Abstract

α-Amylase activities of Aspergillus oryzae grown on dextrin or indigestible dextrin were 7·8 and 27·7 U ml−1, respectively. Glucoamylase activities of the cultures grown on dextrin or indigestible dextrin were 5·4 and 301 mU ml−1, respectively. The specific glucoamylase production rate in indigestible dextrin batch culture reached 1·35 U g DW−1 h−1. In contrast, biomass concentration of A. oryzae in indigestible dextrin culture was 35% of that in dextrin culture. Thus, the culture method using indigestible dextrin has the potential to improve amylolytic enzyme production and fungal fermentation broth rheology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aspergillus oryzae has long been utilized in Japan for the production of fermented foods, such as sake, miso, and soy sauce, and is “genetically recognized as safe” by the US Food and Drug Administration (Barbesgard et al. 1992). It releases various amylolytic enzymes, such as α-amylase, α-glucosidase and glucoamylase, into the culture medium. Generally, the amylolytic enzyme productions are strongly repressed by glucose via the protein CreA (Agger et al. 2002; Ruijter and Visser 1997). To achieve efficient industrial production of the amylolytic enzymes, a low glucose concentration is required or the repression induced by CreA must be diminished or abolished. Starch or related oligosaccharides, such as maltose and dextrin, induce amylolytic enzyme production. Isomaltose also acts as a trigger for amylolytic enzyme production through the transcriptional activator AmyR (Gomi et al. 2000; Kato et al. 2002; Petersen et al. 1999). However, it is difficult to achieve a high rate of enzyme production because of the rapid metabolism of such inducible oligosaccharides in cells producing glucose and the subsequent catabolic repression by glucose.

Indigestible components have been found in starch hydrolysates of such materials as dextrin, maltodextrin and corn syrup. Starch hydrolysates containing the indigestible components are termed “resistant matlodextrins” (Ohkuma et al. 1990). One of these resistant maltodextrin materials, namely Fibersol-2 (Matsutani Chemical Industry, Japan), is produced by a combination of heat and enzymatic treatment of cornstarch, as detailed in US Patent Nos. 5620873 and 5358729. An average molecular weight of Fibersol-2 is 2000, and the dextrose equivalent is below 20. Fibersol-2 is composed not only of α-1,4- and α-1,6-glycosidic bonds, as are present in the native starch, but also contains α-1,2- and α-1,3-linkages and levoglucosan. Due to these structural characteristics, Fibersol-2 contains well-developed, branched particles that are partially hydrolyzed by human digestive enzymes. Fibersol-2 is a white powder and contains about 90% (w/w) of indigestible components. “Indigestible dextrin” is the name used in Japan for Fibersol-2 (Ohkuma and Wakabayashi 2001). We previously reported that indigestible dextrin was an excellent inducer of glucoamylase production in Aspergillus kawachii because it was degraded slowly and released less glucose during submerged cultivation (Sugimoto et al. 2011). However, the function of indigestible dextrin against enzyme production in other aspergilli has not been investigated. In this study, the effects of indigestible dextrin on amylolytic enzyme production in submerged batch cultures of the industrial fungus A. oryzae were investigated.

Materials and methods

Culture conditions

Aspergillus oryzae RIB40 (National Research Institute of Brewing Stock Culture and ATCC-42149) was used throughout this study. Conidia of A. oryzae were inoculated at 5 × 106 spores into 50 ml basal medium (see Table 1) in 200 ml baffled flasks and cultivated with shaking at 180 rpm and 30°C for 72 h.

