Abstract

The potential on N-vanillylnonanamide (NVN) in preventing the attachment of Pseudomonas stutzeri and a Bacillus cereus-group strain was investigated. NVN up to 852 μM was not toxic, nor was it an energy source for either organism. Microbial attachment assays were carried out on glass and polylysine slides. with NVN being dispersed in or applied to the surfaces using a polyurethane coating. NVN at 205 μM inhibited Bacillus adhesion on glass slides by 48% and the percentage did not significantly increase at 852 μM. NVN blended into or sprayed onto the coating at 205 μmol/kg did not prevent adhesion. The compound is therefore not useful as an antifouling product under the tested coating conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biofouling is the undesirable accumulation of microorganisms, plants and animals on a surface (Whelan and Regan 2006). Bacteria are generally the first organisms to colonize surfaces exposed to different environments through adhesion and subsequent biofilm formation. As mature biofilms are invariably recalcitrant to a diversity of treatment strategies, minimizing bacterial attachment and the subsequent formation of biofilms could be advantageous in reducing the early stages of biofouling. The conventional approach to limiting biofouling is chemical abatement by the application of biocides and mechanical cleaning. However mechanical cleaning can be costly and may not be applicable due to the fouled surface’s inaccessibility. On the other hand, some chemicals, such as organotin compounds, pose severe environmental and human health risks, and for this reason they have been banned (Howell and Behrends 2006). The search for suitable non-toxic, or even less-toxic, active natural compounds to incorporate into antifouling coatings could be a successful approach for the prevention of biofouling. Capsaicin (8- methyl-N-vanillyl-6-nonenamide), a pungent compound of hot peppers, the fruit of the Capsicum plant, can prevent the growth of various bacteria, including Pseudomonas and Bacillus spp. (Molina-Torres et al. 1999; Dorantes et al. 2000). Tsuchiya (2001) reported that low capsaicin concentrations fluidize membranes whereas high concentrations rigidify them. Capsaicin was claimed to be an efficient antifoulant against Pseudomonas putida and other bacteria when applied in dispersion at 131 μM, a concentration below its toxic level (Turgut et al. 2004; Xu et al. 2005a, b). The synthetic analogue N-vanillylnonanamide, available commercially, differs from capsaicin chemically by a methyl group and a double bond.

N-vanillylnonanamide has many advantages over natural capsaicin extracts, it is cheaper (the cost of 1 g capsaicin is 5-fold higher than that of 1 g N-vanillylnonanamide) and has fewer impurities. In view of its potential applications, N-vanillylnonanamide anti-adhesion capability was tested both in dispersion and when blended into and spread onto a polyurethane coating.

Materials and methods

Materials

Dissolution of N-vanillylnonanamide (purity ≥ 97%, Sigma-Aldrich) was obtained following a method previously described for capsaicin (Turgut et al. 2004), expect that instead of distilled water phosphate buffer solution was used (PBS, Sigma-Aldrich). N-vanillylnonanamide was added to the liquid medium to give 7, 34, 68, 136, 205 and 852 μM.

Identification of bacteria, growth medium and bacterial surface hydrophobicity

The bacteria were isolated from a biofilm on a household surface; they were characterised as Gram-negaive and Gram-positive microorganisms and had previously been used in our laboratory for other biofilm studies. For identification, total DNA extraction, amplification and partial sequencing were carried out according to Brusetti et al. (2006). The two sequences were compared with the BLASTIN nucleotide sequence database.

Bacteria were grown at 30°C in Plate Count Broth (PCB, Difco) at 150 rpm and all the inocula were taken from rapidly growing cultures. Cell enumeration was calculated from OD540. The wettability of the bacterial cells before and after N-vanillylnonanamide treatment was measured as the contact angle between the water drops and the lawns of bacteria deposited on membrane filters, with a Dataphysics OCA-20 contact angle equipped with a CCD video camera (DataPhysics Instuments GmbH). One hundred and fifty ml of 12 h cell suspension (108 cell/ml) was washed three times with PBS and suspended in 30 ml. The bacterial suspension was filtered using 0.2 μm pore-size nitrile filters air-dried for 1 h to reach the “plateau contact angle”.

