Abstract

The standard TopSpot® technology has been successfully used in the recent years for the highly parallel nanoliter dispensing of bio-chemical substances for microarray printing. It is based on a pneumatically actuated printhead which enables non-contact microarray fabrication at a pitch of typically 500 µm. This paper reports on a new and improved way of operating the printheads termed TopSpot® Vario technology, using an incompressible material between the piezo actuator and the dispensing medium. The advantage of the incompressible medium is the direct relation between the displacement amplitude and the ejected liquid volume. Earlier reports stated that the filling of the printheads is a key issue. In this paper we report on the implementation and characterization of a new printhead design including microchannels for bubble free priming of blind channels. Microarray fabrication was successfully conducted with four different types of protein.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last years, microarrays became a crucial tool for large-scale and high throughput technologies. They enable a fast and parallel detection of thousands of addressable elements in one single experiment (Zhu and Snyder 2003). At the moment it is the most promising application for which the drug discovery process seeks: to develop a biological or chemical entity that, when administered to a patient, will improve the disease symptomatology or actually treat the underlying pathophysiological basis of the particular disease state (Hardiman 2002).

The basic idea of a microarray is a spatially ordered, miniaturized arrangement of a multitude of immobilized reagents (Weller 2003). Only tiny quantities of precious and expensive samples are consumed, stocks that might have taken researchers years to prepare (Mitchell 2002). This low volume requirement and the multiplexed detection capability make optimum use of precious clinical samples. Large sample sets, as required for several biological studies, can be processed in parallel. Additionally microarray assays are rapid and amenable to automation. The assays can be very sensitive, reproducible and quantitative because of the use of optimized detection methods and rigorous quality control (Haab 2003).

One step in performing a microarray assay is the production of the microarray itself. Mainly two production principles are used. First, the on-chip approaches where the features of the microarray are synthesized directly on the substrate (Affymetrix, Inc. 2009, Roche NimbleGen 2009, Febit Biotech GmbH 2009, Agilent Technologies, Inc. 2009, Li et al. 2004). Second, the more commonly used approach of deposition of pre-synthesized molecules by a microarrayer onto the substrate. Commercial available microarrayers currently use contact and non-contact microarray printing. Contact arrayers commonly use different shaped steel pins for direct deposition of droplets onto the substrate by touching the surface with the pins (TeleChem International, Inc. 2009, Perkin Elmer, Inc. 2009, Genomic Solutions, Inc. 2009, BioRad Laboratories 2009, Whatman plc. 2009, Genetix Ltd. 2009, Lin et al. 2004). Non-contact arrayers rely often on piezo-driven ink-jet like dispensers and shoot a droplet onto the substrate without getting in contact with the substrate surface (BioFluidix GmbH 2009, Perkin Elmer, Inc. 2009, microdrop Technologies GmbH 2009, GeSim GmbH 2009, Scienion AG 2009, Genomic Solutions 2009, de Heij et al. 2003, Takagi et al. 2004, Kuoni et al. 2004). The ink-jet printing approaches apparently provide less spot to spot and chip to chip variability than contact printing methods (Park et al. 2004). A few microarrayers which use other technical approaches are also commercially available (Zyomyx, Inc. 2009, Nanogen, Inc. 2009). Last but not least an alternative to purchase an entire microarrayer is to purchase custom made microarrays.

For the high throughput production of microarrays a highly parallel method for dispensing the different reagents is needed. We previously reported on highly integrated TopSpot® printheads with 24 and 96 channels, operated by compression of air (Gutmann et al. 2005). In this paper we report on the use of a new actuation technology (TopSpot® Vario) relying on the displacement of an incompressible but deformable and elastic medium. This guarantees a cross contamination free self-filling of the printhead and a full control of speed and size of the ejected droplets (de Heij et al. 2003, Steinert et al. 2004).

