Abstract

An aerobic microorganism with an ability to utilize phenol as sole carbon and energy source was isolated from phenol-contaminated wastewater samples. The isolate was identified as Bacillus amyloliquefaciens strain WJDB-1 based on morphological, physiological, and biochemical characteristics, and 16S rDNA sequence analysis. Strain WJDB-1 immobilized in alginate–chitosan–alginate (ACA) microcapsules could degrade 200 mg/l phenol completely within 36 h. The concentration of phenol was determined using differential pulse voltammetry (DPV) at glassy carbon electrode (GCE) with a linear relationship between peak current and phenol concentration ranging from 2.0 to 20.0 mg/l. Cells immobilized in ACA microcapsules were found to be superior to the free suspended ones in terms of improving the tolerance to the environmental loadings. The optimal conditions to prepare microcapsules for achieving higher phenol degradation rate were investigated by changing the concentrations of sodium alginate, calcium chloride, and chitosan. Furthermore, the efficiency of phenol degradation was optimized by adjusting various processing parameters, such as the number of microcapsules, pH value, temperature, and the initial concentration of phenol. This microorganism has the potential for the efficient treatment of organic pollutants in wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is an increasing interest in the development of innovative treatments of industrial wastewaters particularly those containing toxic organic pollutants. Phenolic products are toxic to humans and aquatic organisms, which are released in the surface water by a considerable number of industries, mainly by pharmaceutical plants, oil refineries, coke plants, pulp, food-processing industries, and several other chemical plants (Rivas et al. 2003; Gernjak et al. 2003). Phenol is toxic upon ingestion, contact, or inhalation, and it is recommended that human exposure to phenol does not exceed 20 mg on average per day. Also, phenol is toxic to fish and can be lethal at concentrations of 5–25 ppm (Saha et al. 1999; Mollaei et al. 2010). Therefore, treatment of phenol effluents is critical to maintaining both human and wildlife environments. Several methods to remove these chemicals from environmental matrices currently exist including activated carbon adsorption, electrochemical, ozonization, and biological and chemical procedures (Dąbrowski et al. 2005; Mahmoud and Ahmed 2009; Deborde et al. 2008; Santos et al. 2009; Lin et al. 2009). Among these methods, biological degradation is generally preferred because of its lower costs, environmental friendliness, practical and economic viability as it allows forming less hazardous byproducts and realizing complete mineralization of phenol (Chung et al. 2003; Nuhoglu and Yalcin 2005).

A number of microorganisms have been reported to degrade phenol at low concentrations, including Alcaligenes eutrophus (Hughes et al. 1984), Bacillus stearothermophilus (Buswell 1975), Pseudomonas sp. (Bayly and Wigmore 1973), Rhodococcus sp. (Straube 1987), and Trichosporon cutaneum (Neujahr and Varga 1970). Nevertheless, microorganisms suffer from substrate inhibition, whereby microbial growth and concomitant biodegradation of phenol are hindered by the toxicity exerted by high concentrations of the substrate itself. To improve cells' tolerance to severe substrate inhibition and substrate utilization, immobilization of microorganisms offers a great advantage. Sodium alginate and chitosan are the two kinds of natural polymers without toxicity, which are biodegradable and have good biocompatibility. They are widely used in microencapsulation research (Gohel et al. 1994; Lim et al. 1997; King et al. 1999; Yu et al. 1998). Moreover, a point worth mentioning is that both materials are polyelectrolyte polymers, and they contain opposite charges: sodium alginate contains a negative charge, while chitosan contains a positive one. With regard to the properties, they are able to form microcapsules through electrostatic attraction. As the immobilization matrix of choice for environmental practice, alginate-entrapped cells have been used extensively for the bioremediation of numerous toxic chemicals, including phenol (Karigar et al. 2006), naphthalene (Manohar et al. 2001), benzoate (Kim et al. 2002), and ethylbenzene (Parameswarappa et al. 2008). In the encapsulation method, cells can be immobilized within a liquid core surrounded by a thin layer of alginate gel. In a liquid core that has more space for cellular growth; cells can exist at a high density without the carrier (Koyama and Seki 2004).

The determination of phenol concentration is also very vital. Currently, various approaches are being reported on the determination of phenols, such as colorimetry (Zhang 2004), gas chromatography (Ballesteros et al. 1990), high-pressure liquid chromatography (HPLC) (Belloli et al. 1999), spectrophotometry (Frenzel and Krekler 1995), biosensor-based method (Carter et al. 2003), capillary electrophoretic method, and electrochemical method (Rodriguez et al. 1997; Carvalho et al. 2000). In contrast to these methods mentioned above, electrochemical technique has attracted considerable attention because of its simplicity, convenience, and low cost. In the study of determination of phenol concentration, glassy carbon electrode (GCE) is the most commonly employed as the working electrode because it shows high stability and precision in detection (Wang et al. 2008). In this study, differential pulse voltammetry (DPV) was employed to measure the concentration of phenol because of its excellent precision, selectivity and accuracy.

