Abstract

The role of endospore production by Bacillus subtilis CPA-8 on survival during spray-drying was investigated by comparison with a non-spore-forming biocontrol agent Pantoea agglomerans CPA-2. Endospore formation promoted heat resistance in CPA-8 depending on growth time (72 h cultures were more resistant than 24 h ones). The survival of CPA-8 and CPA-2 after spray-drying was determined after being grown in optimised media for 24 and 72 h. Spray-dried 72 h CPA-8 had the best survival (32%), while CPA-2 viability was less than 2%. CPA-8 survival directly related with its ability to produce endospores. Spray-dried CPA-8 reduced Monilinia fructicola conidia germination similarly to fresh cells, demonstrating that spray-drying did not adversely affect biocontrol efficacy. Endospore production thus improves CPA-8 resistance to spray-drying. These results can provide a reliable basis for optimising of the spray-drying formulation process for CPA-8 and other microorganisms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacillus subtilis is one of the most extensively used bacteria in medicine, the food industry, bioremediation and agriculture (Ongena and Jacques 2008; Cutting 2011). In agriculture, B. subtilis along with other species of the Bacillus genus represent approximately half of the commercially available biopesticides on the world market (Fravel 2005). The potential utility of B. subtilis is based on its ability to produce a broad array of anti-fungal lipopeptides. Their spore-forming ability, which provides a high level of resistance to extreme environmental conditions, also makes these bacteria good candidates for developing stable and efficient products (Errington et al. 2003).

Heat-resistant endospores produced by the biocontrol agent B. subtilis CPA-8 have good anti-fungal activity against fruit post-harvest pathogens (Yánez-Mendizábal et al. 2011). CPA-8, whether used alone or in combination with other environmentally friendly strategies, such as hot water (Casals et al. 2010) and curing (Casals et al. 2012), is effective for controlling peach brown rot caused by Monilinia spp. during post-harvest storage. Given these previous results, we evaluated which formulation methods for the preservation of CPA-8 viability and efficacy are required for obtaining a stable commercial product.

Formulation can be accomplished using different drying methods, including freeze-drying, spray-drying and fluidised bed-drying. Although freeze-drying is the most widely used method, spray-drying is 4–7 times less expensive and is more energy-efficient (Santivarangkna et al. 2007). Nevertheless, spray-drying of microorganisms has been less developed commercially because of the low survival rates of the microorganisms in the dried products. Low survival rates are thought to be due to thermal and dehydration stress as well as to low stability under subsequent storage conditions (Ananta et al. 2005).

Biocontrol agents, such as Pantoea agglomerans (Costa et al. 2002), Epicoccum nigrum (Larena et al. 2003a), Penicillium oxalicum (Larena et al. 2003b), P. frequentans (Guijarro et al. 2006) and Candida sake (Abadias et al. 2005), are heat sensitive and spray-drying of them adversely affects their viability. However, spray-drying is suitable for probiotic bacteria (Golowczyc et al. 2010) and for Bacillus thuringiensis (Prabakaran and Hoti 2008).

The spore-forming ability of the beneficial bacteria belonging to the Bacillus genus has been widely cited as an advantage for developing them into efficient bio-pesticide products (Ongena and Jacques 2008). Thus, the endospore-forming ability of CPA-8 is an attractive mechanism by which to preserve the viability of a biological product obtained by spray-drying because the endospores are resistant to the high temperatures involved in the spray-drying process. The aim of this work, therefore, was to determine the role of endospore production by CPA-8 on its survival through the spray-drying process, comparing this microorganism with a non-spore-forming biocontrol agent.

Materials and methods

Microorganisms and culture preparation

Bacillus subtilis CPA-8 and P. agglomerans CPA-2 were originally isolated from nectarine and apple surfaces, respectively. CPA-8 is effective for controlling brown rot in stone fruit (Casals et al. 2010; Yánez-Mendizábal et al. 2011), while strain CPA-2 is used against post-harvest pathogens in citrus and pome fruit (Nunes et al. 2001; 2002).

