Abstract

Anaerobic co-digestion of fruit and vegetable waste (FVW) and abattoir wastewater (AW) was investigated using anaerobic sequencing batch reactors (ASBRs). The effects of hydraulic retention time (HRT) and temperature variations on digesters performances were examined. At both 20 and 10 days biogas production for co-digestion was greater thanks to the improved balance of nutrients. The high specific gas productions for the different digestion processes were 0.56, 0.61 and 0.85 l g−1 total volatile solids (TVS) removal for digesters treating AW, FVW and AW + FVW, respectively. At an HRT of 20 days, biogas production rates from thermophilic digesters were higher on average than from mesophilic AW, FVW and AW + FVW digestion by 28.5, 44.5 and 25%, respectively. However, at 10 days of HRT results showed a decrease of biogas production rate for AW and AW + FVW digestion processes due to the high amount of free ammonia at high organic loading rate (OLR).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The abattoir effluent composed of the wastewater generated from cleaning operations and the untreated blood causes important environmental problems (Saddoud and Sayadi 2007). However, entering this wastewater into a municipal treatment plant without pre-treatment may create severe problems due to its high biological oxygen demand (BOD) and chemical oxygen demand (COD) characteristics. Obviously, this problem is aggravated if the untreated wastewater directly reaches the rivers (Alvarez and Liden 2008).

In wastewater treatment, biological processes are mainly used for the removal of organic pollution. However, aerobic processes are not regarded as a suitable treatment option because of high-energy requirements for aeration, limitations in liquid-phase oxygen transfer rates and large quantities of sludge production (Mittal 2006). Anaerobic digestion of abattoir wastes and animal by-products has recently been considered as an interesting alternative waste management option (Massé and Masse 2001; Wang and Banks 2003). It represents a potential possibility to decrease the environmental pollution, and at the same time provide biogas for local energy needs. In addition, in the specific case of treatment of animal wastes, the remaining stabilized slurry after digestion may be used as a fertilizer (Marchaim et al. 1991; Borja et al. 1998). However, the process is sensitive and prone to failure. Most likely, this can be attributed to the accumulation of high levels of free ammonia resulting from anaerobic degradation of the nitrogen rich protein components of blood (Alvarez and Liden 2008; Fountoulakis et al. 2008). Potential inhibition of methanogenic bacteria by ammonia plays a role in almost all media with high nitrogen content wastes, since ammonia is the end product of anaerobic digestion of proteins. The inhibitory concentration of ammonia varies depending on parameters such as origin of inoculum, substrate, pH, and temperature (Chen et al. 2008; Cuetos et al. 2008). The specific activity of methanogenic bacteria has been found to decrease with increasing ammonia concentrations (Chen et al. 2008).

A particularly important aspect for the digester performance is the Carbon/Nitrogen (C/N) ratio and the buffer capacity (Gomez et al. 2006; Sosnowski et al. 2003). Abattoir wastewater (AW) has high nitrogen content, and should preferably be co-digested with waste that has high carbon content. The nitrogen and phosphorus content in fruit and vegetable waste (FVW) is often low and for this reason co-digestion of abattoir wastewater with FVW as a co-substrate has been proposed as a solution to the problems mentioned above. FVWs are produced in large quantities in markets, and constitute a source of leachate formation in municipal landfills because of their high biodegradability (Bouallagui et al. 2003; Gomez et al. 2006). The whole production of FVW collected from the market of Tunis (Tunisia) has been estimated to be 20–25 tons per day. Where as, in the abattoir Ellouhoum of Tunis, an estimated volume of 200 m3 per day of wastewater is released. Therefore, the combination of AW and FVW treatment could be a practical alternative in Tunis for the simultaneous recycling of different types of organic wastes generated in the same city. The content of nutrients can be balanced and the negative effect of toxic compounds on the digestion process may be decreased giving an increased digestion performance. The co-digestion of several wastes having complementary characteristics is one of the main advantages of anaerobic technology (Murto et al. 2003; Yen and Brune 2007). Its benefits include dilution of potential toxic compounds, improved balance of nutrients, synergistic effect of micro-organisms, increased load of biodegradable organic matter and better biogas yield. Additional advantages include hygienic stabilization and increased digestion rate (Gannoun et al. 2007).

