Abstract

Over 3,000 plant species are cyanogenic. Cyanogenesis is defined as the hydroxynitrile lyase catalysed release of a cyanide group in the form of HCN and the corresponding aldehyde or ketone. When a plant is attacked, HCN released is a self defence mechanism. A special characteristic of enzymatic reactions is that all enzymatic reactions are reversible—hydroxynitrile lyases can also be used for the synthesis of enantiomerically pure cyanohydrins which are of great importance in industry. This article presents a comprehensive review of the role of hydroxynitrile lyases, both in nature and industry, and an insightful. Areas covered include: history, discovery and natural sources of the hydroxynitrile lyase. Molecular cloning for mass production of this enzyme, including detailed information about several successful recombinant hydroxynitrile lyases is also included.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Cyanogenesis

Cyanogenesis is defined as the hydroxynitrile lyase mediated release of HCN and an aldehyde or ketone from a cyanohydrin (Sharma et al. 2005). This two-step process essentially involves two enzymes. In the first step, cyanogenic glycosides in the plant are broken down by β-glycosidases to form glucose and a cyanohydrin. In the second step, this cyanohydrin is broken down by a hydroxynitrile lyase into HCN and an aldehyde or ketone (Zagrobelny et al. 2008). A notorious and deadly poison, HCN exerts its toxic effects by binding to the ferric ion of cytochrome oxidase, an enzyme responsible for 90 % of the total O2 uptake in most cells. Inactivation of this enzyme completely inhibits cellular oxygen utilisation and results in cytotoxic hypoxia and death (Erdman 2003).

This ingenious self-defence mechanism protects the plant from microbial, fungal and animal attack and exists in over 3,000 plant species (Conn 1981; Peterson et al. 2000). Of these 3,000 species, cyanogenic plants are more commonly found in the following families: Linaceae, Gramineae, Euphorbiaceae, Clusiaceae, Olacaceae, Rosaceae, Passifloraceae and Filitaceae (Sharma et al. 2005; Ueatrongchit et al. 2010). Several important crop plants such as sorghum, maize, wheat, sugarcane and cassava, which is a staple food crop for most of sub-Saharan Africa, are also known to be cyanogenic (Conn 1981; Jones 1998; Fokunang et al. 2001). Perhaps our ancestors chose to grow those plants on a large scale as a staple food source because of their built-in pest control mechanism which naturally protects them from voracious insect feeders and bacterial or fungal infections.

Apart from plants, a wide range of organisms, such as fungi, bacteria, lichen, millipedes, arthropods and insects, are also cyanogenic (Zagrobelny et al. 2008). In an interesting article by Kremer and Souissi (2001), an extraordinary method of making use of cyanogenic bacteria is revealed: HCN can also be used as an effective herbicide to inhibit the growth of weed seedlings. In their article, HCN produced naturally by certain cyanogenic rhizobacteria strains occurring on plant roots effectively inhibited the growth of plants. These cyanogenic rhizobacteria, which are found naturally in the rhizosphere, show promise as an environmentally friendly, biological control method for weeds, a welcome alternative to the toxic herbicides in current use. Further research in this area is therefore welcome.

It is interesting, though, to note that at lower concentrations, cyanide is not toxic to a plant and does not inhibit respiration but it still inhibits root hair development and the germination of seeds. However, at higher concentrations, cyanide can inhibit respiration, production of ATP and other cellular processes such as ion uptake or phloem translocation which are dependent on adenosine triphosphate (Eisler 2007; Garcia et al. 2010). Blom et al. (2011) found that volatile-mediated phytotoxicity involved oxidative stress and concluded that high concentrations of HCN produced by bacteria can kill plants.

Hydroxynitrile lyase

Since the late 1990s, hydroxynitrile lyases have been receiving increasing attention from the fine chemical and pharmaceutical industries (Effenberger et al. 1995; Effenberger and Jager 1997). In nature, a cyanohydrin is broken down by a hydroxynitrile lyase into HCN and an aldehyde or ketone. However, in principle, each enzymatic reaction is completely reversible and it is this reversible reaction (Fig. 1) which is so desired by industry. The ability of these enzymes to produce a chiral cyanohydrin by the condensation of HCN with an aldehyde or ketone is advantageous, especially to the pharmaceutical and fine chemical industries. These chiral cyanohydrins are used as building blocks/intermediates for the production of pesticides, medicines, agrochemicals, etc. (Dadashipour et al. 2011). Hydroxynitrile lyase can also be used to detoxify cyanogenic food plants, especially cassava, which forms the staple diet in sub-Saharan Africa (Hasslacher et al. 1996; Fokunang et al. 2001).