CPA-8 and CPA-2 were grown in Biostat-A modular fermenters (Braun Biotech International, Melsungen, Germany) containing 5l optimised growth medium based on crop by products (DSF40-MOL5: 40 g defatted soy flour l−1, 5 g molasses l−1 plus trace salts) for CPA-8, and sucrose/yeast extract medium (10 g sucrose l−1 and 5 g yeast extract l−1) optimised by Costa et al. (2001) for CPA-2. After 24 and 72 h at 30°C, 200 rev min−1 and 100 l h−1 of air feeding, CPA-8 and CPA-2 cultures were harvested. CPA-8 cultures were filtered through glass wool and CPA-2 cells were harvested by centrifugation (~7,000×g for 10 min at 15°C) and resuspended in potassium phosphate buffer (0.05 M pH 6.5). Initial viable cell concentrations of CPA-8 and CPA-2 were determined by plating on nutrient yeast extract/dextrose/agar (NYDA) at 30°C for 24 h. Results were expressed in colony forming units (c.f.u) ml−1.

Heat resistance test of CPA-8 for endospore viability

Heat resistance, and consequently endospore production, of 24 and 72 h CPA-8 cultures were tested. Triplicate samples of each CPA-8 culture (10 ml) grown in the fermenter were taken and held at 80°C for 12 min to kill the vegetative cells as described by Yánez-Mendizábal et al. (2011). Surviving cells corresponding to the number of viable CPA-8 endospores (c.f.u. ml−1) were determined by plating on NYDA at 30°C for 24 h. The number of viable endospores obtained was compared to the initial number of cells present in 24 and 72 h cultures (controls).

Effect of spray-drying on bacterial survival

Suspensions of 200 ml at 109 c.f.u. of CPA-8 and CPA-2 ml−1 were made using 24 or 72 h cultures obtained as described above and were spray-dried in a laboratory-scale spray dryer (SD-05, Lab Plant, UK) using 10% (w/v) MgSO4 as a carrier and protectant (Costa et al. 2002; Abadias et al. 2005). Spray-drying was conducted at an inlet-air temperature of 150°C and a delivery rate of 500 ml h−1, resulting in an outlet temperature of 80°C. The moisture from the spray droplets produced by a jet nozzle (0.5 mm diam.) was evaporated into the drying chamber (21.5 cm diam. 0.5 m). The powder produced passed through a single cyclone separator and was collected in a 250 ml bottle.

The percentage of powder recovery was calculated by taking the difference between the final weight of the powder in the collector bottle and the weight of the solids in the initial suspension. To determine the dry matter in the initial suspensions of 24 or 72 h CPA-8 and CPA-2 cultures and their final spray-dried powders, duplicate samples of 5 ml or 0.5 g, respectively, were dried in a convection oven at 105°C for 24 h.

To determine CPA-8 and CPA-2 survival after spray-drying, triplicate samples of each spray-dried powder (0.3 g) were rehydrated with 50 mM phosphate buffer (5 ml). Samples were shaken vigorously for 1 min and then allowed to rehydrate for 9 min before their viable cell concentrations (c.f.u. g−1) were determined by plating on NYDA. The percentage of surviving cells was calculated in accordance with Cañamás et al. (2008).

Effect of spray-dried CPA-8 on the conidial germination of Monilinia fructicola

The effect of spray-dried CPA-8 on the conidial germination of M. fructicola in vitro was evaluated and compared to that of spray-dried carrier/protectant and fresh cells (72 h culture without spray-drying). M. fructicola aqueous suspension was prepared from sporulated 10 day cultures grown on potato/dextrose/agar (PDA) amended with 1% (v/v) acetone at 25°C. Conidia were harvested and suspended in 70 ml sterile distilled water amended with Tween 80 (one drop per litre) at 5 × 105 conidia ml−1 using a haemocytometer. CPA-8 fresh suspension was prepared from 72 h cultures grown in 250 ml conical flasks containing 50 ml DSF40-MOL5 medium at 30°C and 150 rev min−1 and adjusted to 2 × 109 c.f.u. ml−1 using a haematocytometer. Spray-dried CPA-8 suspension was prepared by rehydrating 72 h CPA-8 powder with 50 mM phosphate buffer at 2 × 109 c.f.u. ml−1. Spray-dried 10% (w/v) MgSO4 solution without CPA-8 was also tested to ensure that the carrier/protectant itself did not have any effect against M. fructicola. Spray-dried CPA-8 and carrier/protectant concentrations were prepared based on the initial powder concentration (c.f.u. g−1), as described above. Treatments were prepared by mixing 4.5 ml M. fructicola suspension with 0.5 ml of CPA-8 fresh cells, spray-dried CPA-8, spray-dried carrier/protectant suspension or 50 mM phosphate buffer (control). Viable cell concentrations (c.f.u. ml−1) were enumerated by plating on NYDA. Then, each mixture, 10 μl, was placed on PDA plates in triplicate and incubated at 25°C for 4–6 h.

