Abstract

The conventional landfilling does not promote sustainable waste management due to uncontrolled emissions which potentially degrade the environment. Pretreatment of municipal solid waste prior to landfilling significantly enhances waste stabilization, reduces the emissions and provides many advantages. Therefore, pretreatment of municipal solid waste methods were investigated. The major objectives of biological pretreatment are to degrade most easily degradable organic matters of MSW in a short duration under controlled conditions so as to produce desired quality for landfill. To investigate the suitable pretreatment method prior to landfilling for developing countries four pretreatment simulators were developed in the laboratory: (i) anaerobic simulator (R1), (ii) aerobic pretreatment simulator by natural convection of air (R2), (iii) aerobic pretreatment simulator by natural convection of air with leachate recirculation (R3) and (iv) forced aeration and leachate recirculation (R4). During the pretreatment organic matter, elemental composition, i.e., carbon, hydrogen, nitrogen and settlement were determined for bench scale experiments. A two-component kinetic model is proposed for the biodegradation of organic matter. Biodegradation kinetic constants were determined for readily and slowly degradable organic matter. The biodegradation of organic matter efficiency in terms of kinetic rate constants for the pretreatment simulators was observed as R4 > R3 > R2 > R1. Biodegradation rate constants for readily degradable matter in simulators R4 and R3 were 0.225 and 0.222 per day. R3 and R4 simulators were more effective in reducing methane emissions about 45% and 55%, respectively, as compared to anaerobic simulator R1. Pretreatment of MSW, by natural convection of air with leachate recirculation R3 is sustainable method to reduce the emissions and to stabilize the waste prior to landfilling.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Landfilling of municipal solid waste (MSW) can usually lead to uncontrolled emissions of leachate and landfill gas (LFG) as a result of percolation and biological transformation processes (Belevi and Baccini 1989). Environmental impact can result from the run-off of the toxic compounds into surface water and groundwater as well as from the gaseous emissions which contribute to the greenhouse effect. The organic matter reduction for a landfill may be achieved either by stabilizing the wastes within the site or by biologically pre-treating the wastes prior to landfilling (Westlake 1997). Biological pretreatment lowers emissions considerably and a reduced amount of less reactive waste is left for landfilling because the organic waste compounds are degraded and stabilized under optimized and controlled conditions (Komilis et al. 1999).

Solid waste pretreatment techniques are traditionally associated with mechanical, thermal and biological pretreatment. These techniques are currently used mostly in combination with the objectives of recovering materials, producing the energy and minimizing the amount of waste to be landfilled. Various pretreatment methods of MSW, i.e., aerobic, anaerobic and composting were tried by several researchers after shredding and separation of the waste. These pretreatment methods were found significantly effective in reducing organic content as COD in leachate and methane yield. Especially aerobic treatment with intensive aeration, watering and turning waste, passive aeration with watering and turning waste and shredding waste without watering and turning were also investigated (Frauke et al. 2000). Factors affecting the choice of pretreatment processes include the composition of MSW, retention times, odor emissions, fate of toxic chemicals and costs. Biological pretreatment of MSW reduced both the organic loading of leachate as well as gas production, especially leachate TOC 23 times lower, compared with leachate from untreated waste (Binner and Zach 2000; Reiger and Bidlingmaier 1995). Both the leachate treatment and biogas recovery costs can be reduced and reduction in leachable organic emissions (due to shortening of the acidogenic stage) achieved. The cost of aerobic pretreatment for the fraction of MSW must be considered while keeping in view the carbon lost during aerobic pretreatment and the corresponding reduction in methane yield (Komilis et al. 1999).

Tenzin et al. (2005) proposed that MSW generated in Asian countries should go under 1 week of bulk composting prior to landfilling or dumping. This would reduce a substantial volume of waste disposal and would further enhance waste stabilization and separation. He has carried out this study by using 1 m3 MSW cage and the volume and volatile solids reduction were recorded. However, many other parameters are required to be explored in order to recommend the period of pretreatment.

