Abstract

This study investigated the effect of exposing a polymerase chain reaction (PCR) mixture to capillary tubing of different materials and lengths, at different contact times and flow rates and the adsorption of major reaction components into the tubing wall. Using 0.5 mm ID tubing, lengths of 40 cm and residence times up to 45 min, none of the tested polymeric materials was found to affect subsequent PCR amplification. However, after exposure of the mixture to tubing lengths of 3 m or reduction of sample volume, PCR inhibition occurred, increasing with the volume to length ratio. Different flow velocities did not affect PCR yield. When the adsorption of individual PCR components was studied, significant DNA adsorption and even more significant adsorption of the fluorescent dye Sybr Green I was found. The results indicate that PCR inhibition in polymeric tubing results from adsorption of reaction components to wall surfaces, increasing substantially with tubing length or sample volume reduction, but not with contact time or flow velocities typical in dynamic PCR amplification. The data also highlight that chemical compatibility of polymeric capillaries with DNA dyes should be carefully considered for the design of quantitative microfluidic devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

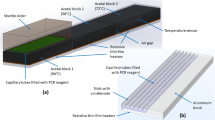

Automation and miniaturisation of DNA amplification by the polymerase chain reaction (PCR) is undergoing intense investigation, due to its enormous potential for fast and high throughput genetic analysis. Designs of PCR devices range from chamber stationary to flow through systems, as well as thermal convection-driven PCR, and fully integrated prototypes have already been presented (Liu et al., 2004). In the case of flow through systems, the contact of the reaction mixture with microchannel surfaces can have a negative impact on PCR amplification, compared with conventional PCR in tubes or microplates, due to increased surface to volume ratios. Concerns around PCR biocompatibility with materials have been expressed since the first PCR microdevices were devised (Shoffner et al., 1996; Taylor et al., 1997; Wilding et al., 1994). Despite the development of strategies to minimize these effects, they still limit the development of PCR, particularly for quantitative purposes (Kricka and Wilding, 2003; Schneegass and Kohler, 2001; Zhang et al., 2006).

Enzyme inhibition and chemical adsorption of reaction components are major mechanisms that can affect quantitative reactions in sequential multiple analyzers (Skeggs, 1966). Similarly, PCR amplification in microcircuits can be affected by the many compounds that have been described to affect PCR (Wilson, 1997). Taq polymerase inhibition in silicon and glass chips has been well studied (Erill et al., 2003; Krishnan et al., 2004) although passivation can overcome surface interactions to some extent (Giordano et al., 2001). Polymeric materials present advantages with respect to silicon or glass substrates, although these vary depending on the material used (Panaro et al., 2004). One aspect not previously accounted for is that even in inert or well passivated surfaces, physical factors such as the contact time, tubing length or shearing induced by flow velocity in the microchannels may influence the adsorption of PCR components and the reaction outcome.

The PCR is performed by thermal cycling of a multicomponent mixture in which the specific components vary with the application or the detection method employed. Diverse chemistry formats used in different studies makes results from one study difficult to extrapolate to users using different chemistries (Arya et al., 2005). Therefore, biocompatibility studies should define as much as possible the identity of the interacting components. Invariably, the PCR mixture includes target DNA, oligonucleotide primers, deoxynucleotides, polymerase enzyme, buffer and salts. For quantitative analysis, an additional reporter dye may be needed as well. It is essential that the stoichometric relationship among the reactants is kept, for they dictate the kinetic and thermodynamic behaviour of the reaction, which determine the so-called PCR efficiency. Furthermore, the compatibility of the detector, typically a fluorescent dye, needs to be studied for it may also lead to false or erratic results.

We therefore studied how physical variables such as material, contact time, tube length or flow rate can impact DNA amplification in polymeric tubing of constant internal diameter (ID) with potential use for microfluidic PCR devices. The interaction of DNA and the commonly used dye Sybr Green I with the tubing wall was explored.

