughly mixed at 60 °C. The solution was then cooled to room temperature and 5 wt.% triethylamine was added as catalyst. The monomer solution was then cast in a parallel plate glass mold with a thickness of 0.035 mm or 1.2 mm. The reaction occurred over an hour at room temperature. The film was then post-cured for 24 h at 120 °C after removal from the mold. PDMS was mixed in a 10:1 ratio and heat cured at 100 °C for 35 min in either a 0.125 mm or 1.2 mm mold.

Thermogravimetric analysis

TGA was performed on the acrylate (low crosslink density), thiol-ene/acrylate, PEN, PC, PI, and PDMS with a Mettler Toledo TGA/DSC 1 in alumina crucibles. Samples were approximately 5 mg, and each material was tested three times. Samples were heated from 25 °C to 700 °C at 20 °C/min in 80 ml/min nitrogen atmosphere. Thiol-ene/acrylate sample was terminated at approximately 20 % degradation due to the strong odor formed upon degradation.

Dynamic mechanical analysis

DMA was performed on the acrylate (low and high crosslink density), thiol-ene/acrylate, PEN, PC, PI, PDMS with a Mettler Toledo DMA 861e/SDTA. The 6 polymers were cut into approximately 1 × 1 mm squares with a thickness of 0.125 mm, and each material was tested once. The mode of deformation was shear at 1 Hz with 1 μm displacement. Samples were tested at a heating rate of 2 °C/min in a nitrogen atmosphere. DMA was also performed on the acrylate (high crosslink density), epoxy/thiol, and epoxy/amine. These polymer samples were approximately 3 mm diameter circles with a thickness of 1.2 mm.

Swelling study

Moisture absorption of the acrylate, thiol-ene/acrylate, PEN, PC, PI, and PDMS was measured by change in weight over time in simulated physiological conditions. Swelling percent, q, was determined according to the formula:

where ws is the swollen weight and wi is the initial, dry sample weight. Six polymer samples of each substrate were placed in sealed glass vials containing phosphate buffer saline and placed in an oven at 37 °C. Samples were approximately cut to 15 mg pieces and with 0.125 mm thickness. Weight was measured at 1, 7, and 28 days.

Ultraviolet/visible spectroscopy

UV–vis was performed on a Shimadzu UV-1601 PharmaSpec spectrophotometer. One hundred scans from 250 to 800 nm were taken through each 0.125 mm sample of SMP1, SMP2, PC, PEN, PI, and PDMS.

Surface roughness

Optical profilometry, a non-contact surface metrology technique that measures light interference to quantify the topological properties of large areas, was performed on unpatterned sheets and patterned traces of Cr/Au (50 nm/300 nm thick) or Au (300 nm thick) on 35 μm thick acrylate or thiol-ene/acrylate substrates on glass. Surface roughness was determined on the as transferred metal surface and at room temperature, 40, 50, 60, 65, 70, 80 and 90 °C for the acrylate system or at room temperature, 30, 35, 40, 45, 50, 60, 70, 105, 150 and 210 °C for the thiol-ene/acrylates systems. Samples were heated to the target temperature on a hot plate, held at temperature for 10 min to insure thermal equilibrium and then air cooled to ambient temperature before being measured. Surface roughness was measured using a Bruker Contour GT-K1 3D Optical Microscope. For the unpatterned sheets of gold: four 4 × 4 mm regions were scanned at each temperature using a Phase Shift Interferometry (PSI) method at 5× magnification under Green (narrow band) light. For the patterned samples; a single 500 × 500 μm region of the ground trace/pad interface was scanned after heating to each temperature using a Vertical Scanning Interferometry (VSI) method at 50× magnification white light. Post-measurement processing consisted of Tilt removal and Basic Statistics calculation performed through Bruker’s Vision64 software.

Electrical characterization

Cr/Au (50 nm/300 nm thick) and Au films (300 nm) were patterned using standard photolithographic processes. Devices consisted of nine traces (n = 9) that were 15 μm wide and had a length that varied from 7 to 10 mm. Resistance was measured at room temperature using a Fluke 115 True RMS Multimeter. A sample for each acrylate (low crosslink density, Cr/Au), thiol-ene/acrylate (Cr/Au), and thiol-ene/acrylate (Au) was heated to the target temperature in a Barnstead International benchtop muffle furnace, held at temperature for 10 min to insure thermal equilibrium and then air cooled to ambient temperature before electrical measurements were taken. The acrylate substrate was tested at 40, 60, 70 and 100 °C. The thiol-ene/acrylate (Cr/Au) was tested at 40, 60, 70, 100, 125, 150, 175, 200, 225, and 250 °C. The thiol-ene/acrylate (Au) was tested at 40, 60, 70, 100, 125, 150, 175, 200, 225, 250, 275, and 300 °C.

Optical microscopy

Nomarski differential interference contrast (DIC) optical microcopy was obtained by a Leica INM 200 optical microscope with a 2.5× objective.

Thin film adhesion

Adhesion of Cr/Au (50 nm/300 nm) or Au (300 nm) transferred to SMP substrates was determined by the application of 1 mil Kapton with silicone adhesive tape (CS Hyde Company, Product 18-1S). The samples were approximately 35 mm wide by 50 mm long and 35 μm thick. One sample for each Cr/Au or Au film on the acrylate (low crosslink density), acrylate (high crosslink density), thiol-ene/acrylate, epoxy/thiol, and epoxy/amine were tested.