The intensity of the microbial activity on which the production of methane depends, is a function of the environment temperature (Kettunen and Rintala 1997). There are three possible ranges of temperature in which the process can be carried out (psychrophilic 15–25°C, mesophilic 35–37°C and thermophilic 50–60°C). Thermophilic systems may be employed, with which improvements were achieved in process efficiency, in the reduction of volatile solids (VS), their conversion into biogas and contaminants removal (Massé and Masse 2001).

The aim of this work was to examine the performance of anaerobic co-digestion of AW and FVW under mesophilic and thermophilic temperature, using anaerobic sequencing batch reactors (ASBRs).

Materials and methods

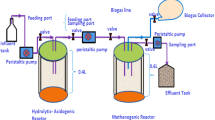

Reactors design and operational conditions

Six laboratory-scale ASBR (R1, R2, R3, R4, R5 and R6) of 2 l effective volume were used. The temperature was controlled at 35°C for R1, R2 and R3 and at 55°C for R4, R5 and R6 by a thermostatically regulated water bath. Peristaltic pumps were used to fill the reactors and to draw off the effluents after settling. Mixing in the reactors was done by a system of magnetic stirring. Each digester was initially inoculated with anaerobic sludge obtained from an active mesophilic (35°C) digester of FVWs treatment plant (Bouallagui et al. 2007).

The ASBRs were operated with cycles including the following four discrete steps: (1) fill (15 min): 100 ml or 200 ml of different wastes (F1, 100%AW, F2, 30%FVW/70%Water and F3, 30%FVW/70%AW) were added to the reactors at the beginning of a cycle, (2) react (21 h): during this phase, the reactors were stirred and organic matter was converted to energy and new cells, (3) settle (2 h and 30 min) : settling started when the react phase was finished, (4) draw off (15 min): at the end of the settling period, the volume of liquid added at the beginning of the cycle was drawn off from the reactors.

Wastes sources and characteristics

The FVWs used in this study were collected from the group market of Tunis. After shredding to small particles and homogenizing, they were stored at 4°C. The AW was collected from an abattoir factory (El Ouardia City, Tunis). The FVW consisted of homogenised courgettes, lettuce, tomatoes, apple, orange, pear, potatoes and carrot to give 8.3% total solid (TS) in which 93% of content was total volatile solid (TVS). Feedstocks were made up by using raw AW and by adding a percentage by volume of water and AW, to FVW. These gave three feedstock’s (Table 1); F1 (100%AW), F2 (30%FVW/70%Water) and F3 (30%FVW/70%AW), with an average TS contents of 0.7, 2.7 and 2.8%, respectively. Analysis of FVW, AW, F1, F2 and F3 were carried out several times and the average compositions are shown in Table 1. The feedstock F1 were used to load R1 and R4, the feedstock F2 were used to load R2 and R5 and the feedstock F3 were used to load R3 and R6.

Technical analysis

The biogas produced was measured daily by gas metre and its composition was estimated using an ORSAT apparatus (Bouallagui et al. 2003). TS, TVS, total suspended solids (TSS), pH, ammonia, alkalinity and total volatile fatty acids (VFAs) were determined according to the APHA standard methods (1995). Total organic carbon (TOC) was measured by catalytic oxidation on a TOC Euroglace analyser. Total nitrogen (TN) was estimated by the Kjeldahl method.

Results and discussion

Reactors performances under mesophilic conditions (35°C)

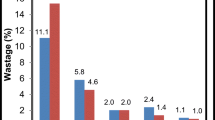

The anaerobic digestions of AW, FVW and the mixture of AW + FVW were investigated at two hydraulic retention time (HRT) (20 and 10 days). The results are illustrated in Fig. 1 and Table 2. First, mesophilic reactors treating AW (R1), FVW (R2) and AW + FVW (R3) were kept during two consecutive HRT of 20 days under an organic loading rate (OLR) of 0.21, 1.24 and 1.28 g TVS l−1 day−1, respectively. The results for co-digestion of the mixture of AW + FVW are better than those obtained from digestions of AW and FVW separately. Biogas yield for co-digestion was higher than AW and FVW digestion thanks to the better C/N ratio of this feedstock. The C/N ratio of the mixture AW + FVW of 22.5 was within the C/N ratio (20–25) required for stable and better biological conversions reported by others on anaerobic digestion of organic wastes (Parkin and Owen 1986; Mshandete et al. 2004; Yen and Brune 2007).