Sources of hydroxynitrile lyase

The first discovery of hydroxynitrile lyase occurred in 1837 by two German chemists Justus von Liebig and Friedrich Wohler. This was found in a bitter almond extract (Hosel 1981). Since then, discoveries have been made: for example, Xu et al. (1988) purified and characterised a hydroxynitrile lyase from Linum usitatissimum (commonly known as Flax). Hughes et al. (1994) purified and characterised a hydroxynitrile lyase from cassava (Manihot esculenta Crantz). Their enzyme was not glycosylated and did not contain a flavin group but did display activity against two natural substrates: acetone cyanohydrin and 2-butanone cyanohydrin. Wajant and Forster (1996) purified and characterised a hydroxynitrile lyase from the rubber tree Hevea brasiliensis. Their enzyme also showed activity toward acetone cyanohydrin. Several other hydroxynitrile lyases have been discovered in Prunus serotina, Prunus lyonii, Prunus capuli, Prunus amygdalus, Mammea americana, Malus communis, Phlebodium aureum, Sorghum bicolour, Sorghum vulgare, Ximenia americana and Sambucus nigra (Sharma et al. 2005). Most of these enzymes showed activity toward mandelonitrile and acetone cyanohydrin. Ueatrongchit et al. (2010) discovered, characterised, and purified a hydroxynitrile lyase from Passiflora edulis (passion fruit), a member of the Passifloraceae family, for the first time. The optimum pH for their enzyme was pH 4, and the optimum temperature was 10 °C. They also found that the spontaneous non-enzymatic reaction which yields a racemic product was almost completely suppressed at the optimum pH and temperature. Dadashipour et al. (2011) discovered a novel hydroxynitrile lyase from Baliospermum montanum. Their enzyme exhibited excellent pH stability in a wide pH range, showed activity in a wide temperature range (perfect for industrial applications) and showed activity toward aromatic aldehydes. Fukuta et al. (2011) discovered a new hydroxynitrile lyase from the Japanese apricot Prunus mume that was active over a broad pH and temperature range. Its amino acid sequence was identical to the hydroxynitrile lyase from Prunus dulcis.

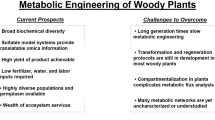

Despite the numerous discoveries, the application of these naturally-occurring enzymes in enantioselective biocatalytic synthesis was sadly limited due to the difficulty of obtaining them in sufficient amounts. The presence and concentrations of various active secondary metabolites in a plant are also known to vary—their presence or concentration depending on season and age (Pichersky and Lewinsohn 2011). A plant extract was therefore not a suitable enzyme source for the development of an industrial biocatalytic process of cyanohydrins.

Recombinant hydroxynitrile lyase

Many industrial and pharmaceutical production processes, which in the past were considered not feasible due to high production costs and limited amounts of starting material such as enzymes and other valuable compounds, are now feasible—thanks to biotechnology. Biotechnology/recombinant DNA technology has equipped us with the tools necessary to mass produce, in a heterologous host, these much needed enzymes which were previously only found in plants or animals. Using recombinant DNA technology: cyanogenic plant samples are collected, their messenger ribonucleic acid mRNA is extracted, the gene coding for the hydroxynitrile lyase is located, cloned and over-expressed in a heterologous host/microbial expression system. There are several advantages to using heterologous expression, the main being cost—enzymes can now be mass produced rapidly and sold at lower prices than those previously sourced from nature. Another important advantage is sustainability—as industry has become more environmentally conscious—always researching cleaner, greener technologies and constantly seeking renewable and sustainable sources of enzymes and other valuable compounds (Terpe 2006; Yesilirmak and Sayers 2009; Chen 2012).

There are numerous examples of the cloning of the hydroxynitrile lyase gene in either a bacteria or yeast species. (Fukuta et al. 2011; Dadashipour et al. 2011; Semba et al. 2008a, b; Breithaupt et al. 1999; Hughes et al. 1994, 1997). Some researchers found that yeasts were the better hosts producing the enzyme in an active, easily accessible form.