Device fabrication

Devices were fabricated in a Class 10000 cleanroom located at the University of Texas at Dallas. Thin films were patterned with standard photolithographic processes on a glass slide utilizing transfer-by-polymerization as previously reported (Ware et al. 2012a). For devices with evaporated chromium/gold (50 nm/300 nm) films, the thin films were patterned with standard photolithographic processes on a glass slide coated with Parylene-C; then, transfer-by-polymerization was used to join the monomer solution with the patterned thin films to make 35 μm thick substrates. Neural interfaces were fabricated with the transfer-by-polymerization of an unpatterned gold film (300 nm); then the gold was patterned on the thiol-ene/acrylate/glass substrate using standard photolithographic processes. Electrodes were patterned with Microposit S1813 photoresist spun on at a speed of 2,000 rpm with an acceleration of 3,000 rpm for 60 s. Samples were baked at 85 °C for 10 min. Exposure was completed with 405 nm light and a dose of 150 mJ/cm2. Photoresist was developed in Microposit MF-319 for 50 s. After electrode patterning, devices were insulated with 500 nm of Parylene-C deposited in a Labcoater 2 (SCS systems), patterned with standard photolithographic processes, and vias were etched with oxygen plasma for 11 min in a Technics Reactive Ion Etching tool with 100 mTorr pressure and 50 W power. Cleaning of the electrode sites was accomplished in a SAMCO UV-Ozone stripper for 50 min with a flow rate of 0.7 L/h. Intracortical electrodes were laser micromachined, bonded to single in-line package socket with Ag-filled epoxy cured at 100 °C for 1 h, and sterilized in a sterile pack with 254 nm UV light for 2 h. The distance between electrodes recording sites is 100 μm. The geometric surface area of the electrode was designed to be 177 μm2 (15 μm diameter), which is centered on a 50 μm wide pad (Fig. 7b). Traces leading from the electrode sites to the bond pads are 15 μm wide with 15 μm in between traces.

Impedance spectroscopy

Impedance spectroscopy of Au electrodes on the thiol-ene/acrylate substrate was performed using a CH Instruments (Austin, TX) potentiostat. Three, 8-channel electrodes (n = 24) were fabricated using full photolithography as described in the supplementary information. A 3-eletrode configuration was used and the tests were performed in 1× phosphate buffered saline with a pH of 7.3–7.5 in ambient conditions. Frequencies between 100 and 10,000 Hz were tested using a 5 mV sinusoidal potential. Devices were placed in vials of phosphate buffered saline (PBS), fixed and sealed in place with plastic wrap and placed in an oven at 37 °C. PBS was added to vials as necessary to ensure electrode sites were immersed in solution for the duration of the experiment.

Surgical implantation

This surgery followed a previously established procedure, but full details are given in the supplementary information for reference (Rennaker et al. 2005). SMP electrodes were inserted to a depth of 800 μm (layer IV/V) in primary auditory cortex of laboratory rats. All animal testing was conducted in accordance with the University of Texas at Dallas Institutional Animal Care and Use Committee Regulations.

Neural recording

Acoustic stimuli were presented to anesthetized animals in a calibrated, free-field speaker in a double-walled acoustic chamber. The chamber consists of two boxes made with 3/4 inch high density sound board. The inside chamber is 25″ × 25″ × 19″ and is covered with 3″ thick Sonex acoustic foam. A head-stage amplifier (Tucker Davis Technologies) was directly attached to the electrode connector. Neural data were digitized at 25 kHz and bandpass filtered from 500 to 5,000 Hz for spikes and 100–500 Hz for local field potentials. Broadband clicks were presented at rates ranging from 4 to 250 Hz for 1 s at suprathreshold intensities (65 dB SPL). A maximum of 100 clicks were played at each stimulus presentation rate (SPR) on a given trial. The click trains were randomly interleaved and repeated 20 times with inter-train-intervals of 1 s. Broadband clicks were 80 ms in duration with 3 dB points at 1.6 and 31.6 kHz. The spectral properties were confirmed using a 1/4″ condenser microphone (ACO Pacific) and analyzed for spectral content using a digital oscilloscope.

3 Results

Neural interfaces with high density electrodes patterned by photolithographic processes enable the observation of neural processes in vivo; however, state-of-the-art devices are commonly fabricated on materials with a modulus 5 to 7 orders of magnitude higher than neural tissue (Fig. 1). By comparing SMPs designed to soften in physiological conditions with materials commonly used in flexible electronics and understanding the change in surface properties of thin film metals on SMP substrates during simulated processing steps, the quality and reliability of a new generation of neural interfaces can be established.

Understanding the thermomechanical properties of the flexible substrate material is critical for successful photolithographic processing. The substrate material and patterned thin film materials experience repeated temperatures cycles from baking photoresists and material depositions. The thermomechanical properties of six candidate polymers, including polymers commonly used as substrates for lithography and two SMP compositions were studied by dynamic mechanical analysis (DMA). The change in storage modulus (G΄) as a function of temperature and the glass transition temperature (Tg) as denoted by the peak of tan delta are shown in Fig. 2a–b. For the engineering thermoplastics, both PEN and PC exhibited glassy behavior until 150 °C with the peak of tan delta of 172 °C and 163 °C, respectively. Additionally, the PI substrate was thermally stable from 25 °C through 300 °C and did not demonstrate a significant change in modulus. PDMS exhibited rubbery behavior from 25 °C to 200 °C with a modulus of 0.75 MPa at 37 °C. The acrylate and thiol-ene/acrylate substrate each began to exhibit viscoelastic behavior near 40 °C with peaks of tan delta at 65 °C and 62 °C, respectively. Both the acrylate and thiol-ene/acrylate substrate are thermoset polymers that exhibit a rubbery modulus (measured in shear) of 0.1 MPa and 4.41 MPa (Tg + 33 °C) respectively.

Dynamic mechanical response of the PI, PEN, PC, PDMS and SMP substrates used for flexible electronics processing that shows storage modulus (G′, shear modulus) as a function of temperature (a). The peak of tan delta indicates the glass transition temperature of the polymers (b). The acrylate and thiol-ene/acrylate SMP substrates have a glass transition near body temperature as compared to the other polymers shown

The thermal stability and moisture absorption of polymeric substrates are two additional properties studied during the selection of a platform substrate for flexible electronics. Thermogravimetric analysis (TGA) measured weight loss as a function of temperature and was used to indicate maximum processing temperature before degradation occurs. In Fig. 3a, the acrylate substrate showed the lowest thermal degradation temperature (5 % weight loss) at 313 °C followed by the thiol-ene/acrylate, PEN, PDMS, PC, and PI at 380, 410, 426, 466 and 580 °C, respectively. While thermal degradation can cause failure during the fabrication of electrical devices, moisture absorption of a polymeric substrate can dictate the long-term performance of both electrical and mechanical properties of flexible electronics.