2 Materials and methods

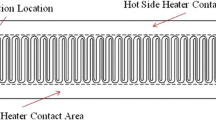

2.1 Polymeric tubing and pumping system

The polymeric tubing used in this study were: FEP (fluoroethylene-propylene) blue, FEP black, FEP orange, high purity PFA (Perfluoralkoxy), PFA natural, PEEK (polyetherketone) orange, Tefzel (fluoropolymer) with internal diameter of 500 μm and were obtained from Upchurch Scientific. Fittings and connectors were also purchased from Upchurch. The tubing was cut to different lenghts according to the experiments being performed. A Harvard PHD 22/2000 syringe pump was used to fill and pass the PCR mixture at constant speed through the tubing. Pumping speeds of 0.1, 0.5, 5 and 10 cm/s, which corresponded to infusion rates of 11.8, 58.9, 589 and 1176 μl/min, were used. Prior to each experiment, the tubing was washed with 70% ethanol, distilled water and flushed repeatedly with air to remove water droplets.

2.2 PCR mixture and experimental design

The PCR mixture was made using the LightCycler FastStart DNA Master Sybr Green I kit (Roche), oligonucleotide primers and the pGEM®-T vector DNA (Promega), as shown in Table 1. An 86-bp fragment was amplified from 10 ng plasmid DNA using the following primers from MWG Biotech (Germany): Forward 5′-AGT CAT TCT GAG AAT AGT GTA TGC GG-3′ and reverse 5′-AGT TCT GCT ATG TGG CGC G-3′. For PCR amplification, the AB7900HT Fast Real Time PCR System was used, with the following thermal profile: initial denaturation (95°C) for 10 min, followed by 30 cycles of denaturation (95°C) for 10 s, annealing (55°C) for 10 s and extension (72°C) for 15 s. Ramp rates were set to 100% and a dissociation curve (dF/dt vs T) was then obtained by heating between 65°C and 95°C at a ramp rate of 2%. Consistency and specificity of PCR amplification was first established, as judged by the presence of a unique prominent peak in the dissociation curve analysis, consistent amplification curve shifting in a 10-fold dilution series and lack of amplification of negative controls.

Twenty or 50 μl of the PCR mixture plus DNA were passed through the tubing to test the effect of the different materials, contact times, lengths of tubing or flow rates. In each experiment, a control aliquot of the same prepared PCR mix not exposed to the tubing was kept in an eppendorf tube under the same conditions of temperature and light, amplified in parallel and its PCR yield was taken as 100%. The cycle threshold (Ct), final fluorescence and PCR efficiency from the samples were compared as a percentage of the control samples. Cycle thresholds were calculated automatically by the ABi software and inspected individually for potential artifacts. Final fluorescence values were taken as the first fluorescence point of the dissociation curve. Efficiencies were calculated with the method of Ramakers et al. (2003). Each test consisted of tripilicate samples and was performed 3 times. Means and standard errors of the mean (S.E.M) were calculated from each experimental values. One-way ANOVA statistical test was used for multiple comparisons.

3 Results and discussion

3.1 Biocompatibility of materials

The first experiments sought to determine whether the PCR mixture interacted chemically upon contact with several materials to inhibit subsequent amplification. Both adsorption of reaction components and release of chemical inhibitors can be estimated in this way by quantitatively comparing subsequent real-time PCR yield of the exposed sample with non-exposed mixture. A 50 μl PCR mixture was passed at a flow rate of 10 mm/s through 40 cm of tubing (contact time = 40 s), collected at the end and amplified. Compared to non-exposed samples, PCR yield, cycle threshold (Ct) and efficiencies of PCR mixtures exposed to the different materials were not significantly different, confirming that a short contact period with these materials does not affect per se the reaction in any measurable extent (Fig. 1(A)). The specificity of the reaction was not altered either, as seen by identical dissociation temperature peaks of samples passed through the different materials (Fig. 1(B)). Tubing segments were then loaded with PCR mixture and let interact for 45 min to explore whether increasing the exposure time resulted in enhanced adsorption and reaction inhibition. The tubing segments were protected from light with foil to avoid artifactual photobleaching of Sybr Green I. After incubation, exposed mixtures were collected and amplified as before. Again, no inhibitory effect was observed in the exposed samples, showing amplification yields and Ct and efficiency values similar to the non-exposed controls (not shown). With natural PFA, the yield decreased slightly, suggesting the presence of inhibiting impurities within natural PFA rather than the plastic itself, since purified PFA performance was among the best of all materials. This result contrasts with PCR inhibition in silicon chips, which is time-dependent and happens relatively quickly (Erill et al., 2003). The tests presented here however, do not intend to explore the interaction of the materials with PCR taking place in situ at temperatures typically used in PCR. They inform that no measurable adsorption of PCR components takes place in the materials at the contact time, tube length and flow rate used.