Hydrolysis test of indigestible dextrin using an amylolytic enzyme preparation from A. oryzae

The enzymatic hydrolysis of maltose, dextrin and indigestible dextrin was measured as follows: to prepare the substrate solution, 2 g maltose, dextrin or indigestible dextrin was dissolved in water up to 98 ml and sterilized by autoclaving for 15 min at 121°C. The enzyme solution was prepared using Gluc-100 (Amano Enzyme Inc, Japan), an amylolytic enzyme preparation from A. oryzae. The enzyme solution which contained 0·1 g Gluc-100 l−1, was sterilized via a 0·22 μm membrane filter. To determine the degree of hydrolysis, 98 ml substrate solution and 2 ml enzyme solution were mixed under aseptic conditions. Each substrate was held at 37°C for 6 h. The increase in glucose concentration was measured using a glucose C2 test kit (Wako Pure Chemicals, Japan). The degree of hydrolysis is shown by the percentage of the amount of glucose generated by the reaction to the amount of substrate used in the reaction.

Assays

The culture product was centrifuged and the supernatant was used to measure amylolytic enzyme activities. Glucoamylase and α-glucosidase activities were measured using a glucose forming activity fractional quantification kit (Kikkoman, Japan), and α-amylase activity was determined using an alpha amylase measuring kit (Kikkoman, Japan). A detailed procedure was carried out according to the manufacturer’s instructions. One unit of glucoamylase activity was defined as the activity that released 1 μmol 4-nitrophenol (PNP) from 4-nitrophenyl β-d-glucoside min−1 at 37°C. One unit of α-glucosidase activity was defined as the activity that released 1 μmol PNP from 4-nitrophenyl α-glucoside min−1 at 37°C. And, one unit α-amylase activity was defined as the activity that released 1 μmol 2-chloro-4-nitriphenol from 2-chloro-4-nitrophenyl 65-azido-65-deoxy-β-maltopentaoside min−1 at 37°C. The biomass concentration was determined after filtering the culture products through Miracloth (EMD Biosciences, Germany). The collected wet mycelia were dried at 105°C for 6 h and their dry weights were measured.

Results and discussion

Enzymatic hydrolysis of indigestible dextrin

In our previous work, the enzymatic hydrolysis of indigestible dextrin by the supernatant of the culture broth of A. kawachii was investigated: the rate of glucose formation from dextrin and indigestible dextrin by enzymatic hydrolysis were 0·47 and 0·1 g glucose l−1 h−1, respectively (Sugimoto et al. 2011). In this present work, the enzymatic hydrolysis of indigestible dextrin by Gluc-100 from A. oryzae was carried out (Fig. 1). Maltose and dextrin were hydrolyzed to 84 and 67% (w/w), respectively, and indigestible dextrin was hydrolyzed to only 10% (w/w). The carbohydrate profile of indigestible dextrin in terms of degree of polymerization (DP) was 1·5% DP1, 2·5% DP2, 4·0% DP3, 12·0% DP4-6, and 80% DP7+ (Ohkuma and Wakabayashi 2001). We speculate that small amounts of glucose were rapidly generated from the DP1, DP2 and DP3 fractions, and that the DP4-6 and DP7+ indigestible fractions were degraded more slowly. These results suggest indigestible dextrin is a poor substrate for enzymatic hydrolysis using the enzymes from A. oryzae compared with maltose and dextrin.

The hydrolysis of indigestible dextrin using Gluc-100, an amylolytic enzyme preparation from A. oryzae. The hydrolyzing reaction was carried out at 37°C for 6 h under aseptic condition. The degree of hydrolysis was shown by the percentage of the amount of glucose generated by the reaction to the amount of substrate used in the reaction. The error bars are the standard deviation from the mean of three replicates

Effect of indigestible dextrin on amylolytic enzyme production in a submerged batch culture of A. oryzae