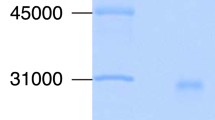

Forster et al. (1996) reported the first recombinant hydroxynitrile lyase. The activity of their purified recombinant Manihot esculenta hydroxynitrile lyase (expressed in Escherichia coli) was 900 U/ml. Their 80 l culture, comprising of 150–200 g wet wt of cells, gave a yield of 4,000 U recombinant enzyme. They claimed that, in order to obtain the same amount of enzyme from plant material, one would have required 100–200 kg dried M. esculenta leaves. Hasslacher et al. (1997) reported high level intracellular expression of a recombinant H. brasiliensis hydroxynitrile lyase in Pichia pastoris which proved to be the most efficient microbial host system. An exceptional yield of 22 g pure enzyme/l of culture broth was achieved.

Semba et al. (2008a) expressed a M. esculenta hydroxynitrile lyase in a yeast and tested the application of this recombinant hydroxynitrile lyase in the production of (S)-mandelonitrile (a useful cyanohydrin) using an immobilised enzyme reactor. They also found that the hydroxynitrile lyase accepted a wider substrate range when compared with the S. bicolor hydroxynitrile lyase, which is exactly what industry is currently searching for. Semba et al. (2008a) reported that productivity in Escherichia coli was low so they used Saccharomyces cerevisiae as host. The yeast expressed a recombinant hydroxynitrile lyase with a specific activity of 3.5 U/mg soluble protein. They also tested (S)-mandelonitrile production using an immobilised recombinant M. esculenta hydroxynitrile lyase. Inorganic supports showed better adsorption ability than organic supports and silica gel was the best—the enzyme immobilised on silica gel was used for more than 20 batches and did not show any loss in conversion rate or enantioselectivity. Overall, after 22 batches, 23.3 kg benzaldehyde was converted to 28.6 kg (S)-mandelonitrile. This shows that production can be successful on a large scale for industrial purposes.

Semba et al. (2008b) also experimented with the production of recombinant M. esculenta hydroxynitrile lyase using what they termed as low temperature cultivation. When the temperature was lowered, the cell yield and ratio of soluble enzyme increased significantly. The enzyme activity and yield at 17 °C was 850 times higher than those obtained at 37 °C. Their rate of hydroxynitrile lyase production was 3,000 U/h. Dadashipour et al. (2011) expressed a B. montanum hydroxynitrile lyase in E. coli. At first, the researchers experienced problems with expression at optimum temperature—having encountered a high level of inactive protein production as inclusion bodies. They therefore used a lower temperature for protein expression, as described by Semba et al. (2008b); Qing et al. (2004), which allowed them to obtain at least a small amount of the soluble or native form of the enzyme. Aromatic aldehydes and ketones were the preferred substrates for their enzyme (when compared with aliphatic substrates). The highest specific activity for their enzyme was 178 U/mg. Fukuta et al. (2011) expressed a gene coding for the hydroxynitrile lyase in Pichia pastoris as an active, highly glycosylated protein. An activity of 209 U/l culture supernatant was measured in a cyanohydrin synthesis reaction, which corresponded to the amount of enzyme that can be isolated from 800 g of plant material. Their new enzyme accepted a wide range of substrates including aromatic and aliphatic carbonyl compounds.

Is the recombinant hydroxynitrile lyase as good as the native one?

A legitimate question which was rather well answered in an informative article by Hughes et al. (1997) who compared the secondary structures, specific enzyme activities, optimum temperatures, optimum pH, and isoelectric focusing of the recombinant M. esculenta enzyme with the native one. The recombinant and native enzymes were similar in every way except one: isoelectric focusing. The recombinant enzyme had a more basic mean isoelectric point of 5.1 whilst that of the native enzyme was 4.5.

The search for new hydroxynitrile lyases

Although recombinant DNA technology has now provided a way to mass produce these desirable enzymes for industrial applications, the ever-evolving world of pharmaceuticals and fine chemicals, the need for more environmentally friendly pesticides and herbicides, and greater environmental awareness with regard to industrial processes have now led researchers to search for hydroxynitrile lyases that have novel substrate specificity. This, hopefully, will lead to the manufacture of new types of medication, pesticides, etc. One of the main restrictions in the use of hydroxynitrile lyases today is their narrow substrate range and sometimes unstable behaviour under industrial conditions. As can be seen in the previous sections, the majority of the hydroxynitrile lyases discovered to date show activity toward mandelonitrile and acetone cyanohydrin. The search for novel or improved hydroxynitrile lyases, which will hopefully have a novel or wider substrate specificity has therefore begun once again.