2 TopSpot® Vario principle

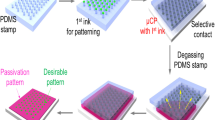

The basic elements of the TopSpot® Vario technology are a micromachined printhead made from silicon and Pyrex glass (Steinert et al. 2004), an elastomer sheet and a piston (Fig. 1). The one mm thick elastomer sheet (Sylgard 186, Dow Corning) is placed between the piston and the printhead on top of the nozzle array. The piston is actuated by a piezo stack actuator enabling displacement of the elastomer of up to 15 µm. The movement of the piston is thus transferred into a direct displacement of the liquid contained in the nozzles which causes the droplets to be ejected.

The filling of the printhead takes place through capillary forces. Surface tension transports the liquid from each reservoir to the corresponding ejection nozzle. Also the refilling after droplet ejection is accomplished by capillary forces.

The key problem during printhead priming is a reliable cross-contamination free and bubble free filling of the printheads. In earlier experiments (de Heij et al. 2003) it was not possible to reliably prevent cross-contamination between the channels when inserting the elastomer after the printhead has been filled. Vice versa, if the elastomer is placed before printhead filling, air bubbles are trapped inside the nozzles. Latter form a fluidic capacity preventing the actuation energy to be fully coupled into the droplet generation.

To avoid these air bubbles a principle for bubble free priming of blind-channels reported earlier (Steinert et al. 2004) was integrated into the printhead design.

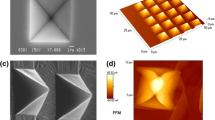

3 Bubble-free printhead priming

Trapping of air inside the channel system can be avoided by a two step channel structure as depicted in Fig. 2. Fig. 2(a) shows the implementation of the two-level microchannel structure for bubble free filling of blind channels into the TopSpot® Vario printhead design. The working principle is explained by the cross sections in Fig. 2(b). Liquid flows from the microchannels on the bottom side of the silicon layer to the via. There it changes to the top side into the lower level of the nozzle inlet channel and flows towards the nozzle. A sharp step between lower and upper level prevents liquid transfer into the upper level at this stage. At the blind end of the microchannel the sharp step is removed and changeover into the upper level is enabled. After liquid transfer the upper level is filled in reverse direction displacing air out of the air outflow channel. As last preparation step the prestress on the elastomer is raised to seal off the air outflow channel. A fabricated 24 channel TopSpot® Vario printhead with implemented two-level microchannel design is shown in Fig. 3.

4 Experiments

The TopSpot® Vario technology was extensively tested for its printing performance with respect to the piezo actuation and the elastomer parameters. Printing performance was characterized by observing droplet volume, droplet velocity, array homogeneity, stable operation and system malfunctions. Figure 4 shows the experimental setup. A stroboscopic camera (Mocon-RT, Visit GmbH) was used for recording the droplet flight. Droplet volume and velocity were directly determined from the taken images by an image analysis software. Additionally a fluorescence scanner (BioAnalyzer 4S/4F, LaVision Biotech) was used for measuring diameters and integral intensities of the corresponding microarray spots. A laser vibrometer (Laser Doppler Vibrometer, Polytec GmbH) was used for measuring piezo stroke and speed.

Main objective of the reported experiments was to find the influence of piezo stroke, piezo speed and elastomer prestress on droplet volume, droplet speed and array homogeneity. Afterwards the system performance was characterized by repeating one printing experiment ten times with fixed parameters set to the optimum values determined before. Finally the maximum printing frequency, the maximum stable dispensable liquid viscosity and the long time performance were evaluated.

5 Results

5.1 Droplet volume

The volume of the ejected droplets can be tuned by the piezo stroke in a linear fashion. Six different piezo strokes between 2.5 µm and 13.5 µm were evaluated and the corresponding droplet volumes were measured. Figure 5 shows the results. As expected from the direct displacement principle, the ejected droplet volume is proportional to the piezo stroke. It can be tuned between 250 pl and 1,500 pl for the described setup. A degradation of the CV of the 24 droplet volumes within one array (inter nozzle reproducibility) was observed with increasing piezo stroke. The inter nozzle reproducibility of droplet volume increased from 7.5% at a small piezo stroke (2.5 µm) up to 10.2% at maximum piezo stroke (13.5 µm).