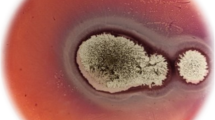

Aspergillus oryzae was cultured using indigestible dextrin and amylolytic enzyme production was compared between different carbon sources: dextrin, maltose and glucose (Table 1). The production of amylolytic enzyme using dextrin or maltose was increased when compared with glucose as the carbon source. These results correspond to the results of previous work reporting that amylolytic enzyme production in A. oryzae was induced by dextrin and maltose (Minetoki et al. 1995). α-Amylase and α-glucosidase activities were about 3·6 and 2·7-fold higher in indigestible dextrin cultures compared with the dextrin culture. In our previous report, the glucoamylase activities of the indigestible dextrin batch culture and the dextrin batch culture were 275·2 and 105·1 mU ml−1, respectively, indicating 2·6-fold higher activity in the indigestible dextrin batch culture (Sugimoto et al. 2011). High α-amylase and α-glucosidase production in A. oryzae and high glucoamylase production in A. kawachii, observed in the indigestible dextrin batch culture will have resulted from the absence of glucose and simultaneous presence of maltooligosaccharides throughout growth. We speculated the derepression caused by CreA and the induction caused by AmyR might occur simultaneously when indigestible dextrin is used as a culture substrate, resulting in greatly increased amylolytic enzyme production in A. oryzae and A. kawachii. Surprisingly, glucoamylase activity in the indigestible dextrin culture of A. oryzae was about 55-fold higher than glucoamylase activity in the dextrin culture. As far as we know, glucoamylase production in a submerged batch culture of A. oryzae has never been reported to be this high. Thus, the effect of indigestible dextrin on glucoamylase production is more significant than its effects on α-amylase and α-glucosidase production. It is expected that, in addition to the known CreA and AmyR regulatory system, an unknown novel regulatory system is involved in higher glucoamylase production in A. oryzae using indigestible dextrin. The effect of the physical characteristics of the long chain length of indigestible components (e.g., DP7+ indigestible fractions) on glucoamylase production during the submerged batch culture of A. oryzae is very interesting. Further investigation into the physiological status of the mycelia in the indigestible dextrin culture by using metabolome and transcriptome analysis will provide new perspectives on the technology of amylolytic enzyme production.

This culture method can also be used for heterologous protein production by filamentous fungi. When using A. oryzae, the target proteins are usually expressed in fusion constructs with the promoter region of the α-amylase gene (amyB) or glucoamylase gene (glaA), and the transformants are cultivated with starch or related oligosaccharides, such as dextrin and maltose (Nakajima et al. 2006). Because indigestible dextrin may activate transcription of these genes, target protein production can be easily improved by only using indigestible dextrin as a carbon source in these heterologous protein production systems.

This batch culture system, based on the use of indigestible dextrin, appears to have the potential to greatly enhance amylolytic enzyme production at the industrial scale. Imai et al. (1994) reported that specific glucoamylase production rate in A. oryzae RIB642 during fed-batch culture, employing the specific glucose consumption rate as an indicator, achieved 0·8 U g DW−1 h−1. In our experiment, the specific GA production rate was 1·35 U g DW−1 h−1 during batch culture using indigestible dextrin as a carbon source. Thus, indigestible dextrin improves GA productivity in A. oryzae RIB40 without applying complicated cultivation techniques.

A further important point was that hyphal growth in a submerged culture of A. oryzae RIB40 was decreased by the use of indigestible dextrin. In general, high cell density submerged cultivation suffers from high viscosity of the cultivation broth that often leads to mass transfer limitation (Agger et al. 2001). For aerobic submerged cultivation, the transfer of sufficient oxygen to active cells is critically important (Garcia-Ochota and Gomez 2009). To maintain the dissolved O2 concentration at the desired level, the carbon source feed rate was controlled during fed-batch cultivation (Li et al. 2000). In our experiments, the biomass concentration of A. oryzae in batch culture using indigestible dextrin was only 35% of that in dextrin culture. It is expected that this culture mode has the potential to improve viscous fermentation broth rheology of A. oryzae in industrial enzyme production.

The newly developed batch culture system using indigestible dextrin is expected to improve the culture technology suitable for enhancing substance production capability in A. oryzae to its maximum, and is considered to greatly contribute to increased utilization and industrialization of A. oryzae.

