Abstract

The application of five water-soluble, halogen-free, alkylammonium-based ionic liquids (ILs) as additives for advanced crystallization of lysozyme was investigated. Their biocompatibility was determined by long-term measurement of the overall mean relative enzyme activities. These were maximally reduced by about 10–15% when up to 200 g IL l−1 was added. Sitting-drop vapor diffusion crystallization experiments revealed that the addition of some of the ILs led to less crystal polymorphism and precipitation was avoided reliably even at larger NaCl concentrations. The addition of ILs tended to result in larger crystals. The kinetics of lysozyme crystallization were significantly enhanced using ILs as crystallization additives, e.g. by a factor of 5.5 when 100 g ethanolammonium formate l−1 was added. ILs with “soft” anions, such as formate or glycolate, were superior to ILs with “hard” anions, like nitrate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The application of crystallization as a purification step of proteins is economically attractive because the number of required cost-intensive chromatography steps can be reduced. Furthermore, crystallized proteins may offer superior properties compared to liquid formulations or amorphous lyophilisates due to better handling, longer shelf-life, and higher purity (Schmidt et al. 2004). Furthermore, crystalline pharmaceutical proteins may provide the advantageous possibility of controlled slow release of activity (Basu et al. 2004). The empirical crystallization methods for structural analysis of proteins have been applied for decades and, consequently, optimized techniques have emerged (Bergfors 1999). However, due to the complexity of the involved systems and the lack of transferability of experimental findings, the crystallization step still represents a bottleneck in many cases. In fact, many proteins are difficult to crystallize or do not crystallize at all. Here, very little systematic knowledge exists. As a consequence, existing crystallization processes are typically slow and the yields as well as the reproducibilities are often low. Therefore, a new strategy was sought in order to advance the crystallization process. Here, the application of biocompatible, water-soluble ionic liquids (ILs) as crystallization additives may be promising. However, such a strategy has not been investigated much in the past. ILs are organic salts which are liquid at room temperature and virtually have zero vapor pressure (Seddon 1997). ILs already have proven their advantageous properties as novel solvents in a number of applications (Wasserscheid and Welton 2002; Song 2004; Yang and Pan 2005).

The toxicity of ILs has been investigated using different methods (Ranke et al. 2004; Swatloski et al. 2004) and some biocompatible ILs have been identified. The first work on protein crystallization using ILs as additives was reported by Garlitz et al. (1999). Lysozyme crystallized easier using about 40–50 g ethylammonium nitrate l−1 compared to pure aqueous solutions. Furthermore, enzymes retained their activity and had a higher stability in aqueous solutions with addition of ILs. Additionally, ILs were a useful additive for improving the monodispersity of those types of proteins which exhibit multiple aggregation states. According to Seddon (1997), ILs are able to suppress conventional solvation and solvolysis phenomena. However, the nature of solvation in ILs is complex. Although the process of hydrogen-bonding in molecular and ionic solvents is mechanically similar, the presence of proximal counter ions complicates the analysis of specific interactions (Znamenskiy and Kobrak 2004). Therefore, more detailed studies are necessary to be able to reflect the possible enzyme-solvent interactions and to provide structural information about how the ILs interact with the protein and replace the interactions of water (Song 2004; Yang and Pan 2005). Obviously, there is a large demand for basic research on a molecular level in this field which is actually under way worldwide. On the other hand, enough experience already exists in order to simultaneously perform applied research studying the crystallization process with ILs on a macroscopic basis. This is the aim of the present work, to investigate the impact of biocompatible, water-soluble ILs as crystallization additives in order to advance the crystallization process. Lysozyme was chosen as the exemplary protein.

Materials and methods

Ionic liquids (ILs), protein, microorganism, and chemicals

Five different ILs were used in the present study which were all easily water-soluble. Some properties and the chemical structures of the ILs are given in Table 1. IL1.1, IL1.2, and IL4 were supplied by IoLiTec GmbH & Co. KG, Denzlingen, Germany. IL2 and IL3 were supplied by Bioniqs Ltd., York, Great Britain. IL1.1 and IL1.2 have a primary alkylammonium cation, IL2 has a secondary alkylammonium cation, IL3 has a tertiary alkylammonium cation, and IL4 has a quaternary alkylammonium cation. Lysozyme from chicken egg white was purchased from Sigma-Aldrich, Taufkirchen, Germany (No. 62971). Micrococcus lysodeicticus, used for the lysozyme activity test, was from Sigma-Aldrich. All other chemicals were analytical grade purchased from Merck, Darmstadt, Germany.