(A) Comparative PCR yield and cycle threshold Ct (in cycle number) of quantitative PCR amplification of a reaction mixture passed through 40-cm of tubing of the following polymeric materials: (PO) Peek orange; (T) Tefzel; (FO) FEP orange; (PN) PFA natural; (FN) FEP black; (FB) FEP blue; (P) high purity PFA. (CTRL), control non-exposed mixture. (B) Dissociation curves of the amplified product in the different materials

3.2 Influence of length to volume ratio

The surface to volume ratio (SV ratio) of a fluid sample inside a receptacle is an index that reflects its degree of exposure to the exterior. For a sample slug inside a cylindrical microcapillary tubing, its value is inversely proportional to the inner radius r (SV ratio = 2/r) and, given a certain tube radius, is independent of the length of the slug. However, as the sample travels through the tubing, the extent to which the slug surface interacts with the tubing is dependent on the distance travelled. The longer the distance travelled, the more extensive this interaction will be. Additionally, as the sample volume decreases, any surface interaction will be more significant. We studied in detail this relationship by modifying either the volume for a fixed length of tubing, or the tubing length for a given sample volume. Therefore, rather than tube length alone, it was the length to volume ratio (LV ratio) what was studied.

A range of different LV ratios were tested, using highly purified PFA for these experiments. First, either 20 or 50 μl aliquots of PCR mix were passed at a velocity of 10 mm/s through 40 cm of PFA tubing, collected at the end of the tube and amplified. Identical samples not exposed to the plastic were amplified in parallel as controls. As shown in Fig. 2, after being passed through 40 cm, the 20 μl sample amplified significantly less (yield: 55%) than the 50 μl sample (yield: 73%), in turn amplifying less than the controls. In a second set of experiments, 20 μl or 50 μl PCR samples were pumped through 3 m of PFA tubing. As before, reducing the sample volume to 20 μl resulted in a lower amplification yield (7%) than with the 50 μl sample (36%) (Fig. 2). When comparing the results of the same sample volume passed either through 40 cm or 3 m, it becomes apparent that increasing the length of the tube also resulted in decreased amplification yield in both 20 and 50 μl samples. These results are compiled in Fig. 3, which shows that PCR amplification yield decreases as the LV ratio closely following an exponential decay relationship (R 2 = 0.98).

3.3 Influence of flow velocity

PCR amplification consists of repetitive cycles of heating and cooling of the reaction mixture for short periods of time. Amplification yield is thus dependent on the residency time of the reaction mixture at every temperature in the thermal cycle. Flow through PCR, in which the sample circulates inside microchannels must have precise control of the flow velocity of the mixture travelling through the different temperature regions. Devices with different dimensions and designs will then need different flow velocities to achieve the same denaturation, annealing or extension times. In addition, for one particular device, the velocity may change for amplification of templates requiring different thermal profiles.

Following the same experimental design of previous sections, we investigated whether a range of flow velocities (0.1 cm/s to 10 cm/s) influences the amplification yield of a 50 μl sample at 2 different tubing lengths (40 cm and 3 m). The results, shown in Fig. 4, showed no evidence of flow velocity influencing PCR yield. Although slow velocities seemed to decrease yield, there was strictly no statistical evidence supporting such view. Moreover, when the Ct values were analyzed, no differences between velocities were seen, meaning that DNA quantitation was not altered at any velocity. At longer lengths of tubing (3 m), where important inhibition occurs as shown previously, varying the velocity between 0.5 mm/s and 5 cm/s did not make alter PCR yield either. These results indicate that adsorption or inhibition of PCR does not significantly differ at different speeds in PFA tubing, which is consistent with our initial observation that contact time does not influence the PCR yield.