In China, composition of the MSW is very complicated as it varies from city to city and from season to season. The amount of MSW produced increases rapidly with the rate of 8–10% annually which has made China one of the countries under the biggest burden of waste treatment in the world (Zhang 1998; Shi 1998; Xu 2004). Waste production rate per capita per day in the ten big cities, i.e., Beijing, Shanghai, Tianjin, Guangzhou, Shenzhen, Dalian, Shenyang, Maanshan Hangzhou and Anshan ranges from 0.66 to 2.62 kg (Xu 2004). Landfilling is dominant method of MSW disposal; about 90% of MSW generated is disposed of in the landfills, 9% composted and only 1% incinerated (Xu 2004). Incineration is increasing and composting proportion is decreasing due to the poor quality of compost and less market. The organics, plastic and moisture contents are increasing rapidly. Owing to the mixed waste with high moisture content, heating value is also low (Zhao 1998; Nie et al. 1999; Feng 1999). Further, in mixed wastes containing high organics and moisture content, the problems of leachate treatment and LFG emissions are very serious. The conventional landfill technology has caused both high economic and social costs (Xu 2004).

The study was carried out by various authors, which was mainly on the composting process and its dynamics (Kaiser 1996; Nakasaki et al. 1998; Xi et al. 2005). No much work was carried out on the process of biodegradation of organic matter at different operational conditions. Kinetics of the aerobic biological degradation of shredded MSW waste in liquid phase was carried out by Ewa et al. (2002). In his study grounded organic fraction of waste pulp was suspended in water and aerated. However, in the present study mixed MSW with various sizes from 1 to 50 mm was used and pretreatment simulators were run at different operational modes.

To devise the suitable pretreatment method and its kinetics, four pretreatment simulators were developed and examined minutely at bench scale. These were anaerobic simulator (R1), aerobic pretreatment simulator by natural convection of air (R2), aerobic pretreatment simulator by natural convection of air with leachate recirculation (R3) and forced aeration with leachate recirculation (R4). To determine waste biodegradability and to generate a usable measure for the loss of organic matter during pretreatment, it was deemed necessary to determine process kinetics using data obtained in this study under controlled conditions. In pretreatment, all types of waste are not degraded with the same rate. Readily degradable wastes degradation rate constant must be different from the slowly degradable wastes. From experimental study of the first few weeks, degradation rate of organic matter was higher than the rest of the study period. Therefore, in this study a two-component kinetic model is proposed for the biodegradation of organic matter. Biodegradation kinetic constants were then determined for readily and slowly degradable matter during pretreatment of MSW.

Biodegradation kinetic rate constants presented in this paper can be used to predict reduction rate of readily and slowly degradable organic matter for pretreatment facility. This would help in designing pretreatment device and estimation of necessary pretreatment duration.

Materials and methods

Operational modes

Three aerobic pretreatment simulators (PTS) were designed at different operational modes and one anaerobic simulator to simulate the conventional landfills only for comparative purposes which are given in Table 1. In all the PTS input MSW was same. Tap water was added to all the PTS every week to simulate the rain fall. The thermo pore sheets were wrapped around the PTS and heating bed sheets were also wrapped over them to avoid the environmental temperature effect on the PTS. Leachate was re-circulated once a day in R3 and R4 simulators. Air in the waste mass was injected continuously only in R4 simulators. Aeration rate of the pump varied from 10 to 50 l/h and it was controlled by the temperature. When temperature was decreasing due to air cooling, the rate of air injection was also decreasing.

Salient features of PTS

The PTS were manufactured by using organic glass. The diameter and height of the PTS were 0.2 and 0.6 m. The volume of the PTS was 19 l. In all the PTS, leachate collection sumps were provided at the bottom to collect the leachate. The pictorial view of the experiments and section of reactor are shown in Fig. 1a and b. Leachate collection pipe was only opened to collect the leachate and then closed. In the aerobic PTS, the leachate collection pipe was provided at the bottom and perforated pipe was installed above it to dissipate the air in the waste mass by natural convection or to pump air in it, and central space of PTS of 25 mm diameter was filled with stones for air dissipation in the waste mass. Exhaust pipe was provided at the top so that heat, water vapors and gas can pass through.

