Abstract

The reactants produced by action of a purified unique dye-decolorizing peroxidase, DyP, on a commercial anthraquinone dye, Reactive Blue 5, were investigated using electrospray ionization mass spectrometry (ESI-MS), thin-layer chromatography (TLC), and 1H- and 13C- nuclear magnetic resonance (NMR). The results of ESI-MS analysis showed that phthalic acid, a Product 2 (molecular weight 472.5), and a Product 3 (molecular weight 301.5), were produced. Product 2 and Product 3 were generated by usual peroxidase reaction, whereas phthalic acid was generated by hydrolase- or oxygenase-catalyzed reaction. One potential associated product, o-aminobenzene sulfonic acid, was found to be converted to 2,2′-disulfonyl azobenzene by ESI-MS and NMR analyses. From these results, we propose, for the first time, the degradation pathway of an anthraquinone dye by the enzyme DyP.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthetic dyes are widely used in many industries worldwide. Around 106 tons of dyes are produced annually, of which 1–1.5 × 105 tons are released to the environment in wastewater (Stolz 2001). As many dyes are very stable, the discarded dyes remain long-term in the environment and thus accumulate (Anliker 1979; McMullan et al. 2001). Some dyes are converted to harmful compounds such as benzidine (Chung and Stevens 1993). Concerns have been raised that such artificial compounds may be xenobiotics and it is widely considered that they should not be released into the environment. Therefore, microbial degradation of synthetic dyes has been explored. In particular, biodegradation of azo dyes, which make up more than half of the dyes synthesised each year, has been extensively explored and biodegradative mechanisms have been researched in detail (Banat et al. 1996; Fang et al. 2004; Fu and Viraraghavan 2001; Kim et al. 1995; McMullan et al. 2001; Stolz 2001; Young and Yu 1997).

Such dyes are degraded mainly by peroxidases such as lignin peroxidase (LiP), manganese peroxidase (MnP), and versatile peroxidase (Chivukula et al. 1995; Goszczynski et al. 1994; Heinfling et al. 1998; Ollikka et al. 1993; Pasti and Crawford 1991; Vyas and Molitoris 1995). These peroxidases withdraw hydrogen from hydroxyl groups of dyes and generate radical compounds. The radical reaction proceeds and the dyes are either degraded or polymerized to other molecules. In fact, several degradation pathways for azo dyes have been proposed (Chivukula et al. 1995; Goszczynski et al. 1994). In the peroxidase reaction, cleavage of azo bonds may occur in dyes with hydroxyl groups (Goszczynski et al. 1994). In contrast, there are but a few reports on biodegradation of anthraquinone dyes, which, along with azo dyes, are widely used in many industries. Little information on the degradation mechanisms of such dyes has been published (Itoh et al. 1996, 1998). To date, degradation of the anthraquinone structure by known peroxidase reactions might be considered to be difficult, because the anthraquinone frame contains no hydrogens that can be withdrawn by peroxidase. In fact, no model of the in vitro degradation of anthraquinone dyes by peroxidase has been published, even though the pseudoperoxidase activity of ferrylmyoglobin promotes oxidative degradation of a hydroxyl anthraquinone compound (Cartoni et al. 2004) and horseradish peroxidase indirectly degrades anthracycline by acting on hydroquinone (Reszka et al. 2005).

Notably, Thanatephorus cucumeris Dec 1 (formerly named Geotrichum candidum Dec 1), a basidiomycete, degrades anthraquinone dyes as well as azo dyes (Kim et al. 1995). Recently, we found that the complete in vitro decolorization of an anthraquinone dye was achieved by the concerted action of two peroxidases, namely DyP and TcVP1 (Sugano et al. 2006). In particular, DyP is a unique enzyme, for the following reasons. The enzyme contains a heme group and catalyzes peroxidase reactions, but shows no primary structural homology to other known general peroxidases (Sugano et al. 1999, 2000). Recently, DyP has been shown to be a member of a novel heme peroxidase family; this advance became possible when the complete tertiary structure of the enzyme was obtained (Sugano et al. 2007). Other heme proteins similar to DyP have been identified (Scheibner et al. 2008; Sturm et al. 2006; Zubieta et al. 2007a, b). Interestingly, DyP has anthraquinone dye decolorization activity (Kim and Shoda 1999), but does not completely decolorize such dyes. The final reaction products when DyP acts on a deep blue-colored anthraquinone dye, Reactive Blue 5 (RB5), are red–brown. These products were completely decolorized by TcVP1 (Sugano et al. 2006).

