Abstract

Four microbial fuel cells (MFCs) inoculated with different bacterial species were constructed. The species were Pseudomonas putida, Comamonas testosteroni, Corynebacterium gultamicum, and Arthrobacter polychromogenes. The MFCs were operated under identical continuous flow conditions. The factors affecting the capabilities of the MFCs for treating organic matter and generating power were evaluated and compared. The factors include microbial species type, organic loading, and substrate degradation rate. For all four MFCs, power output increased with the organic loading rate. Power density also increased with the substrate degradation rate. These findings implied that more organic matter was utilized for power generation at higher organic loading and substrate degradation rates. However, coulombic efficiency increased with decreased organic loading and substrate degradation rates. Apparently, all four MFCs had low efficiencies in generating power from organic matter. These low efficiencies are attributed to the long distance between the anode and the cathode, as well as to the small ratio of the proton exchange membrane surface area to the anode chamber surface area. These features may have caused most of the protons produced in the anode chamber to leave the chamber with the effluent, which led to the low power generation performance of the MFCs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial fuel cells (MFCs) can convert organic matter to electricity by using bacteria as biocatalysts (Oh and Logan 2006; Du et al. 2007). Bacteria in, the anodic chamber will use the organic matter to produce electrons and protons. The electrons will be transferred to the cathode through a conductive material containing a resistor. The protons will also migrate to the cathode through the solution across a proton exchange membrane (PEM). Both electrons and protons will finally be depleted in the cathode chamber, coupled with the reduction of O2 to water (Kim et al. 2002; Rabaey and Verstraete 2005; Logan and Regan 2006; Oh and Logan 2006; Ieropoulos et al. 2010).

Power generation performance of MFC has been analysed using pure cultures including Aeromonas hydrophila (Pham et al. 2003), Candida melibiosica (Hubenova and Mitov 2009), Clostridium acetobutylicum (Finch et al. 2011), C. butyricum EG3 (Park et al. 2001), C. thermohydrosulfuricum (Mathuriya and Sharma 2009), Enterococcus gallinarum (Rabaey et al. 2004), Escherichia coli (Schroder et al. 2003; Zhang et al. 2008), Shewanella oneidensis (Biffinger et al. 2008; Watson and Logan 2010), Rhodoferax ferrireducens (Chaudhuri and Lovley 2003) and Shewanella putrefaciens (Kim et al. 1999, 2002). Bond and Lovely (2003), for example, studied the power generation performance of Geobactor sulfurreducens in MFC and obtained current production of 65 mA/m2 (electrode surface) and the poised-potential of 163–1143 mV/m2. Rabaey et al. (2004) also claimed that the average power densities were 23.3 ± 6.2 W/m2 of anode for Pseudomonas aeruginosa, 4.9 ± 1.8 W/m2 of anode for isolate KRA1, and 28.4 ± 2.3 W/m2 of anode for isolate KRA3. They also concluded that the pure cultures yield lower power outputs than the mixed consortium. Sun et al. (2009) also found that higher power density of MFC can be obtained more easily by a mixed culture than a pure culture. However, Min et al. (2005) compared the power generation performance between a pure culture, Geobactor metallireducens, and a mixed culture, and reported power output of 40 ± 1 mW/m2 for the former and 38 ± 1 mW/m2 for the latter.

Oh and Logan (2006) claimed that power generation in MFC is a function of the surface areas of the PEM and the cathode relative to that of the anode. For a fixed anode and cathode surface area, the power density increased as the PEM size increased. Ghangrekar and Shinde (2007) also studied the performance of a membrane-less MFC treating wastewater and concluded that under variable external resistance, the power density increased with decrease in distance between electrodes and decrease in area of anode. They also found that variation in the surface area of anode showed no significant effects on the voltage and the current production. Therefore, they suggested that transport of electrons from the bulk liquid to the electrode surface is the limiting parameter for electricity production in MFC. Rodrigo et al. (2007) used a continuous-flow type of MFC and studied the effects of organic loading and oxygen fed to the cathode on the power production performance of MFC. They concluded that only a very small fraction (about 0.25%) of influent COD was used for the generation of electricity and the influent COD limited the electricity generation but not the COD removal rate.