Droplet volume versus piezo stroke. Error bars represent the CV of 5% of mean droplet volume of one array between the experiments (including printhead washing and refilling). Bottom pictures show records of stroboscopic camera and fluorescence scanner for two different droplet volumes (printing solution: 3 M betaine/6× SSC + 2 µM Dyomics DY555; slide: epoxy modified glass slide)

5.2 Droplet speed

The droplet velocity can be controlled by tuning the piezo speed. As reported earlier there exists a certain stable range—depending on the liquid properties—where exactly one droplet is ejected out of each nozzle (de Heij et al. 2003). Velocities above that range produce satellite droplets following the main droplet. Speeds below that value result in an unstable droplet tear-off. This observation could be verified by an experiment with piezo stroke set to 5 µm and tuning piezo speed between 50 mm/s and 120 mm/s (see Fig. 6). The dotted lines in Fig. 6 give the stable range which was found for piezo speeds between 60 mm/s and 70 mm/s using 3 M betaine/6× SSC as printing liquid.

5.3 Elastomer prestress force

The influence of the prestress exerted on the elastomer on the inter nozzle reproducibility was measured for various prestress forces between 6 N and 14 N. The records in Fig. 7 show that with increasing elastomer prestress force the droplet homogeneity decreased. The absolute values of droplet velocity and volume were not influenced remarkably in the tested range but the corresponding CVs were (see table in Fig. 7).

5.4 System performance

The conclusion from the previous three paragraphs is that best results in terms of array homogeneity can be found for a small piezo stroke (2.5 µm) and a small elastomer prestress force (6 N). Hence, to quantify the overall performance of the system, an experiment with a prestress force of 6 N and a piezo stroke of 2.5 µm was repeated ten times using a fluorescence marked aqueous solution (3 M betaine/6× SSC + 2 µM Dyomics DY555) as printing solution. A mean droplet volume of all 24 droplets of one array was measured at 270 pl with a CV of 5% over all ten experiments (including printhead washing and refilling between the experiments). The inter nozzle reproducibility of spot diameters within one print was in average 2.4% and below 3.4% in all experiments. The inter nozzle reproducibility of droplet volumes was determined to be 7.5%. The intra nozzle reproducibility of the droplet volume (CV of the volume of 100 subsequently ejected droplets out of the same nozzle) was measured at 1.9%.

5.5 Printing frequency

Printing frequency was increased in 100 Hz steps and the system performance was observed to estimate the maximum frequency where stable operation could still be guaranteed. At a frequency of 500 Hz the first satellite droplets appeared and printing became unstable. Thus, a maximum printing frequency of 400 Hz can be considered as upper limit for safe operation. This is much higher than typical frequencies currently used for micro array printing.

5.6 Liquid viscosity

Experiments using different mixtures of aqueous glycerol solutions as printing medium were performed to estimate the maximum dispensable liquid viscosity. While 60 wt.% aqueous glycerol solution (viscosity of 11 mPa s) could still be ejected in stable operation, no droplet tear off could be observed anymore using a 70 wt.% aqueous glycerol solution (viscosity of 23 mPa s). Furthermore, at constant piezo stroke, a decrease of droplet volume with increasing liquid viscosity was observed. At a piezo stroke of 13 µm the droplet volume decreased from 1,600 pl using dispensed water (viscosity of 1 mPa s) down to 600 pl using 60 wt.% aqueous glycerol solution as printing solution (see Fig. 8).

5.7 Longtime performance

Changes in array homogeneity or droplet volume with increasing number of prints in one experiment were measured to evaluate the long term performance of the technology. Printing frequency was set to 1 Hz and spot integral intensity and diameter were analyzed after several time intervals. Figure 9 shows the results.

Longtime performance. Arrays with droplet volumes of 270 pl were printed consecutively with a frequency of 1 Hz. Spot diameter (SD) and spot integral intensity (SI) were measured with a fluorescence scanner in the shown intervals. After 18,000 prints one nozzle stopped printing and the experiment was stopped

Spot diameter (SD) and spot integral intensity (SI) as well as the corresponding CVs (SDCV: 1.7%–3%; SICV: 5.8%–7.4%) remained constant during the entire printing time of 5 h. After 5 h the first system malfunction was observed due to intermission of one nozzle and printing was stopped after 18,000 prints.