To date, we have not identified the red–brown products or presented the degradation pathway of RB5 treated with DyP. Here, we report the identification of one of the red–brown products obtained by DyP action and propose a reasonable RB5 degradation pathway. This is the first report to confirm an in vitro enzymatic degradation pathway of a hydroxyl-free anthraquinone dye.

Materials and methods

Chemicals

The structure of RB5 is shown in Fig. 1. Aminobenzene sulfonic acid (ABS) and phthalic acid were from Kanto Chemical Co. (Tokyo, Japan). All other chemicals used were of analytical grade and were commercially available unless specified otherwise.

Enzyme

Purified DyP, prepared by the method described in our previous reports (Sugano et al. 1999, 2000), was used for the present study. Enzyme assays were performed as reported previously (Sugano et al. 2000). One unit (U) of enzyme activity was defined as the amount of the enzyme that decolorized (decrease in absorption at 600 nm was measured) 1 μmol of RB5 at 30°C in 1 min.

Preparation of reaction products of RB5 treated with DyP

RB5 (final concentration 0.15 mM) and 2 U of DyP were dissolved in 25 mM citrate buffer (pH 3.2) and H2O2 (final concentration 0.2 mM) was added to start the enzyme reaction, at 30°C. After 10 min, the reaction solution was cooled and stored at −80°C. A 0.15 mM authentic phthalic acid sample was prepared in the same buffer and stored at −80°C.

Electrospray ionization mass spectrometry (ESI-MS), together with high performance liquid chromatography (HPLC), for analysis of reaction products, was achieved using the following system. A Waters 2690/996 HPLC equipped with a photo diode array detector and operating at 210–400 nm was used to deliver samples to the MS detector (Waters ZMD Alliance LC/MS system, Nippon Waters Co., Tokyo, Japan). For sample separation, a Symmetry C18 column (2.1 ϕ × 150 mm) was used. A linear gradient from 0% methanol in 5 mM ammonium acetate, to 80% (v/v) methanol in the same salt solution, over 20 min, at a flow rate of 0.2 ml/min, was applied. Both positive (ES+) and negative (ES−) ion modes were explored.

Preparation of reaction products when ABS was acted upon by DyP

To assist in characterization of the reaction products obtained when DyP degraded RB5, ABS was used as a substrate of the enzymatic reaction. ABS (final concentration 6 mM) was dissolved in 25 mM citrate buffer (pH 3.2) and DyP (final concentration 0.6 μM) was admixed; the spectrum from 600 to 200 nm was explored. H2O2 (final concentration 6 mM) was added to the mixture and incubation proceeded at 30°C for 24 h. To remove DyP, the reaction products were treated by ultrafiltration (cutoff 10 kDa) and the filtrate was recovered. The filtrate was freeze-dried, and the contents later analyzed by thin-layer chromatography (TLC). Otherwise, the filtrate was used directly, without freeze-drying, for HPLC and ESI-MS analyses.

NMR analysis of ABS treated with DyP

Fifty milligram of freeze-dried sample was dissolved in 400 μl of water and TLC was performed on a silica gel 60 F254 glass plate (200 × 200 mm, Merck Ltd Japan) developed with methanol–ethyl acetate [3:1 (by volume)]. Colored bands were identified visually. Colored reaction products were collected, with silica gel from the glass plate, using a spatula, and suspended in methanol–ethyl acetate [3:1 (by volume)]. The suspension was centrifuged to remove the silica gel and then filtered through a membrane filter (pore size 0.45 μm). The solvent was removed by rotary evaporation and the residue analyzed by 1H and 13C nuclear magnetic resonance (NMR) spectroscopy at 300 MHz (and 293 K) with a JNM-AL300 FT-NMR, and at 500 MHz (and 293 K) with a JNM-GX500 FT-NMR (JEOL, Tokyo Japan), respectively. The liquids d-DMSO and CD3OD were used as solvents for 13C-NMR and 1H-NMR, respectively. The integration numbers for 1H-NMR and 13C-NMR analyses were 64 and 1,688, respectively.