Jiang et al. (2009) reported that the COD removal rate increased as the anodic pH increased from 6.0 to 7.2 in a MFC with mixed cultures. Further increasing the anodic pH to 7.55 resulted in a significant drop in COD removal rate. However, anodic pH only marginally affected MFC power output at pH > 7.2. In the study of Mohan et al. (2010), a batch-operated single-chambered MFC and mixed anaerobic consortia were used to treat composite vegetable waste with the loading rates of 2.08, 1.39, and 0.7 kg COD/m3/day. They found that higher power output (57.38 mW/m2) was observed at lower substrate load. The efficiency of organic matter converted to power can also be expressed by coulombic efficiency which is typically in the range from 5 to 38% (Min and Logan 2004; Wang et al. 2008).

Most researches were conducted to evaluate the MFC performance by using single culture or mixed culture (including biological sludge). Therefore, it might be interesting to evaluate and compare the effects of microbial species, organic loading, and substrate degradation rate on the power generation capability of MFCs.

Materials and methods

Pure cultures and artificial wastewater

Pure cultures of two Gram-negative (Pseudomonas putida and Comamonas testosteroni) and two Gram-positive (Corynebacterium gultamicum and Arthrobacter polychromogenes) bacteria were used. These bacteria contain either high or low surface charges (Zeta potentials) on their cell surfaces (Juang 2001). Gram-negative bacteria also have thinner cell walls than Gram-positive bacteria. These different features led us to speculate that these microorganisms may display different electron and proton transport characteristics. Hence, they may also have different power generation capabilities. The four pure cultures were purchased from the Bioresource Collection and Research Center in Taiwan, and were incubated in our laboratory. Each species was grown in 250 ml sterile artificial wastewater without aeration, and was allowed to acclimatize for 2 weeks. All species grew rapidly, and were then transferred to the anode chambers of four MFCs. P. putida was placed in MFC 1, Corynebacterium gultamicum in MFC 2, Comamonas testosteroni in MFC3, and A. polychromogenes in MFC 4.

The artificial wastewater was prepared with 1000 mg glucose/l, 300 mg nutrient broth/l, 167 mg NH4Cl/l, 25 mg K2HPO4/l, 25 mg NaH2PO4/l, 5 mg FeCl3/l, 100 mg MgCl2/l, 10 mg MnSO4/l, and 133 mg CaCl2/l. For Comamonas testosteroni and A. polychromogenes, 25 mg NaOH/l and 175 mg NaHCO3/l were added to adjust the different pH levels of the wastewater (Juang and Chiou 2007). The artificial wastewater was autoclaved, and the delivery tubes were disinfected with 95% ethyl alcohol before each use.

MFC design and operational condition

All four MFCs had the same sizes and configurations. Figure 1a shows the schematic diagram of an MFC. For each MFC system, two same-sized graphite carbon electrodes (CCM-400C; Central Carbon Co., Ltd., Taiwan) were used for both anode and cathode (6.3 cm length × 4 cm width × 3 mm thickness). The electrodes were fixed in the respective anodic and cathodic chambers by fully inserting them into the liquids in both chambers. Therefore, each microorganism interacted directly with the anodic electrode. Both anodic and cathodic chambers were made of Plexiglas acrylic sheets, and each chamber had an effective water volume of 797 cm3 (8.3 cm side water depth × 9.8 cm width × 9.8 cm length). All chambers were disinfected with 95% ethyl alcohol before use. The anodic and the intermediate chambers were sealed with superglue. All covers and connections were sealed with silicone to achieve anaerobicity in the anode chamber during operation.