6 Discussion and conclusion

A novel method for tunable and highly parallel picoliter dispensing, the TopSpot® Vario technology, has been presented. It can be used for non-contact printing of microarrays. A technique for bubble-free priming of blind channels described in (Steinert et al. 2004) was successfully implemented into the printhead design. This solved one of the major problems of the TopSpot® Vario technology—the cross contamination free and bubble free printhead priming—reported earlier (de Heij et al. 2003, Steinert et al. 2004).

With the new printhead design various experiments have been performed to study the printing performance. For example, by adjusting the piezo actuator stroke the droplet volume can be tuned linearly in a range between 250 pl and 1,500 pl for aqueous solutions. Stable operation, which means that only one droplet is ejected out of each nozzle, could be achieved in this case by setting the piezo actuator speed between 60 mm/s and 70 mm/s.

The observed increase of inter nozzle CV with increasing droplet volumes suggests that higher spot diameters should be achieved by multiple printing of small droplets into each other instead of ejecting only one large droplet. Best printing performance was found at a droplet volume of 270 pl with an inter- and intra nozzle reproducibility of droplet volume of 7.5% and 1.9% respectively. The CV of droplet volume between different experiments (including printhead washing and refilling) was measured to be 5%. Printing was stable up to frequencies of 400 Hz. Liquids with viscosities of up to 11 mPa s (corresponds to 60 wt.% aqueous glycerol solution) could be successfully dispensed up to 18,000 times during one experiment in stable operation. Table 1 summarizes the overall performance of the TopSpot® Vario system used for the experiments. In addition to the liquids considered in detail in this paper many other liquids have been successfully dispensed to fabricate microarrays with a similar quality like reported for aqueous solutions (see Table 1).

The presented results prove that the TopSpot® Vario technology can compete with other state-of-the-art non-contact microarrayers (BioFluidix GmbH 2009, Perkin Elmer, Inc. 2009, microdrop Technologies GmbH 2009, GeSim GmbH 2009, Scienion AG 2009, Genomic Solutions 2009, de Heij et al. 2003, Takagi et al. 2004, Kuoni et al. 2004) with respect to reproducibility and performance. In terms of parallelism and speed it even outperforms most of the other technologies. Thus, the real benefit of the TopSpot® Vario technology lies in the highly flexible high-throughput microarray production.

References

Affymetrix, Inc., The GeneChip® System: an integrated solution for expression and DNA analysis, https://www.affymetrix.com/support/technical/brochures/genechip_system_brochure.pdf. Accessed February 2, 2009

Agilent Technologies, Inc., SurePrint Technology, http://www.chem.agilent.com/en-US/Products/Instruments/dnamicroarrays/pages/gp557.aspx. Accessed February 2, 2009

BioFluidix GmbH, Liquid Handling for Science and Industry, http://www.biofluidix.com/index.php?id=49&L=2&tx_ttnews[tt_news]=undefined&tx_ttnews[backPid]=undefined. Accessed February 2, 2009

BioRad Laboratories, Microarray Systems, http://www.biorad.com/LifeScience/pdf/Bulletin_2856.pdf. Accessed February 2, 2009

B. de Heij, C.P. Steinert, H. Sandmaier, R. Zengerle, Sens Actuators A 103, 88–92 (2003) doi:10.1016/S0924-4247(02)00321-7

H. Febit Biotech GmbH, Geniom Biochips, http://www.febit.com/go/en/products/geniom-biochips/. Accessed February 2, 2009

Genetix Ltd, QArraye Microarrayer Systems, http://www.genetix.com/enxhtml/product.aspx?pid=63. Accessed February 2, 2009

Genomic Solutions, Inc., Nanoliter dispensing, http://genomicsolutions.com/nanoliter-dispensing/. Accessed February 2, 2009

Genomic Solutions, Inc., SynQUADTM Technology, http://www.genomicsolutions.com/instruments/synquad.aspx. Accessed February 2, 2009

GeSim GmbH, Non-Contact Piezoelectric Dispensers, http://www.gesim.de/front_content.php?idcat=76&lang=2 Accessed February 2, 2009

O. Gutmann, R. Kuehlewein, S. Reinbold, R. Niekrawietz, Lab Chip 5(6), 675–681 (2005) doi:10.1039/b418765b

B.B. Haab, Proteomics 3(11), 2116–2122 (2003) doi:10.1002/pmic.200300595

G. Hardiman, Pharmacogenomics 3(3), 293–297 (2002) doi:10.1517/14622416.3.3.293

A. Kuoni, M. Boillat, N.F. de Rooij, Proceedings of IEEE International Conference on Micro Electro Mechanical Systems, Maastricht, The Netherlands, Jan. 25–29, 2004, pp. 466–469.