In this article, to better understand phenol degradation in aqueous solution, we isolated and characterized the phenol-degrading bacteria which were identified by morphological, physiological, and biochemical tests, and 16S rDNA sequence analysis. Then, the pure culture of phenol degrading bacteria, B. amyloliquefaciens strain WJDB-1, was immobilized in alginate–chitosan–alginate (ACA) microcapsules using different immobilization methods to compare the phenol degradation activities of the free and the immobilized cells. The optimal conditions to produce microcapsules with higher phenol degradation efficiency were investigated by changing the concentrations of sodium alginate, calcium chloride, and chitosan. Single factor experiments for determining the effects of parameters, such as the amount of microcapsules, pH value, the temperature, and the initial concentration of phenol, were carried out to find the optimal conditions for phenol degradability.

Materials and methods

Materials

Sodium alginate was purchased from Tianjin BODI Chemical Co. Ltd. Chitosan with degree of deacetylation of 85% was obtained from Ocean Biochemical Corporation (Zhejiang, China). Beef Extract, Peptone, and Agar Powder were purchased from Beijing Shuangxuan Microbe Culture Medium Products Factory. Phenol with grater than 99% purity was obtained from Beijing Chemical Factory. All other reagents and solvents were of analytic grade and were used without further purification. All chemicals were prepared with deionized water purified via Milli-Q unit. All the mediums used were autoclaved in advance.

Isolation and identification of microorganism

The bacteria were isolated by the enrichment culture technique at 30°C from phenol-contaminated wastewater samples from Jiuquan industrial effluents in Gansu province, China. Phenol-containing mineral salt medium (MSM) was used for the isolation of bacteria. The MSM was composed of 0.5 g/l KH2PO4, 0.5 g/l K2HPO4, 0.2 g/l MgSO4·7H2O, 0.1 g/l CaCl2, 0.2 g/l NaCl, 1.0 g/l NH4NO3, 0.01 g/l MnSO4·H2O, and 0.01 g/l Fe2(SO4)3·3H2O with 100 mg/l phenol as the sole carbon and energy source, and the pH value was adjusted to 7.0 with NaOH or HCl. All media and Erlenmeyer flasks fitted with cotton plugs were autoclaved at 121°C for 20 min for sterilization before use. 5 ml of the industrial effluents was added to 50 ml MSM. The samples were incubated at 30°C for 120 h in a rotary shaker with a speed of 150 rpm. When the phenol content became depleted, 5 ml of the cultures were transferred to fresh MSM to initiate the degradation. Afterward, phenol concentration was increased stepwise, varying from 100 mg/l to final 400 mg/l at the rate of 100 mg/l at each step. After four transfers of consecutive enrichments had been carried out, dilutions of culture were inoculated on MSM agar plates incubated at 30°C for 24 h. Agar plates contained 20 g of agar per liter of the medium. Then, the predominant colonies were transferred to fresh MSM agar plates two times to ensure culture purity. Each isolate was then tested for its ability to cause degradation of phenol at 200 mg/l. One of the obtained isolates, which exhibited the best phenol degradability, was selected for further degradation study.

The bacterial isolate was examined using cell morphology, gram reaction, standard physiological and biochemical tests, and 16S rDNA sequence analysis. The morphological investigation was prepared using a DMBA200 optical microscope. The DNA extracts from bacterial isolate were amplified by PCR with primers, 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-GGTTACCTTGTTACGACTT-3′). The reaction was performed in a total volume of 50 μl, containing 5 μl of 10 × PCR buffer, 2.5 μl of 2 mM dNTP mixture, 2 μl each of primers, 1 μl of Taq DNA polymerase, 1 μl of template DNA, and remaining dH2O (to make up to 50 μl). The PCR amplification was carried out under the following conditions: predenaturation at 94°C for 5 min, 36 cycles of denaturation at 94°C for 1 min, annealing at 55°C for 1 min, and extension at 72°C for 2 min, followed by final extension at 72°C for 10 min. Then, the PCR products were examined through electrophoresis. The 16S rDNA gene sequence was determined directly by Shanghai Bio. Tech. Company. The sequences obtained were compiled and compared with sequences in the GenBank databases using BLAST program. A maximum likelihood phylogenetic tree was generated by neighbor-joining methods.