ESI-MS analysis of ABS treated with DyP

The reaction mixture after ABS was treated with DyP was applied to HPLC and fractionated. The separation column was an Asahipak NH2-P50 (4.6 ϕ × 250 mm) and the elution solvent was 50 mM cyclohexyl aminopropane sulfonic acid (CAPS) adjusted to pH 11 with 2 M NaOH. The red–brown-colored elution volume was collected and applied to the ESI-MS (JEOL, Accu TOF CS JMS-T40 instrument) at a constant rate of 0.2 ml/min using H2O:MeOH [1:1 (by volume)]. The analysis was performed in the positive ion (ES+) mode and the scan interval was 1 s. The nebulizing and drying gas flow rates were 600 and 50 l/h of nitrogen, respectively. The nebulizing chamber and ion source temperatures were 250 and 80°C, respectively. The electrospray, orifice, and ring lens voltages were 2.0 kV, 85, and 15 V, respectively.

Results and discussion

Reaction products of RB5 treated with DyP

Changes in the visible spectrum of RB5 treated with DyP are shown in Fig. 1. The absorbance at 600 nm decreased and absorbances at 400–500 nm increased as the color of the reaction solution became red–brown. A molecular ion corresponding to RB5 [i.e., m/z of 772(ES−) or 774(ES+)] was not observed on MS analysis after enzyme reaction. Instead, three distinct molecular ion signals appeared, indicating reaction products. The first product (Product 1) had a molecular ion at m/z of 167(ES+) as shown in Fig. 2a. Furthermore, the molecular ion at m/z of 149(ES+) suggested that the compound was easily dehydrolyzed. As these mass spectrometric characteristics corresponded to those of authentic phthalic acid, as shown in Fig. 2b, and as the retention times of authentic phthalic acid and the reaction product on HPLC were identical (data not shown), we identified this product as phthalic acid. The second product (Product 2) showed molecular ions at m/z of 471 (ES−) and 473 (ES+), as shown in Fig. 3a. The molecular mass of Product 2 corresponded to that of RB5 without the anthraquinone frame [shown as an inset (in Fig. 3a)]. Therefore, phthalic acid was generated by an oxidative ring-opening of the anthraquinone frame. As far as this reaction is concerned, DyP appears to be a hydrolase or oxygenase rather than a peroxidase, although H2O2 was indispensable for the reaction. Jones (2001) reported that water released from H2O2 by the heme peroxidase reaction plays a significant role in influencing the reactivity of peroxidases, supporting the idea that DyP might have a unique reaction mechanism in addition to the peroxidase-type activity. The third product (Product 3) showed molecular ions at m/z values of 300(ES−) and 302(ES+), as shown in Fig. 3b. The molecular mass of Product 3 corresponded to that of Product 2 without ABS [shown as an inset (in Fig. 3b)]. When the enzyme reaction time was prolonged, the molecular ion peak corresponding to Product 2 disappeared, whereas that of Product 3 remained. Therefore, Product 2 was further converted to Product 3, and m- or p-ABS, by DyP.

a Mass spectra of Product 2 (MW 472) of RB5 treated with DyP. Above, negative ion mode (ES−); Below positive ion mode (ES+). Deduced structural formula of Product 2 is shown as inset. b Mass spectra of Product 3 (MW 301) of RB5 treated with DyP. Above negative ion mode (ES−); Below positive ion mode (ES+). Deduced structural formula of Product 3 is shown as inset

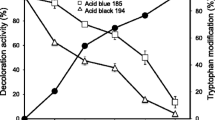

In this pathway, o-ABS, and m- or p-ABS, must also be produced. However, we could not detect these chemicals. We speculate that ABS was immediately converted to other products by DyP action. In fact, the color of the reaction products of each aminobenzene sulfonic acid treated by DyP was red–brown, although ABS is colorless. Moreover, this color appeared similar to that of RB5 treated with DyP, as shown in Fig. 4.