Comparison of the thermal degradation properties by TGA shows the temperature range over which these samples are chemically stable (a). Moisture absorption in simulated physiological conditions shows that both the acrylate and thiol-ene/acrylate SMP substrates maintain similar water uptake compared to commercially available substrates (b). Comparison of the optical transmission of ultraviolet and visible light through thiol-ene/acrylate, acrylate, PC, PEN, PI, and PDMS is shown (c)

In Fig. 3b, fluid (phosphate buffered saline) uptake as a function time was determined for the four benchmark materials and the two SMP substrates in a simulated physiological system. Over 28 days, the engineering thermoplastics, PDMS and both SMP substrates had less than 3 % uptake of fluid. At 28 days, the PDMS had 0.22 ± 0.12 % fluid uptake; PEN had 0.36 ± 0.30 %; PC had 0.74 ± 0.50 %; and PI had 1.98 ± 0.26 %. The acrylate SMP had 1.50 ± 0.95 % fluid uptake, while the thiol-ene/acrylate SMP had 2.19 ± 0.26 %. Monitoring the amount of swelling a polymer exhibits in physiological conditions is important due to its ability to affect both the mechanical and insulating properties of the substrate.

For some applications in flexible electronics and biomedical devices, such as the optical stimulation of neural tissue, it is also necessary to quantify the optical clarity of the polymeric substrate. Ultraviolet–visible spectroscopy (UV–vis) measured the ratio of the transmitted of light to incident light through a sample. The SMP materials both showed high transmittance around 90 % that was comparable to both PC and PDMS as shown in Fig. 3c. However, the PEN substrate had a maximum 73 % transmission with less than 16 % transmission at 390 nm. The PI substrate had a maximum 67 % transmission and less than 1 % transmission at 505 nm.

While SMP substrates possess some of the beneficial properties of benchmark materials used in flexible electronics (i.e. thermal stability and low moisture absorption), the Tg near body temperature make SMP substrates distinctly different than commercially available materials. Change in surface roughness was used to understand the behavior of thin film metals on SMP substrates during photolithographic processing steps. Optical profilometry of transferred, unpatterned Cr/Au or Au thin films on the SMP substrates was used to characterize surface roughness (Rq) as a function of annealing temperature in Fig. 4a. The as-transferred Rq was 7.96 ± 2.34 nm, 5.34 ± 3.87 nm, and 15.96 ± 0.56 nm for the acrylate (Cr/Au), thiol-ene/acrylate (Cr/Au), and thiol-ene/acrylate (Au) substrates, respectively. The relatively unchanged surface roughness at 40 °C for the three samples is shown in Fig. 4b, d, and f. Beyond 40 °C, the acrylate substrate demonstrated a dramatic increase in surface roughness compared to both thiol-ene/acrylate substrates. Upon heating to 70 °C the acrylate sample surface roughened to 396.7 ± 173.8 nm while the thiol-ene/acrylate sample increased in Rq to 26.24 ± 16.24 and 42.78 ± 5.08 nm for the Cr/Au and Au thin films, respectively. At 90 °C, the acrylate substrate had a comparatively high surface roughness of 559.8 ± 369.4 nm (Fig. 4c). Furthermore, at 210 °C, the thiol-ene/acrylate substrates roughened to exhibit Rq values of 93.22 ± 57.55 and 144.0 ± 9.53 nm for the Cr/Au and Au thin films, respectively (Fig. 4e, g). Heating above Tg results in a change in surface roughness for all three materials, but the change in surface roughness is much lower on the thiol-ene/acrylate substrate. Representative optical profilometry figures for each temperature can be found in the supplementary information in Figure S3–5.

Patterned thin film materials were also annealed at various temperatures on the SMP substrates as further simulation of photolithographic processing steps to build flexible bioelectronics devices on selected substrates. For these devices, change in normalized resistance was used as a benchmark for device continuity as a function of annealing temperature as shown in Fig. 5a. A nine-channel device was annealed at each temperature; detailed device information can be found in the supplementary information. Loss in continuity was determined by the inability to measure resistance across the patterned conductor, and the experiment was terminated at the temperature where continuity was not found in the device. For the patterned traces, the as deposited resistivity of the Cr/Au was 84.1 ± 11.1 nΩ · m (n = 36) on acrylate and 84.0 ± 10.4 nΩ · m (n = 72) on thiol-ene/acrylate; the resistivity of the Au film on thiol-ene/acrylate was 66.7 ± 2.76 nΩ · m (n = 81). The Cr/Au films on the acrylate SMP substrate exhibited loss of electrical continuity on three channels at 75 °C and all nine channels at 100 °C, while the Cr/Au film on the thiol-ene/acrylate substrate did not show loss of continuity until 250 °C. On the other hand, the Au film on the thiol-ene/acrylate substrate did not show failure at the highest temperature tested (300 °C). Patterned devices on SMP substrates were also scanned with optical profilometry at various annealing temperatures. This revealed a large change in surface roughness across the patterned device in the acrylate SMP device at 90 °C, while both Cr/Au and Au devices did not show large changes in surface roughness across the patterned conductors up to 210 °C (Fig. 5b–d).