Hernandez et al. (2004) screened for hydroxynitrile lyase activity in the crude extracts of several edible plants. Seeds of Cucumis melo, Cydonia oblonga and Annona cherimolia, as well as the leaves of Prunus persica, Prunus avium, Prunus domestica, Prunus serotina var. Capuli and Pouteria sapota exhibited activity. They were also the first to report hydroxynitrile lyase activity in the C. melo seed. Until 2004, no hydroxynitrile lyase activity had been reported for any member of the Cucurbitaceae family. Their crude extracts biocatalysed the transformation of benzaldehyde to mandelonitrile with varying degrees of enantioselectivity, some better than others. New alternative enzyme sources were found.

Asano et al. (2005) screened for new hydroxynitrile lyases from 163 plants from 74 families using their own, in-house developed HPLC method. Rosaceae, Euphorbiaceae, Leguminosae, Passifloraceae, Araceae and other families were tested and partially-purified (R)-hydroxynitrile lyases from P. edulis and Eriobotrya japonica showed activity toward benzaldehyde and an aliphatic ketone. This again confirms that hydroxynitrile lyases with varying substrate specificities do occur and this provides an incentive to search for more.

Andexer et al. (2009) suggested the following two methods or strategies: the first being a function-based or activity-based approach, and the second a sequence-based approach. The first approach involves selecting a plant from a family that is known to contain cyanogenic species and then screening their crude/tissue extracts for the desired activity. The second involves synthesising double-stranded cDNA from the plants mRNA, sequencing the double-stranded cDNA and then scanning this sequence (using various databases) for a sequence similar to available, known hydroxynitrile lyase sequences. The similar sequence can then be synthesised and cloned into a microbial host using recombinant DNA technology for over-expression. However, a major limitation of the sequence-based approach is that an undiscovered or novel hydroxynitrile lyase could be very easily missed, especially if one is only comparing a plants cDNA sequence to those of already discovered enzymes. Wajant and Forster (1996) found that there were no obvious sequence homologies among P. serotina hydroxynitrile lyase, M. esculenta hydroxynitrile lyase or the S. bicolor hydroxynitrile lyase (Wajant and Mundry 1993). Therefore, trying to look for a similar sequence would not be an ideal approach.

As part of this renewed interest, two papers offering alternative screening methods, one novel, and the other a modern take on a classical method are of particular interest and worth noting.

Krammer et al. (2007) developed a novel hydroxynitrile lyase screening assay, concentrating specifically on its application in high-throughput screening of E. coli mutant libraries. This method can also be used to discover improved hydroxynitrile lyase variants and makes use of a key substrate. Only colonies carrying the gene coding for the desired enzyme will be able to break down the substrate, resulting in a visible colorimetric reaction when a by-product is detected, for example, when HCN is detected, the test paper will turn blue, as in the case of the hydroxynitrile lyase.

Takos et al. (2010) developed a cyanogenic screening test for plants. This method is based on the method by Feigl and Anger (1966) and makes use of a single freeze-thaw tissue cycle. A visible colorimetric reaction is produced on a specially prepared filter paper upon detection of HCN (a concise blue spot), as used by Krammer et al. (2007) as well. This method allows for the screening of plant samples for cyanogenic activity on a rapid and large scale (up to 96 samples or more at one time).

Conclusion and perspectives

Hydroxynitrile lyases, a concept or technology which was thought, by some, to be outdated, having had its hey-day in the 1980s and 1990s, is slowly gaining new interest. Recombinant DNA technology has solved the initial concerns regarding lack of availability and insufficient amounts of this enzyme for industrial application. Pharmaceutical companies have realised how essential this enzyme is to produce numerous novel medicines and pesticides. But, the search is on again, this time not for a way to produce more hydroxynitrile lyase for industrial applications, but to find a previously undiscovered hydroxynitrile lyase and, more importantly, to find a hydroxynitrile lyase that has novel substrate specificity.