After each incubation time, three agar discs (containing aliquots as described above) from each replicate were removed using a cork borer and placed into a Petri plate. Conidia germination was stopped by adding 1 ml 25% NH4OH on a filter paper placed into the petri plates. Then, the petri plates were closed and stored at 4°C overnight until microscopic examination could be performed. Fifty single conidia per disc (150 per replicate; 450 per treatment) were examined. Conidia were considered germinated when the germ tube was equal to or longer than the smallest diameter of the conidia. The percentage of conidia germination at different treatments and incubation times was then calculated.

Statistical analysis

Bacterial concentrations are given as log c.f.u. g−1 values to improve homogeneity of variances. The general linear model procedure of SAS system (GLM, Statistical Analysis Systems Institute, V8, Cary, NC) was performed on the experimental data for the percentage of viability of spray-dried CPA-8 and CPA-2 and for the percentage of conidial germination and the means were separated using the Student–Newman–Keuls (SNK) test (P < 0.05).

Results

Heat resistance of CPA-8 by endospore production

The heat resistance of CPA-8 in 24 and 72 h cultures induced by endospore production is shown in Fig. 1. Resistance to incubation at 80°C depended on the age of the culture and on endospore production. While the number of viable cells (vegetative cells + endospores) in 24 h CPA-8 cultures decreased from 4.9 × 1010 to 2.3 × 107 c.f.u. g−1 (approx. a 3.2 log reduction corresponding to the number of vegetative cells killed by heat incubation at 80°C), the number of viable cells in 72 h CPA-8 cultures only decreased from 3.6 × 1010 to 8 × 109 c.f.u. g−1 (approx. a 0.7 log reduction).

Cell (filled square) and endospore (square with upper left to lower right fill) production by B. subtilis CPA-8 from 24 and 72 h cultures. Each bar represents the average of three independent replications and different letters indicate significant differences between culture age (P < 0.05) according to SNK’s test

Comparison of CPA-8 and CPA-2 survival after spray-drying

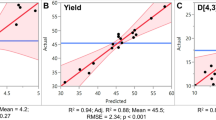

Survival of B. subtilis CPA-8 and P. agglomerans CPA-2 after spray-drying is shown in Fig. 2. The ability to survive the drying process varied considerably between the two investigated microorganisms, although in both cases, survival was dependent on the age of the spray-dried bacteria. Spray-dried 24 h CPA-8 and CPA-2 had low survivals, only 0.1% and 6.3%, respectively. In contrast, spray-dried 72 h CPA-8 had a higher survival (32%) than obtained with spray-dried 72 h CPA-2 (1.8%). The number of viable cells in spray-dried 24 and 72 h CPA-8 cultures was 8.4 × 106 and 3.3 × 109 c.f.u. g−1, respectively, with reductions of 3.7 log and 1.1-log compared to the number of total viable cells present before drying (Fig. 1).

Viability of 24 (filled square) and 72 h (square with upper left to lower right fill) B. subtilis CPA-8 and P. agglomerans CPA-2 after spray-drying at 150°C and 500 ml h−1 using 10% (w/v) MgSO4 as carrier and 50 mM phosphate buffer as rehydration medium. Each bar represents the average of three independent replications and different letters indicate significant differences between biocontrol agents (P < 0.05) according to SNK’s test

The percentage of recovery from the spray-drying powder was, in general, low for CPA-8 (30%) and CPA-2 (32%) because laboratory spray-dryers lose dust material at a higher rate than is found in industrial spray-dryers. The percentage of moisture using 10% MgSO4 as a protectant in the CPA-2 powder was 25%, which is considered too high for storage, and in CPA-8 12%, which was acceptable, considering that moisture content recommended in commercial biological products falls between 8 and 12%.