Glass slides and coating preparation

Microscope glass slides (Menzel GmbH) and coated polylysine slides (VWR International), both of 2.5 × 7.5 cm, were used as substrata.

Polyurethane was synthesized by mixing oxydrilated polyester resin T535 (Alcea) with aliphatic biureto polyisocyanate in toluene at 10/10.66 (w/w). The coating was applied by brush onto the slide surfaces to give an average thickness of 20 μm, and then left to air dry for 48 h.

The capsaicinoid incorporation into, and its spreading onto, the polyurethane coating was achieved in two ways: (i) by dissolving the N-vanillylnonanamide at 205 μmol/kg; (ii) a polyurethane coating was applied to the surface, then a calculated amount of N-vanillylnonanamide in the same solvent was sprayed on this surface. In both cases the aim was for a final concentration of 205 μmol/kg of dried coating.

Equipment for the characterisation of the glass surfaces

Contact angle measurements (θw) were carried out at room temperature using the contact angle goniometer DataPhysics OCA 20 system (DataPhysics Instuments GmbH). The gloss of the slides and coatings was measured using a glossmeter Multi-Gloss 268 (Konica Minolta) equipped with a tungsten lamp (2.5 V/60 mA) operating at 20°, 60° and 85°. The surface morphology was evaluated with an optical microscope equipped with video camera and digital image analysis, and an Environmental Scanning Electron Microscope Evo 50EP (Zeiss). A ThermoNicolet Nexsus FT-IR spectrophotometer (Thermo Electron Corporation) equipped with ATR Silver Gate Specac and Ge crystal was used for attenuated total-reflectance measurements to indicate the changes in the main characteristics of the coating with and without the capsaicinoid.

Toxicity evaluation

Toxicity experiments were conducted at 30°C in PCB medium with both bacteria at 106 cells/ml, with N-vanillylnonanamide at 205 and 852 μM. The growth rates with or without N-vanillylnonanamide were determined. N-Vanillylnonanamide without cells was used as the control. The negative control was all the combinations but without the antifoulant. The toxicity of N-vanillylnonanamide was evaluated using an overnight bacterial suspension 10-fold serially diluted in PBS and 100 μl of each dilution was plated on PC A without and with 205 or 852 μM N-vanillylnonanamide. The plates were incubated overnight at 30°C and the number of colony-forming units counted.

N-Vanillylnonanamide as the sole carbon and energy source

A mineral medium (KH2P04 30 g/1, Na2HP04 70 g/1, NH4C1 10 g/1, pH 7) was used to which N-vanillylnonanamide was added up to 852 μM as the sole carbon and energy source. Bacteria were added 106 cells/ml and grown at 30°C. Samples were taken up to 14 days. The positive control was mineral medium supplemented with the same concentration of glucose.

DAPI staining and permeabilisation

The slides were fixed with a 4% paraformaldehyde solution in PBS, held for 2 h on ice, and then washed twice with PBS. The samples inside an in situ frame (1 cm2 area, Eppendorf) adhered to a glass slide were stained with 25 μl DAPI (4′, 6-diamidino-2-phenylindole dihydrochloride, 10 μg/ml working solution), then incubated in the dark for 5 min and washed twice with PBS. Positive DAPI-stained cells were visualised by epifluorescence microscopy. Images were collected using a digital camera.

Bacterial attachment study

Glass slides held static at 90° in a 50 ml plastic flask were collected from the incubation assay after 24, 48, 72, and 144 h. Each flask contained an initial population 106 cells/ml in 20 ml of PCB medium added with N-vanillylnonanamide at 0, 7, 34, 68, 136, 205 and 852 μM. In addition, the bacterial media were analysed at 540 nm to evaluate if growth in liquid was inhibited by the compound. The number of adhered cells per cm2 was esimated using ImageJ 1.34s (http://rsbweb.nih.gov/ij/). A total of 2,641 observations were considered for N-vanillylnonanamide dispersed in the liquid medium, 1,176 for N-vanillylnonanamide blended into the polyurethane coating and 1,000 for N-vanillylnonanamide spread onto the coated slides. A three- and two-way analysis of variance (ANOVA) via MATLAB software (Version 7.0, The MathWorks Inc) were applied to evaluate, for each microorganism, the effect of the substratum, N-vanillylnonanamide concentration and time on attachment. Tukey’s honestly significant different test was used for pairwise comparison to determine the significance of the data (statistically significant results P values < 0.05, non-significant results P > 0.05).