3.4 Adsorption of individual PCR components in the tubing walls

From the previous experiments we know that when a PCR mixture travels long distances in polymeric capillary tubing, subsequent amplification is inhibited. The underlying reason could be adsorption of reaction components or inhibitory chemicals being shed from the tubing to the mixture en passage. We studied the first possibility in more detail by measuring the fluorescence of a complete PCR mixture before and after passing through 3 m of PFA tubing at a velocity of 0.5 mm/s. Only the original fluorescence of the mixture was measured in these experiments but no subsequent amplification. As seen in Fig. 5, the fluorescence of the mixture decreased dramatically after being passed through PFA tubing, indicating that DNA, Sybr Green I or both were being adsorbed. Greater than 90% inhibition was observed whether the mixture contained 10 ng or 0.1 ng of plasmid DNA.

The components responsible for fluorescence in our PCR mixture are the target DNA and the Sybr Green I dye. To learn whether DNA or Sybr Green were being adsorbed, we omitted either one, one at a time, and exposed the other component to the tubing. Afterwards, the omitted component was added in the appropriate proportion, following the protocol outlined in Table 1 to complete the mix, and the fluorescence was then compared with a control mixture in which no component was exposed to the tubing. When the Sybr Mix was the omitted component (and DNA exposed), the fluorescence was inhibited by 59% with respect to the original signal, as seen in Fig. 5. This meant that about half of the DNA was being absorbed by the tubing wall upon passage through 3 m of tubing. When the DNA was omitted and Sybr Mix exposed, almost complete abrogation of the fluorescence was observed (Fig. 5). This indicates that both DNA and Syb Green are being adsorbed by the tubing although, clearly, Sybr Green to a greater extent. This explains why in the previous experiment fluorescence was equally lost using two different DNA concentrations.

It was somehow surprising that DNA was adsorbed at the extension that it did, since at the pH and temperature conditions of the experiment, DNA is a polyanionic molecule that would not be expected to bind to hydrophobic surfaces (Allemand et al., 1997). This has been suggested also in silicon chips based on experimental data (Erill et al., 2003) but obviously it is still possible that hydrophobic interactions still can occur between the DNA backbone and the plastic surface in the conditions of the present experiments. More significant was that Sybr Green was almost completely adsorbed, which has strong implications for the design of microfluidic devices for quantitative PCR. This is essential, since it is ultimately the DNA dye what reports the progress of PCR amplification in real time. If the dye is being adsorbed, even if the reaction proceeds fully, the fluorescent signal to quantitate will be affected.

In summary, the materials tested are usable candidates a priori in the design of microfluidic PCR devices for subsystems such as reagent delivery or liquid handling without significant adsorption or reaction poisoning. Up to 40 cm of tubing can be used safely, but longer lengths (3 m) of tubing can inhibit severely subsequent amplification. Residence time and flow velocity do not affect adsorption within the parameters tested here, which were quite typical for an amplification reaction. We found that when using 3 m lengths, both DNA and Sybr Green are adsorbed substantially to the tubing walls. Other mixture components including nucleotides, oligonucleotide primers and polymerase enzyme can still be adsorbed or denatured, modifying PCR efficiency, although the present experiments did not investigate this possibility. Based on the present results, however, quantitative PCR based on Sybr Green chemistry is incompatible with the polymeric tubing tested and alternative designs such as the biphasic microfluidic PCR (Dorfman et al., 2005; Walsh et al., 2006), should constitute a valid alternative, provided appropriate control of the fluid dynamics can be achieved.

References

J.F. Allemand, D. Bensimon, L. Jullien, A. Bensimon, and V. Croquette, pH-dependent specific binding and combing of DNA. Biophys. J. 73(4), 2064–2070 (1997).