Schematic diagram of an MFC (same for the other MFCs) (a) and experimental design of this study (b). Note: When the potential readings became stable for a few days, the influent and effluent water samples of MFCs and the potential readings at the last 2 days of each phase were taken for COD analysis and power density calculation, respectively

A peristaltic pump was used to pump a fixed amount of artificial wastewater into each anodic chamber. The inflow and outflow of each anodic chamber were located 1 cm above the bottom and 1 cm below the top of the chamber, respectively. The effluent of the anodic chamber first flowed into a water-seal box, and then overflowed into an intermediate chamber so that anaerobicity was maintained in the anode chamber. The liquid in the intermediate chamber was periodically discharged by a peristaltic pump, which was controlled by a timer. This process ensured that continuous flow conditions at different flow rates were maintained by the MFCs. The liquid in the intermediate chamber was first discharged before the anodic chamber effluent was collected for analysis. The fresh overflow from the water seal box was then collected. For oxygen supply to the electrochemical reaction, air was purged into each cathodic chamber by an air stone connected with a blower. The dissolved oxygen (DO) concentration was maintained at 7.1–7.5 mg/l. The cathodic electrolyte used in the cathodic chamber was a mixture of 30.8 mM KH2PO4·H2O (adjusted to pH ~ 7.0 by 1 M HNO3) and aerated water. Sludge mixing in the anodic chamber was performed using a stirrer, whereas mixing in the cathodic chamber was only achieved through aeration. The mixing in anodic chamber was very slow only to reduce the substrate gradient and to provide effective contact between the substrate and the culture.

The anodic and cathodic chambers were separated by a PEM (Nafion 117, Dupont Co., USA). The membrane was installed in a Plexiglas acrylic pipe (1.5 cm inner diameter and 23 cm total length) connecting the anodic and cathodic chambers. The MFCs were designed as open loop systems. The anode and the cathode were connected externally with a concealed copper wire, and power production was measured at the external load resistances of 500 and 1000 Ω adjusted using a resistor box. The distance between the anode and the cathode was approx. 36.5 cm, which may be too large to obtain high power levels. However, the purpose of the present research was not to attain high power levels but to examine the behaviors of MFCs with different pure cultures. These MFCs had the same sizes and configurations. They were also operated at the same time under the same flow rate conditions. Therefore, the results of the present study can be used to interpret and compare the power generation capabilities of the four MFCs.

The MFCs were operated at ambient 24–26°C. All systems ran under identical continuous flow conditions at four different rates (0.5, 1, 1.44, and 2.88 l/day) to compare the power generation capabilities of the MFCs. For the anodic chamber, the hydraulic retention times (HRTs) at the four different flow rates were 38.3, 19.1, 13.3, and 6.6 h, respectively. Figure 1b shows the experimental design of the present study. The artificial wastewater (influent) and the effluents from the anodic chambers were collected for analysis. The performance of an MFC system was considered stable when both COD removal efficiency and power output are stable. The flow rate was set to 0.5 l/day in phase 1, and the potential (voltage) of each MFC was measured almost every day at external load resistances adjusted to 500 and 1000 Ω until the system was stable. When the potential readings became stable for a few days, the influent and effluent water samples of MFCs and the potential readings at the last 2 days of each phase were taken for COD analysis and power density calculation, respectively. The average COD concentration and the average potential of both days were then used for the analysis (Fig. 1b). In the same way, MFC power production and water quality under the flow rates of 1, 1.44, and 2.88 l/day were evaluated.

Analyses of water quality and power generation

The influents (artificial wastewater) and the effluents of the anodic chambers were collected for water quality analyses. All effluent samples were filtered through filter papers (Whatman grade 934AH) before COD analysis. COD was determined using the closed reflux method mentioned in the standard methods of Clesceri et al. (2001). The pH, temperature, and DO (DO200; YSI, Inc., USA) of the water in the cathodic chamber were also measured.

The voltages and currents (at adjusted external load resistances of 500 and 1000 Ω) were measured using a digital multimeter with a data acquisition unit (U1253B; Agilent Technologies, Malaysia). They were converted to power (mW) and power density (mW/m3 of liquid volume in the anodic chamber or mW/m2 surface area of the anode plate). The voltage and current readings on the digital multimeter obtained using the data acquisition software Agilent GUI Data Logger (Agilent Technologies, Inc., USA) were allowed to stabilize for about 5–10 min before each measurement. The readings were then recorded every 10 s continuously for 3 min and were averaged (Fig. 2). Each MFC was continuously operated for more than 1 month, and the potentials were measured everyday. Therefore, the coulombic efficiency was estimated by the method described by Behera and Ghangrekar (2009). For the theoretical coulombic amount calculations, we assumed that four moles of electrons were produced per mole of COD in the artificial wastewater (Behera and Ghangekar 2009; Rodrigo et al. 2009; Sun et al. 2009). The coulombic efficiency (Ce) was calculated as Ce = MI/Fnq∆COD where M is the molecular weight of O2 (= 32), I is the current, F is Faraday’s constant (= 96,500), n is the number of electrons exchanged per mol of O2 (= 4), q is the volumetric influent flow rate and ∆COD is the difference in the influent and effluent COD.