Preparation of microcapsule and morphological observation

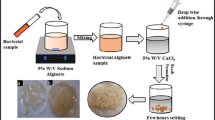

The microbial cells were activated at 30°C in the nutrient medium (5 g/l yeast extract, 10 g/l peptone, 5 g/l NaCl) to which 200 mg/l of phenol was added for adaptation for 48 h. Activated cells in the late-exponential phase were harvested as inoculums. Then, the activated cells were inoculated into the culture medium (100 ml) in 250-ml Erlenmeyer flasks to yield an initial cell concentration of 1.5 × 108 cells/ml. The cells were then harvested by centrifugation at 10,000 rpm at 4°C for 10 min, and washed with sterile distilled water to eliminate cell debris and intermediate components. The microcapsules were prepared by the methods reported previously (Qi et al. 2006). In brief, the microbial cells were suspended in 1.5% alginate solution. The cell-alginate suspension was extruded into 100 mM calcium chloride solution using the syringe to obtain the micro-beads. After being hardened for 30 min, the microscale gel beads containing bacteria were obtained. The 0.5% (w/v) chitosan solution was added to calcium alginate gel beads at the volume ratio of about 1:5 (beads:solution) to form membranes followed, by rinsing with 0.9% (w/v) NaCl solution to remove the excess chitosan. Then, 0.15% alginate solution was added to counteract charges on the membrane. At last, the gel enclosed in the ACA membrane was liquidized with 55 mmol/l sodium citrate to result in the ACA microcapsules with liquid cores. All the microcapsules in this experimental study were prepared according to this method. The concentrations of some materials might be varied to find optimal conditions for obtaining higher degradation efficiency.

The size and shape as well as the surface of the microcapsules were characterized using scanning electron microscopy (SEM, JSM-5600LV, JEOL, Japan).

Phenol degradation

A comparative study of phenol degradation by free and immobilized cells of strain WJDB-1 in phosphate buffer (pH 7.0) was carried out in batch cultures. The phenol-degrading bacteria were harvested after 48 h of growth (1.5 × 108 cells/ml) from 40 ml of culture medium. The bacteria pallet was obtained by centrifugation at 10,000 rpm at 4°C for 10 min. One half was used for immobilization in ACA microcapsules, the other half was suspended in 10 ml phosphate buffer.

Assays were carried out in a series of 100-ml Erlenmeyer flasks containing approximately 200 mg/l phenol and phosphate buffer, the total operating volume of the flasks being fixed at 30 ml. The flasks were inoculated with microcapsules and free cells. Control flask, inoculated with microcapsules in the absence of bacteria, was incubated in parallel under the same conditions to ascertain the evaporation or adsorption losses of phenol. All the flasks were incubated in a rotary shaker with a speed of 150 rpm at 30°C for up to 36 h. Samples of the flasks were separately taken every 6-h intervals for residual phenol analysis.

The optimal conditions of preparing microcapsules were investigated by changing the concentrations of sodium alginate, calcium chloride, and chitosan. Then, the effects of the number of microcapsules, pH value, the temperature, and the initial concentration of phenol were investigated in the experiment of phenol degradation. The initial values of pH are 6.0, 7.0, 8.0, 9.0, and 10.0; the temperatures are 10, 20, 25, 30, 35, and 40°C; and the initial concentrations of phenol are 114.55, 181.32, 271.20, 378.57, and 500.90 mg/l.

DPV analysis of phenol

The concentration of phenol was measured at certain intervals using DPV. The electrochemical cell used for studies consists of a three-electrode system and a CHI 1210A electrochemical workstation. The working electrode was GCE. Before electrochemical measurements, the working electrode was polished with 0.05 μm γ-alumina to get mirror-like finish, and then cleaned ultrasonically in twice-distilled water for about 2 min. The counter electrode was a platinum wire, while Ag/AgCl electrode served as reference electrode. The scanning potentials ranged from 0.2 to 1.0 V.

Results and discussion

Microorganism identification

After being isolated by the enrichment culture technique, the microorganism was examined based on its morphological, physiological, and biochemical characteristics, and 16S rDNA sequence analysis, which was identified as the genus B. amyloliquefaciens. The results of the most important reactions of the physiological and biochemical properties are summarized in Table 1. The partial 16S rDNA sequence of strain WJDB-1 obtained by sequencing was found to be 1456 bp and was submitted to the GenBank database under accession no. JN133899. Preliminary comparison of the sequence against the GenBank databases indicated that the members of the genus B. amyloliquefaciens were its closest phylogenetic neighbors. The neighbor-joining tree is shown in Fig. 1. Therefore, the isolate was designated as B. amyloliquefaciens strain WJDB-1.