Reaction products of ABS treated with DyP

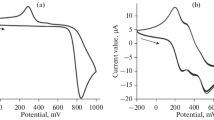

When ABS was used as the substrate for DyP action, the reaction mixture changed to red–brown from colorless, as shown in Fig. 4b. The red–brown compound showed an Rf of 0.6 on TLC. In addition, on TLC analysis, an undeveloped product, brown in color, showed a high molecular weight (>80,000) by gel filtration chromatography. This means that polymerization was also accelerated. It has been reported that 2,5-diaminobenzene sulfonic acid was polymerized by horseradish peroxidase (Alva et al. 1997). When the reaction mixture was applied to HPLC, the red–brown compound eluted at 10.6 min. This compound was named the “ABS derivative (Product 4)”. The 1H-NMR spectra of o-ABS and Product 4 are shown in Fig. 5a and b, respectively. Product 4 was found to have no carbon apart from the benzene ring, from 13C-NMR data [(500 MHz DMSO) δ 148.8, 148.0, 127.9, 113.8, 113.2, 111.5]. In the 1H-NMR spectra (Fig. 5a, b), the proton signals of Product 4 were similar to those of o-ABS, indicating that the product contained an ortho-substituted benzene ring similar to that found in o-ABS. Furthermore, the 1H-NMR signals of the four distinct proton types in the compound were upfield of those of the protons of o-ABS, as shown in Fig. 5, suggesting that the electron-donating group of o-ABS (–NH2) was changed to an electron-withdrawing group. As Product 4 was a colored compound, this group was deduced to be the azo group (–N=N–). This process is explained by the reaction mechanism of a typical peroxidase (such as horseradish peroxidase) and a spontaneous chemical reaction. The typical peroxidase reactions are two-electron redox pathways consisting of three sequential reactions (Dunford 1999):

1H-NMR spectra of a ABS [(300 MHz, CD3OD) δ 7.90 (1H, d), 7.48 (1H, d), 7.36 (1H, t), 7.27 (1H, t)] and b Product 4 [(300 MHz, CD3OD) δ 7.61 (1H, d), 7.15 (1H, t), 6.79 (1H, d), 6.63 (1H, t)]. Proton signals indicated by circles correspond to those signals from phenyl. Structural formulas of o-ABS and 2,2′-disulfonyl azobenzene are shown as inset of a and b, respectively. c Mass spectrum of Product 4 at positive ion mode. The ion peaks at 365 and 586 correspond to m/z (M + Na)+ and (M + Na + CAPS)+, respectively. Structural formula of identified reaction product is shown as inset

If AH2 corresponds to o-ABS, A2H2 corresponds to 1,2-bis(2-sulfonylphenyl)hydrazine. As 1,2-bis(2-sulfonylphenyl)hydrazine is also a substrate for a general peroxidase reaction, because hydrogen is available for withdrawal, this material would be further converted to 2,2′-disulfonyl azobenzene by DyP. From the ESI-MS spectrum (Fig. 5c), a molecular ion at m/z 365 appeared, indicating that Product 4 is identical to the sodium additive of 2,2′-disulfonyl azobenzene (M + Na)+. No molecular ion corresponding to m/z 343 (M + H)+ was observed because a large amount of Na+ was contained in the assay sample; the pH was adjusted to pH 11 with NaOH. Another molecular ion appeared at m/z 586, indicating a sodium-plus-cyclohexyl aminopropane sulfonic acid (CAPS) additive to 2,2′-disulfonyl azobenzene (M + Na + CAPS)+. This strongly suggests that DyP catalyzes the typical peroxidase reaction in addition to a DyP-specific reaction on anthraquinones. This characteristic might be shared with other DyP-type peroxidases (Sturm et al. 2006; Zubieta et al. 2007a). Based on these results, we can now propose a reasonable degradation pathway of RB5 by DyP, as shown in Fig. 6. It is notable that we have already reported that the red–brown compounds are completely decolorized by a versatile peroxidase, TcVP1, although the end-products of RB5 treated with DyP were red–brown in color (Sugano et al. 2006).

Conclusion

In conclusion, this is the first report to propose a reasonable anthraquinone degradation pathway achieved by a unique peroxidase, DyP. Importantly, phthalic acid and red–brown compounds were generated in the degradation process. One of the red–brown compounds was formed by a general peroxidase reaction, whereas phthalic acid is suggested to be generated not by a peroxidase effect but via a hydrolase- or oxygenase-catalyzed reaction. This study suggests that DyP is a novel bifunctional enzyme.