Results and discussion

Wastewater treatment characteristics

The influent and effluent characteristics of the four MFC anode chambers are listed in Table 1. The operational data, treatment efficiencies, and substrate degradation rates are listed in Table 2. The COD removal efficiency and the substrate degradation rate in the anodic cells with lower influent pH (i.e., MFCs 1 and 2) were higher than those with higher influent pH (i.e., MFCs 3 and 4). According to the data in Table 2, a lower influent pH apparently favored organic matter removal efficiency and degradation rate in the anode chamber, in accordance with the report of Behera and Ghangrekar (2009). As the flow rate increased the HRT decreased in the anode chamber. The time required by the microorganisms in the anodic chamber to degrade organic matter decreased with increased flow rate. Therefore, the average COD removal efficiency of each culture decreased. However, the COD degradation rate in the anodic chambers increased as the flow rates increased from 0.5 to 2.88 l/day. The exception was that of A. polychromogenes, which decreased when the flow rate reached 2.88 l/day. Rodrigo et al. (2007) reported that a small part (about 0.25%) of wastewater COD was used for power generation. Therefore, the COD degradation rates of all four MFCs at different flow rates were expected to affect the MFC power generation performance. This will further be discussed in the following section.

Effects of wastewater pH and microorganism type on MFC performance

The power generation performances of the four MFCs are shown in Fig. 2. The data shown are the daily potential averages. During the first operational phase (flow rate of 0.5 l/day), the MFCs stabilized after 12 days of operation. In the other phases (flow rate = 1, 1.44, and 2.88 l/day), they stabilized after 4–5 days. The voltage outputs of the four MFCs always dropped or remained almost constant in the first few days of each phase, and then gradually increased until stabilized. The voltage outputs were higher in MFCs 3 and 4 (Comamonas testosteroni and A. polychromogenes, respectively) than in MFCs 1 and 2 (P. putida and Corynebacterium gultamicum, respectively). The average voltages were 30, 34, 37.4, and 51.2 mV for MFC 3 under stable operation conditions in phases 1–4 (external resistance load = 1000 Ω), respectively. The average voltages were 28.4, 28.4, 29.8, and 29.3 mV for MFC 4 under stable operation conditions in phases 1–4 (external resistance load = 1000 Ω), respectively. The average voltages were much lower for MFCs 1 and 2, which were operated under a lower pH condition. The average voltages were 7.6, 11.8, 12.8, and 14.4 mV for MFC 1, as well as 4.8, 7.8, 10.6, and 11.4 mV for MFC 2 under stable operation conditions in phases 1–4 (external resistance load = 1000 Ω), respectively. The lower pH in MFCs 1 and 2 might have inhibited the power generation activity of P. putida and Corynebacterium glutamicum. As mentioned above, the COD removal efficiency and the substrate degradation rate in the anodic cells were higher for P. putida and Corynebacterium glutamicum than for Comamonas testosteroni and A. polychromogenes. Therefore, a lower pH may reduce the power generation functions of both bacteria by partially inhibiting the conversion of degraded COD to electricity in MFCs 1 and 2. Similar results have also been reported by other researchers. Gil et al. (2003) reported that the highest current was observed between pH 7 and pH 8, and the values were lower at pH 9 and below pH 6. Ren et al. (2007) reported that power production significantly decreased when the pH in the anode chamber dropped to 5.2 due to the acidic products of fermentation. Behera and Ghangrekar (2009) also concluded that a higher feeding pH (8.0) favored a more effective extracellular electron transfer and a higher power production. Jiang et al. (2009) also revealed that a higher anodic pH favored a higher MFC power output. A low MFC pH apparently inhibited the activity of electrogenic bacteria, resulting in the severe inhibition of power generation.