The change in initial resistance was measured as function of annealing temperature on patterned devices (a). Patterned devices are shown by optical profilometry. The acrylate with Cr/Au shows failure at 90 °C (b). The thiol-ene/acrylate with Cr/Au (c) and thiol-ene/acrylate with Au (d) are shown at 210 °C with no failure

To further understand the stability and adhesion of thin film Au and Cr/Au on SMP substrates, three additional thermoset polymers were synthesized. Transfer-by-polymerization was used to join Cr/Au and Au films to these substrates with varying crosslink densities (denoted by Gr ′), adhesion, and cure stresses as shown in Table 1. The three polymers were an acrylate with higher crosslink density, an epoxy/thiol, and an epoxy/amine. DMA curves of the thermomechanical properties compared to the acrylate and thiol-ene/acrylate SMPs are shown in Fig. 6. After transfer, the films were placed on a hot plate for 10 min at 115 °C. Nomarski DIC optical microscopy was chosen to qualitatively highlight the change in surface topography of the thin films. Adhesion was determined by the application of Kapton tape with silicone adhesive and removed. Delamination of Au and cracking of Cr/Au films on both acrylate substrates with low and high crosslink density was observed. The thiol-ene/acrylate, epoxy/thiol, and epoxy/amine polymers all show zero delamination of Au without the Cr adhesion layer as well relatively low change in surface topography in the Nomarski DIC optical micrographs. The Cr/Au films did not crack on either thiol-based substrates, but cracks were formed in the epoxy/amine substrate.

Flexible, softening neural interfaces were fabricated with Au electrode conductors and Parylene-C insulation on the thiol-ene/acrylate substrate. Photolithographically defined features as small as 5 μm have been successfully fabricated on the thiol-ene/acrylate SMP substrate (Fig. 7a). In Fig. 7b, an intracortical electrode array fabricated for in vitro and in vivo testing is shown. The change in impedance as a function of swelling time in simulated physiological conditions was measured for three, 8-channel intracortical gold electrodes with a site size of 177 μm2. The impedance spectrogram from 100 to 10,000 Hz is shown for a 60 day time period in Fig. 7c. The initial average impedance of the three devices was 2.09 ± 0.841 MΩ at 1 kHz (95 % C.I.), as shown in Fig. 7d. Channels that showed impedance greater than 4 MΩ at any time point were excluded for the remainder of the study. After 60 days, 22 of 24 electrodes maintained electrical continuity and had an average impedance of 52.3 ± 13.3 kΩ (95 % C.I.).

Optical micrograph taken of photolithographically defined recording electrodes on thiol-ene/acrylate substrate with a minimum feature size of 5 μm (a). Optical micrograph of the intracortical electrode array used for in vitro and in vivo testing is shown (b). Impedance spectroscopy was measured as a function of swelling time showing how electrodes maintain functionality in simulated physiological conditions (c). Change in impedance at 1 kHz as a function of swelling time in physiological conditions is shown (d)

Intracortical electrode arrays on thiol-ene/acrylate substrates were implanted in the primary auditory cortex of three rats for a period of 60 days. Acoustic stimuli were presented as broadband clicks to anesthetized animals to quantify driven neural activity. Six of the eight channels were used for recording due to the recording hardware configuration. For each of the implanted animals, driven local field potentials were measured in all animals up to the 8 week time point at which point the experiment was terminated. Figure 8a–f shows the average auditory evoked response for two animals at various time points with a broadband click stimulus at 50 ms. These results provide an initial demonstration of the long term recording capability of neural interfaces based on flexible, softening thiol-ene/acrylate SMP substrates.

4 Discussion

Progress in flexible electronics has come via polymer substrates that facilitate the fabrication of micro-scale features using standard photolithographic processes. In the past, processing these polymeric substrates through standard photolithography has demanded a specific set of materials’ properties: high Tg, high thermal stability, low moisture absorption, and (as possible) resistance to various solvents. However, as shown in Fig. 1, these materials such as PC, PI and PEN tend to have a modulus much higher than tissue, and as a result the biocompatibility of implantable devices remains a challenge. PDMS on the other hand suffers from an inability to maintain requisite stiffness for the fabrication of thin film electrodes as well as for the insertion of devices. These polymer properties are dictated by the polymer substrate composition and are often difficult to modify when using commercially available materials for thin film device development.

This work follows a different approach to fabricate functional bioelectronic devices. Here, a responsive polymer system is designed to be capable of being processed via standard photolithography, above, below and through its Tg, such that final device properties (such as softening after insertion) are not sacrificed for device fabrication. This yields a chemically and mechanically adaptable polymer substrate for softening, implantable devices that supports the fabrication of micro-scale features with photolithography. By understanding the property-processing relationships of these polymer-based devices, a broader design paradigm for designing flexible bioelectronics is developed. Furthermore, two SMP-based materials, based on this design framework, are described and a functional softening neural interface that can record information from the auditory cortex of laboratory rats is demonstrated.

More specifically, photolithographic processing of micro-scale electronics requires multiple heating cycles (from 20 °C to 85–115 °C) to bake photoresist during the patterning of multi-layered devices. DMA shows how the thermomechanical properties of these six materials behave as a function of temperature in Fig. 2a–b. Generally, flexible substrates are processed below the onset of Tg to maintain a rigid substrate with good adhesion to prevent the failure of thin film materials. This failure is typically caused by the large increase in the coefficient of thermal expansion of polymers at Tg, which is the case for the engineering thermoplastics PEN and PC (Gleskova et al. 2006). The PI could potentially be used at temperatures in excess of 300 °C since it does not show softening over the temperature range studied due to rigid backbone chemistry and molecular orientation that gives rise to the low coefficient of thermal expansion at high temperatures (Pottiger et al. 1994). Correspondingly, the PI does not soften in vivo and allow control of modulus after implantation to optimize tissue interactions. On the other hand, the elastomeric nature of PDMS from 25 to 200 °C makes it difficult to pattern the micro-scale features required for neural interfaces using processes developed for stiff, planar silicon wafers (Delivopoulos et al. 2011). Transfer techniques or shadow masking have been successfully implemented, but suffer from multi-layer alignment problems and challenges with encapsulation (Meitl et al. 2006). Furthermore, there has been little evidence in the past of polymer substrates that meet the design criteria to support photolithographic process both above and below Tg without substantial adaptation of standard processes.

