Abstract

This paper describes a simple reversible hydrogel patterning method for 3D cell culture. Alginate gel is formed in select regions of a microfluidic device through light-triggered release of caged calcium. In the pre-gelled alginate solution, calcium is chelated by DM-nitrophen (DM-n) to prevent cross-linking of alginate. After sufficient UV exposure the caged calcium is released from DM-n causing alginate to cross-link. The effect of using different concentrations of calcium and chelating agents as well as the duration of UV exposure is described. Since the cross-linking is based on calcium concentration, the cross-linked alginate can easily be dissolved by EDTA. We also demonstrate application of this capability to patterned microscale 3D co-culture using endothelial cells and osteoblastic cells in a microchannel.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microengineered hydrogels are commonly used in tissue engineering and also facilitate the creation of physiologically relevant cellular microenvironments (Cukierman et al. 2001; Peppas et al. 2006; Griffith and Swartz 2007; Nichol and Khademhosseini 2009). Since microscale heterogeneity in chemical composition and geometry play an important role in cellular functions and tissue development, microscale engineering techniques of hydrogels have been useful tools for cell biology and tissue engineering (Nelson et al. 2006; Nelson and Tien 2006; Sands and Mooney 2007; Fishbach et al. 2009). It has become evident that three-dimensional (3D) cell culture provides more physiological cellular environments compared to conventional two-dimensional cell cultures (Griffith and Swartz 2007; Yamada and Cukierman 2007). Since the architecture and chemical composition of hydrogels can be easily engineered, hydrogels have been utilized for 3D cell culture systems (Hahn et al. 2006; Choi et al. 2007; Gillette et al. 2008; Kloxin et al. 2009). The geometry of hydrogels has been controlled by the use of elastic molds (Tang et al. 2003; Franzesi et al. 2006; Golden and Tien 2007; Yan et al. 2008a, b) and photocrosslinkable hydrogels (Koh et al. 2002; Arcaute et al. 2006; Tsang et al. 2007; Panda et al. 2008). These patterning techniques have recently been applied to 3D co-culture systems to create in vivo-like culture systems or tissue constructs (Tan and Deasi 2004; Tsang et al. 2007; Wong et al. 2008; Panda et al. 2008; Nichol and Khademhosseini 2009; Sung and Shuler 2009). However, these techniques lack reversibility, which is an important characteristic in engineering cellular microenvironments in vitro. The reversibility of hydrogels facilitates tissue engineering (Nelson and Tien 2006), and allows selectively capture and release of cells for further analysis (Plouffe et al. 2009). Although several types of hydrogels are thermo-reversible, these hydrogels have mainly been used as 2D scaffolds or as injectable cell carriers (Yan et al. 2008a, b; Chen and Cheng 2009). Furthermore, these hydrogels and techniques cannot be applied to ionically cross-linked hydrogels (Franzesi et al. 2006). In this study, we describe a simple reversible gelation method for 3D cell culture using light-triggered ionic cross-linking of alginate.

Alginates are naturally derived polysaccharides composed of β-D-mannuronic acid (M-unit) and α-L-guluronic acid (G-unit) monomers. The aqueous alginate solution can form gels when its molecules come into contact with divalent cations such as calcium ions. The ions bond cooperatively between the G-blocks of adjacent alginate chains during gelling (Rowley et al. 1999). The gelled alginates have been used as synthetic extracellular matrices, where arginine-glycine-aspartic acid (RGD)-containing peptides that are covalently immobilized onto alginate chains can function as adhesion ligands for their integrin receptors (Alsberg et al. 2001). In addition, the distinct advantage of alginate hydrogels is the controllable degradation which has been utilized for sequential release of growth factors to induce angiogenic effects (Hao et al. 2007). The controlled formation of alginate hydrogels such as generation of alginate microbeads has been reported using microfluidic devices (Liu et al. 2006; Braschler et al. 2005; Cabodi et al. 2005). One challenge is the difficulty of achieving precise spatial control over release/delivery of calcium or other divalent metals in microfluidic devices to cross-link the alginate hydrogels. Here, we describe a method to selectively cross-link alginate in selected regions within microfluidic devices using controlled release of calcium through photolysis of a caged calcium complex. We further demonstrate co-culture of osteoblasts and endothelial cells in a microchannel where osteoblasts inside the alginate hydrogel are surrounded by the endothelial cells.