In anaerobic PTS, the leachate collection sump was provided at the bottom and exhaust pipes were provided at the top for gas collection. The pipe was connected with water cylinder containing sodium chloride 25% solution. The gas generated volume was measured in accordance with the displacement of water from the cylinder.

Sampling techniques

Samples weighing about 5–10 g were collected from three sampling ports. Three sampling ports were kept at both sides of the reactors while stoppers were used to close them after sampling. The sampling ports were opened one by one for a while and closed immediately after sampling.

Characteristics of waste

The MSW was brought from the Beishen Shu landfill Beijing. Considering the size of reactors, the plastic bags, glasses and metals were separated and residual waste fractions according to size and composition of waste were determined as shown in Tables 2 and 3. Waste samples were air dried before composition analysis and classification, according to size.

Experimental methods

Samples were collected from the fresh waste prior to pretreatment and during pretreatment from the PTS. The MSW samples were processed prior to analysis (Mahar et al. 2007). They were analyzed for moisture content, temperature, bulk density, organic matter and elemental analysis, i.e., Carbon (C), Hydrogen (H) and Nitrogen (N). Bulk density was only analyzed for fresh and pretreated waste.

pH was determined by preparing the slurry by adding 1 l of distilled water to 500 g of the waste sample. The calibrated pH meter was used for measuring the pH value of the sample. Temperature was measured with thermometer manufactured in Shanghai, China which was inserted inside every reactor. Settlement was measured with the help of measuring tape and average value was obtained.

Organic matter (OM) was determined by measuring the volatile solids by standard method (APHA 1992). Samples were dried at 105°C to a constant weight and placed in desiccators. Two gram dried MSW was placed in pre-weighed porcelain crucibles and placed in the muffle furnace at 600°C for 2 h. Samples were removed and allowed to cool in desiccators to a constant weight. The percent weight loss on ignition yields the total amount of volatile solids or OM.

Approximately, 1 mg dry sample was used to analyze the carbon, hydrogen and nitrogen by using elemental analyzer (Equipment CE-440, EAI U.S.). For analysis manufacturer’s recommended procedure was adopted.

Experimental results discussions

Moisture content

The moisture content was analyzed from every PTS. Variation in the moisture results is shown in Fig. 2. To simulate the rainfall, water was added to every simulator regularly. In the first 2 weeks, water addition rate was high about 460 ml per week therefore level was increased when moisture addition rate decreased from third week to 200 ml per week, moisture content also reached to initial level after 4 weeks. After 6 weeks, water addition was stopped and moisture content of R3 and R4 was found reduced significantly. However, moisture content in the R1 was not much reduced while little reduction was observed in R2. This shows that water has been evaporated due to heat generated during the aerobic biodegradation of organic matter.

Temperature

Temperature of every PTS was measured and room temperature was recorded. The temperature variation was observed significantly because of small size of the simulators and decrease of room temperature. Leachate recirculation and forced aeration have also affected temperature of the simulators as shown in Fig. 3. In the first 2 weeks, room and R1 simulators temperature remained the same. But an aerobic simulator temperature remained in high range and only little variation was observed due to above reasons. Such behavior was also reported by (Fayad et al. 2006). After 3 weeks all simulators were wrapped with thermo pore sheets in first layer and heating bed sheets in the second layer. Simulators temperature was increased and remained in the range of 28–37°C till 6th week with some fluctuations caused by water addition and aeration. On 50th day, as heating bed was plugged off, the temperature of simulators R3 and R4 reached to room temperature and remained in the same range for a week. However, the temperature of R1 simulator remained more than 5°C above the room temperature, but in R2 it was 2–3°C higher than that of the room temperature. This shows that R3 and R4 have been stabilized.