Research in flexible electronics has also developed a wide variety of thin film dielectric materials with advanced insulating and optical properties. However, many of these materials require deposition at elevated temperatures, and the importance of choosing a polymeric substrate taking both processing and application into consideration is paramount. While TGA studies show that all six substrates are thermally stable above 300 °C, again the poor adhesion, drop in modulus, and dimensional stability of polymers above Tg due to increase in free volume associated with the phase change has generally limited high temperature (200–300 °C) processes to the more thermally stable PI substrates (Fig. 3a). If a material can maintain dimensional stability with good adhesion to thin film conductors during photolithography while in the rubbery state but below degradation, it is also possible that these substrates could support thin film deposition at temperatures above Tg as well. The flexibility to process electronics on flexible polymeric substrates regardless of temperature up to degradation can lead to the sophisticated devices necessary to further biological studies.

Moisture absorption is also a critical design factor for flexible electronics used for biomedical applications. High levels of moisture absorption in physiological conditions can lead to high leakage currents, attenuation of the electrical signals, and changes in polymer mechanical properties (Behl and Lendlein 2007; White 1969). In simulated physiological conditions, phosphate buffered saline at 37 °C, the acrylate and thiol-ene/acrylate both show low moisture absorption similar to that of polyimide, Fig. 3b. Since the SMP substrates are designed with a Tg only slightly above body temperature, low moisture absorption can be used as a mechanism to induce a controlled change in modulus as previously reported. However, a large absorption of fluid could lead to dimensional instability and failure of thin film materials on polymer substrates, which generally limits the application of many polymers commonly used as biocompatible materials.

The optical properties of the polymer substrate are of importance due to the recent advance of optogenetics in neuroscience (Yizhar et al. 2011). Figure 3c highlights the transparency of both acrylate and thiol-ene/acrylate substrates compared to other polymer substrates throughout the entire visible spectrum. Additionally, the thiol-ene system has been previously used to enhance the properties of micro-optical systems (Jin et al. 2011). A fully integrated device that could contain both waveguides for stimulation and sensing electrodes on the same substrate with tunable chemical and mechanical properties could be of great importance to the field of neurophysiology (Maesoon et al. 2011).

The SMP substrates are unique compared to the benchmark materials due to their thermoset networks and relatively low (~60 °C) Tg, which is in the middle of the photolithographic processing temperature range, Fig. 2a–b. This is a divergence from common methodologies for processing on polymeric substrates for flexible electronics. During photoresist baking at 85 °C, the substrates soften through Tg and remain in the rubbery state for the duration of the bake; substrates are then cooled back to room temperature for photopatterning. Due to the necessity to go through Tg during electrode fabrication, the substrate must have sufficient dimensional stability and adhesion to the thin film material to sustain such extremes. While the acrylate and thiol-ene/acrylate SMP substrates share low moisture absorption and thermal stability similar to materials currently used in flexible electronics, the stability of patterned and unpatterned thin films at temperatures common in standard photolithographic processes has not been addressed.

The change in surface roughness as a function annealing temperature of unpatterned thin films on SMP substrates was measured by optical profilometry to simulate photolithography temperature cycles, Fig. 4a. A comparison is made between acrylate and thiol-ene/acrylate substrate with Cr/Au and Au films. Generally, Au films have poor adhesion to polymer substrates and require the presence of a Cr adhesion layer to prevent delamination. In the thiol-ene/acrylate system, the well-known thiol-Au bond enables the Au film to adhere such that wet photolithography processes can be efficiently completed without the use of the Cr layer (Ulman 1996). The large change in surface roughness initiating at 40 °C for the Cr/Au films on the acrylate system corresponds to the onset of Tg seen in Fig. 2a. This increase in surface roughness could indicate the poor dimensional stability of the acrylate substrate that eventually led to cracking of the Cr/Au film at 50 °C for the unpatterned film and 70 °C for the patterned device. Control of surface roughness is vital to insure the reliability and reproducibility enabled by standard photolithographic processes. More specifically, if the surface roughness changes during various temperature cycles, especially across Tg during processing, this reliability is jeopardized. The relatively low change in surface roughness for both the Cr/Au and Au films on the thiol-ene/acrylate substrate, even at temperatures greater than 200 °C, demonstrates the improved dimensional stability of the polymer substrate at temperatures common in photolithography.

Further evidence of thin film continuity during temperature processing is shown by measuring the change in normalized resistance as a function of annealing temperature, Fig. 5a. As the films were annealed, the resistance decreased similarly for each substrate due to the recrystallization in evaporated films (Dorey and Knight 1969). Loss in continuity of patterned devices on acrylate substrates at temperatures just above the Tg confirms that the thin film electrodes cannot remain electrically continuous with increasing annealing temperature (Fig. 5b). Alternatively, the patterned devices on thiol-ene/acrylate samples show superior stability at much higher annealing temperatures enabling the Au films to withstand temperatures as high as 300 °C.While both SMPs share a similar Tg, the two SMP substrates vary in crosslink density, adhesion to the thin films, and cure stress, only the thiol-ene/acrylate substrate supports the thin film without cracking at temperatures greater than 40 °C.

To elucidate the effect of crosslink density, adhesion based on thiol content and cure stress on thin film conductors on SMP substrates, three additional polymers were synthesized to transfer Au and Cr/Au thin films (Fig. 6a–b). The results of this study are summarized in Table 1. An acrylate SMP was made with a rubbery modulus similar to the thiol-ene/acrylate substrate, but the substrate still possesses the inherently high cure stresses resulting from the free radical polymerization. The high and low crosslink density acrylates exhibited similar behavior, poor adhesion to gold and significant cracking in Cr/Au films. This behavior suggests that crosslink density alone is not sufficient in describing the two observed behaviors. Epoxy/thiol and epoxy/amine substrates were also synthesized to provide substrates with low cure stresses and moderate crosslink densities, similar to the thiol-ene/acrylate substrate. These systems are also well known for good adhesion to a variety metals. Categorically these polymers showed good adhesion to both Au and Cr/Au films. The adhered metallic films did not show the large change in surface roughness and significant cracking seen in the acrylic systems when heated through Tg, although the epoxy/amine substrate did cause some cracking the in more brittle Cr/Au film. One interesting note is the adhesion of the epoxy/amine to the Au film, which could denote the favorable adhesion of other polymer systems without the presence of a thiol group to Au films. Future evaluation of thermoset polymers as substrates for flexible bioelectronics should further elucidate the importance of adhesion, cure stresses and crosslink density. These results, however, do open the possibility of a wide range of chemistries available for biomedical devices with flexible electronics that can be tuned for both processing and biocompatibility.