References

Andexer JN, Langermann JV, Kragl U, Pohl M (2009) How to overcome limitations in biotechnological processes-examples from hydroxynitrile lyase applications. Trends Biotechnol 27:599–607

Asano Y, Tamura K, Doi N, Ueatrongchit T, H-Kittikun A, Ohmiya T (2005) Screening for new hydroxynitrilases from plants. Biosci Biotechnol Biochem 69:2349–2357

Blom D, Fabbri C, Eberl L, Weisskopf L (2011) Volatile mediated killing of Arabidopsis thaliana by bacteria is mainly due to hydrogen cyanide. Appl Environ Microbiol 77:1000–1008

Breithaupt H, Pohl M, Bonigk W, Heim P, Schimz KL, Kula MR (1999) Cloning and expression of (R)-hydroxynitrile lyase from Linum usitatissimum (Flax). J Mol Catal B Enzym 6:315–322

Chen R (2012) Bacterial expression systems for recombinant protein production: E. coli and beyond. Biotechnol Adv 30:1102–1107

Conn EE (1981) Cyanogenic glycosides. In: Stumpf PK, Conn EE (eds) The biochemistry of plants: a comprehensive treatise-secondary plant products. Academic Press, New York, pp 479–500

Dadashipour M, Yamakazi M, Momonoi K, Tamura K, Fuhshuku K, Kanase Y, Uchimura E, Kaiyun G, Asano Y (2011) S-Selective hydroxynitrile lyase from a plant Baliospermum montanum: molecular characterization of recombinant enzyme. J Biotechnol 153:100–110

Effenberger F, Jager J (1997) Synthesis of the adrenergic bronchodilators (R)-terbutaline and (R)-salbutamol from (R)-cyanohydrins. J Org Chem 62:3867–3873

Effenberger F, Eichhorn J, Roos J (1995) Enzyme catalyzed addition of hydrocyanic acid to substituted pivalaldehydes—a novel synthesis of (R)-pantolactone. Tetrahedr Asymm 6:271–282

Eisler R (2007) Cyanide. In: Eisler’s encyclopaedia of environmentally hazardous priority chemicals. Elsevier, Rio de Janeiro, pp 216

Erdman WA (2003) Cyanide. In: Ellenhorn’s medical toxicology: diagnosis and treatment of human poisoning, 3rd edn. Lippincott Williams & Wilkins, Baltimore, pp 1155–1168

Feigl F, Anger V (1966) Replacement of benzidine by copper ethylacetoacetate and the tetrabase as spot test reagent for HCN and cyanogen. Analyst 91:282–284

Fokunang CN, Tomkins PT, Dixon AGO, Tembe EA, Salwa B, Nukenine EN, Horan I (2001) Cyanogenic potential in food crops and its implication in Cassava (Manihot esculenta Crantz) production. Pak J Biol Sci 4:926–930

Forster S, Roos J, Effenberger F, Wajant H, Sprauer A (1996) The first recombinant hydroxynitrile lyase and its application in the synthesis of (S)-cyanohydrins. Angew Chem Int Ed Engl 35:437–439

Fukuta Y, Nanda S, Kato Y, Yurimoto H, Sakai Y, Komeda H, Asano Y (2011) Characterisation of a new (R)-hydroxynitrile lyase from the Japanese apricot Prunus mume and cDNA cloning and secretory expression of one of the isozymes in Pichia pastoris. Biosci Biotechnol Biochem 75:214–220

Garcia I, Castellano JM, Vioque B, Solano R, Cotor C, Romero LC (2010) Mitochondrial beta-cyanoalanine synthase is essential for root hair formation in Arabidopsis thaliana. Plant cell 22:3268–3279

Hasslacher M, Schall M, Hayn M, Griengl H, Kohlwein SD, Schwab H (1996) Molecular cloning of the full length cDNA of (S)-hydroxynitrile lyase from Hevea brasiliensis. J Biol Chem 271:5884–5891

Hasslacher M, Schall M, Hayn M, Bona R, Rumbold K, Luckl J, Griengl H, Kohlwein SD, Schwab H (1997) High level intracellular expression of hydroxynitrile lyase from the tropical rubber tree Hevea brasiliensis in microbial hosts. Protein Expr Purif 11:61–71

Hernandez L, Luma H, Ruiz-Teran F, Vazquez A (2004) Screening for hydroxynitrile lyase activity in crude preparations of some edible plants. J Mol Catal B Enzym 30:105–108