Settlement

The settlement was only recorded in the aerobic PTS. In the first week, R3 simulator settlement rate was better than R4 simulator, which may be due to forced aeration this filled voids with air and caused decrease in temperature. But in the third week settlement rate had reached to the level of R3 simulator. After 40 days further settlement did not occur (Fig. 4). Similarly, the R2 simulator settlement rate increased further in last 2 weeks and then minimized. R1 reactor was anaerobic reactor which was air tight. Owing to this reason, settlement was not measured. From the settlement data, it is concluded that higher settlement was achieved in R4 with following order R4 > R3 > R2. When no further decomposition of organic matter was evident; the rate of settlement became minimum or zero. The maximum settlement was observed about 50% of the initial waste depth as shown in Fig. 4.

Organic matter and elements analysis

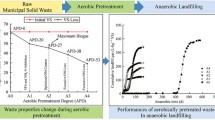

Organic matter reduced significantly with the pretreatment of MSW. OM reduction was observed during the pretreatment in PTS R1, R2, R3 and R4 from 50.6% to 38%, 22%, 19% and 17%, respectively, as shown in Fig. 5. Net OM reduction was estimated to be 45%, 66%, 71% and 75% in PTS R1, R2, R3 and R4, respectively. OM reduction was observed less in simulators R1 as compared to other aerobic PTS. Similar trend was also observed in the other elemental analysis, i.e., C, H and N. Carbon reduction was observed with the pretreatment in PTS R1, R2, R3 and R4 from 28 to 21%, 14.9%, 14.24% and 14.23%, respectively, as shown in Fig. 6. Nitrogen reduction was observed with the pretreatment from 1.24% to 1, 0.71%, 0.75% and 0.78% in PTS R1, R2, R3 and R4, respectively. C/N ratio was decreased from 22.58 to 21, 19.84, 18.49, and 18.24 in R1, R2, R3 and R4, respectively, as mentioned in the Table 4. Nitrogen losses vary depending on several environmental factors, such as aeration, moisture content and temperature (Bishop and Godfrey 1983). The narrow C/N ratio (22.58:1) has also caused nitrogen losses (Tiquia and Tam 2000) which are found in this study. Nitrogen mineralization during passive aeration involves several biochemical reactions that occur during transformation process. Degradation of protein, urea, or uric acid produces ammonium (NH4). During this process, high pH, high temperature, and moisture determine the NH3/NH4 + balance and the NH3 emission. Another step of degradation is the nitrification, which transforms NH4 + into NO3 − (nitrate) by oxidation (aerobic conditions).

PTS R4 had worked better in removing organic matter than R3, R2 and R1. Similarly, R3 was better than R2 and R1. Like-wise, R2 was better than R1. The results of R4 PTS showed that OM was degraded with leachate recirculation and forced aeration effectively than the passive aeration. Like-wise, R3 PTS the passive aeration with leachate recirculation is more effective to reduce the OM and other substances than the only passive aeration. R4 simulator is 10% better than the R3, however, in R4 simulator extra energy was required for forced aeration.

Bulk density

The bulk density of fresh and pretreated waste was determined. The fresh waste density was observed about 496.89 kg/m3. After pretreatment, it was increased to 950, 1,005 and 1,059 kg/m3 for PTS R2, R3, and R4, respectively. The significant increase in the bulk density was observed due to decay of OM and particle size reduction of waste. The bulk density, increase indicates the removal of light weight organics. The residual waste has more proportion of inorganic having more weight and less volume. The bulk density increase was also observed in following sequence in pretreatment technologies as: R4 > R3 > R2. Bulk density increase in passive aeration with leachate recirculation was observed 5% less than the forced aeration with leachate recirculation technology. With increase in the density of MSW due to pretreatment, the landfill air space could be saved.