The neighbor-joining tree was constructed and bootstrapped (1000 iterations) to represent the relationship between the phenol-degrading strain WJDB-1 and representative species of the genus Bacillus amyloliquefaciens and related genera. Bootstrap values are noted on the branch, and the scale bar (0.0005) represents nucleotide substitution per 100 nucleotide

Microcapsule morphology

Figure 2a shows the SEM image of the microcapsule, illustrating that the microcapsules have good, regular shapes, with diameter of about 800 ± 50 μm. The SEM images of some microcapsules are also given in the supporting information (Fig. S1); the morphology of the outer surface of the microcapsules was further observed, as shown in Fig. 2b. The microcapsule shows a crinkled surface structure. Some micropores can be observed on the surface of the microcapsules, which help them reduce mass-transfer resistance. Besides, the liquid phase in the core of microcapsules can improve the cell growth compared with conventional solid cores (Qi et al. 2006). Such an increase in mass-transfer efficiency could make the environment inside the beads more amenable for the entrapped cells to improve phenol degradation.

DPV curves of phenol

The DPV curves of phenol ranging from 2 to 20 mg/l in pH 7.0 sodium phosphate buffer solutions at GCE are shown in Fig. 3. Typically, an anodic peak located at approximately 0.7 V. Further, the oxidation peak current was proportional to phenol concentration in the range from 2 to 20 mg/l in accordance with the regression equation of Ipa (μA) = 0.1107c (mg/l) + 1.519 (R = 0.9955). When the concentration of phenol was higher, it needed to be diluted to the linear range for facilitating determination.

Phenol degradation using free and immobilized cells of strain WJDB-1

The degradability rates of phenol by the free and the immobilized cells of strain WJDB-1 were compared (Fig. 4). As seen in Fig. 4, in the control studies, removal of only 3.3% phenol occurred throughout the experiment, indicating that no significant phenol losses due to evaporation or adsorption by the microcapsules occurred in the culture flasks. Obviously, the immobilized cells of strain WJDB-1 have higher efficiency of phenol biodegradation than the free cells have. The phenol concentration in the flask inoculated with microcapsules dropped to almost zero after 36 h, while similar microcapsules with free cells still retained 30 mg/l. The use of encapsulated microorganism samples as a chemical reagent offers significant advantages in terms of increasing the stability of free cells, and of a more simplified and cheaper process. This will be of direct practical value for wastewater treatment in general. However, this level of phenol did not significantly inhibit the degradation rates of the suspended cells. Apparently, the external and internal mass transfer resistances of substrates (phenol and oxygen) in the microcapsule were not the critical factors for controlling the degradation process. On the other hand, the immobilized cells have lower phenol degradation rate than the suspended ones (Adav et al. 2007). Hence, the capsules made by ACA could protect the bacteria from the toxicity of phenol. These micro-environments could prevent the direct interaction between the enzyme surface and a potentially harmful reaction medium as organic solvents and supercritical fluids.

The optimal conditions for making microcapsules

The control studies indicated no significant phenol losses due to evaporation or adsorption on the sterile support. Because of the addition of the microcapsules, the volume of the solution might be different, and so, the concentrations of phenol might have slight differences. The optimal conditions for preparing microcapsules were investigated through single factor experiment. Assays were carried out in a series of 100-ml Erlenmeyer flasks containing phosphate buffer (pH 7.0). Results for degradation by cells entrapped in alginate (1.5–3.0%, w/v), calcium chloride (0.1–0.4 mol/l), and chitosan (0.5–2.0%, w/v) capsules are given in Fig. 5. Using an initial phenol concentration of approximately 200 mg/l, the time for degradation by immobilized cells was 36 h. When the concentration of sodium alginate increased, the diameter of the microcapsules would become larger and the mechanical strength stronger, while 2.0% sodium alginate had the best degradation rate. There was no considerable difference between the performances of cells immobilized in different calcium chloride concentrations (0.1–0.4 mol/l) within 36 h. However, the efficiency of phenol degradation by 0.1 mol/l calcium chloride microcapsules could reach up to 88.3% in 24 h. Cells immobilized in different concentrations of chitosan were found to be similar to different concentrations of sodium alginate, and 1.5% chitosan was found to be the best choice. Therefore, 2.0% sodium alginate, 0.1 mol/l calcium chloride, and 1.5% chitosan were chosen as the optimal conditions for preparing microcapsules.