At the same time, TVS removal of 73, 76 and 84% were achieved in digesters R1, R2 and R3, respectively. It is very likely that the high degradation efficiency in the co-fermentation was due to an improved ratio of nutrients and better availability of the organic substances, which facilitate their assimilation by anaerobic consortium and increases the degree of degradation (Krupp et al. 2005). These results are in agreement with those obtained by Fernández et al. (2005) which reported a TVS removal within the range of 70–80% for anaerobic co-digestion of organic fraction of municipal solid waste and fats, and better than those (40–55%) obtained by Callaghan et al. (1999) and Dinsdale et al. (2000) for anaerobic co-digestion of organic wastes.

Under these conditions, levels of average total VFAs of below 1,500, 3,000 and 2,000 mg l−1 were detected at the start-up of AW, FVW and AW + FVW digestion, respectively. After one HRT, operation of reactors was stable and the values of VFAs decreased in any of the three reactors to rich 250, 330 and 180 mg l−1, respectively (Fig. 1).

The average values of free ammonia (FA) during the steady state in the digesters after one HRT of 20 days (Table 2) were below the toxic limits reported in the literature (Liu and Sung 2002; Gallert and Winter 1997). It is generally believed that FA concentrations below 200 mg l−1 are beneficial to anaerobic process since nitrogen is an essential nutrient for anaerobic microorganisms (Liu and Sung 2002). The release of ammonia from the organic proteins provoked an increase in alkalinity concentrations of the systems, leading to an average value for the period lower than 2,000–4,000 mg l−1; the recommended values for standard rate sewage sludge digesters (Koster and Lettinga1998; Sharma et al. 2000).

In the major cases of operations, the pH increased during anaerobic digestion due to the mineralization of organic matter. The pH values in reactors R1 and R3 treating AW and the co-substrate AW + FVW, respectively, were expected to be higher than those for the reactor R2 treating FVW alone. The pH values which remained between 7.0 and 7.4 are better for the growth and activity of methanogenic micro organisms.

Solids concentration in the reactors remained constant, without any formation of foam or floating layers during functioning. As the performance of these reactors was stable, their HRT was reduced to 10 days, increasing the OLR. The OLR was set at 0.42 g TVS l−1 day−1 for the reactor fed with AW (digester R1), 2.48 g TVS l−1 day−1 for the reactor fed with FVW (digester R2) and 2.56 g TVS l−1 day−1 for the reactor fed with AW and FVW (digester R3). Figure 1 shows that, at the beginning of this new period consisting of an increase in OLR and a decrease in HRT, the systems were characterized by an increase in the values of alkalinity until the steady state was reached. Once a period equivalent to two HRTs had elapsed, the systems were capable of adjusting to the new established conditions. Although higher values for the parameters (VFAs, alkalinity, ammonia) were observed compared to the results obtained from the previous period, except, the pH in the digester R2 which decreased from 7 to 6.8 (Table 2). The systems were able to reach and maintain stable profiles until the end of the period. The high stability of the reactors was confirmed by the VFAs concentrations (Fig. 2), of below 500, 800 and 400 mg l−1, detected in the effluents of R1, R2 and R3, respectively.

On decreasing HRT and increasing the organic loading, it was observed an increase in the volume of gas produced with a high VS removal. In all circumstances, the pH value of the systems always remained between 6.8 and 7.6. VFAs concentrations were much lower than the concentrations reported in other studies of AW and FVW, in which, their accumulation cause the inhibition of the anaerobic process (Bouallagui et al. 2005; Salminen et al. 2001). Daily biogas rates increased with increased loading. Their average values were 0.26 l day−1 in the anaerobic digestion of AW, 1.53 l day−1 in the anaerobic digestion of FVW, and 2.53 l day−1 with the mixture of AW and FVW. Specific gas production in the anaerobic digestions of AW and FVW were 0.43 and 0.40 l g−1 TVS removal, respectively, and 0.58 l g−1 TVS removal in the co-digestion of AW + FVW. This result is in agreement with the research carried out by other authors (Cuetos et al. 2008; Fountoulakis et al. 2008), and prove that the adaptation of methanogenic microorganisms to different kinds of organic waste is feasible.