Determination of the maximum lysozyme solubility in water and in buffered IL-water solutions

Equilibrated saturated solutions of lysozyme in demineralized water with and without acetate buffer and in buffered aqueous solutions with 100 g ILs l−1 were made using a laboratory rotator (neoLab GmbH, Heidelberg, Germany) at 5 rev min−1 for 1 h. These solutions were centrifuged at 13,000 g for 3 min. The UV absorbance of the supernatant was measured at 280 nm and compared to a calibration standard.

Determination of the activity of lysozyme in aqueous solutions with and without ILs

The lysozyme activity test is based on the ability of the enzyme to break down the cell wall of Micrococcus lysodeicticus via hydrolyzation of the β-1,4 linkages between N-acetylmuramic acid and N-acetyl-d-glucosamine residues in peptidoglycan and between N-acetyl-d-glucosamine residues in chitodextrin. Gram-positive cells like Micrococcus are quite susceptible to this hydrolysis since their cell walls have a high proportion of peptidoglycan. Suspensions of 2.8 mg Micrococcus lysodeicticus l−1 in 1 M phosphate buffer, a pH 5.5, were prepared. Sample solutions with 100 mM acetate buffer, pH = 5.5, were made with a lysozyme at 1 g l−1 using a laboratory rotator at 20 rev min−1 for 2 h. The activity measurements were performed in a 96-well optical bottom, microtiter plate (Nunc GmbH & Co. KG, Wiesbaden, Germany) using a thermostatable ultra-microplate reader. The operating temperature was set to 33 ± 0.1°C. Relative activities of lysozyme solutions were calculated from the quotients of the measured absolute protein activities of the IL-water solution and the IL-free aqueous solution at a given time. The concentrations of the ILs were varied between 50 and 200 g l−1.

Sitting-drop vapor-diffusion crystallization experiments

The sitting-drop crystallization experiments were performed at room temperature in 24-well Chryschem plates type HR3-158 (Hampton Research Corp., Aliso Viejo, CA, USA) sealed with Crystal Clear sealing tape (Manco Inc., Avon, OH, USA). The sitting-drop tray had a diameter of about 6 mm and a maximum filling volume of about 40 μl. For each tray, 10 μl lysozyme solution was mixed with 10 μl respective reservoir solution containing buffer and crystallization additives. The lysozyme concentration was altered between 10 and 50 g l−1. The concentration of the conventional antisolvent NaCl was between 20 and 50 g l−1 and the concentration of the ILs was from 25 to 100 g l−1. All concentration data refer to the start concentrations in the trays. An acetate buffer with a pH of 4 was used. Due to the different basicity of IL1.1, IL2, and IL3, the pH in the respective sitting-drops varied from 6.2 to 7.0. Microphotographs of the sitting-drops were made using a microscope type Zeiss Axioplan (Carl Zeiss MicroImaging GmbH, Göttingen, Germany) and a digital camera type DSC-S75 (Sony Deutschland GmbH, Köln). The experimental set-up was designed in order to prevent shocks and/or vibrations acting upon the crystallization plates.

Determination of crystallization kinetics

The crystallization kinetics were obtained via the determination of the total cross-sectional crystal surface of the sitting-drop microphotographs as a function of time. For this purpose, a public domain image processing software was used (ImageJ, version 1.37v, http://rsb.info.nih.gov/ij). Crystallization equilibrium was reached when the measured cross-sectional crystal surface was at maximum and constant. The normalized total cross-sectional crystal surface was calculated from the quotient of the actual value divided by the maximum total cross-sectional crystal surface at equilibrium. For comparison of the crystallization kinetics, a parameter t90 was introduced which was defined as the time to reach 90 % of the measured maximum cross-sectional crystal surface at equilibrium.