Based on the power outputs of the four bacteria, we suspected that the Gram-negative bacteria (P. putida and Comamonas testosteroni) can generate more power than the Gram-positive bacteria (Corynebacterium glutamicum and A. polychromogenes) under the same operational conditions and wastewater characteristics. However, further studies need to be undertaken to confirm these assumptions. Figure 2 also shows that the voltage outputs increased with the flow rate (shorter retention time) in the anode chambers. As mentioned above, the COD degradation rate in the anodic chambers increased as the flow rates increased from 0.5 to 2.88 l/day. Therefore, more COD was possibly degraded and used for power generation at higher flow rates.

Effect of organic loading on MFC performance

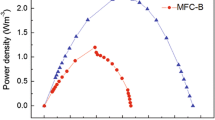

Figure 3 shows a good linear relationship between power density and current density at different COD loading rates on all four MFCs (external load resistance = 1000 Ω). The coefficients of determination (R 2) were 0.9455, 0.9237, 0.9402, and 0.7574 for P. putida, Corynebacterium glutamicum, Comamonas testosteroni and A. polychromogenes, respectively. As the COD loading increased from 0.96 to 4.94 kg/m3/day for P. putida and Corynebacterium glutamicum, increased from 0.78 to 4.46 kg/m3/day for Comamonas testosteroni and A. polychromogenes, the current density and the power density for the four cultures increased. The exception was A. polychromogenes, wherein the current density and the power density decreased when the COD loading reached 4.46 kg/m3/day. The current density and the power density for A. polychromogenes decreased when the COD loading reached 4.46 kg/m3/day. These results indicate that A. polychromogenes had a maximum power generation at COD loading between 1.96 and 4.46 kg/m3/day, and its power generation performance was inhibited at the COD loading of 4.46 kg/m3/day. The maximum power generation of this bacteria may be close to 0.16 mW/m2 (external load resistance = 1000 Ω and COD loading = 1.96 kg/m3/day). Under the same COD loading and wastewater pH conditions, Comamonas testosteroni displayed better power generation function than A. polychromogenes, and P. putida displayed better power generation function than Corynebacterium glutamicum.

Figure 4 also shows good linear relationships between power density and COD loading rate on P. putida, Corynebacterium glutamicum and Comamonas testosteroni at the external load resistances of 500 and 1000 Ω. The coefficients of determination (R 2) were 0.7325 and 0.7634 for P. putida, 0.9366 and 0.715 for Corynebacterium glutamicum, as well as 0.9968 and 0.9993 for Comamonas testosteroni at the external load resistances of 500 and 1000 Ω, respectively. These results imply that power output increased as COD loading rate increased from 0.78 to 4.46 kg/m3/day. Apparently, more organic matter could be used for power generation at higher organic loading rates. However, this result differed from that reported by Mohan et al. (2010), who used composite vegetable waste as the MFC substrate. Rodrigo et al. (2007) claimed that generated power density mainly depends on the organic matter, and also reported higher power outputs at lower substrate loads.

The linear relationship between power density and COD loading rate was low on A. polychromogenes at the external load resistances of 500 and 1000 Ω, with R 2 values of only 0.4581 and 0.3565, respectively. Therefore, P. putida, Corynebacterium glutamicum, and Comamonas testosteroni MFCs can be used as biosensors to measure influent COD loadings effectively at a loading strength of at least less than 4.94 kg/m3/day. However, A. polychromogenes can only be used as a biosensor to measure influent COD loadings effectively at a loading strength of at least up to 1.96 kg/m3/day. Among the four MFCs, MFC 3 displayed the highest power density at the same COD loading than others. A higher power density was also notably observed at a higher external load resistance.

Coulombic efficiency can be used to express the efficiency of power production per unit of organic matter utilized by a microorganism (Min and Logan 2004). Figure 5 shows the relationship between coulombic efficiency and COD loading rate in the four MFCs at external load resistances of 500 and 1000 Ω. The relationships between coulombic efficiency and COD loading rate were similar for all MFCs. The highest coulombic efficiency was seen at COD loading rates between 2.0 and 2.5 kg/m3/day for P. putida, between 2.0 and 2.5 kg/m3/day for Corynebacterium glutamicum, between 1.0 and 1.5 kg/m3/day for Comamonas testosteroni, as well as between 0.5 and 1 kg/m3/day for A. polychromogenes. Apparently, coulombic efficiency increases with decreased COD loading rates.