2 Materials and methods

2.1 Materials and equipment

Poly(dimethylsiloxane) (PDMS)(Slygard 184) was purchased from Dow Corning (Midland, MI). SU-8 50 was purchased from MicroChem (Newton, MA). Sodium alginate (Protananal LF20/40, FMC Biopolymer, Philadelphia, PA) was irradiated with 5Mrad Cobalt source to produce the low molecular weight alginate (Kong et al. 2002). The alginate was coupled with G4RGDSP peptides purchased from Peptides International (Louisville, KY) to a density of 2 peptides/polymer chain (Rowley et al. 1999). DM-nitrophenTM was purchased from EMD Bioscience (San Diego, CA). SpheroTM fluorescent particles were purchased from Spherotech (Libertyville, IL). Thin cover glasses were purchased from Fisher Scientific (Pittsburg, PA). Ethylenediamine tetraacetic acid (EDTA) was purchased from Sigma-Aldrich (St. Louis, MO). Human umbilical vein endothelial cells (HUVECs) were purchased from Lonza (Basel, Switzerland). Cell culture reagents were purchased from Invitrogen (Carlsbad, CA) unless otherwise mentioned. Orange and green CellTracker kits were purchased from Invitrogen. All images were taken by a CCD camera (Hamamatsu Orca-ER) mounted on an inverted microscope (Nikon, TE-300). The microscope was supplied with a mercury lamp (Osram, HBO 100 W/2) with a UV bandpass filter (330–380 nm) (Nikon).

2.2 Fabrication of microfluidic channels

Microfluidic channels were fabricated using soft lithography (Duffy et al. 1998). We used two kinds of microchannels, a microchannel (W × H = 300 μm × 100 μm) containing three-inlet channels (W × H = 300 μm × 100 μm) (Fig. 1) and a microchannel (W × H = 100 μm × 200 μm) with side chambers (W × L × H = 200 μm × 200 μm × 200 μm) (Fig. 2). Briefly, PDMS prepolymer was mixed with curing agent at a weight ratio of 10 (prepolymer): 1 (curing agent). The mixture was then cast onto a 4 in. silicon wafer having 100 μm thick or 200 μm positive relief patterns of SU-8 of microchannels and cured at 60ºC overnight. The cured PDMS layer was peeled from the silicon wafer. Holes of 3 mm diameter were punched through the cured PDMS substrates and used as reservoirs. The cured PDMS substrate and a clean thin cover glass (thickness = 0.13–0.17 mm) were pre-treated with oxygen plasma for about ~30 s at 500 mm-torr before bonding together.

Patterned gelation of alginate hydrogels in a 1-inlet-3-outlet microchannel. (A) A schematic shows the top view of the microchannel. (B) Alginate-DM-nitrophen solution mixed with green fluorescent beads was loaded into the channel via the inlet until the flow stopped. (C) A schematic shows the position of a photomask during UV exposure. (D) A schematic shows regions of non-crosslinked (light green) and crosslinked (dark green) alginate hydrogels after UV exposure. (E) PBS solution was applied from the inlet to remove the non cross-linked alginate; cross-linked alginate hydrogels remained in channels. (F) 0.1 M EDTA was applied to dissolve hydrogels from all channels. Scale bar shown in (B) is 300 µm

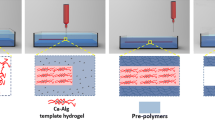

Patterned co-culture of endothelial cells and MC3T3 cells in a straight microchannel with side chambers. (A) Alginate-DM-nitrophen solution mixed with MC3T3 cells labeled with CellTracker green was loaded into the microchannel. (B) A photomask placed underneath the channel only allowed 20 s UV exposure to the side chambers. (C) This cross-linked alginate and immobilized MC3T3 cells are only in the side chambers. (D) Endothelial cell suspension where the cells were labeled with CellTracker orange was introduced into the channel after washing out non-cross-linking alginate solution and MC3T3 cells. (E, F) The endothelial cells (red fluorescence) stayed in the straight channel, while the MC3T3 cells (green fluorescence) remained in the side chamber where the alginate maintains the cells in position and in a non-spread rounded state. Scale bars shown in (E) and (F) are 200 µm