Single factor experiment for phenol degradation

The effect of reaction variables such as the number of microcapsules, pH value, temperature and the initial concentration of phenol was studied and the results were delineated below.

Effect of microcapsules' number

Experiments were performed to study the influence of the number of microcapsules on phenol degradation in aqueous solution. A set of tests was carried out by varying the number of microcapsules added from 700 to 2100 capsules with an initial phenol concentration of approximately 200 mg/l at pH 7.0 and 30°C after 36-h reaction time. A summary of the experimental results for the removal efficiency of phenol with various numbers of microcapsules is shown in Fig. 6. It can be observed that the removal of phenol increased with large number microcapsules. Phenol was reduced after 36 h by 88%, 92%, and 100% with the microcapsules dosage of 700, 1400, and 2100 capsules, respectively. Therefore, 2100 was chosen as the optimal number of capsules and was used in further degradation experiments.

Effect of pH

It is widely known that the pH value of degradation medium would influence the activity of enzymes and, thereby the microbial growth rate. Besides, it might also affect the structure of the capsule (Gong et al. 2006). Most heterotrophic bacteria favor neutral environment. Nevertheless, there are bacterial strains which can thrive outside this limit which belongs to the group of acidophiles (growth in lower pH) or alkaliphiles (growth in higher pH) (Veenagayathri and Vasudevan 2010).

As the ACA microcapsules were unstable in strong acidic environment, when the pH was lower than 6.0, some microcapsules were destroyed. Therefore, the pH values ranging only from 6.0 to 10.0 was studied on phenol degradation experiments under identical environmental conditions by the microcapsules (2100 capsules) at 30°C after 36-h reaction time, and the results are presented in Fig. 7. It is evident from Fig. 7 that removal of 200 mg/l phenol was accelerated with decreasing pH value down to pH 6.0, beyond which the removal efficiency started to decrease, indicating an optimal pH value of 6.0 for best performance. This result is related to the polycationic nature of the matrix because the carboxylic parts of alginate attract H+ around them, making H+ concentrated around the active parts of the immobilized cells decrease accordingly (Chung et al. 2003). Hence, the pH of buffer solution has to be lowered to provide optimal concentration of H+ for strain WJDB-1.

Above the optimal pH, the removal efficiencies were 93.0% and 86.7% at pH 7.0 and 8.0, respectively. However, when the pH values were higher than 8.0, biodegradation efficiency was affected significantly. The removal efficiency of phenol reduced to 66.7% at pH 9.0, with only 34.8% at pH 10.0. At the higher pH value, the bacteria grew slowly and the enzyme activity was lower—even some of the bacteria would die—and, thus, the ability of the enzyme to catalyze the transformation of phenol decreased. Hence, the removal efficiency decreased with increasing pH value. These pH values created unfavorable growth conditions for the bacterial population. Overall, the optimal pH value for growth and phenol degradation was determined to be 6.0.

Effect of temperature

Regarding the temperature effect, the temperature for higher phenol removal efficiency was found to be near 30°C. However, the rate and the efficiency of phenol degradation are relatively sensitive to deviations outside the optimal temperature range (Mordocco et al. 1999). A variation of 5°C may cause a decrease in phenol degradation rate by at least 50% at the lower end, and almost by 100% at the higher end (Marrot et al. 2006).

The biodegradation of phenol (approximately 200 mg/l) in experiments at six different temperature values from 10 to 40°C was carried out after 36-h reaction time at pH 6.0. The flasks were kept in a water bath, where the temperature could be controlled within ±1°C. The experimental results are shown in Fig. 8. It can be seen that the optimal values of temperature for phenol biodegradation was observed as 25°C. At 25°C, the degradation rate was significantly higher than the rates at 10°C and 40°C; the phenol degradation efficiency could reach up to 100%. After 36 h, the degradation efficiency at 30°C could also reach up to 97%. However, biodegradation rates were almost identical at both 20°C and 35°C, and the degradation efficiency is less than 83%. This differentiation might be due to the differences in penetration efficiency of phenol into the cells of strain WJDB-1 through the cell membrane (Polymenakou and Stephanou 2005). Higher temperatures seemed to negatively affect the activity of the bacteria and, hence, hindered its biodegradation capabilities. It is believed that sudden exposure to temperatures higher than 35°C may have detrimental effect on the bacterial enzymes that are usually responsible for the benzene ring cleavage, which is the main step in the biological degradation process (El-Naas et al. 2009). On the other hand, exposure to lower temperatures is expected to slow down the bacterial activity. When the microorganisms immobilized, they were in carrier-specific micro-environment, so that the optimal temperature would change. The most favorable temperature range for the microcapsules to degrade phenol was 25–30°C. Thus, it is clear that the phenol degradation is temperature dependent.