As validation that these design criteria are important, devices were fabricated on the thiol-ene/acrylate substrate to create functional neural interfaces and driven neural activity was recorded from laboratory rats. The thiol-ene/acrylate SMP substrate was selected for fabrication of a high density, softening neural interface, due to its compatibility with standard photolithographic processes. An intracortical electrode array was fabricated with gold conductors, Parylene-C insulation, and a minimum feature size of 5 μm, Fig. 7a–b. Small feature sizes are critical to minimize the footprint of high density, implantable electrodes. Impedance spectroscopy in simulated physiological conditions was performed in order to validate long-term electrical functionality. Gold electrodes insulated with Parylene-C on the thiol-ene/acrylate substrate demonstrated a decrease in impedance after 2 weeks in simulated physiological conditions, Fig. 7c–d. One possible reason for the decrease in impedance is the delamination of the Parylene-C insulation to expose a larger electrochemical surface area, which is common in neural interfaces (Cogan 2008). Nevertheless, greater than 90 % (22 of 24) channels maintained electrical continuity for 8 weeks. A high percentage of functional electrodes over long time periods are enabled by the stability and adhesion of thin film electrodes on the thiol-ene/acrylate substrate, which will aid biological studies by maintaining electrical functionality on a softening substrate.

Intracortical electrodes were also implanted into the primary auditory cortex of three rats. Broadband clicks were presented as auditory stimuli to anesthetized animals to elicit a driven response. Driven local field potentials were recorded for 8 weeks when the experiment was terminated as shown in Fig. 8a–f. For a given electrode size, it is hypothesized that electrode materials with larger electrochemical surface area and higher charge injection capacity such as titanium nitride or carbon nanotubes with lower impedance will be necessary for future recordings of neurological activity. However, these results do demonstrate a promising new substrate for neural interfaces that support fabrication and use, both above and below Tg, of thin film electrodes for effective long term in vivo studies. Future work consists of understanding the changes in electrical and mechanical properties of softening substrates for biomedical devices, improving electrode stability with advanced materials for electrodes and encapsulation, and developing substrates that continue to approach the modulus of neural tissue.

5 Conclusions

Tools that enable researchers to interface with biological tissue reliably for long periods of time have the potential to enhance the understanding of complex neurological processes and develop therapies for neurodegenerative diseases. This work demonstrated that a flexible polymer substrate with enhanced dimensional stability and adhesion based on a thiol-ene/acrylate SMP substrate can be used as a platform for the development of neural interfaces and other bioelectronics. A dimensionally stable polymer substrate capable of cleanroom processing at elevated temperatures will also enable the use of complex devices that incorporate thin film sensors based on organic and inorganic materials that previously only been demonstrated on commercially available substrates. By controlling the crosslink density, adhesion to thin-film materials and cure stress of a polymeric material, substrates can be designed to facilitate both processing, above and below Tg, and application of biomedical devices with thin film electronics. These design parameters may help solve the next generation of clinical problems for which traditional flexible electronics materials and approaches have been limited.

References

A. Altuna, L. Menendez de la Prida, E. Bellistri, G. Gabriel, A. Guimerá, J. Berganzo, R. Villa, L.J. Fernández, SU-8 based microprobes with integrated planar electrodes for enhanced neural depth recording. Biosens. Bioelectron. 37(1), 1–5 (2012)

M. Behl, A. Lendlein, Shape-memory polymers. Materials Today 10(4), 20–28 (2007)

M. Berggren, A. Richter–Dahlfors, Organic bioelectronics. Adv. Mater. 19(20), 3201–3213 (2007)

M. Cakmak, Y.D. Wang, M. Simhambhatla, Processing characteristics, structure development, and properties of uni and biaxially stretched poly(ethylene 2,6 naphthalate) (PEN) films. Polym. Eng. Sci. 30(12), 721–733 (1990)

K.C. Cheung, in Thin-Film Microelectrode Arrays for Biomedical Applications Implantable Neural Prostheses, 2, ed. by D. Zhou, E. Greenbaum (Springer, New York, 2010), pp. 157–190

S.F. Cogan, Neural stimulation and recording electrodes. Annu. Rev. Biomed. Eng. 10(1), 275–309 (2008)

E. Delivopoulos, I.R. Minev, S.P. Lacour. Evaluation of negative photo-patternable PDMS for the encapsulation of neural electrodes. Neural Engineering (NER), 2011 5th International IEEE/EMBS Conference on, 2011, pp. 490–494.

A.P. Dorey, J. Knight, The variation of resistance of gold films with time and annealing procedure. Thin Solid Films 4(6), 445–451 (1969)

K. Gall, C.M. Yakacki, Y. Liu, R. Shandas, N. Willett, K.S. Anseth, Thermomechanics of the shape memory effect in polymers for biomedical applications. J. Biomed. Mater. Res. A 73A(3), 339–348 (2005)

H. Gleskova, I. Cheng, S. Wagner, Z. Suo. Thermomechanical criteria for overlay alignment in flexible thin-film electronic circuits. Appl. Phys Lett. 88(1), 011905-011905-011903 (2006).