Effect of spray-dried CPA-8 on the conidial germination of M. fructicola

Figure 3 shows the effect of spray-dried CPA-8 at 2 × 108 c.f.u. ml−1 on the conidial germination of M. fructicola in comparison with untreated conidia, CPA-8 fresh cells (72 h culture without spray-drying) at 2 × 108 c.f.u. ml−1 and spray-dried 10% MgSO4 without bacteria used as a carrier/protectant. After 4 h at 25°C, spray-dried CPA-8 and fresh cells reduced the spore germination of M. fructicola from 85 (untreated control) to 0.4 and 1.8%, respectively. Spray-dried 10% MgSO4 without CPA-8 did not inhibit conidial germination with a percentage of conidia germination of 89% similar to that observed for the untreated control. When the incubation time was increased to 6 h, spray-dried CPA-8 retained its strong effect, reducing conidial germination to 4.9% and remaining comparable to CPA-8 fresh cells (0%). Conidial germination in spray-dried 10% MgSO4 samples and the untreated control were increased to 97 and 98%, respectively.

Effect of fresh cells, spray-dried B. subtilis CPA-8 (at 2 × 108 c.f.u. ml−1) and spray-dried carrier/protectant on M. fructicola conidia germination after 4 (filled square) and 6 h (square with upper left to lower right fill) at 25°C. Treatments consisted of the following: 0.5 ml 50 mM phosphate buffer (CK), CPA-8 fresh culture (CPA-8 fresh), spray-dried 10% (w/v) MgSO4 without CPA-8 in 50 mM phosphate buffer (10% MgSO4) and spray-dried 72 h CPA-8 using 10% MgSO4 as carrier/protectant (10% MgSO4 + CPA-8) and 50 mM phosphate buffer as the rehydration medium mixed with 4.5 ml M. fructicola suspension at 5 × 105 conidia ml−1. Each bar represents the average of three independent replications and different letters indicate significant differences between treatments (P < 0.05) according to SNK’s test

Discussion

Spray-drying can produce stable products of certain bacterial species used as biocontrol agents. However, with the high temperatures involved during the spray-drying process, the species require a certain level of thermo tolerance (Golowczyc et al. 2010). The level of thermo tolerance is related to the natural ability of the microorganisms to form heat-resistant structures and to the optimal growth phase for desiccation survival. Both of these are dependent on the organism being used. In the present work, spray-drying was suitable for the preservation of the post-harvest biocontrol agent B. subtilis CPA-8 based on its heat resistance by endospore production. CPA-8 was compared to another well-known biocontrol agent, P. agglomerans CPA-2 used here as a model for non-spore-forming microorganisms.

Endospores are produced Bacillus spp. as a means of surviving temperatures up to 80–85°C (Errington 2003). This ability is important to the biocontrol agent formulation process, especially in drying systems, such as spray-drying, that use high temperatures. CPA-8 is a heat-resistant bacterium able to survive at 80°C through endospore production, and endospores demonstrate good efficacy in controlling Monilinia species on peaches and nectarines (Yánez-Mendizábal et al. 2011). Based on these facts, our first step was to evaluate the heat resistance of CPA-8 produced in a low-cost optimised medium. Results obtained showed that although the vegetative cells of 24 and 72 h cultures could not survive at 80°C, cells that had differentiated into endospores were heat-resistant. This suggested that the ability of CPA-8 to produce endospores could provide the thermo tolerance required for its preservation under spray-drying. However, the heat resistance of CPA-8 was higher in 72 h cultures than it was in 24 h cultures. This suggests a relationship between CPA-8 heat resistance, endospore concentration and bacterial growth phase. As described by Errington (2003), B. subtilis sporulation is very much dependent upon the decline nutrients during the stationary phase. In practical terms, this result is important when selecting the optimal growth phase of CPA-8 for spray-drying.