References

Alva KS, Kumar J, Marx KA, Tripathy SK (1997) Enzymatic synthesis and characterization of a novel water-soluble polyaniline: poly (2,5-diaminobenzenesulfonate). Macromolecules 30:4024–4029. doi:10.1021/ma961544h

Anliker R (1979) Ecotoxicology of dyestuffs—a joint effort by industry. Ecotoxicol Environ Saf 3:59–74. doi:10.1016/0147-6513(79)90060-5

Banat IM, Nigam P, Singh D, Marchant R (1996) Microbial decolorization of textile-dye-containing effluents. Bioresour Technol 58:217–227. doi:10.1016/S0960-8524(96)00113-7

Cartoni A, Menna P, Salvatorelli E, Braghiroli D, Giampietro R, Animati F, Urabani A, Boccio PD, Minotti G (2004) Oxidative degradation of cardiotoxic anticancer anthracyclines to phthalic acids. J Biol Chem 279:5088–5099. doi:10.1074/jbc.M306568200

Chivukula M, Spadaro JT, Renganathan V (1995) Lignin peroxidase catalized oxidation of sulfonated azo dyes generates novel sulfophenyl hydroperoxides. Biochemistry 34:7765–7772. doi:10.1021/bi00023a024

Chung KT, Stevens E Jr (1993) Degradation of azo dyes by environmental microorganisms and heliminths. Environ Toxicol Chem 12:2121–2132. doi:10.1897/1552-8618(1993)12[2121:DOADBE]2.0.CO;2

Dunford HB (1999) Heme peroxidases. Wiley-VCH, New York

Fang H, Wenrong H, Yuezhong L (2004) Biodegradation mechanisms and kineteics of azo dye 4BS by a microbial consortium. Chemosphere 57:293–301. doi:10.1016/j.chemosphere.2004.06.036

Fu Y, Viraraghavan T (2001) Fungal decolorization of dye wastewaters—a review. Bioresour Technol 79:251–262. doi:10.1016/S0960-8524(01)00028-1

Goszczynski S, Paszczynski A, Pasti-Grigsby MB, Crawford RL, Crawford DL (1994) New pathway for degradation of sulfonated azo dyes by microbial peroxidases of Phanerochaete chrysosporium and Streptomyces chromofuscus. J Bacteriol 176:1339–1347

Heinfling A, Martínez MJ, Martínez AT, Bergbauer M, Szewzyk U (1998) Transformation of industrial dyes by manganese peroxidases from Bjerkandera adusta and Pleurotus eryngii in a manganese-independent reaction. Appl Environ Microbiol 64:2788–2793

Itoh K, Kitade Y, Yatone C (1996) A pathway for biodegradation of anthraquinone dye, C. I. disperse red 15, by a yeast strain Pichia anomala. Bull Environ Contam Toxicol 56:413–418. doi:10.1007/s001289900059

Itoh K, Kitade Y, Yatone C (1998) Oxidative biodegradation of an anthraquinone dye, pigment violet 12, by Coriolus versicolor. Bull Environ Contam Toxicol 60:786–790. doi:10.1007/s001289900695

Jones P (2001) Roles of water in heme peroxidase and catalase mechanisms. J Biol Chem 276:13791–13796

Kim SJ, Shoda M (1999) Purification and characterization of a novel peroxidase from Geotricum candidum Dec 1 involved in decolorization of dyes. Appl Environ Microbiol 65:1029–1035

Kim SJ, Ishikawa K, Hirai M, Shoda M (1995) Characteristics of a newly isolated fungus, Geotrichum candidum Dec 1, which decolorizes various dyes. J Ferment Bioeng 79:601–607. doi:10.1016/0922-338X(95)94755-G

McMullan G, Meehan C, Conneely A, Kirby N, Robinson T, Nigam P, Banat IM, Marchant R, Smyth WF (2001) Microbial decolourisation and degradation of textile dyes. Appl Microbiol Biotechnol 56:81–87. doi:10.1007/s002530000587

Ollikka P, Alhonmaki K, Leppanen VM, Glumoff T, Raijola T, Suominen I (1993) Decolorization of azotriphenyl methane, heterocyclic, and polymeric dyes by lignin peroxidase isozymes from Phanerochaete chrysosporium. Appl Environ Microbiol 59:4010–4016