Results

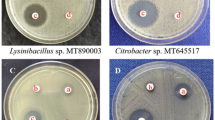

Identification of bacteria

For the Gram-positive bacterium, similarities of the closest relatives found in BLASTN searches were 99% both with Bacillus cereus and Bacillus thuringiensis, closely related bacteria of the B. cereus sensu-lato group. For the Gram-negative bacterium, similarities of the closest relatives found in BLASTN searches were 99% with Pseudomanas stutzeri.

Toxicity test and bacterial ability to use N-vanillylnonanamide as the sole source of C and energy

The growth test results are reported in Table 1. There was no significant difference among the growth rates with or without N-vanillylnonanamide (P Bacillus : 0.256; P Pseudomonas : 0.733). Furthermore, N-vanillylnonanamide did not affect the growth of the bacteria in solid medium (P Bacillus : 0.757; P Pseudomonas : 0.542). Hence, N-vanillylnonanamide was not toxic to either microorganism. Although the B. cereus- group and P. stutzeri strains grew in mineral media when supplemented with glucose, they did not grow on N-vanillylnonanamide as sole carbon and energy source. The pH remained neutral and constant in all the experiments.

Superficial properties of the glass slides and bacterial cells

Without N-vanillylnonanamide, the water contact angles on the bacterial lawns ranged from 18.1° ± 2.0 for P. stutzeri to 19.5°± 5.1 for the B. cereus-group strain. When the cells were in a N-vanillylnonanamide suspension, the water contact angles on the bacterial lawns ranged from 16.7°± 1.7 for P. stutzeri to 21.5°± 2.9 for the B. cereus-group strain. Both uncoated glass substrata were very wettable. However, polylysine slightly increased the water repellence of the surface (glass slide: 18.6°± 1.0; polylysine glass slide: 29.9° ± 1.6). The polyurethane coating masked the wettability properties of the glass surfaces, making both the coated substrata hydrophobic (polyurethane-coated glass slide: 89.97° ± 1.68; polyurethane-coated polylysine glass slide: 95.6° ± 1.9, considering that water repellent surfaces show angles >90°). In addition, the selected coating did not modify surface gloss. N-Vanillylnonanamide in the polyurethane coating did not modify the ATR coating spectrum. Using the environmental scanning electron microscope, the surface morphology of the polyurethane-coated glass substrata without and with N-vanillylnonanamide appeared the same.

DAPI staining and bacterial attachment on coated and uncoated glass slides without N-vanillylnonanamide

Stained Bacillus spores are shown in the Fig. 1. Both Bacillus and Pseudomonas formed biofilms at a later time.

DAPI-staining of B. cereus-group spores. Cells were dehydrated in an ethanol series (50, 80, and 100% v/v ethanol) for 1 min. Adhesion of spores to the surface: first step of biofilm formation. The same area is shown in the bright-field view (a) and epifluorescence microscope field with DAPI filter cube (b). Magnification of 1,000X under oil immersion. Bars represent 10 μm

Table 2 shows the average of the adhered cells and the contact angle for the following substrata: the glass slide (basically slightly acid and wettable), the polylysine glass slide (probably conferring a positive charge to the surface) and the inorganic glass slide and polylysine glass slide coated with polyurethane (probably conferring water repellence properties to the surfaces). Coated glass slide and polylysine glass slide showed no significant difference in attachment whatever the microorganism considered (P Bacillus : 0.616; P Pseudomonas : 0.677). Thus, we refer to coated polylysine glass slide and coated glass slide as polyurethane-coated glass slides. B. cereus-group strain adhesion was more abundant on glass slide rather than polylysine glass slide, but it did not changed when P. stutzeri adhesion was considered. The lowest microbial adhesion was obtained for hydrophobic polyurethane-coated slides.