Effect of substrate degradation rate on MFC performance

A good linear relationship existed between COD degradation rate and power density (as mW/m3 of anode chamber), as shown in Fig. 6. The R 2 were 0.7044, 0.8984, 0.9978, and 0.8195 at the external load resistance of 1000 Ω, as well as 0.6899, 0.8577, 0.9994, and 0.7487 at the external load resistance of 500 Ω for P. putida, Corynebacterium glutamicum, Comamonas testosteroni and A. polychromogenes, respectively. A higher power density was observed at higher COD degradation rates (see Fig. 6), implying that more COD was utilized for power generation at higher COD degradation rates. However, according to the equations in Fig. 6, the slope of the linear equation was the highest for Comamonas testosteroni (2.796 at 1000 Ω and 1.625 at 500 Ω) among all cultures. This implied that each unit of COD degraded by Comamonas testosteroni generated the most.

Figure 7 shows the relationships between coulombic efficiency and COD degradation rate in the four MFCs at the external load resistances of 500 and 1000 Ω, which are similar for each MFC. The highest coulombic efficiency was seen at the COD degradation rate between 0.8 and 1.0 kg/m3/day for P. putida, between 1.3 and 1.5 kg/m3/day for Corynebacterium glutamicum, between 0.4 and 0.6 kg/m3/day for Comamonas testosteroni, and between 0.2 and 0.4 kg/m3/day for A. polychromogenes. A higher coulombic efficiency apparently occurs at lower COD degradation rates. More organic matter may be degraded in the anodic chambers when a high COD degradation rate was not efficiently utilized for power generation.

Relationship between coulombic efficiency and resistance

Figure 8 shows that a lower resistance corresponded to a higher coulombic efficiency. The differences in coulombic efficiency mean that some electrons are consumed by some mechanisms other than the cathode reaction (Gil et al. 2003). However, coulombic efficiency values reported by some researchers varied for different reactor designs, types of wastewaters, temperatures etc., but were normally higher than 0.33% (Behera and Ghangrekar 2009; Min and Logan 2004; Wang et al. 2008). The distance between the anode and cathode was large (36.5 cm), and the ratio of the PEM surface area to the anode chamber surface area (side wall) was very small (0.022) in the present study. As a result, the protons produced in the anode chamber may have not had enough time to migrate to the cathode. Many protons possibly left the anode chamber with the effluent, causing the low MFC coulombic efficiency in this study.

The coulombic efficiency for each culture was also affected by flow rate. Comamonas testosteroni showed a higher coulombic efficiency at the lower flow rate of 1 l/day. A. polychromogenes displayed the highest coulombic efficiency at the flow rate of 0.5 l/day. However, significant decreases in coulombic efficiency occurred as the flow rates increased to 1, 1.44, and 2.88 l/day. Both P. putida and Corynebacterium glutamicum displayed the highest coulombic efficiencies at the flow rate of 1.44 l/day. These results were in accordance with the relationships between coulombic efficiency and COD loading rate (see Fig. 5). Figure 9 shows that except for Corynebacterium glutamicum (MFC 2), good linear relationships existed between resistance and coulombic efficiency for P. putida (MFC 1), Comamonas testosteroni (MFC 3), as well as A. polychromogenes (MFC 4) at different flow rates. On the other hand, a good linear relationship between resistance and coulombic efficiency for Corynebacterium glutamicum was only found at the flow rate of 1.44 l/day.

Conclusions

All cultures displayed different treatment efficiencies and degradation rates of organic matter. Under a low pH condition in the anode chamber, P. putida expressed a higher power production performance than Corynebacterium glutamicum. Under a high pH condition in the anode chamber, Comamonas testosteroni displayed a higher power production performance than A. polychromogenes. A low influent pH may favor organic matter removal efficiency and degradation rate in the anode chamber. As the flow rate increased, the average COD removal efficiencies of the four bacteria decreased. On the contrary, the COD degradation rates of the four bacteria increased as the flow rate increased from 0.5 to 2.88 l/day. The exception was A. polychromogenes, whose COD degradation rate decreased when the flow rate reached 2.88 l/day.