Results and discussion

Determination of the maximum lysozyme solubility in water and in buffered IL-water solutions

The results of the lysozyme solubility measurements are presented in Table 2. As expected, solubility was highest in pure water. The addition of acetate buffer reduced the solubility markedly. The solubility of lysozyme dropped significantly when 100 g l−1 ILs were added to the aqueous solutions. The reduction of solubility was least with IL4. Interestingly, for IL1.1 and IL3, the decrease to 28–30 g l−1 was in the same order of magnitude of an aqueous lysozyme solution with about 20–25 g NaCl l−1. With 100 g IL1.2 l−1, the solubility of lysozyme was very low. The solubility measurements without ILs were well in accordance with data of Howard et al. (1988).

Determination of the activity of lysozyme in aqueous solutions with and without ILs

The time-courses of the activity of lysozyme dissolved in water without ILs was monitored during time periods of 56–70 days. As can be seen from Fig. 1, the activity data scattered noticeable. The solid lines represent linear fits to the experimental data. The activity of the dissolved lysozyme stored at 4°C dropped rather fast initially. Then, the negative slope was relatively small and about 70% of the initial activity was reached after 70 days. In contrast to this, the time course of the activity of the dissolved lysozyme stored at 21°C was approximately linear from the beginning on, however, the negative slope was comparatively larger. Hence, about 70% of the initial activity was reached after 56 days. This temperature dependent behavior was expected since the lower storage temperature preserved the enzyme activity. The relative lysozyme activities of the solutions containing ILs are given in Table 3. As can be seen, the overall mean relative enzyme activities over time were reduced by about 10–15% for IL1.1, IL1.2, IL2, and IL3. On the other hand, the addition of 125–200 g l−1 of IL4 apparently led to a slight increase of enzyme activity due to possible renaturating effects. Such behavior has been described in the literature (Summers and Flowers 2000; Lange et al. 2005). The results indicate that the chosen alkylammonium-based water-soluble ILs were well suitable for the present application involving biologically active proteins.

Sitting-drop vapor-diffusion crystallization experiments

At first, sitting-drop crystallization experiments of lysozyme without the addition of ILs were performed at variable protein and NaCl concentrations. At medium concentrations of about 20–40 g l−1 for both protein and NaCl, tetragonal crystals were obtained in most cases. However, at NaCl concentrations above 40 g l−1, in addition to the tetragonal lysozyme crystals, precipitation occurred frequently and sea urchin-like formations consisting of monoclinic crystal needles structured around amorphous aggregates appeared sometimes (see Fig.2A). This polymorphism was described earlier by Muschol and Rosenberger (1997). Next, sitting-drop crystallization experiments of lysozyme with the addition of IL3 were performed. The IL3 concentration was varied between 25 and 100 g l−1 and the NaCl concentration was in the range of 30–50 g l−1. Independently of the varying concentrations of IL3 and NaCl, tetragonal-like shaped crystals were obtained. Interestingly, no precipitation and no polymorphism was observed anymore even at higher NaCl concentrations. Similar results were obtained with IL1.1 (see Fig. 2B), IL2, and IL4. In contrast to this, the addition of IL1.2 led to spontaneous precipitation followed by slow partial or total transformation of precipitate into fascicular structures of monoclinic crystals (see Fig. 2C). Furthermore, the experiments showed that the addition of ILs tended to result in larger crystals. This is demonstrated in Fig. 2D using IL4 as crystallization additive. Here, the largest crystal length was 1.6 mm. The overall largest crystal length of 1.7 mm was achieved with 25 g IL1.1 l−1 after 50 h while the largest crystal length without addition of ILs of 1.1 mm was achieved after 48 h.

Microphotographs of lysozyme crystals with different morphologies at equilibrium in sitting-drops with 50 mM acetate buffer. (A) No IL, cLysozyme = 10 g l−1, cNaCl = 45 g l−1, pH = 4.0, tetragonal crystals and sea urchin-like formations consisting of monoclinic crystal needles structured around amorphous aggregates. (B) 62.5 g ethanolammonium formate (IL1.1) g l−1, cLysozyme = 50 g l−1, cNaCl = 25 g l−1, pH = 6.7, tetragonal crystals. (C) 100 g ethylammonium nitrate l−1 (IL1.2), cLysozyme = 50 g l−1, cNaCl = 25 g l−1, pH = 5.4, fascicular structure of monoclinic crystals. (D) 25 g l−1 choline dihydrogenphosphate (IL4), cLysozyme = 50 g l−1, cNaCl = 25 g l−1, pH = 5.2, tetragonal crystals