In summary our studies determined that the microbial adherence to materials occurred in the following order: (i) for P. stutzeri, polylysine glass slide = glass slide > polyurethane coated slides, (ii) for the B. cereus-group strain, glass slide > polylysine glass slide = polyurethane coated slides.

Bacterial attachment on slides immersed in liquid medium containing N-vanillylnonanamide

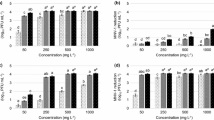

Cell growth (i.e. the OD540) was not inhibited by the compound. N-Vanillylnonanamide led to a significant reduction in the Bacillus coverage: 48% on glass slide when 205 μM of N-vanillylnonanamide was dispersed in buffer (P: 0.03) (Fig. 2a). The maximum concentration of 852 μM N-vanillylnonanamide did not significantly improve the above performance. Dispersed N-vanillylnonanamide did not hinder cell adhesion on polylysine glass slide (Fig. 2b). P. stutzeri adhesion on both glass slide and polylysine glass slide was not affected by the presence of N-vanillylnonanamide up to 205 μM (Pglass slide: 0.55;Ppolylysine: 0.95). The maximum concentration of 852 μM N-vanillylnonanamide exhibited no adhesion inhibition activity.

Adhesion assay on glass slide: significative reduction in the B. cereus-group coverage at 205 μM N-vanillylnonanamide concentration (a). No significative differences were observed for P. stutzeri whatever the concentration of N-vanillylnonanamide (b). Graphs were obtained by multicomparison analysis at 95% confidence interval. NVA = N-vanillylnonanamide

Bacterial attachment on slides coated with polyurethane containing N-vanillylnonanamide

N-Vanillylnonanamide when entrapped in the coating was at 205 μmol per kg dried polymer, corresponding to the effective liquid concentration used in the tests. The ANOVA results clearly showed that the N-vanillylnonanamide-incorporated coating was not able to reduce bacterial adhesion across all surfaces, neither for P. stutzeri nor for the B. cereus-group (P Pseudomonas : 0.870; P Bacillus : 0.06). Also when we sprayed the N-vanillylnonanamide the results were not indicative of decreased microbial adhesion (P Pseudomonas : 0.107; P Bacillus : 0.159).

Discussion

The anti-adhesion capability of N-vanillylnonanamide has been said to be the same as the natural analogue capsaicin (Dombkowski et al. 2006). Although N-vanillylnonanamide at 30 μM strongly inhibited zebra mussel macrofouling (Angarano et al. 2007), no detailed investigation at the biofilm level has ever been carried out.

Before evaluating N-vanillylnonanamide as a potential antifoulant we studied its potential impact on the growth of two bacteria. The selected bacteria seemed good candidates for anti-biofilm studies as they were previously isolated from a biofilm. They were chosen for this study as Bacillus and Pseudomonas had already been target genera for antifouling research using capsaicin (Molina-Torres et al. 1999; Dorantes et al. 2000). Dorantes et al. (2000) observed that about 0.044 μmol of natural capsaicin showed inhibitory activity towards the growth of the Listeria monocytogenes, Salmonella typhimurium and Bacillus cereus. In our study the synthetic analogue of capsaicin, N-vanillylnonanamide, did not affect, in terms of toxicity, bacterial growth at concentrations of up to 852 μM.

It was recently claimed that capsaicin and vanillylamine were utilised as a sole source of carbon and energy by, respectively, Capsicum-associated strains of Variovorax and Ralstonia, and Pseudomonas and Variovorax (Flagan and Leadbetter 2006). Both the B. cereus-group and P. stutzeri strains grew well in a mineral salt medium supplemented with the same concentration of glucose, but they were not able to utilise N-vanillylnonanamide as a growth nutrient. When the attachment of hydrophilic P. stutzeri and B. cereus-group strains to the uncoated and polyurethane-coated surfaces in the absence of N-vanillylnonanamide was investigated, bacterial adhesion was found more efficient on uncoated slide surfaces compared to polyurethane-coated ones, suggesting that just coating with polyurethane is already an antifouling option. This could be easily explained by the fact that the contact angle measurements showed a more hydrophobic behaviour for the polyurethane-coated surfaces.