M. Arya, I.S. Shergill, M. Williamson, L. Gommersall, N. Arya, and H.R. Patel, Basic principles of real-time quantitative PCR. Expert. Rev. Mol. Diagn. 5(2), 209–219 (2005).

K.D. Dorfman, M. Chabert, J.H. Codarbox, G. Rousseau, P. de Cremoux, and J.L. Viovy, Contamination-free continuous flow microfluidic polymerase chain reaction for quantitative and clinical applications. Anal. Chem. 77(11), 3700–3704 (2005).

I. Erill, S. Campoy, N. Erill, J. Barbe, and J. Aguilo, Biochemical analysis and optimization of inhibition and adsorption phenomena in glass-silicon PCR-chips. Sensors and Actuators B-Chem. 96(3), 685–692 (2003).

B.C. Giordano, E.R. Copeland, and J.P. Landers, Towards dynamic coating of glass microchip chambers for amplifying DNA via the polymerase chain reaction. Electrophoresis 22(2), 334–340 (2001).

L.J. Kricka and P. Wilding, Microchip PCR. Anal. Bioanal. Chem. 377(5), 820–825 (2003).

M. Krishnan, D.T. Burke, and M.A. Burns, Polymerase chain reaction in high surface-to-volume ratio SiO2 microstructures. Anal. Chem. 76(22), 6588–6593 (2004).

R.H. Liu, J. Yang, R. Lenigk, J. Bonanno, and P. Grodzinski, Self-contained, fully integrated biochip for sample preparation, polymerase chain reaction amplification, and DNA microarray detection. Anal. Chem. 76(7), 1824–1831 (2004).

N.J. Panaro, X.J. Lou, P. Fortina, L.J. Kricka, and P. Wilding, Surface effects on PCR reactions in multichip microfluidic platforms. Biomed. Microdevices 6(1), 75–80 (2004).

C. Ramakers, J.M. Ruijter, R.H. Deprez, and A.F. Moorman, Assumption-free analysis of quantitative real-time polymerase chain reaction (PCR) data. Neurosci. Lett. 339(1), 62–66 (2003).

I. Schneegass and J.M. Kohler, Flow-through polymerase chain reactions in chip thermocyclers. J. Biotechnol. 82(2), 101–121 (2001).

M.A. Shoffner, J. Cheng, G.E. Hvichia, L.J. Kricka, and P. Wilding, Chip PCR. I. Surface passivation of microfabricated silicon-glass chips for PCR. Nucleic. Acids Res. 24(2), 375–379 (1996).

L.T. Skeggs, New dimensions in medical diagnoses. Anal. Chem. 38(6), 31A–44A (1966).

T.B. Taylor, E.S. Winn-Deen, E. Picozza, T.M. Woudenberg, and M. Albin, Optimization of the performance of the polymerase chain reaction in silicon-based microstructures. Nucleic. Acids. Res. 25(15), 3164–3168 (1997).

E.J. Walsh, C. King, R. Grimes, and A. Gonzalez, Influence of segmenting fluids on efficiency, crossing point and fluorescence level in real time quantitative PCR. Biomed. Microdevices. 8(1), 59–64 (2006).

P. Wilding, M.A. Shoffner, and L.J. Kricka, PCR in a silicon microstructure. Clin. Chem. 40(9), 1815–1818 (1994).

I.G. Wilson, Inhibition and facilitation of nucleic acid amplification. Appl. Environ. Microbiol. 63(10), 3741–3751 (1997).

C. Zhang, J. Xu, W. Ma, and W. Zheng, PCR microfluidic devices for DNA amplification. Biotechnol. Adv. 24(3), 243–284 (2006).

Acknowledgments

We thank Anne McHugh and Claire O’Sullivan for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gonzalez, A., Grimes, R., Walsh, E.J. et al. Interaction of quantitative PCR components with polymeric surfaces. Biomed Microdevices 9, 261–266 (2007). https://doi.org/10.1007/s10544-006-9030-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-006-9030-6