2.3 Experimental setup for MC3T3 cell and endothelial cell cultures in alginate

MC3T3 cells were maintained in minimal essential medium (α-MEM) supplemented with 10% fetal bovine serum (FBS), 1% penicillin, 1% streptomycin, and 1% glutamine in a humidified 5% CO2 incubator at 37°C (Xiao et al. 1997). After the cells were seeded, the culture medium was replaced daily. Human umbilical vein endothelial cells (HUVECs) were maintained in EGM-2 culture medium in a humidified 5% CO2 incubator at 37°C. The culture medium was replaced every other day. MC3T3 cells were trypsinized followed by centrifuging. The resulting cell pellet (~ 105 cells) was resuspended in 3% (wt/vol) alginate solution. The cell-alginate was then mixed with the caged calcium compound prepared by 13.3 mM CaCl2 and 6.7 mM DM-nitrophen at 1:1 ratio before adding into microchannels. For co-culture experiments, MC3T3 cells and HUVECs were labeled with CellTracker green (5 µM) and CellTracker orange (10 µM) for 30 min before seeding the cells, respectively. C2C12 cells were provided in courtesy of Dr. Shian-huey Chiang at the University of Michigan and maintained in Dulbecco’s modified Eagle’s medium (DMEM) supplemented with 15% fetal bovine serum (FBS), 1% penicillin, 1% streptomycin, and 1% glutamine in a humidified 5% CO2 incubator at 37°C. For C2C12 cell viability tests, we used the commercially available Viability/Cytotoxicity kit for mammalian cells (Invitrogen, L-3224) and followed the protocol provided by the company.

3 Results and discussion

3.1 Formation of alginate hydrogels using DM-nitrophenTM

The strategy to release calcium from the calcium caged DM-nitrophenTM (DM-n) compounds is based on the photochemical scission of its ethylenediamine tetraacetic acid (EDTA) backbone. UV photolysis breaks the Ca2+ coordination sphere into two, yielding low affinity fragments that consequently release the caged calcium (Ellis-Davis 2007). The dissociation constant (K d ) of DM-n after UV exposure is around 3–6 mM at pH = 7.2 (Ellis-Davis 2003). The minimal calcium concentration required for gelling of alginate hydrogels is also in the low millimolar range (Hughes et al. 1980). We used calcium release from DM-nitrophen by photolysis as the calcium source to form alginate hydrogels in microfluidic devices. Region selective formation of alginate hydrogels was performed by UV irradiation through a specific feature of a photomask.

We first optimized concentrations and ratios of the DM-nitrophenTM and calcium ions for the light-triggered cross-linking of alginate. DM-n has been used as an ideal caged calcium chelator with a very low dissociation constant of Ca2+ (K d = 5 nM) that dramatically increases after UV photolysis (Ellis-Davis 2003). The dissociation constants of DM-n before and after UV photolysis are very different and the photolyzed fragments have K d similar to that of alginate (Ellis-Davis 2003). The key to performing light-triggered alginate hydrogel formation is to find concentrations of calcium, DM-n, and alginate that gives alginate bound calcium ion concentrations low enough to prevent pre-gelling before UV exposure, but release sufficient free calcium from DM-n after UV exposure for alginate gelation. We tested several mixtures of different concentrations of DM-n and total Ca2+, which includes free calcium ion, caged calcium, and alginate pre-associated calcium concentrations, at a fixed concentration of alginate of 1.5% (Table 1). Varying degrees of gelling were observed from the five alginate solutions after UV exposure. The first calcium bound to DM-n is very strong (Kd of nanomolar). The second calcium ion, however, will be bound weaker. Alginate itself can have some calcium without going through extensive crosslinking. Once the DM-n is photolyzed, the Kd of the fragments is still 3–6 mM and is not that different from the Kd of calcium with alginate. Thus, not only the ratio of Ca2+ to DM-n is important, but the absolute concentrations also play crucial roles in using light-directed release of caged calcium to generate alginate hydrogels. The combination of [DM-n] = 6.7 mM and [total Ca2+] = 13.3 mM was the best; most calcium ions were chelated by DM-n and the concentration of unbound calcium was relatively low without completely cross-linking the alginate. Because of the high cost of DM-n, structures large enough to directly measure the Young’s modulus conveniently and reliably could not be prepared (Kong et al. 2003). The qualitative appearance suggests the modulus to be equal or softer than alginate hydrogels prepared by directly mixing with 6.7 mM calcium sulfate, which is known to give a modulus of 2.4 kPa.