Reactors performances under thermophilic conditions (55°C)

Under thermophilic condition, digestions of AW (digester R4), FVW (digester R5) and the mixture of AW + FVW (digester R6) were also evaluated. The results are illustrated in Fig. 2 and Table 3. At the HRT of 20 days, biogas production rates from the experimental thermophilic digesters (R4, R5 and R6) were higher on average than from mesophilic digesters (R1, R2 and R3) by 28.5, 44.5 and 25%, respectively. The composition of the biogas from thermophilic digesters was the same as from the other digesters ranging from 58 to 62% methane (Table 3).

The values of biogas yields obtained for the co-digestion of AW and FVW are higher than 0.6 l g−1 TVS feed. This relatively high specific gas production is a result of the efficient degradation of the AW and FVW, and as a consequence of the high theoretical methane potential of lipids, proteins and carbohydrates (Alvarez and Liden 2008; Salminen and Rintala 1999).

On decreasing HRT to 10 days and after a few days of functioning (around day 45 of the study in digester R4, and day 52 in digester R6), the volume of biogas decreased progressively (Fig. 2). This decrease was followed by a drop in methane production from values of 60–62% to values of below 40–44% in both reactors (Table 3). The short HRT of 10 days resulted in overloading and subsequent failure of the digestion of the AW and the codigestion process. The results showed a decrease of biogas production rate due to the high amount of FA (987 and 953 mg l−1 for AW and AW + FVW digestions, respectively). Gallert and Winter (1997) studied the anaerobic digestion of organic wastes and reported that methane production was inhibited 50% by 220 l−1 FA at 37°C and by 690 l−1 FA at 55°C, indicating that thermophilic flora tolerated at least twice as much FA as compared to mesophilic flora. In fact, the ammonia nitrogen is an important intermediate and potential inhibitor in the anaerobic digestion process. High concentration of total ammonia nitrogen in the digester would decrease the methanogen activity and further accumulation could fail the anaerobic digestion (Cuetos et al. 2008). Among the four types of anaerobic microorganisms, the methanogens are the least tolerant and the most likely to cease growth due to ammonia inhibition. As ammonia concentrations were increased in the range of 4,051–5,734 mg l−1, acidogenic populations in the granular sludge were hardly affected while the methanogenic populations lost 56.5% of its activity (Koster and Lettinga 1988).

The high ammonia nitrogen concentration in the effluent indicated a high mineralisation of organic nitrogen during treatment. Alkalinity in the reactors was increased three to five times during treatment. Effluent alkalinity tended to increase with temperature from an average of 3,900, 1,300 and 4,400 mg l−1 at 35°C to 8,900, 2,500 and 10,500 mg l−1 at the highest OLR at 55°C for AW, FVW and the mixture of AW + FVW digestion, respectively. Based on theoretical considerations and experimental results with municipal solids waste, it’s concluded that effluent alkalinity should increase as operating temperature is increased (Chen et al. 2008; Massé and Masse 2001). For AW, however, the alkalinity generated during treatment is mainly produced by the mineralisation of protein in to ammonia. The latter combines with the carbon acid in solution to form ammonia bicarbonate buffer (Cuetos et al. 2008). A high protein mineralisation at 55°C than 35°C may account for the difference in effluent alkalinity (Fountoulakis et al. 2008).

A slight increase in effluent pH with temperature was noted. The pH values (7.8–8) in the thermophilic reactors were expected to be slightly higher than those reported as suitable for the development of methanogenic microorganisms. Therefore, as a result of the increase in pH, the free ammonia concentration increases, and becomes inhibitory for the development of microorganisms. The hydrophobic ammonia molecule may diffuse passively in to the cell, causing proton unbalance, and/or potassium deficiency (Chen et al. 2008).

Conclusion

An interesting option for improving yields of anaerobic digestion of organic wastes is co-digestion. This study shows that a combined treatment of different Tunisian organic waste types like FVW, and AW in a mesophilic and thermophilic co-digestion processes gives the possibility of treating wastes, which cannot be easily treated separately. A sequencing batch co-digestion process using these substrates can be expected to result in a reduction of the volatile solid contents of between 73 and 86% and give a biogas yield of about 0.3–0.73 l g−1 TVS added at OLRs until to 2.56 g TVS l−1 day−1.