Hosel W (1981) In: Vennesland B, Conn EE, Knowles CJ, Westley J, Wissing F (eds) Cyanide in biology, 1st edn. Academic Press, London, pp 217–232

Hughes J, Carvalho FJPDC, Hughes MA (1994) Purification, characterization, and cloning of a α-hydroxynitrile lyase from Cassava (Manihot esculenta Crantz). Arch Biochem Biophys 311:496–502

Hughes J, Lakey JH, Hughes MA (1997) Production and characterization of a plant α-hydroxynitrile lyase in Escherichia coli. Biotechnol Bioeng 53(3):322–328

Jones DA (1998) Why are so many food plants cyanogenic? Phytochemistry 47:155–162

Krammer B, Rumbold K, Tschemmernegg M, Pöchlauer P, Schwab H (2007) A novel screening assay for hydroxynitrile lyases suitable for high-throughput screening. J Biotechnol 129:151–161

Kremer RJ, Souissi T (2001) Cyanide production by Rhizobacteria and potential for suppression of weed seedling growth. Curr Microbiol 43:182–186

Peterson CJ, Tsao R, Aimee LE, Coats JR (2000) Insecticidal activity of cyanohydrin and monoterpenoid compounds. Molecules 5:648–654

Pichersky E, Lewinsohn F (2011) Convergent evolution in plant specialised metabolism. Annu Rev Plant Biol 62:549–566

Qing G, Ma LL, Khorchid A, Swapna GVT, Mal TK, Takayama MM, Xia B, Phadtase S, Ke H, Acton T, Montelione GT, Ikura M, Inouye M (2004) Cold shock induced high yield protein production in Escherichia coli. Nat Biotechnol 22:877–882

Semba H, Dobashi Y, Matsui T (2008a) Expression of hydroxynitrile lyase from Manihot esculenta in yeast and its application in (S)-Mandelonitrile production using an immobilised enzyme reactor. Biosci Biotechnol Biochem 72:1457–1463

Semba H, Ichige E, Imanaka T, Atomi H, Aoyagi H (2008b) Efficient production of active form of recombinant cassava hydroxynitrile lyase using Escherichia coli in low temperature culture. Appl Microbiol Biotechnol 79:563–569

Sharma M, Sharma NN, Bhalla TC (2005) Hydroxynitrile lyases: at the interface of biology and chemistry. Enzyme Microb Technol 37:279–294

Takos A, Lai D, Mikkelsen L, Hachem MA, Shelton D, Motawia MS, Olsen CE, Wang TL, Martin C, Rook F (2010) Genetic screening identifies cyanogenesis-deficient mutants of Lotus japonicus and reveals enzymatic specificity in hydroxynitrile glucoside metabolism. Plant Cell 22:1605–1619

Terpe K (2006) Overview of bacterial expression systems for heterologous protein production: from molecular and biochemical fundamentals to commercial systems. Appl Microbiol Biotechnol 72:211–222

Ueatrongchit T, Tamura K, Ohmiya T, Kittikun A, Asano Y (2010) Hydroxynitrile lyase from Passiflora edulis: purification, characteristics and application in asymmetric synthesis of (R)-mandelonitrile. Enzyme Microb Technol 46:456–465

Wajant H, Forster S (1996) Purification and characterization of hydroxynitrile lyase from Hevea brasiliensis. Plant Sci 115:25–31

Wajant H, Mundry KW (1993) Hydroxynitrile lyase from Sorghum bicolor: a glycoprotein heterotetramer. Plant Sci 89:127–133

Xu LL, Singh BK, Conn EE (1988) Purification and characterization of acetone cyanohydrin lyase from Linum usitatissimum. Arch Biochem Biophys 263:256–263

Yesilirmak F, Sayers Z (2009) Heterologous expression of plant genes. Int J Plant Genom. doi:10.1155/2009/296482

Zagrobelny M, Bak S, Lindberg Moller B (2008) Cyanogenesis in plants and arthropods. Phytochemistry 69:1457–1468

Acknowledgments

We would like to thank Mr. Kevin Slaney for his assistance with the chemical structures used in this review.

Conflict of interest

The authors report no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kassim, M.A., Rumbold, K. HCN production and hydroxynitrile lyase: a natural activity in plants and a renewed biotechnological interest. Biotechnol Lett 36, 223–228 (2014). https://doi.org/10.1007/s10529-013-1353-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-013-1353-9