Effect of initial phenol concentration

Initial concentration of phenol plays an important role in the biodegradation process. Phenol degradation by microbial cells has generally been known to be inhibited by higher concentration of phenol itself, leading to extended lag time for phenol degradation (Gernjak et al. 2003; Jia et al. 2005). To assess the phenol tolerance of immobilized cells and to evaluate degradation at higher initial concentrations, batch cultures using the microcapsules were conducted using initial concentrations of 114.55, 181.32, 271.20, 378.57, and 500.90 mg/l. Fig. 9 shows the effect of the initial concentration of phenol on the phenol degradation using strain WJDB-1 at pH 6.0 and 25°C. It was found that increasing the initial phenol concentration resulted in longer phenol degradation time and lower degradation efficiency. The average degradation rates of different concentrations were calculated, and the results are shown in Fig. 10. This study showed that the best degradation rate was obtained at phenol concentration of up to 378.57 mg/l. Beyond this, the degradation rate decreased. This decrease may be due to the toxicity of phenol.

The toxicity of phenol at high concentrations may inhibit biodegradation through lower efficiency or culture death. These effects were likely due to the ability of phenol to damage microbial cells through alteration of the selective permeability of the cytoplasmic membrane and enzyme deactivation (Hsieh et al. 2008). However, whenever the microorganisms were compatible to the environment, they also had good degradation rate. Degradation could be nearly completed if the reaction time increased with increasing phenol concentration. For instance, with initial phenol concentrations of 114.55, 181.32, and 271.20 mg/l, all of the phenol could be degraded in reaction times of 30, 36 and 38 h, respectively. However, strong inhibitory effects were present with a phenol concentration of 500.90 mg/l. The phenol degradation rate was only 78.6% after 60 h. Hence, the toxicity of phenol was still the serious problem for improving the biodegradation efficiency.

Conclusions

This study has described above the phenol biodegradation using the bacterium Bacillus amyloliquefaciens strain WJDB-1 immobilized in ACA microcapsules, which was isolated from phenol-contaminated wastewater samples and identified based on morphological, physiological, and biochemical characteristics, and 16S rDNA sequence analysis. The ACA microcapsules offered a favorable microenvironment for microbial cells. The optimal microcapsule numbers, temperature, and pH value for the ACA microcapsules studied at 200 mg/l phenol were 2100 capsules, 25°C, and pH 6.0, respectively. Degradation tests for the strain at various phenol concentrations suggested that the strain completely degraded phenol with no time lag at an initial phenol concentration no more than 270 mg/l. Thus, the use of immobilized cells can act as an effective method for phenol degradation. The concentration of phenol was determined using DPV at the GCE with a linear calibration curve of between peak current and phenol concentration ranging from 2.0 to 20.0 mg/l. This method combined the biodegradation with the electrochemical determination of phenol.

References

Adav SS, Chen MY, Lee DJ, Ren NQ (2007) Degradation of phenol by Acinetobacter strain isolated from aerobic granules. Chemosphere 67:1566–1572. doi:10.1016/j.chemosphere.2006.11.067

Ballesteros E, Gallego M, Valcárcel M (1990) Gas chromatographic determination of phenol compounds with automatic continuous extraction and derivatization. J Chromatogr A 518:59–67. doi:10.1016/S0021-9673(01)93162-0

Bayly RC, Wigmore GJ (1973) Metabolism of phenol and cresols by mutants of Pseudomonas putida. J Bacteriol 113:1112–1120

Belloli R, Barletta B, Bolzacchini E, Meinardi S, Orlandi M, Rindone B (1999) Determination of toxic nitrophenols in the atmosphere by high-performance liquid chromatography. J Chromatogr A 846:277–281. doi:10.1016/S0021-9673(99)00030-8

Buswell JA (1975) Metabolism of phenol and cresols by Bacillus stearothermophilus. J Bacteriol 124:1077–1083

Carter RM, Blake RC, Nguyen TD, Bostanian LA (2003) Near real-time biosensor-based detection of 2,4-dinitrophenol. Biosens Bioelectron 18:69–72. doi:10.1016/S0956-5663(02)00107-0

Carvalho RM, Mello C, Kubota LT (2000) Simultaneous determination of phenol isomers in binary mixtures by differential pulse voltammetry using carbon fibre electrode and neural network with pruning as a multivariate calibration tool. Anal Chim Acta 420:109–121. doi:10.1016/S0003-2670(00)01012-6