The results of the digesters performances showed that the variation in HRT under mesophilic conditions had not a considerable effect on the organic matter removal. However it permitted a significant increase in biogas rates and a slightly decrease in specific biogas production. At 20 days of HRT the biogas yield was significantly increased from 0.68 l g−1 TVS removal in digester R3 to 0.85 l g−1 TVS removal in digester (R6), by increasing the temperature from 35°C to 55°C. At 55°C the short HRT of 10 days resulted in overloading and subsequent failure of the digestion of the AW and the co-digestion process. The outlet pH and alkalinity values increased with the increase of the OLR and temperature, which could fail the biogas production.

References

Alvarez R, Liden G (2008) Semi-continuous co-digestion of solid slaughterhouse waste, manure, and fruit and vegetable waste. Rene Energ 33:726–734. doi:10.1016/j.renene.2007.05.001

American Public Health Association/American Water Works Association/Water Environment Federation (1995) Standard methods for the examination of water and wastewater, 19th edn, Washington DC

Borja R, Banks CJ, Wang Z, Mancha A (1998) Anaerobic digestion of slaughterhouse wastewater using a combination sludge blanket and filter arrangement in a single reactor. Bioresour Technol 65:125–133. doi:10.1016/S0960-8524(98)00004-2

Bouallagui H, Ben Cheikh R, Marouani L, Hamdi M (2003) Mesophilic biogas production from fruit and vegetable waste in a tubular digester. Bioresour Technol 86:85–89. doi:10.1016/S0960-8524(02)00097-4

Bouallagui H, Touhami Y, Ben Cheikh R, Hamdi M (2005) Bioreactors performance used in anaerobic digestion of fruit and vegetable wastes. Process Biochem 40:989–995. doi:10.1016/j.procbio.2004.03.007 Review

Bouallagui H, Rachdi B, Hamdi M (2007) Anaerobic co-digestion of abattoir wastewater and the fruit and vegetable fraction of the municipal wastes. Proceeding of the international conference: technologies for industrial wastewater treatment and reuse in the Mediterranean region. 24–26 May, Jerba

Callaghan FJ, Wase DA, Thayanithy JK, Forster CF (1999) Co-digestion of waste organic solids: batch studies. Bioresour Technol 67:117–122. doi:10.1016/S0960-8524(98)00108-4

Chen Y, Cheng JJ, Creamer Kurt S (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99:5956–5959. doi:10.1016/j.biortech.2007.10.038

Cuetos MJ, Gomez X, Otero M, Moran A (2008) Anaerobic digestion of solid slaughterhouse waste (SHW) at laboratory scale: influence of co-digestion with the organic fraction of municipal solid waste (OFMSW). Biochem Eng J 40:99–106. doi:10.1016/j.bej.2007.11.019

Dinsdale RM, Premie GC, Hawkes FR, Hawkes DL (2000) Two-stage anaerobic co-digestion of waste activated sludge and fruit/vegetable waste using inclined tubular digesters. Bioresour Technol 72:159–168. doi:10.1016/S0960-8524(99)00105-4

Fernández A, Sánchez A, Font X (2005) Anaerobic co-digestion of a simulated organic fraction of municipal solid wastes and fats of animal and vegetable origin. Biochem Eng J 26:22–28. doi:10.1016/j.bej.2005.02.018

Fountoulakis MS, Drakopoulou S, Terzakis S, Georgaki E, Manios T (2008) Potential for methane production from typical Mediterranean agro-industrial by-products. Biom Bioen 32:155–161. doi:10.1016/j.biombioe.2007.09.002

Gallert C, Winter J (1997) Mesophilic and thermophilic anaerobic digestion of source- sorted organic waste: effect of ammonia on glucose degradation and methane production. Appl Microbiol Biotechnol 48:405–410. doi:10.1007/s002530051071

Gannoun H, Ben Othman N, Bouallagui H, Hamdi M (2007) Mesophilic and thermophilic anaerobic co-digestion of olive mill wastewaters and abattoir wastewaters in an up flow anaerobic filter. Ind Eng Chem Res 46:6737–6743. doi:10.1021/ie061676r