Pasti MB, Crawford DL (1991) Relationship between the abilities of streptomycetes to decolorize three anthron-type dyes and to degrade lignocellulose. Can J Microbiol 37:902–907

Reszka KJ, Wagner BA, Burns CP, Britigan BE (2005) Effects of peroxidase substrates on the amplex red/peroxidase assay: antioxidant properties of anthracycline. Anal Biochem 342:327–337. doi:10.1016/j.ab.2005.04.017

Scheibner M, Hülsdau B, Zelena K, Nimtz M, de Boer L, Berger RG, Zorn H (2008) Novel peroxidases of Marasmius acorodonius degrade β-carotene. Appl Microbiol Biotechnol 77:1241–1250. doi:10.1007/s00253-007-1261-9

Stolz A (2001) Basic and applied aspects in the microbial degradation of azo dyes. Appl Microbiol Biotechnol 56:69–80. doi:10.1007/s002530100686

Sturm A, Schierhorn A, Lindenstrauss U, Lilie H, Brüser T (2006) YcdB from Escherichia coli reveals a novel class of Tat-dependently translocated hemoproteins. J Biol Chem 281:13972–13978. doi:10.1074/jbc.M511891200

Sugano Y, Sasaki K, Shoda M (1999) cDNA cloning and genetic analysis of a novel decolorizing enzyme, peroxidase gene dyp from Geotrichum candidum Dec 1. J Biosci Bioeng 87:411–417. doi:10.1016/S1389-1723(99)80087-5

Sugano Y, Nakano R, Sasaki K, Shoda M (2000) Efficient heterologous expression in Aspergillus oryzae of a unique dye-decolorizing peroxidase, DyP, of Geotrichum candidum Dec 1. Appl Environ Microbiol 66:1754–1758. doi:10.1128/AEM.66.4.1754-1758.2000

Sugano Y, Matsushima Y, Shoda M (2006) Complete decolorization of the anthraquinone dye Reactive Blue 5 by the concerted action of two peroxidases from Thanatephorus cucumeris Dec 1. Appl Microbiol Biotechnol 73:862–871. doi:10.1007/s00253-006-0545-9

Sugano Y, Muramatsu R, Ichiyanagi A, Sato T, Shoda M (2007) DyP, a unique dye-decolorizing peroxidase, represents a novel heme peroxidase family: Asp171 replaces the distal histidine of classical peroxidases. J Biol Chem 282:36652–36658. doi:10.1074/jbc.M706996200

Vyas BR, Molitoris HP (1995) Involvement of an extracellular H2O2-dependent ligninolytic activity of the white rot fungus Pleurotus ostreatus in the decolorization of remazol brilliant blue R. Appl Environ Microbiol 61:3919–3927

Young L, Yu J (1997) Ligninase-catalysed decolorization of synthetic dyes. Water Res 31:1187–1193. doi:10.1016/S0043-1354(96)00380-6

Zubieta C, Joseph R, Krishna SS, McMullan D, Kapoor M, Axelrod HL, Miller MD, Abdubek P, Acosta C, Astakhova T, other 37 authors (2007a) Identification and structural characterization of heme binding in a novel dye-decolorizing peroxidase, TyrA. Proteins 69:234–243. doi:10.1002/prot.21673

Zubieta C, Krishna SS, Kapoor M, Kozbial P, McMullan D, Axelrod HL, Miller MD, Abdubek P, Ambing E, Astakhova T, other 34 authors (2007b) Crystal structures of two novel dye-decolorizing peroxidases reveal a β-barrel fold with a conserved heme-binding motif. Proteins 69:223–233. doi:10.1002/prot.21550

Acknowledgments

We thank Dr. Kazutsugu Matsumoto, Meisei University, for helpful discussion on identification of reaction products, and Dr. Yoshiyuki Nakamura, Tokyo Institute of Technology, and Etsuko Suzuki, Japan Waters Co., for technical support during NMR analysis and LC-MS analysis, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sugano, Y., Matsushima, Y., Tsuchiya, K. et al. Degradation pathway of an anthraquinone dye catalyzed by a unique peroxidase DyP from Thanatephorus cucumeris Dec 1. Biodegradation 20, 433–440 (2009). https://doi.org/10.1007/s10532-008-9234-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-008-9234-y