The photolysis of caged calcium compound of DM-n is intrinsically very rapid. Neuro-scientists have used caged compounds for exocytosis studies in the synaptic terminal, for instance, and reported that a light flash can cause a jump in [Ca2+] from tens of nM to tens of μM in the synaptic terminal almost instantaneously (Rettig and Neher 2002). The extinction coefficient, a measure of how well a substance absorbs electromagnetic waves, of DM-n is 4300 M−1CM−1 (Ellis-Davis 2007). In the case of gelation of the alginate hydrogel using DM-n, the concentration of DM-n is on the order of mM and the path of UV light through microfluidic systems (several hundred microns) is much longer than through a cell (several microns). We investigated the extent of gelling of the alginate hydrogel using different UV exposure times (Table 2) from a 100 W mercury lamp commonly used in fluorescence microscopy. 1 s and 5 s UV exposure time did not induce the cross-linking of the alginate, indicating insufficient calcium release from the caged calcium compounds. By increasing UV exposure up to 15 s and longer (estimated 10 mJ/cm2), the alginate solution became a solid gel. The solid gel formation may require various UV exposure time depending on the depth of the microchannel. Long duration of UV exposure may also damage cells. Hence the minimal UV exposure time was investigated to ensure the formation of the alginate hydrogels with the least damage to cells. In subsequent experiments, we applied 15 s or 20 s UV exposure to cross-link the alginates in the microchannels.

A photomask with a specific feature can restrict UV exposed regions. We investigated the diffusion of UV light as it comes through a rectangular feature (W × L = 100 μm × 1 cm) on a photomask that was aligned to five parallel microchannels so that only one channel is exposed directly to UV light (data not shown). The widths of the five channels were 100 μm and the spacing between the channels was 50 μm. All five microchannels were pre-loaded with the alginate-caged calcium solutions, exposed with 15 s UV, and then washed with DI water. No flow was generated in the one microchannel exposed to UV, indicating the alginate was cross-linked, whereas the alginate solution in the four other adjacent microchannels was removed. This suggests that the diffusion of UV light is sufficiently small.

3.2 Reversible gelation using alginate with caged calcium compound

As an initial in-channel reversible gelation experiment, we first cross-linked alginate in selective regions and then reversed the gelation in a one-inlet-three-outlet microchannel. The entire microchannel was pre-loaded with the alginate-caged calcium solution (Fig. 1(a), (b)). Region-selective UV light exposure was performed through a photomask (Fig. 1(c)) and the microchannel was washed by DI water from the inlet. Figure 1(e) shows that the non-cross-linked alginate was removed from the inlet to the left outlet while the cross-linked alginate remained in the other two outlet channels, demonstrating region-selective patterning of the alginate hydrogels in microchannels. Figure 1(f) shows the reopening of the two outlet channels by flowing 0.1M EDTA solution from the inlet. One unique characteristic of the alginate hydrogel is the ability to reverse the gelling by calcium chelators such as EDTA. This is different from other photopolymerizable hydrogels such as poly(ethylene glycol) (PEG) and 2-hydroxyethyl methacrylate (HEMA), which are irreversibly cross-linked by covalent bonds. This reversibility of the alginate hydrogel may be useful in controlling of microfluidic valves (Sershen et al. 2005) as well as in situations where it is desirable to harvest cells from inside gels.

3.3 Patterned co-culture in microchannels using photopatterning of alginate hydrogels

We demonstrate co-culture of MC3T3 cells and HUVECs in a microfluidic device using the light-triggered cross-linking of alginate hydrogel. First, we performed cell viability tests over a 12-hour culture period in PDMS microwells to ensure that cells can survive under high concentration of DM-n (6 mM) and 15-second UV exposure. Above 90% of C2C12 cells were alive, which was similar to the control results without exposure to light nor DM-n. We patterned two types of cells in a microchannel with side chambers. In the first step, MC3T3 cells labeled with Cell Tracker green in RGD coupled alginate-DM-n solution was introduced into the microchannel (Fig. 2(A)). Only the side chambers were exposed to UV light to region-selectively cross-link the alginate (Fig. 2(B), (C)). The non-crosslinked alginate located in the straight channel was washed out and replaced with a suspension of HUVECs labeled with CellTracker orange. The HUVECs were located in the straight channel while the MC3T3 cells remained in the alginate gels in the side chambers (Fig. 2(D)). An important consideration is the resolution or the degree of blurring of the gelling at the edge of the light exposed region. There are two counter-acting events that cause blurring of the structures and patterns formed: (1) scattering or diffraction of light which may cause release of calcium and gelling beyond the region of interest, and (2) diffusing away of released calcium or diffusing in of unphotolyzed DM-n which would reduce gelling in the light exposed regions. With the minimal light exposure conditions we use to minimize cell damage, the latter of the two effects is more dominant. For example, in the experiment shown in Fig. 2(E) and (F), ~15 µm of the light exposed region still has insufficient cross-linking of the alginate to withstand washing.