Gomez X, Cuetos MJ, Cara J, Moran A, Garcıa AI (2006) Anaerobic co-digestion of primary sludge and the fruit and vegetable fraction of the municipal solid wastes. Conditions for mixing and evaluation of the organic loading rate. Rene Energ 31:2017–2024. doi:10.1016/j.renene.2005.09.029

Kettunen RH, Rintala JA (1997) The effect of low temperature (5–29°C) and adaption on the methanogenic activity of biomass. Appl Microbiol Biotechnol 48:570–576. doi:10.1007/s002530051098

Koster IW, Lettinga G (1988) Anaerobic digestion at extreme ammonia concentrations. Biolog Was 25:51–59. doi:10.1016/0269-7483(88)90127-9

Krupp M, Schubert J, Widmann R (2005) Feasibility study for co-digestion of sewage sludge with OFMSW on two wastewater treatment plants in Germany. Waste Manag 25:393–399. doi:10.1016/j.wasman.2005.02.009

Liu T, Sung S (2002) Ammonia inhibition on thermophilic aceticlastic methanogens. Water Sci Technol 45:113–120

Marchaim U, Levanon D, Danai O, Musaphy S, Chen Y, Inbar Y, Klinger I (1991) A suggested solution for slaughterhouse wastes: uses of the residual materials after anaerobic digestion. Bioresour Technol 37:127–134. doi:10.1016/0960-8524(91)90200-4

Massé DI, Masse L (2001) The effect of temperature on slaughterhouse wastewater treatment in ASB reactors. Bioresour Technol 76:91–98. doi:10.1016/S0960-8524(00)00105-X

Mittal GS (2006) Treatment of wastewater from abattoirs before land application—a review. Bioresour Technol 97:1119–1135. doi:10.1016/j.biortech.2004.11.021

Mshandete A, Kivaisi A, Rubindamayugi M, Mattiasson B (2004) Anaerobic batch co-digestion of sisal pulp and fish wastes. Bioresour Technol 95:19–24. doi:10.1016/j.biortech.2004.01.011

Murto M, Bjornsson L, Mattiasson B (2003) Impact of food industrial waste on anaerobic co-digestion of sewage sludge and pig manure. J Environ Manage 70:101–107. doi:10.1016/j.jenvman.2003.11.001

Parkin GF, Owen WF (1986) Fundamental of anaerobic digestion of wastewater sludge. J Environ Eng 112:867–920

Saddoud A, Sayadi S (2007) Application of acidogenic fixed-bed reactor prior to anaerobic membrane bioreactor for sustainable slaughterhouse wastewater treatment. J Hazard Mater 149:700–706. doi:10.1016/j.jhazmat.2007.04.031

Salminen EA, Rintala JA (1999) Anaerobic digestion of poultry slaughtering wastes. Environ Technol 20:21–28. doi:10.1080/09593332008616788

Salminen E, Einola J, Rintala J (2001) Characterisation and anaerobic batch degradation of materials accumulating in anaerobic digesters treating poultry slaughterhouse waste. Environ Technol 22:577–585. doi:10.1080/09593332208618261

Sharma VK, Testa C, Lastella G, Cornacchia G, Comparato MP (2000) Inclined-plug-flow type reactor for anaerobic digestion of semi-solid waste. Appl Energy 65:173–185. doi:10.1016/S0306-2619(99)00084-7

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid waste. Adv Environ Res 7:609–617. doi:10.1016/S1093-0191(02)00049-7

Yen H-W, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98:130–134. doi:10.1016/j.biortech.2005.11.010

Wang Z, Banks CJ (2003) Evaluation of a two stage anaerobic digester for the treatment of mixed abattoir wastes. Process Biochem 38:1267–1273. doi:10.1016/S0032-9592(02)00324-2

Acknowledgments

The authors wish to acknowledge the Ministry of Superior Education and Scientific Research and Technology, which has facilitated the carried work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouallagui, H., Rachdi, B., Gannoun, H. et al. Mesophilic and thermophilic anaerobic co-digestion of abattoir wastewater and fruit and vegetable waste in anaerobic sequencing batch reactors. Biodegradation 20, 401–409 (2009). https://doi.org/10.1007/s10532-008-9231-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-008-9231-1