Determination of crystallization kinetics

During the experiments for the determination of the crystallization kinetics, the protein and NaCl concentrations were kept constant at 50 g l−1 and 25 g l−1, respectively. Fig. 3 shows typical microphotographs of tetragonal-like shaped lysozyme crystals during transient growth in sitting-drops using IL3 as crystallization additive. As can be seen, the growth of distinct lysozyme crystals could be followed easily and the cross sectional crystal surface as a function of time could be obtained via image processing. Exemplary results for two independent experiments using IL1.1 are presented in Fig. 4. Due to the basic nature of IL1.1, the pH in the sitting-drops varied from 6.3 to 7.0. The crystallization kinetics were significantly increased by 10–18-fold with rising concentrations of the IL from 25–100 g l−1. Crystallization equilibrium using 100 g l−1 of IL1.1 was reached as early as 5–8 h after the start. Clearly, reproducibility was poor. However, vapor-diffusion experiments, in general, do not yield good reproducibilities.

Exemplary microphotographs of tetragonal-like shaped lysozyme crystals during transient growth in sitting-drops used for the determination of the crystallization kinetics. 100 g N,N-dimethylethanolammonium glycolate (IL3) l−1, cLysozyme = 50 g l−1, cNaCl = 25 g l−1, 50 mM acetate buffer, pH = 6.2. (A) 1 h after start of experiment. (B) after 2 h (C) after 3 h (D) after 4 h

Exemplary time-courses of the normalized total cross-sectional crystal surface of sitting-drops using ethanolammonium formate (IL1.1). cLysozyme = 50 g l−1, cNaCl = 25 g l−1, 50 mM acetate buffer, pH = 6.3–7.0. Two independent experiments for each concentration level of IL. The required time to reach crystallization equilibrium is given in brackets. (A) 25 g l−1 □ (50 h); ● (146 h). (B) 62.5 g l−1 □ (26 h); ● (50 h). (C) 100 g l−1 □ (5 h); ● (8 h). The mean measurement error was 10%

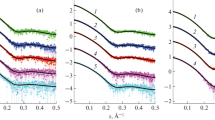

Figure 5 gives a comparison of the time-courses of the normalized total cross-sectional crystal surface of sitting-drops with and without the addition of ILs as crystallization additives. The fastest crystallization kinetics without the addition of ILs was measured using 30 g lysozyme l−1, 40 g NaCl l−1, and 50 mM acetate buffer at pH 4.0. The pH in the sitting-drop experiments with ILs using 50 mM acetate buffer varied from 5.2 to 7 due to the different basicity of the ILs. The fastest crystallization kinetics were observed with IL1.1 followed by IL3 and IL2, each with concentrations of 100 g l−1. The crystallization kinetics with IL4 were the slowest. For quantification, the parameter t90 was calculated from the experimental data. The results are presented in Table 4. The t90-reference value without addition of ILs was 22 h. The strongest advancement of the crystallization kinetics using ILs was achieved with 100 g IL1.1 l−1 where a 5.5-fold increase was observed. The t90-value for IL1.2 was not available because image processing of the fascicular structures was not possible. The addition of 100 g IL2 l−1 resulted in a 29% increase in crystal growth kinetics. The second strongest increase of the crystallization kinetics by 4.4-fold was achieved with 100 g IL3 l−1. Finally, a 31% deceleration of the crystallization kinetics was measured using 100 g IL4 l−1. This deceleration, however, yielded comparatively larger crystals.