Our results showed that survival of CPA-8 after spray-drying was better (32%) than that achieved by the non-spore-forming bacterium P. agglomerans CPA-2 (1.8%). This confirms that CPA-2 is heat sensitive, as was reported by Costa et al. (2002), and further demonstrates that survival was not improved using 72 h cells. CPA-8 survival in 24 h cultures after drying was low compared to the survival rate obtained with 72 h cultures. Similar results were described by Corcoran et al. (2004) for Lactobacillus rhamnosus; when stationary phase cells gave the highest recovery after drying (31–50%), whereas early log-phase cells exhibited 14% survival, and lag phase cells showed the highest susceptibility, with only a 2% cell survival. In the present study, both sampling times are within the stationary phase, but the quantity of endospores is larger at 72 h than at 24 h. The survival levels for 24 and 72 h old cultures after spray-drying were 8.4 × 106 and 3.3 × 109 c.f.u. g−1, respectively, which seems to be directly correlated to the concentration of endospores obtained in 24 and 72 h cultures (2.3 × 107 and 8 × 109 c.f.u. g−1, respectively). These results support the hypothesis that endospores are the survival form of B. subtilis CPA-8 and that endospore production improved the heat resistance of B. subtilis CPA-8 to spray-drying formulation systems. Moreover, CPA-8 growth phase is an important parameter to take into account during its preservation under spray-drying.

One of the most important prerequisites of microbial formulations for commercial use is that they retain their biocontrol efficacy. Results of the present study demonstrate that the CPA-8 formulation obtained by spray-drying almost completely inhibited M. fructicola conidia germination similarly than CPA-8 fresh culture. Spray-dried carrier/protectant without bacterium did not itself demonstrate biocontrol effect. These observations indicate that the spray-drying process did not have any negative effect on the biocontrol efficacy of CPA-8.

From a practical point of view, 29% powder recovery, 12.3% moisture content and 32% viability with a 3.3 × 109 c.f.u. g−1 final product concentration of spray-dried CPA-8 achieved in this study could be considered acceptable for a biological product. Commercial products, such as Serenade, for example, have final product concentrations around 5–7 × 10 c.f.u. g−1. Considering that CPA-8 product was obtained without preconditioning the microorganism to drying and by using non-optimised carriers/protectants and conditions, our results are promising and have the potential to be improved in the future. Studies conducted by Teixidó et al. (2006) and Cañamás et al. (2008) have demonstrated that the preservation of microorganisms used as biocontrol agents can be improved by induction of desiccation tolerance using different methodologies, such as by growing the microorganisms in a w modified media or under sublethal thermal stress conditions. Bacillus-based products can also be formulated by producing heat-stressed endospores and by using inorganic and organic carriers (Chung et al. 2007; Sorokulova et al. 2008).

In conclusion, Bacillus subtilis CPA-8 can survive spray-drying while the non-spore-forming CPA-2 cannot. CPA-8 survival was directly related to the microorganism’s ability to produce endospores that improved its resistance to the high temperatures required in the drying process and the dried product retained high efficacy to inhibit M. fructicola conidia germination. Spray-drying, is therefore a suitable method for CPA-8, preserving both viability and biocontrol efficacy. To our knowledge, although the behaviour of many spray-dried biocontrol agents has been studied (usually with less promising results), this is the first report in which endospore production by a B. subtilis strain has been shown to be related to its survival of the spray-drying process. Moreover, our results contribute to the general understanding of the main criteria that must be considered when selecting a biocontrol agent: culture growth point and the stress resistance of the cells.

References

Abadias M, Teixidó N, Usall J, Solsona C, Viñas I (2005) Survival of the post-harvest biocontrol yeast Candida sake CPA-1 after dehydration by spray-drying. Biocontrol Sci Technol 15:835–846

Ananta E, Volkert M, Knorr D (2005) Cellular injuries and storage stability of spray-dried Lactobacillus rhamnosus GG. Int Dairy J 15:399–409

Cañamás TP, Viñas I, Usall J, Magan N, Solsona C, Teixidó N (2008) Impact of mild heat treatments on induction of thermo tolerance in the biocontrol yeast Candida sake CPA-1 and viability after spray-drying. J Appl Microbiol 104:767–775

Casals C, Teixidó N, Viñas I, Silvera E, Lamarca N, Usall J (2010) Combination of hot water, Bacillus subtilis CPA-8 and sodium bicarbonate treatments to control post-harvest brown rot on peaches and nectarines. Eur J Plant Pathol 128:51–63

Casals C, Elmer PAG, Viñas I, Teixidó N, Sisquella M, Usall J (2012) The combination of curing with either chitosan or Bacillus subtilis CPA-8 to control brown rot infections caused by Monilinia fructicola. Post-harvest Biol Technol 64:126–132