Chung TP, Tseng HY, Juang RS (2003) Mass transfer effect and intermediate detection for phenol degradation in immobilized Pseudomonas putida systems. Process Biochem 38:1497–1507. doi:10.1016/S0032-9592(03)00038-4

Dąbrowski A, Podkościelny P, Hubicki Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon—a critical review. Chemosphere 58:1049–1070. doi:10.1016/j.chemosphere.2004.09.067

Deborde M, Rabouan S, Mazellier P, Duguet JP, Legube B (2008) Oxidation of bisphenol A by ozone in aqueous solution. Water Res 42:4299–4308. doi:10.1016/j.watres.2008.07.015

El-Naas MH, Al-Muhtaseb SA, Makhlouf S (2009) Biodegradation of phenol by Pseudomonas putida immobilized in polyvinyl alcohol (PVA) gel. J Hazard Mater 164:720–725. doi:10.1016/j.jhazmat.2008.08.059

Frenzel W, Krekler S (1995) Spectrophotometric determination of total phenolics by solvent extraction and sorbent extraction optosensing using flow injection methodology. Anal Chim Acta 310:437–446. doi:10.1016/0003-2670(95)00141-L

Gernjak W, Krutzler T, Glaser A, Malato S, Caceres J, Bauer R, Fernández-Alba AR (2003) Photo-Fenton treatment of water containing natural phenolic pollutants. Chemosphere 50:71–78. doi:10.1016/s0045-6535(02)00403-4

Gohel MC, Sheth MN, Patel MM, Jani GK, Patel H (1994) Design of chitosan microspheres containing diclofenac sodium. Indian J Pharm Sci 56:210–214

Gong XC, Luo GS, Yang WW, Wu FY (2006) Separation of organic acids by newly developed polysulfone microcapsules containing triotylamine. Sep Purif Technol 48:235–243. doi:10.1016/j.seppur.2005.07.030

Hsieh FM, Huang C, Lin TF, Chen YM, Lin JC (2008) Study of sodium tripolyphosphate-crosslinked chitosan beads entrapped with Pseudomonas putida for phenol degradation. Process Biochem 43:83–92. doi:10.1016/j.procbio.2007.10.016

Hughes EJL, Bayly RC, Skurray RA (1984) Evidence for isofunctional enzymes in the degradation of phenol, m- and p-toluate, and p-cresol via catechol meta-cleavage pathways in Alcaligenes eutrophus. J Bacteriol 158:79–83

Jia X, Wen J, Jiang Y, Bai J, Cheng X (2005) Modeling for batch phenol biodegradation with immobilized Alcaligenes faecalis. AIChE J 52:1294–1303. doi:10.1002/aic.10744

Karigar C, Mahesh A, Nagenahalli M, Yun DJ (2006) Phenol degradation by immobilized cells of Arthrobacter citreus. Biodegradation 17:47–55. doi:10.1007/s10532-005-3048-y

Kim JH, Jeong WH, Karegoudar TB, Kim CK (2002) Stable degradation of benzoate by Klebsiella oxytoca C302 immobilized in alginate and polyurethane. Biotechnol Bioprocess Eng 7:347–351. doi:10.1007/BF02933519

King A, Hellerstrom C, Sandler S, Kulseng B, Andersson A, Skjak-Braek G (1999) Glucose metabolism in vitro of cultured and transplanted mouse pancreatic islets microencapsulated by means of a high-voltage electrostatic field. Diabetes Care 22:B121–B126

Koyama K, Seki M (2004) Cultivation of yeast and plant cells entrapped in the low-viscous liquid core of an alginate membrane capsule prepared using polyethylene glycol. J Biosci Bioeng 97:111–118. doi:10.1016/S1389-1723(04)70177-2

Lim LY, Wan LSC, Thai PY (1997) Chitosan microspheres prepared by emulsification and ionotropic gelation. Drug Dev Ind Pharm 23:981–985. doi:10.3109/03639049709149150

Lin K, Liu W, Gan J (2009) Oxidative removal of bisphenol A by manganese dioxide: efficacy, products, and pathways. Environ Sci Technol 43:3860–3864. doi:10.1021/es900235f

Mahmoud SS, Ahmed MM (2009) Electrocatalytic oxidation of phenol using Ni-Al2O3 composite-coating electrodes. J Alloys Compd 477:570–575. doi:10.1016/j.jallcom.2008.10.160

Manohar S, Kim CK, Karegoudar TB (2001) Enhanced degradation of naphthalene by immobilization of Pseudomonas sp. strain NGK1 in polyurethane foam. Appl Microbiol Biotechnol 55:311–316. doi:10.1007/s002530000488