O. Graudejus, P. Görrn, S. Wagner, Controlling the morphology of gold films on poly(dimethylsiloxane). ACS Appl. Mater. Interfaces 2(7), 1927–1933 (2010)

A.R. Grayson, R.S. Shawgo, A.M. Johnson, N.T. Flynn, Y. Li, M.J. Cima, R. Langer, A BioMEMS review: MEMS technology for physiologically integrated devices. Proc. IEEE 92(1), 6–21 (2004)

W.M. Grill, S.E. Norman, R.V. Bellamkonda, Implanted neural interfaces: biochallenges and engineered solutions. Annu. Rev. Biomed. Eng. 11, 1–24 (2009)

J.L. Halary, F. Lauprêtre, L. Monnerie. Polymer materials: Macroscopic properties and molecular interpretations (Wiley, Hoboken, NJ, 2011)

J.P. Harris, J.R. Capadona, R.H. Miller, B.C. Healy, K. Shanmuganathan, S.J. Rowan, C. Weder, D.J. Tyler, Mechanically adaptive intracortical implants improve the proximity of neuronal cell bodies. J. Neural Eng. 8(6), 066011 (2011a)

J.P. Harris, A.E. Hess, S.J. Rowan, C. Weder, C.A. Zorman, D.J. Tyler, J.R. Capadona, In vivo deployment of mechanically adaptive nanocomposites for intracortical microelectrodes. J. Neural Eng. 8(4), 046010 (2011b)

N.G. Hatsopoulos, J.P. Donoghue, The science of neural interface systems. Annu. Rev. Neurosci. 32, 249 (2009)

C.E. Hoyle, A.B. Lowe, C.N. Bowman, Thiol-click chemistry: a multifaceted toolbox for small molecule and polymer synthesis. Chem. Soc. Rev. 39(4), 1355–1387 (2010)

S. Isoda, M. Kochi, H. Kambe, Molecular aggregation of solid aromatic polymers. II. Mechanical properties of aromatic polyimide film. J. Polym. Sci. Polym. Phys. Ed. 20(5), 837–844 (1982)

P. Jin, N. Liu, J. Lin, J. Tan, P.D. Prewett, Replication of micro-optical elements with continuous relief by ultraviolet embossing with thiol-ene-based resist. Appl. Opt. 50(21), 4063–4067 (2011)

D.R. Kipke, W. Shain, G. Buzsáki, E. Fetz, J.M. Henderson, J.F. Hetke, G. Schalk, Advanced neurotechnologies for chronic neural interfaces: new horizons and clinical opportunities. J. Neurosci. 28(46), 11830 (2008)

T.Y. Lee, J. Carioscia, Z. Smith, C.N. Bowman, Thiol−Allyl Ether−Methacrylate ternary systems. Evolution mechanism of polymerization-induced shrinkage stress and mechanical properties. Macromolecules 40(5), 1473–1479 (2007)

A. Lendlein, S. Kelch, Shape-memory polymers. Angew. Chem. Int. Ed. 41, 2034 (2002)

A. Lendlein, R. Langer, Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 296(5573), 1673–1676 (2002)

C. Li, J. Han, C.H. Ahn, Flexible biosensors on spirally rolled micro tube for cardiovascular in vivo monitoring. Biosens. Bioelectron. 22(9–10), 1988–1993 (2007)

T. Liang, Y. Makita, S. Kimura, Effect of film thickness on the electrical properties of polyimide thin films. Polymer 42(11), 4867–4872 (2001)

H. Lu, J.A. Carioscia, J.W. Stansbury, C.N. Bowman, Investigations of step-growth thiol-ene polymerizations for novel dental restoratives. Dent. Mater. 21(12), 1129–1136 (2005)

W.A. MacDonald, M.K. Looney, D. MacKerron, R. Eveson, R. Adam, K. Hashimoto, K. Rakos, Latest advances in substrates for flexible electronics. J. Soc. Inf. Disp. 15(12), 1075–1083 (2007)

I. Maesoon, C. Il-Joo, W. Fan, K.D. Wise, Y. Euisik. Neural probes integrated with optical mixer/splitter waveguides and multiple stimulation sites. Micro Electro Mechanical Systems (MEMS), 2011 I.E. 24th International Conference on, pp. 1051–1054 (2011).

A. Mata, A. Fleischman, S. Roy, Characterization of polydimethylsiloxane (PDMS) properties for biomedical micro/nanosystems. Biomed. Microdevices 7(4), 281–293 (2005)

M.A. Meitl, Z.-T. Zhu, V. Kumar, K.J. Lee, X. Feng, Y.Y. Huang, I. Adesida, R.G. Nuzzo, J.A. Rogers, Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 5(1), 33–38 (2006)

J.P. Mercier, J.J. Aklonis, M. Litt, A.V. Tobolsky, Viscoelastic behavior of the polycarbonate of bisphenol A. J. Appl. Polym. Sci. 9(2), 447–459 (1965)

H. Metz, J. McElhaney, A.K. Ommaya, A comparison of the elasticity of live, dead, and fixed brain tissue. J. Biomech. 3(4), 453–458 (1970)

R.G. Nuzzo, F.A. Fusco, D.L. Allara, Spontaneously organized molecular assemblies. 3. Preparation and properties of solution adsorbed monolayers of organic disulfides on gold surfaces. J. Am. Chem. Soc. 109(8), 2358–2368 (1987)

G. Pearson, W. Read Jr., W.L. Feldmann, Deformation and fracture of small silicon crystals. Acta Metall. 5(4), 181–191 (1957)

M.T. Pottiger, J.C. Coburn, J.R. Edman, The effect of orientation on thermal expansion behavior in polyimide films. J. Polymer Sci., Part B: Polymer Phys. 32(5), 825–837 (1994)

D.T. Reilly, A.H. Burstein, V.H. Frankel, The elastic modulus for bone. J. Biomech. 7(3), 271–275 (1974)

R.L. Rennaker, S. Street, A.M. Ruyle, A.M. Sloan, A comparison of chronic multi-channel cortical implantation techniques: manual versus mechanical insertion. J. Neurosci. Methods 142(2), 169–176 (2005)