References

Agger T, Spohr AB, Nielsen J (2001) α-Amylase production in high cell density submerged cultivation of Aspergillus oryzae and A. nidulans. Appl Microbiol Biotechnol 1:81–84

Agger T, Petersen JB, O’Connor SM, Murphy RL, Kelly JM, Nielsen J (2002) Physiological characterisation of recombinant Aspergillus nidulans strains with different creA genotypes expressing A. oryzae alpha-amylase. J Biotechnol 3:279–285

Barbesgard P, Heldt-Hansen HP, Didenrichsen B (1992) On the safety of Aspergillus oryzae; a review. Appl Microbiol Biotechnol 36:569–572

Garcia-Ochota F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial process: an overview. Biotechnol Adv 27:153–176

Gomi K, Akeno T, Minetoki T, Ozeki K, Kumagai C, Okazaki N, Iimura Y (2000) Molecular cloning and characterization of a transcriptional activator gene, amyR, involved in the amylolytic gene expression in Aspergillus oryzae. Biosci Biotechnol Biochem 4:816–827

Imai Y, Suzuki M, Masamoto M, Nagayasu K, Kishimoto M (1994) Glucoamylase production of Aspergillus oryzae in fed-batch culture using a stastical regression model. J Ferment Bioeng 78:310–314

Kato N, Murakoshi Y, Kato M, Kobayashi T, Tsukagoshi N (2002) Isomaltose formed by alpha-glucosidases triggers amylase induction in Aspergillus nidulans. Curr Genet 1:43–50

Li ZJ, Shukala V, Fordyce AP, Pedersen AG, Wenger KS, Marten MR (2000) Fungal morphology and fragmentation behavior in a fed-batch Aspergillus oryzae fermentation at the production scale. Biotechnol Bioeng 70:300–312

Minetoki T, Gomi K, Kitamoto K, Kumagai C, Tamura G (1995) Characteristic expression of three amylase-encoding genes, agdA, amyB, and glaA in Aspergillus oryzae transformants containing multiple copies of the agdA gene. Biosci Biotechnol Biochem 12:2251–2254

Nakajima K, Asakura T, Maruyama J, Morita Y, Oike H, Shimizu-Ibuka A, Misaka T, Sorimachi H, Arai S, Kitamoto K, Abe K (2006) Extracellular production of neoculin, a sweet-tasting heterodimeric protein with taste-modifying activity by Aspergillus oryzae. Appl Environ Microbiol 5:3716–3723

Ohkuma K, Wakabayashi S (2001) Fibersol-2: a soluble, non-digestible, starch-derived dietary fibre. In: McCleary BV, Prosky L (eds) Advanced dietary fibre technology. Blackwell Science, Oxford, pp 509–552

Ohkuma K, Matsuda I, Katta Y, Hanno Y (1990) Pyrolysis of starch and its digestibility by enzyme. Denpun Kagaku 37:104–114 (in Japanese)

Petersen KL, Lehmbeck J, Christensen T (1999) A new transcriptional activator for amylase genes in Aspergillus. Mol Gen Genet 4–5:668–676

Ruijter GJ, Visser J (1997) Carbon repression in Aspergilli. FEMS Microbiol Lett 2:103–114

Sugimoto T, Horaguchi K, Shoji H (2011) Indigestible dextrin stimulates glucoamylase production in submerged culture of Aspergillus kawachii. J Ind Microb Biotechnol. doi:10.1007/s10295-011-0988-6

Acknowledgment

The authors are thankful to Matsutani Chemical Industry, Japan, for the gift of indigestible dextrin.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sugimoto, T., Shoji, H. Indigestible dextrin is an excellent inducer for α-amylase, α-glucosidase and glucoamylase production in a submerged culture of Aspergillus oryzae . Biotechnol Lett 34, 347–351 (2012). https://doi.org/10.1007/s10529-011-0777-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-011-0777-3