Landfill gas emissions

Landfill gas emissions were estimated to determine LFG reduction with pretreatment of MSW as compared to untreated MSW. The LFG generation rate was estimated by using carbon balance method. The degradable organic carbon (DOC) was estimated some where else (Mahar 2007). The theoretical methane was calculated from DOC. Fresh waste DOC was taken according to the components of waste, i.e., 0.199. For pretreated waste DOC was reduced according to the percentage of reduction of OM in the PTS. Residual DOC after pretreatment was calculated about 0.11, 0.07, 0.06 and 0.05 in PTS R1, R2, R3 and R4, respectively. DOCf, MCF and F were assumed as 0.82, 0.80 and 0.52.

where: DOCi = Degradable organic carbon waste type i; DOCf = Fraction of organic carbon degradable; MCF = Methane correction factor; F = Percentage of methane, i.e., 52%; W = Weight of the MSW in Tons.

The methane generation was estimated for pretreated MSW PTS R1, R2, R3 and R4, i.e., 69.72, 44.37, 38.03 and 31.69 m3/tons, respectively. Methane emission reduction was observed in R2, R3 and R4 simulators in comparison to R1 which was determined about 36%, 45% and 55% respectively.

Proposed kinetic model and its parameter estimation

A two-component kinetic model is proposed for biodegradation of organic matter. One component corresponds to slowly degradable organic matter and the second corresponds to easily/readily degradable matters. The combined decay of readily degradable OM and slowly degradable OM can be shown by following expression as:

where: y 1(t) is the slowly degradable component and y 2(t) is the readily degradable component; n = types of the waste; in this study, n = 1–2; n = 1 slowly degradable matter and n = 2 readily degradable matter; Y 1 and Y 2 = fractions of slowly and readily degradable organic matter at time t = 0; k 1 and k 2 = degradation rate constants per day for slowly and readily degradable organic matters; t = pretreatment duration in days.

The experimental data was used to estimate the degradation rate constants for these components and also assumed that it follows the first order decay rate as:

It can be written in differential form as:

Then it is integrated as:

The constant can be removed as mentioned in above expression, supposing that slowly degradable portion of data is at t = t 1 and y = y 1 and it can be written as:

Biodegradation rate constant k 1 can be determined by plotting the data Ln(y 1) versus t 1 and fitting the linear curve. The slope of the line would be k 1 and constant. The log of constant gave the value of Y 1. In this way, we can obtain the Y 1(t). It can be written as:

The Y 2(t) can be obtained from the following expression as:

The values of y 2 versus t were plotted and the values below zero were neglected. The y 2 values above zero were considered which had some contribution to differentiate the time period during which readily organic matter were used up. To determine the biodegradation constant of readily degradable matter Ln(y 2) versus t were plotted and linear curve was fitted to it. The slope of the line was k 2 and constant found as given below:

Similarly as discussed as, we obtained y 2(t). It can be written as:

Total decay of MSW is combination of the two first order decay models which gave the second order kinetic model and it can be written as follows:

The kinetic model parameters were estimated from the experimental data in accordance with the above procedure. PTS were developed at lab scale in different environmental conditions. The biodegradation rate constants kn per day, and fraction of organic matter coefficients Yn were estimated as given in Table 5.

Discussions

The model parameters were used to run the model for pretreatment duration. The simulated data was obtained. The experimental and simulated data plots were compared. The anaerobic PTS R1 in which readily degradable fraction had very little contribution, only 0.029 fractions of organic matter, were hydrolyzed and degraded as shown in Table 5 in Y 2 column. This shows that very little amount of readily degradable matter is hydrolyzed and not degraded up to the end of study period. First order decay rate constant values were also less. It can be seen from k 1 and k 2 values in Table 5 as well as from Fig. 7. However, anaerobic pretreatment simulator is following the second order decay model owing to the shredded waste and water input in the simulator. This has caused OM hydrolyzed and washed out with water. The experimental data and model data, plots show very less mean square error as given in Fig. 8.