Comparison of the time-courses of the normalized total cross-sectional crystal surface of sitting-drops with 50 mM acetate buffer with ILs (□; cLysozyme = 50 g l−1, cNaCl = 25 g l−1) and without ILs (●; cLysozyme = 30 g l−1, cNaCl = 40 g l−1, pH = 4.0). The required time to reach crystallization equilibrium is given in brackets. (A) 100 g l−1 IL1.1, pH = 7.0 (5 h). (B) 100 g l−1 IL2, pH = 6.2 (50 h). (C) 100 g l−1 IL3, pH = 6.2 (124 h). (D) 100 g l−1 IL4, pH = 5.2 (66 h). The mean measurement error was 10%

The results indicate that the kinetics of lysozyme crystallization were significantly enhanced by addition of water-soluble ionic liquids. ILs with “soft” anions like formate or glycolate were superior to ILs with “hard” anions like nitrate. Precipitation could be avoided reliably even at larger salt concentrations and crystal polymorphism was reduced compared to experiments without ionic liquids. Furthermore, the addition of ILs tended to result in larger crystals. Future investigations have to be performed in order to evaluate the removal of ionic liquids from the protein crystals. Here, according to Cvetkovic et al. (2005), the diffusive removal by simple washing of the crystals seems to be a possible promising way.

References

Basu SK, Govardhan CP, Jung CW, Margolin AL (2004) Protein crystals for the delivery of biopharmaceuticals. Expert Opin Biol Ther 4:301–317

Bergfors TM (ed) (1999) Protein crystallization: techniques, strategies, and tips. A laboratory manual. International University Line, Biotechnology Series, La Jolla

Cvetkovic A, Picioreanu C, Straathof AJJ, Krishna R, van der Wielen LAM (2005) Quantification of binary diffusion in protein crystals. J Phys Chem B 109:10561–10566

Garlitz LA, Summers CA, Flowers RA, Borgstahl GEO (1999) Ethylammonium nitrate: a protein crystallization reagent. Acta Cryst D 55:2037–2038

Howard SB, Twigg PJ, Baird JK, Meehan EJ (1988) The solubility of hen egg-white lysozyme. J Cryst Growth 90:94–104

Lange C, Patil G, Rudolph R (2005) Ionic liquids as refolding additives: N´-alkyl and N′-(ω-hydroxyalkyl) N-methylimidazolium chlorides. Protein Sci 14:2693–2701

Muschol M, Rosenberger F (1997) Liquid-liquid phase separation in supersaturated lysozyme solutions and associated precipitate formation/crystallization. J Chem Phys 107:1953–1962

Ranke J, Mölter K, Stock F, Bottin-Weber U, Poczobutt J, Hoffmann J, Ondruschka B, Filser J, Jastorffa B (2004) Biological effects of imidazolium ionic liquids with varying chain lengths in acute Vibrio fischeri and WST-1 cell viability assays. Ecotoxicol Environ Safety 58:396–404

Schmidt S, Havekost D, Kaiser K, Kauling J, Henzler H-J (2004) Kristallisation für die Aufarbeitung von Proteinen. Chem Ing Tech 76:819–822

Seddon KR (1997) Ionic liquids for clean technology. J Chem Technol Biotechnol 68:351–356

Song CE (2004) Enantioselective chemo- and bio-catalysis in ionic liquids. Chem Commun:1033–1043

Summers CA, Flowers RA (2000) Protein renaturation by the liquid organic salt ethylammonium nitrate. Protein Scie 9:2001–2008

Swatloski RP, Holbrey JD, Memon SB, Caldwell GA, Caldwell KA, Rogers RD (2004) Using Caenorhabditis elegans to probe toxicity of 1-alkyl-3-methylimidazolium chloride based ionic liquids. Chem Commun: 668–669

Wasserscheid P, Welton T (eds) (2002) Ionic liquids in synthesis. Wiley/VCH, Weinheim

Yang Z, Pan W (2005) Ionic liquids: green solvents for nonaqueous biocatalysis. Enzyme Microbial Technol 37:19–28

Znamenskiy V, Kobrak MN (2004) Molecular dynamics study of polarity in room-temperature ionic liquids. J Phys Chem B 108:1072–1079

Acknowledgements

The authors thank Lorenz Chatwell and Arne Skerra for valuable advices in the initial phase of the work. The authors also acknowledge the experimental contribution of Hannes Schmid.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hekmat, D., Hebel, D., Joswig, S. et al. Advanced protein crystallization using water-soluble ionic liquids as crystallization additives . Biotechnol Lett 29, 1703–1711 (2007). https://doi.org/10.1007/s10529-007-9456-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-007-9456-9