In summary, we describe a light-directed in-channel hydrogel patterning technology. The technology is unique in using alginate as the hydrogel and calcium as the light-released cross-linking agent. The technology provides four advantages for microfluidic hydrogel formation: (i) reversibility of gelling, (ii) biocompatibility with living cells, (iii) ability to take advantage of the wealth of alginate chemistry and knowledge, and (iv) ability localize gelling in ways otherwise difficult to control using calcium crosslinking such as forming 3D co-cultures. While the reversible gelling is an advantage for some applications such as flow switching and cell retrieval, this also does lead to two disadvantages such as (i) reduced resolution at the edge of light exposure and (ii) high cost of DM-n limiting fabrication of large structures.

4 Conclusion

We demonstrate that DM-n can be used as a source of calcium to form alginate hydrogel upon UV exposure. We optimized the concentrations of DM-n and CaCl2 for a given alginate concentration of 1.5% to enable efficient gelation upon exposure without pre-exposure gelation. This strategy enabled reversible regulation of fluid flow direction in a one-inlet-three-outlet microchannel where gelation stops flow into channels and dissolution of the hydrogels using EDTA solution restores flow through those channels. Furthermore, the alginate hydrogel formation method is biocompatible with mammalian cell culture and enabled convenient patterned co-culture of two different cell types embedded in alginate hydrogels in a microfluidic device. The high cost of DM-n limits fabrication of large structures or continuous production of structures such as is performed in stopped flow lithography (Dendukuri et al. 2007), but the strategy of light-directed patterning of alginate hydrogels described here is envisioned to be useful for reversible flow manipulation, in vitro 3D cell culture, and other alginate hydrogel applications in microfluidic systems.

References

E. Alsberg, K.W. Anderson, R.T. Franceschi, D.J. Mooney, J. Dent. Res. 80, 2025–2029 (2001)

K. Arcaute, B.K. Mann, R.B. Wicker, Ann. Biomed. Eng. 34, 1429–1441 (2006)

T. Braschler, R. Johann, M. Heule, L. Metref, P. Rnaud, Lab Chip 5, 553–559 (2005)

M. Cabodi, N.W. Choi, J.P. Gleghorn, C.S.D. Lee, L.J. Bonassar, A.D.J. Stroock, J. Am. Chem. Soc. 127, 13788–13789 (2005)

J.-P. Chen, T.-H. Cheng, Polymer 50, 107–116 (2009)

D. Dendukuri, S.S. Gu, D.C. Pregibon, T.A. Hatton, P.S. Doyle, Lab Chip 7, 818–828 (2007)

D.C. Duffy, J.C. McDonald, O.J.A. Schueller, G.M. Whitesides, Anal. Chem. 70, 4974–4984 (1998)

G.C.R. Ellis-Davis, Nat. Methods. 4, 619–628 (2007)

G.C.R. Ellis-Davis, Meth Enzymol. 360A, 226–238 (2003)

N.W. Choi, M. Cabodi, B. Held, J.P. Gleghorn, L.J. Bonassar, A.D. Stroock, Nat. Mater. 7, 908–915 (2007)

E. Cukierman, R. Pankov, D.R. Stevens, K.M. Yamada, Science 294, 1708–1712 (2001)

C. Fishbach, H.J. Kong, S.X. Hsiong, M.B. Evangelista, W. Yuen, D.J. Mooney, Proc. Natl. Acad. Sci. U.S.A. 106, 399–404 (2009)

G.T. Franzesi, B. Ni, Y. Ling, A.J. Khademhosseini, J. Am, Chem. Soc. 128, 15064–15065 (2006)

B.M. Gillette, J.A. Jensen, B. Tang, G.J. Yang, A. Bazargan-Lari, M. Zhong, S.K. Sia, Nat. Mater. 7, 636–640 (2008)