D.C. Rodger, A.J. Fong, W. Li, H. Ameri, A.K. Ahuja, C. Gutierrez, I. Lavrov, H. Zhong, P.R. Menon, E. Meng, J.W. Burdick, R.R. Roy, V.R. Edgerton, J.D. Weiland, M.S. Humayun, Y.-C. Tai, Flexible parylene-based multielectrode array technology for high-density neural stimulation and recording. Sensors Actuators B Chem. 132(2), 449–460 (2008)

J.A. Rogers, R.G. Nuzzo, Recent progress in soft lithography. Mater. Today 8(2), 50–56 (2005)

D.L. Safranski, K. Gall, Effect of chemical structure and crosslinking density on the thermo-mechanical properties and toughness of (meth)acrylate shape memory polymer networks. Polymer 49(20), 4446–4455 (2008)

T. Saxena, L. Karumbaiah, E.A. Gaupp, R. Patkar, K. Patil, M. Betancur, G.B. Stanley, R.V. Bellamkonda, The impact of chronic blood–brain barrier breach on intracortical electrode function. Biomaterials 34(20), 4703–4713 (2013)

A.F. Senyurt, H. Wei, C.E. Hoyle, S.G. Piland, T.E. Gould, Ternary Thiol−Ene/Acrylate photopolymers: effect of acrylate structure on mechanical properties. Macromolecules 40(14), 4901–4909 (2007)

T. Someya, T. Sekitani, S. Iba, Y. Kato, H. Kawaguchi, T. Sakurai, A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. U. S. A. 101(27), 9966 (2004)

T. Stieglitz, M. Schuettler, B. Rubehn, T. Boretius, J. Badia, X. Navarro. Evaluation of polyimide as substrate material for electrodes to interface the peripheral nervous system. Neural Engineering (NER), 2011 5th International IEEE/EMBS Conference on, pp. 529–533 (2011).

J. Subbaroyan, D.C. Martin, D.R. Kipke, A finite-element model of the mechanical effects of implantable microelectrodes in the cerebral cortex. J. Neural Eng. 2, 103 (2005)

A. Ulman, Formation and structure of self-assembled monolayers. Chem. Rev. 96(4), 1533 (1996)

G. Urban, G. Jobst, F. Keplinger, E. Aschauer, O. Tilado, R. Fasching, F. Kohl, Miniaturized multi-enzyme biosensors integrated with pH sensors on flexible polymer carriers for in vivo applications. Biosens. Bioelectron. 7(10), 733–739 (1992)

J. Viventi, D.-H. Kim, L. Vigeland, E.S. Frechette, J.A. Blanco, Y.-S. Kim, A.E. Avrin, V.R. Tiruvadi, S.-W. Hwang, A.C. Vanleer, D.F. Wulsin, K. Davis, C.E. Gelber, L. Palmer, J. Van der Spiegel, J. Wu, J. Xiao, Y. Huang, D. Contreras, J.A. Rogers, B. Litt, Flexible, foldable, actively multiplexed, high-density electrode array for mapping brain activity in vivo. Nat. Neurosci. 14(12), 1599–1605 (2011)

T. Ware, D. Simon, D.E. Arreaga-Salas, J. Reeder, R. Rennaker, E.W. Keefer, W. Voit, Fabrication of responsive, softening neural interfaces. Adv. Funct. Mater. 22(16), 3470–3479 (2012a)

T. Ware, D. Simon, K. Hearon, C. Liu, S. Shah, J. Reeder, N. Khodaparast, M.P. Kilgard, D.J. Maitland, R.L. Rennaker II, W.E. Voit, Three-dimensional flexible electronics enabled by shape memory polymer substrates for responsive neural interfaces. Macromol. Mater. Eng. 297(12), 1193–1202 (2012b)

T. Ware, D. Simon, C. Liu, T. Musa, S. Vasudevan, A.M. Sloan, E.W. Keefer, R.L. Rennaker, W. Voit, Thiol-ene/Acrylate substrates for softening intracortical electrodes. J. Biomed. Mater. Res. B Appl. Biomater. (2013). doi:10.1002/jbmb.32946

M.L. White, Encapsulation of integrated circuits. Proc. IEEE 57(9), 1610–1615 (1969)

D.F. Williams, On the mechanisms of biocompatibility. Biomaterials 29(20), 2941–2953 (2008)

I. Willner, B. Willner, Biomaterials integrated with electronic elements: en route to bioelectronics. Trends Biotechnol. 19(6), 222–230 (2001)

O. Yizhar, L.E. Fenno, T.J. Davidson, M. Mogri, K. Deisseroth, Optogenetics in neural systems. Neuron 71(1), 9–34 (2011)

Acknowledgements

The authors would like to thank the FDA for the use of the Bruker Contour GT-K1 3D Optical Microscope. The opinions and/or conclusions expressed are solely those of the authors and in no way imply a policy or position of the Food and Drug Administration. This material is based partially based upon work supported from several sources: the National Institutes of Neurological Disorders and Stroke 5R01DC008982; the National Science Foundation Partnerships for Innovation and Graduate Research Fellowship under Grant No. 1147385; FUSION support from the State of Texas.

Author declaration

“Syzygy Memory Plastics, Inc. funds undergraduate research in the Advanced Polymers Research Laboratory (APRL) at the University of Texas at Dallas. Taylor Ware and Walter Voit have a significant financial interest in Syzygy Memory Plastics, Inc. This financial interest has been disclosed to UT Dallas and a conflict of interest management plan is in place to manage the potential conflict of interest associated with this research program.”

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 1383 kb)

Rights and permissions

About this article

Cite this article

Simon, D., Ware, T., Marcotte, R. et al. A comparison of polymer substrates for photolithographic processing of flexible bioelectronics. Biomed Microdevices 15, 925–939 (2013). https://doi.org/10.1007/s10544-013-9782-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-013-9782-8