With 205 μM of N-vanillylnonanamide in dispersion, the adhesion of the B. cereus-group on glass slide (but not on polylysine glass slide) was reduced by 48% compared to the control. Increasing the N-vanillylnonanamide concentration did not significantly improve this percentage. No bacterial adhesion reduction was observed for P. stutzeri whatever the surfaces and concentrations considered. As there were no obvious differences in the wettability of the B. cereus-group and the P. stutzeri cells, with or without antifoulant, we must search for other explanations of the mechanism of action of N-vanillylnonanamide rather than look at the changes of hydrophobicity.

We proved that after the addition of the N-vanillylnonanamide to the polymeric coating, there were neither surface modifications nor significant differences in bacterial adhesion. This result suggests that the capsaicinoid, once blended into a polyurethane coating, is no longer able to affect bacterial attachment. A possible reason could be the low leaching of the substance from the polyurethane coating, so we sprayed the antifoulant on the polyurethane coating surface. However, also N-vanillylnonanamide on the polyurethane coating was ineffective against biofouling, therefore the possible explanation of leaching was excluded. The fact that the compound did not work when immobilized on the substratum might also be explained by the fact that it does not act to change membrane fluidity (Tsuchiya 2001).

This study suggests that N-vanillylnonanamide, tested at the same concentrations successfully adopted in other studies (Xu et al. 2005b), is not an effective antifoulant compound when embedded in a polymer matrix.

References

Angarano M-B, McMahon RF, Hawkins DL, Schetz JA (2007) Exploration of structure-antifouling relationships of capsaicin-like compounds that inhibit zebra mussel (Dreissena polymorpha) macrofouling. Biofouling 23:295–305

Brusetti L, Borin S, Mora D, Rizzi A, Raddadi N, Sorlini C, Daffonchio D (2006) Usefulness of length heterogeneity-PCR for monitoring lactic acid bacteria succession during maize ensiling. FEMS Microbiol Ecol 56:154–164

Dombkowski RA, Doellman MM, Head SK, Olson KR (2006) Hydrogen sulfide mediates hypoxia-induced relaxation of trout urinary bladder smooth muscle. J Exp Biol 209:3234–3240

Dorantes L, Colmenero R, Hernandez H, Mota L, Jaramillo ME, Fernandez E, Solano C (2000) Inhibition of growth of some foodborne pathogenic bacteria by Capsicum annum extracts. Int J Food Microbiol 57:125–128

Flagan SF, Leadbetter JR (2006) Utilization of capsaicin and vanillylamine as growth substrates by Capsicum (hot pepper)-associated bacteria. Environ Microbiol 8:560–565

Howell D, Behrends B (2006) A methodology for evaluating biocide release rate, surface roughness and leach layer formation in a TBT-free, self-polishing antifouling coating. Biofouling 22:303–315

Molina-Torres J, Garcia-Chavez A, Ramirez-Chavez E (1999) Antimicrobial properties of alkamides present in flavouring plants traditionally used in Mesoamerica: affinin and capsaicin. J. Ethnopharmacol 64:241–248

Tsuchiya H (2001) Biphasic membrane effects of capsaicin, an active component in Capsicum species. J Ethnopharmacol 75:295–299

Turgut C, Newby BmZ, Cutright T (2004) Determination of optimal water solubility of capsaicin for its usage as a non-toxic antifoulant. Environ Sci Pollut Res 11:7–10

Whelan A, Regan F (2006) Antifouling strategies for marine and riverine sensors. J Environ Monitor 8:880–886

Xu Q, Barrios CA, Cutright T, Newby BZ (2005a) Evaluation of toxicity of capsaicin and zosteric acid and their potential application as antifoulants. Environ Toxicol 20:467–474

Xu Q, Barrios CA, Cutright T, Newby BZ (2005b) Assessment of antifouling effectiveness of two natural product antifoulants by attachment study with freshwater bacteria. Environ Sci Pollut Res 12:278–284

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Villa, F., Giacomucci, L., Polo, A. et al. N-vanillylnonanamide tested as a non-toxic antifoulant, applied to surfaces in a polyurethane coating. Biotechnol Lett 31, 1407–1413 (2009). https://doi.org/10.1007/s10529-009-0031-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-009-0031-4