L.G. Griffith, M.A. Swartz, Nat. Rev. Mol. Cell Biol. 7, 211–224 (2007)

A.P. Golden, J. Tien, Lab Chip 7, 720–725 (2007)

M.S. Hahn, J.S. Miller, J.L. West, Adv. Mater. 18, 2679–2684 (2006)

X. Hao, E.A. Silva, A. Mansson-Broberg, K. Grinnemo, A.J. Siddiqui, G. Dellgren, E. Wardell, L.A. Brodin, D.J. Mooney, C. Sylven, Cardiovasc. Res. 75, 178–185 (2007)

L. Hughes, D.A. Ledward, J.R. Mitchell, C.J. Summerlin, Texture Studies 11, 247–256 (1980)

A.M. Kloxin, A.M. Kasko, C.N. Salinas, K.S. Anseth, Science 324, 59–63 (2009)

W.G. Koh, A. Revzin, M.V. Pishko, Langmuir 18, 2459–2462 (2002)

H.J. Kong, E. Wong, D.J. Mooney, Macromolecules 36, 4582–4588 (2003)

H.J. Kong, K.Y. Lee, D.J. Mooney, Polymer 43, 6239–6246 (2002)

K. Liu, H. Ding, J. Liu, Y. Chen, X. Zhao, Langmuir 22, 9453–9457 (2006)

C.M. Nelson, M.M. VanDuijn, J.L. Inman, D.A. Fletcher, M.J. Bissell, Science 314, 298–300 (2006)

C.M. Nelson, J. Tien, Curr. Opin. Biotechnol. 17, 518–523 (2006)

J.W. Nichol, A. Khademhosseini, Soft Matter 5, 1312–1319 (2009)

P. Panda, S. Ali, E. Lo, B.G. Chung, T.A. Hatton, A. Khademhosseini, P.S. Doyle, Lab Chip 8, 1056–1061 (2008)

N.S. Peppas, J.Z. Hily, A. Khademhosseini, R. Langer, Adv. Mater. 18, 1345–1360 (2006)

B.D. Plouffe, M.A. Brown, R.K. Iyer, M. Radisic, S.K. Murthy, Lab Chip 9, 1507–1510 (2009)

J. Rettig, E. Neher, Science 298, 781–785 (2002)

J.A. Rowley, G. Madlambayan, D.J. Mooney, Biomaterials 20, 45–53 (1999)

R.W. Sands, D.J. Mooney, Curr. Opin. Biotechnol. 18, 448–453 (2007)

S.R. Sershen, G.A. Mensing, M. Ng, N.J. Halas, D.J. Beebe, J.L. West, Adv. Mat. 17, 1366–1368 (2005)

J.H. Sung, M.L. Shuler, Lab Chip 9, 1385–1394 (2009)

W. Tan, T.A. Deasi, Biomaterials 25, 1355–1364 (2004)

M.D. Tang, A.P. Golden, J. Tien, J. Am. Chem. Soc. 125, 12988–12989 (2003)

V.L. Tsang, A.A. Chen, L.M. Cho, K.D. Jadin, R.L. Sah, S. DeLong, J.L. West, S.N. Bhatia, FASEB J. 21, 790–801 (2007)

A.P. Wong, R. Perez-Castillejos, J.C. Love, G.M. Whitesides, Biomaterials 29, 1853–1861 (2008)

G. Xiao, Y. Cui, P. Ducy, G. Karsenty, R.T. Franceschi, Mol. Endo. 11, 1103–1113 (1997)

K.Y. Yamada, E. Cukierman, Cell 130, 601–610 (2007)

H. Yan, A. Nyjnen, J. Ruokolainen, D. Farrar, J.E. Gough, A. Saiani, A.F. Millar, Faraday Discuss 139, 71–84 (2008a)

H. Yan, Y. Zhao, C. Qiu, H. Wu, Sens. Actuators, B 132, 20–25 (2008b)

Acknowledgement

This material is based on work supported by the U.S. Army Research Laboratory and the U.S. Army Research Office under Contract Grant DAAD19-03-1-0168 and the NIH (HG004653).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chueh, Bh., Zheng, Y., Torisawa, Ys. et al. Patterning alginate hydrogels using light-directed release of caged calcium in a microfluidic device. Biomed Microdevices 12, 145–151 (2010). https://doi.org/10.1007/s10544-009-9369-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-009-9369-6