MFCs inoculated with different cultures displayed different power production performances. Although P. putida and Corynebacterium glutamicum displayed higher COD degradation rates, their voltage outputs were lower than those of Comamonas testosteroni and A. polychromogenes. A low pH may reduce the power generation functions of P. putida and Corynebacterium glutamicum by partially inhibiting the conversion of degraded COD to electricity. For the four bacteria, the power output increased as the COD loading rate increased. More organic matter could evidently be used for power generation at higher organic loading rates. However, a maximum power output was reached at a certain COD loading rate, after which the power output decreased. This was found in the case of the A. polychromogenes MFC. A high coulombic efficiency was observed at low COD loading rates.

A high power density seemed to occur at high COD degradation rates, implying that more COD was utilized for power generation at higher COD degradation rates. Among the four bacteria, each unit of COD degraded by Comamonas testosteroni generated the most power. Higher coulombic efficiencies occurred at lower COD degradation rates and at a lower external load resistance. In a continuous-flow MFC, a long distance between the anode and cathode or a small ratio of the PEM surface area to the anode chamber surface area (side wall) caused most of the protons produced in the anode chamber to leave the chamber with the effluent. Consequently, power output and coulombic efficiency of the MFCs decreased. Further studies would be necessary to improve MFC electricity production by decreasing the distance between electrodes and increasing the surface area ratio of PEM to the anode chamber.

References

Behera M, Ghangrekar MM (2009) Performance of microbial fuel cell in response to change in sludge loading rate at different anodic feed pH. Bioresour Technol 100:5114–5121

Biffinger JC, Byrd JN, Dudley BL, Ringeisen BR (2008) Oxygen exposure promotes fuel diversity for Shewanella oneidensis microbial fuel cells. Biosens Bioelectron 23:820–826

Bond DR, Lovley DR (2003) Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69:1548–1555

Chaudhuri SK, Lovley DR (2003) Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat Biotechnol 21:1229–1232

Clesceri LS, Greenberg AE, Eaton AD (2001) Standard methods for the examination of water and wastewater. American Public Health Association (APHA), American Water Works Association (AWWA), and Water Environment Federation (WEF), Washington, DC

Du Z, Li H, Gu T (2007) A state of the art review on microbial fuel cells: a promising technology for wastewater treatment and bioenergy. Biotechnol Adv 25:464–482

Finch AS, Mackie TD, Sund CJ, Sumner JJ (2011) Metabolite analysis of Clostridium acetobutylicum: fermentation in a microbial fuel cell. Bioresour Technol 102:312–315

Ghangrekar MM, Shinde VB (2007) Performance of membrane-less microbial fuel cell treating wastewater and effect of electrode distance and area on electricity production. Bioresour Technol 98:2879–2885

Gil GC, Chang LS, Kim BH, Kim M, Jang JK, Park HS, Kim HJ (2003) Operational parameters affecting the performance of a mediator-less microbial fuel cell. Biosens Bioelectron 18:327–334

Hubenova Y, Mitov M (2009) Potential application of Candida melibiosica in biofuel cells. Bioelectrochemistry 78:57–61

Ieropoulos I, Winfield J, Greenman J (2010) Effects of flow-rate, inoculum and time on the internal resistance of microbial fuel cells. Bioresour Technol 101:3520–3525

Jiang J, Zhao Q, Zhang J, Zhang G, Lee D (2009) Electricity generation from bio-treatment of sewage sludge with microbial fuel cell. Bioresour Technol 100:5808–5812

Juang DF (2001) Effects of mono- and di-valent cations on the zeta potential and settling velocity of activated sludge. J Chin Inst Environ Eng 11:11–20

Juang DF, Chiou LJ (2007) Microbial population structures in activated sludge before and after the application of synthetic polymer. Int J Environ Sci Technol 4:119–125

Kim BH, Kim HJ, Hyun MS, Park DH (1999) Direct electrode reaction of Fe(III) reducing bacterium, Shewanella putrefaciens. J Microbiol Biotechnol 9:127–131