Chung S, Lim HM, Kim (2007) Formulation of stable Bacillus subtilis AH18 against temperature fluctuation with highly heat-resistant endospores and micropore inorganic carriers. Appl Microbiol Biotechnol 76:217–224

Corcoran BM, Ross RP, Fitzgerald GF, Stanton C (2004) Comparative survival of probiotic lactobacilli spray-dried in the presence of prebiotic substances. J Appl Microbiol 96:1024–1039

Costa E, Teixidó N, Usall J, Atarés E, Viñas I (2001) Production of the biocontrol agent Pantoea agglomerans strain CPA-2 using commercial products and by-products. Appl Microbiol Biotechnol 56:367–371

Costa E, Teixidó N, Usall J, Fons E, Gimeno V, Delgado J, Viñas I (2002) Survival of Pantoea agglomerans strain CPA-2 in a spray-drying process. J Food Prot 65:185–191

Cutting SM (2011) Bacillus probiotics. Food Microbiol 28:214–220

Errington J (2003) Regulation of endospore formation in Bacillus subtilis. Nat Rev Microbiol 1:117–126

Fravel DR (2005) Commercialization and implementation of biocontrol. Annu Rev Phytopathol 43:337–359

Golowczyc M, Silva J, Abraham A, De Antoni G, Teixeira P (2010) Preservation of probiotic strains isolated from kefir by spray-drying. Lett Appl Microbiol 50:7–12

Guijarro B, Larena I, Melgarejo P, De Cal A (2006) Effect of drying on conidial viability of Penicillium frequentans, a biological control agent against peach brown rot disease caused by Monilinia spp. Biocontrol Sci Technol 16:257–269

Larena I, De Cal A, Liñán M, Melgarejo P (2003a) Drying of Epicoccum nigrum conidia for obtaining a shelf-stable biological product against brown rot disease. J Appl Microbiol 94:508–514

Larena I, Melgarejo P, De Cal A (2003b) Drying of conidia of Penicillium oxalicum, a biological control agent against Fusarium wilt of tomato. J Phytopathol 151:600–606

Nunes C, Usall J, Teixidó N, Viñas I (2001) Biological control of post-harvest pear diseases using a bacterium Pantoea agglomerans (CPA-2). Int J Food Microbiol 70:53–61

Nunes C, Usall J, Teixidó N, Fons E, Viñas I (2002) Post-harvest biological control by Pantoea agglomerans (CPA-2) on golden delicious apples. J Appl Microbiol 92:247–255

Ongena M, Jacques P (2008) Bacillus lipopeptides: versatile weapons for plant disease biocontrol. Trends Microbiol 16:115–125

Prabakaran G, Hoti SI (2008) Optimization of spray-drying conditions for the large-scale preparation of Bacillus thuringiensis var. israelensis after downstream processing. Biotechnol Bioeng 100:103–107

Santivarangkna C, Kulozik U, Foerst P (2007) Alternative drying processes for the industrial preservation of lactic acid starter cultures. Biotechnol Prog 23:302–315

Sorokulova IB, Krumnow AA, Pathirana S, Mandell AJ, Vodyanoy V (2008) Novel methods for storage stability and release of Bacillus spores. Biotechnol Prog 24:1147–1153

Teixidó N, Cañamás TP, Abadias M, Usall J, Solsona C, Casals C, Viñas I (2006) Improving low water activity and desiccation tolerance of the biocontrol agent Pantoea agglomerans CPA-2 by osmotic treatments. J Appl Microbiol 101:927–937

Yánez-Mendizábal V, Usall J, Viñas I, Casals C, Marín S, Solsona C, Teixidó N (2011) Potential of a new strain of Bacillus subtilis CPA-8 to control the major post-harvest diseases of fruit. Biocontrol Sci Technol 21:409–426

Acknowledgments

The authors were grateful to the Spanish Government, Ministerio de Asuntos Exteriores y de Cooperación and Agencia Española de Cooperación Internacional para el Desarrollo grant scholarship 0000447486 (V. Yánez), the University of Lleida Organic Project and the INTERREG REDBIO European Project for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yánez-Mendizabal, V., Viñas, I., Usall, J. et al. Endospore production allows using spray-drying as a possible formulation system of the biocontrol agent Bacillus subtilis CPA-8. Biotechnol Lett 34, 729–735 (2012). https://doi.org/10.1007/s10529-011-0834-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-011-0834-y