S. Li, D. Bowerman, N. Marthandan, S. Klyza, J. Am. Chem. Soc. 126(13), 4088–4089 (2004) doi:10.1021/ja039565w

S.C. Lin, F.G. Tseng, H.M. Huang, Y.F. Chen, Sens. Actuators B Chem. 99(1), 174–185 (2004) doi:10.1016/S0925-4005(03)00554-9

Microdrop Technologies GmbH, Microdrop—Materials by Inkjet Technology, http://www.microdrop.com/wDeutsch/technology/microdrop.shtml?navid=27. Accessed February 2, 2009

P. Mitchell, Nat. Biotechnol 20(3), 225–229 (2002) doi:10.1038/nbt0302-225

Nanogen, Inc., Nanogen Begins Shipments of NanoChip 400 Systems, http://www.nanogen.com/presscenter/pressreleases/1409/. Accessed February 2, 2009

P.J. Park, Y.A. Cao, S.Y. Lee, J.W. Kim, J. Biotechnol 112(3), 225–245 (2004)

Perkin Elmer, Inc., Piezorray—Non-Contact Microarraying System, http://las.perkinelmer.com/content/relatedmaterials/brochures/bro_piezorray.pdf. Accessed February 2, 2009

Perkin Elmer, Inc., Print Perfect Arrays the First Time…, http://las.perkinelmer.com/content/relatedmaterials/brochures/fly_spotarray.pdf. Accessed February 2, 2009

Roche NimbleGen, Array Synthesis, http://www.nimblegen.com/technology/manufacture.html. Accessed February 2, 2009

A.G. Scienion, sciFLEXARRAYER S3—the versatile tool for ultra-low volume applications in R&D, http://www.scienion.de/index.php?mid=41&vid=&lang=en. Accessed February 2, 2009

C. Steinert, H. Sandmaier, M. Daub, B. de Heij, Zengerle, Proc. of IEEE MEMS 2004, Maastricht, The Netherlands, Jan. 25–29, pp. 224–228

C.P. Steinert, I. Goutier, O. Gutmann, H. Sandmaier, Sensors Actuators A 116(1), 171–177 (2004) doi:10.1016/j.sna.2004.04.007

F. Takagi, R. Kurosawa, D. Sawaki, S. Kamisuki, M. Takai, K. Ishihara, M. Atobe, Proceedings of IEEE International Conference on Micro Electro Mechanical Systems, Maastricht, The Netherlands, Jan. 25–29, 2004, pp. 276–279.

TeleChem International, Inc., Products—Printing Technology—Stealth Technology, http://arrayit.com/Products/Printing/Stealth/stealth.html. Accessed February 2, 2009

M.G. Weller, Anal. Bioanal. Chem 375(1), 15–17 (2003) doi:10.1002/0471721190

Whatman plc., Microcaster Arrayer, http://www.whatman.com/MicroCaster_Arrayer.aspx. Accessed February 2, 2009

H. Zhu, M. Snyder, Curr. Opin. Chem. Biol. 7(1), 55–63 (2003) doi:10.1016/S1367-5931(02)00005-4

Zyomyx, Inc., “Assay Service”, Protein Profiling Biochip, http://www.zyomyx.com/docs/BioassayService.PDF. Accessed February 2, 2009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Steinert, C.P., Kalkandjiev, K., Zengerle, R. et al. TopSpot® Vario: a novel microarrayer system for highly flexible and highly parallel picoliter dispensing. Biomed Microdevices 11, 755–761 (2009). https://doi.org/10.1007/s10544-009-9289-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-009-9289-5