The aerobic PTS R2 is following the second order rate of decay having more value of k 2 and Y 2. The readily degradable matter was degraded in 24 days as shown in Fig. 9. Slow and readily degradable rates constants k 1 and k 2 were found more in R2 than in R1 simulator, i.e., about 0.013 and 0.123 per day, respectively. The experimental and simulated data plots were compared less mean square error which can be seen in Fig. 10 and Table 5.

The aerobic PTS R3’s experimental condition has significant influence to degrade organic matter from the MSW. It can be seen in Fig. 11. The kinetic coefficients per day k 1, k 2 and fractions of slowly and readily components Y 1 and Y 2 were determined about 0.013, 0.222, 0.386, and 0.121, respectively. These coefficient values were higher than R1 simulator. Like-wise, k 2 and Y 2 were also higher than R2 simulator. This shows that R3 works better than R2 and R1. The readily degradable matter was degraded in 18 days (Fig. 11). This shows that leachate recirculation has influenced to degrade the readily degradable matter with passive aeration. The experimental data and simulated data are compared in Fig. 12, which follow second order decay rate and have very less mean square error.

The aerobic PTS R4 experimental conditions have also significant influence on degradation of the organic matter of the MSW during the pretreatment. It can be seen in Fig. 13. The kinetic coefficients per day k 1, k 2 and fractions of slowly and readily degradable components Y 1 and Y 2 were determined to be about 0.013, 0.222, 0.405 and 0.101, respectively. These coefficients were also higher than R1 and R2 simulators. The biodegradation rate constants k 1, k 2, were also higher than R3 simulator. However, coefficient Y 2 was less than R3. This shows that in R4 simulator, amount of easily degradable matter was less degraded than R3 while kinetic degradation rate constant was more than R3. This followed first order decay rate. The easily degradable matter were used up very rapidly in 12 days which can be seen in Fig. 13, whereas, it took 18 days in R3 simulator. This depicts that leachate recirculation and forced aeration have influenced degradation of both the readily degradable and slowly degradable matter. The experimental data and simulated data are compared, possessing very less mean square error as shown in Fig. 14 and followed the second order decay rate. From kinetics constants, we come to know how many days are required to oxidize the readily and slowly degradable organic matter for four pretreatment techniques. This would help in design of pretreatment facility and estimation of necessary pretreatment duration.

Conclusions

From experimental and kinetic study the following conclusions are made:

-

1.

Pretreatment of MSW prior to landfilling is significantly effective not only to reduce the biodegradable organic matter from waste and hence reduces emissions from the landfill.

-

2.

Net OM reduction was observed 45%, 66%, 71% and 75% in PTS R1, R2, R3 and R4, respectively. OM reduction was observed less in anaerobic simulator R1 as compared to other aerobic PTS. Similar trend was also observed in other elemental analysis, i.e., C, H and N Carbon reduction was observed with pretreatment in PTS R1, R2, R3 and R4 from 28% to 21%, 14.9%, 14.24% and 14.23%, respectively. It is observed that R4 and R3 are more effective in reducing OM of MSW. The bulk density also increased in R4 and R3 in comparison with R2 and R1.

-

3.

From kinetic study biodegradation rate constants for easily degradable matter in PTS R4, R3, R2 and R1 were observed to be 0.255, 0.222, 0.123 and 0.049 per day and for slowly degradable matter these were as 0.015, 0.013, 0.013 and 0.005 per day. From comparison of kinetic values, it is observed that R4 simulator was 12% more efficient in removing the easily degradable matter than R3. The R3 was 44% more efficient than the R2 while R2 was 60% more efficient than R1. After making analytical study and thorough observation of the comparison referred above, it is evident that R4 simulator is more efficient than that of all other simulators; it is expensive and needs more resources to inject air in it. Although R3 and R2 have also good organic removal efficiency, R3 showed merits better consideration than R2 because of leachate recirculation.

-

4.

Methane emission reductions were about 36%, 45% and 55% in R2, R3 and R4 simulators, respectively, as compared to R1 anaerobic simulator.