Kim HJ, Park HS, Hyun MS, Chang IS, Kim M, Kim BH (2002) A mediator-less microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens. Enzyme Microb Technol 30:145–152

Logan BE, Regan JM (2006) Electricity-producing bacterial communities in microbial fuel cells. Trends Microbiol 14:512–518

Mathuriya AS, Sharma VN (2009) Bioelectricity production from paper industry waste using a microbial fuel cell by Clostridium species. J Biochem Technol 1:49–52

Min B, Logan BE (2004) Continuous electricity generation from domestic wastewater and organic substrates in a flat plate microbial fuel cell. Environ Sci Technol 38:5809–5814

Min B, Cheng S, Logan BE (2005) Electricity generation using membrane and salt bridge microbial fuel cells. Water Res 39:675–1686

Mohan SV, Mohanakrishna G, Sarma PN (2010) Composite vegetable waste as renewable resource for bioelectricity generation through non-catalyzed open-air cathode microbial fuel cell. Bioresour Technol 101:970–976

Oh S, Logan BE (2006) Proton exchange membrane and electrode surface areas as factors that affect power generation in microbial fuel cells. Appl Microbiol Biotechnol 70:162–169

Park HS, Kim BH, Kim HS, Kim HJ, Kim GT, Kim M, Chang IS, Park YK, Chang HI (2001) A novel electrochemically active and Fe(III)-reducing bacterium phylogenetically related to Clostridium butyricum isolated from a microbial fuel cell. Anaerobe 7:297–306

Pham CA, Jung SJ, Phung NT, Lee J, Chang IS, Kim BH, Yi H, Chun J (2003) A novel electrochemically active and Fe(III)-reducing bacterium phylogenetically related to Aeromonas hydrophila, isolated from a microbial fuel cell. FEMS Microbiol Lett 223:129–134

Rabaey K, Verstraete W (2005) Microbial fuel cells: novel biotechnology for energy generation. Trends Biotechnol 23:291–298

Rabaey K, Boon N, Siciliano SD, Verhaege M, Verstraete W (2004) Biofuel cells select for microbial consortia that self-mediate electron transfer. Appl Environ Microbiol 70:5373–5382

Ren Z, Ward TE, Regan JM (2007) Electricity production from cellulose in a microbial fuel cell using a defined binary culture. Environ Sci Technol 41:4781–4786

Rodrigo MA, Cañizares P, Lobato R, Paz R, Sáez C, Linares JJ (2007) Production of electricity from the treatment of urban waste water using a microbial fuel cell. J Power Sources 169:198–204

Rodrigo MA, Cañizares P, García H, Linares JJ, Lobato J (2009) Study of the acclimation stage and of the effect of the biodegradability on the performance of a microbial fuel cell. Bioresour Technol 100:4704–4710

Schroder U, Nieben J, Scholz F (2003) A generation of microbial fuel cells with current outputs boosted by more than one order of magnitude. Angew Chem Int Ed Engl 42:2880–2883

Sun J, Hu Y, Bi Z, Cao Y (2009) Improved performance of air-cathode single-chamber microbial fuel cell for wastewater treatment using microfiltration membranes and multiple sludge inoculation. J Power Sources 187:471–479

Wang X, Feng Y, Lee JH (2008) Electricity production from beer brewery wastewater using single chamber microbial fuel cell. Water Sci Technol 57:1117–1121

Watson VJ, Logan BE (2010) Power production in MFCs inoculated with Shewanella oneidensis MR-1 or mixed cultures. Biotechnol Bioeng 105:489–498

Zhang T, Cui C, Chen S, Yang H, Shen P (2008) The direct electrocatalysis of Escherichia coli through electroactivated excretion in microbial fuel cell. Electrochem Commun 10:293–297

Acknowledgment

The authors would like to express their gratitude and appreciation to the National Science Council (NSC) of Taiwan for the financial support of this research under Contract No. 99-2221-E-276-004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Juang, DF., Yang, PC., Chou, HY. et al. Effects of microbial species, organic loading and substrate degradation rate on the power generation capability of microbial fuel cells. Biotechnol Lett 33, 2147–2160 (2011). https://doi.org/10.1007/s10529-011-0690-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-011-0690-9