Marrot B, Barrios-Martinez A, Moulin P, Roche N (2006) Biodegradation of high phenol concentration by activated sludge in an immersed membrane bioreactor. Biochem Eng J 30:174–183. doi:10.1016/j.bej.2006.03.006

Mollaei M, Abdollahpour S, Atashgahi S, Abbasi H, Masoomi F, Rad I, Lotfi AS, Zahiri HS, Vali H, Noghabi KA (2010) Enhanced phenol degradation by Pseudomonas sp. SA01: gaining insight into the novel single and hybrid immobilizations. J Hazard Mater 175:284–292. doi:10.1016/j.jhazmat.2009.10.002

Mordocco A, Kuek C, Jenkins R (1999) Continuous degradation of phenol at low concentration using immobilized Pseudomonas putida. Enzyme Microb Technol 25:530–536. doi:10.1016/S0141-0229(99)00078-2

Neujahr HY, Varga JM (1970) Degradation of phenols by intact cells and cell-free preparations of Trichosporon cutaneum. Eur J Biochem 13:37–44. doi:10.1111/j.1432-1033.1970.tb00896.x

Nuhoglu A, Yalcin B (2005) Modeling of phenol removal in a batch reactor. Process Biochem 40:1233–1239. doi:10.1016/j.procbio.2004.04.003

Parameswarappa S, Karigar C, Nagenahalli M (2008) Degradation of ethylbenzene by free and immobilized Pseudomonas fluorescens-CS2. Biodegradation 19:137–144. doi:10.1007/s10532-007-9121-y

Polymenakou PN, Stephanou EG (2005) Effect of temperature and additional carbon sources on phenol degradation by an indigenous soil Pseudomonad. Biodegradation 16:403–413. doi:10.1007/s10532-004-3333-1

Qi WB, Ma J, Yu WT, Xie YB, Wang W, Ma XJ (2006) Behavior of microbial growth and metabolism in alginate–chitosan–alginate (ACA) microcapsules. Enzyme Microb Technol 38:697–704. doi:10.1016/j.enzmictec.2005.10.003

Rivas FJ, Beltrán FJ, Gimeno O, Alvarez P (2003) Optimisation of Fenton’s reagent usage as a pre-treatment for fermentation brines. J Hazard Mater B96:277–290. doi:10.1016/s0304-3894(02)00217-0

Rodriguez IN, Zamora MB, Salvador JMB, Leyva JAM, Hernandez-Artiga MP, Cisneros JLHH (1997) Voltammetric determination of 2-nitrophenol at a bentonite-modified carbon paste electrode. Mikrochim Acta 126:87–92. doi:10.1007/BF01242667

Saha NC, Bhunia F, Kaviraj A (1999) Toxicity of phenol to fish and aquatic ecosystems. Bull Environ Contam Toxicol 63:195–202. doi:10.1007/s001289900966

Santos VL, Monteiro AS, Braga DT, Santoro MM (2009) Phenol degradation by Aureobasidium pullulans FE13 isolated from industrial effluents. J Hazard Mater 161:1413–1420. doi:10.1016/j.jhazmat.2008.04.112

Straube G (1987) Phenol hydroxylase from Rhodococcus sp. P1. J Basic Microbiol 27:229–232. doi:10.1002/jobm.3620270415

Veenagayathri K, Vasudevan N (2010) Effect of pH, nitrogen sources and salts on the degradation of Phenol by the bacterial consortium under saline conditions. Int J Biotechnol Biochem 6:783–791

Wang XG, Wu QS, Ding YP (2008) Enhancement of surfactants in the electrochemical determination of phenols and the mechanisms research. Colloids Surf A 329:119–124. doi:10.1016/j.colsurfa.2008.07.003

Yu C, Cunningham M, Rogers C, Dinbergs ID, Edelman ER (1998) The biological effects of growth factor-toxin conjugates in models of vascular injury depend on dose, mode of delivery, and animal species. J Pharm Sci 87:1300–1304. doi:10.1021/js980086i

Zhang TY (2004) Study on extracting and determination polyphenols in red bean. China Food Additives 5:99–100. doi:CNKI:SUN:ZSTJ.0.2004-05-025

Acknowledgments

This study is supported by the National Natural Science Foundation of China under Grant Nos. 20577017 and J0730425.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lu, D., Zhang, Y., Niu, S. et al. Study of phenol biodegradation using Bacillus amyloliquefaciens strain WJDB-1 immobilized in alginate–chitosan–alginate (ACA) microcapsules by electrochemical method. Biodegradation 23, 209–219 (2012). https://doi.org/10.1007/s10532-011-9500-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-011-9500-2