References

APHA (1992) Standard methods for determination of water and waste water, 18th edn. American Public Health Association, Washington

Belevi H, Baccini P (1989) Long-term behavior of municipal solid waste landfills. Waste Manag Res 743–756

Binner E, Zach A (2000) Improvement of municipal solid waste quality for landfilling by means of mechanically-biologically pretreatment. Waste Manag Res 18:25–32. doi:10.1034/j.1399-3070.2000.00094.x

Bishop PL, Godfrey C (1983) Nitrogen variations during sludge composting. Biocycle 24:34–39

Ewa LB, Bizukojc M, Ledakowicz S (2002) Kinetics of the aerobic biological degradation of shredded municipal solid waste in liquid phase. Water Res 36:2124–2132. doi:10.1016/S0043-1354(01)00418-3

Fayad W, Sadik S, El Fadel M (2006) Effect of combined air injection and leachate recirculation biodegradation of MSW, pp 1–28. http://webfea-lb.fea.aub.edu.lb/faculty/salah/papers/FayadSadekElFadel. Accessed 6 June 2006

Feng MQ (1999) Developing trend and present status of municipal solid waste treatment. Environ Sanit Eng 7:145–147

Frauke K, Gernod D, Kornelia TD (2000) Mechanical and biological waste treatment? Introduction and decision-making tools for application in developing countries. http://www.gtz.de/eng. Accessed till 4 Apr 2006

Kaiser J (1996) Modeling composting as a microbial ecosystem: a simulation approach. Econ Model 9:25–37

Komilis DP, Ham RK, Stegmann R (1999) The effect of municipal solid waste pretreatment on landfill behavior: a literature review. Waste Manag Res 17:10–19

Mahar RB (2007) Sustainable landfill: bio-pretreatment of MSW of MSW prior to landfilling and its effects. PhD Thesis Tsinghua University, Beijing

Mahar RB, Liu J, Yue D, Nie YF (2007) Biodegradation of organic matters from mixed unshredded municipal solid waste through air convection before landfilling. J Air Waste Manag Assoc 57:39–46

Nakasaki K, Akakura N, Atsumi K (1998) Degradation patterns of organic material in batch and fed-batch composting operations. Waste Manag Res 5:484–489. doi:10.1177/0734242X9801600511

Nie YF, Li JH, Niu DJ, Bai QZH (1999) Current municipal solid waste status and management strategy in china. Urban Environ 13:14–18

Reiger A, Bidlingmaier W (1995) Investigations regarding landfill behavior of different pretreated waste. In: Christensen TH, Cossu R, Stegmann R (eds) Proceedings Sardinia 1995, Fifth International Sanitary Landfill Symposium. Cagliari, Italy, pp 957–965

Shi Y (1998) Current status and counter measures of refuse in Beijing res. Environ Sci 3:40–56

Tenzin N, Visvannathan C, Basnayake B (2005) Pretreatment of municipal solid waste prior to landfilling. Waste Manag 25:997–1003. doi:10.1016/j.wasman.2005.06.006

Tiquia SM, Tam NFY (2000) Fate of nitrogen during composting of chicken litter. Environ Pollut 110:535–541. doi:10.1016/S0269-7491(99)00319-X

Westlake K (1997) Sustainable landfill—possibility or pipe-dream? Waste Manag Res 15:435–461

Xi B, Wei Z, Liu H (2005) Dynamic simulation for domestic solid waste composting processes. J Am Sci 1:34–45

Xu HY (2004) State statistical bureau. China Statistical Year Book, China

Zhang W (1998) Situation and management of urban domestic refuse in China. Environ Prog 8:41–43

Zhao QH (1998) Current status and development policies of final disposal of urban garbage in Guangzhou. Res Environ Sci 11:42–44

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahar, R.B., Liu, J., Li, H. et al. Bio-pretreatment of municipal solid waste prior to landfilling and its kinetics. Biodegradation 20, 319–330 (2009). https://doi.org/10.1007/s10532-008-9222-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-008-9222-2