Abstract

Genetically improved farmed tilapia is increasingly getting popular in Bangladesh. It has high production potential. Its dominant production technology ranges from extensive to improved extensive particularly in the rural areas. This study estimates levels and determinants of farm-level technical efficiency of tilapia farmers of Bangladesh using stochastic frontier production function involving a model for technical inefficiency effects. Data from fifty tilapia farmers of Jessore district are used in the analysis. The mean technical efficiency level of the tilapia farmers is 78%, and thus, the farmers operate 22% below the frontier production. Inefficiency effect is significant, and age, education, income, culture length, pond age, pond depth, water colour and pond tenure, as a group, are significant determinants of technical inefficiency. By operating at full technical efficiency levels, tilapia yield can be improved from the current level of 7.36–8.96 tons per hectare. The decision to add or not to add inputs is sometimes taken arbitrarily and not based on technology requirement. There is a lack of understanding of the technology practices. Fisheries extension efforts are required for proper understanding of the technology practices, further adoption and spread. For promotion of tilapia production, quality feed and seed at affordable price needs to be ensured.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fisheries sector in Bangladesh currently contributes 4.64% (MoF, Ministry of Finance 2010) to the overall gross domestic product (GDP), 23% to the agricultural GDP and 5.10% to the foreign exchange earnings through export (Sarder 2007). It supplies about 63% of animal protein intake, and 12.8 million people of the country are directly or indirectly dependent on this sector for their livelihood. It is estimated that 73% of rural households are involved in some type of freshwater aquaculture on floodplains throughout the country (Mazid 1999). Income-generating opportunities for rural households are the most promising in the fisheries sector (MoP, Ministry of Planning 2005; DoF 2006). Aquaculture has the potential to provide new employment opportunities in the rural areas by increasing both self-employment and demand for hired labour (Karim et al. 2006).

Bangladesh is uniquely rich and diverse in water resources. Due to favourable climatic condition, the water bodies are highly productive, and aquaculture is an important commercially viable activity (DoF 2003). Bangladesh inland waters rank third after China and India in terms of fish biomass production (FAO 2000). The total fish production of the country in 2007–2008 is estimated at 2,563,296 ton. Inland open waters cover an area of 4,047,316 ha contributing 41.36% to the total fish production (DoF 2009) of the country. On the other hand, inland closed water constitutes only 528,390 ha but contributes 39.23% to the total fish production. Marine water accounts for 19.41% to the total fish production (DoF 2009). For the last two decades, growth of fish production from inland open waters has been very slow due to a variety of natural and man-made reasons. World Bank (1991), Lewis (1997), Planning Commission (1998) identified (1) overfishing caused by population pressure, (2) indiscriminate killing of juveniles and destruction of spawning grounds, (3) obstruction of migration routes, shrinkage of floodplain due to construction of irrigation structures, (4) siltation, (5) flood prevention control and (6) use of agrichemicals as the main reasons for declining inland openwater fish production. Aquaculture has been playing very significant role in providing fish supply since the mid eighties. Production growth rate is the highest in aquaculture. Several aquaculture technologies have been developed by the Bangladesh Fisheries Research Institute (BFRI) and the Department of Fisheries (DoF) of which culture of carp, prawn, exotic catfish, pangas and tilapia are important. Most fish farming practices follow extensive to improved-extensive practices. By making use of full potential of available water resources, technologies and higher inputs intensities, more fish production can be achieved from aquaculture.

GIFT is increasingly becoming popular not only in Bangladesh but also in the worldwide. It is the second most important cultured species in the world after carps. Price of the tilapia has been on the increase in Bangladesh. The species has good export market. Despite all these, tilapia production has flourished at a slower rate as compared to major Indian carps (ruhu, catla and mrigal) and silver carp. Tilapia shares only about 7% (DoF 2009) of the production of all ponds while major Indian carps share about 55%. The country has high potential for tilapia production as it can be grown in wide range of culture systems, including small-scale, low-input, rural ponds, semi-intensive, intensive and commercial operations (Chowdhury et al. 2007). Innumerable derelict ponds and household backyard ditches of the country can be utilised for tilapia production. More production of tilapia would mean more nutrition, more income for the farmers and more foreign exchange earning through export. Thus, fish farmers need to be familiar with the tilapia production technology and improve production efficiency so that its contribution to the economy is increased gradually.

Efficiency-oriented study on tilapia farming has been very limited in Bangladesh, although some studies on carps (Sharma and Leung 2000a; ICLARM 2001; Arjumanara et al. 2004) and prawn-carp (Alam and Jahan 2008), pangas (Alam 2011) are available. Dey et al. (2000a) made an investigation on the production and consumption status of tilapia of selected Asian countries including Bangladesh. Dey et al. (2000c) analysed the comparative performance of the GIFT strain on an average as well as on an efficient farm and assessed its nature in five Asian countries namely, Bangladesh, China, Philippines, Thailand and Vietnam. But none of these two studies has estimated the level of technical efficiency of the tilapia producers and examined the factors affecting inefficiency. It is with this backdrop, the present study is undertaken to investigate the technical efficiency and the factors affecting inefficiency in tilapia farming of Bangladesh. It is expected that the study would generate meaningful insights that fisheries extension personnel can use to disseminate knowledge gap to the tilapia farming community.

Tilapia farming and its status in Bangladesh

Tilapia has a long history of farming in Bangladesh. The Mozambique tilapia (O. mosambicus) was first introduced to Bangladesh from Thailand in 1954 (Ahmed et al. 1996). However, this species was not widely accepted for aquaculture because of its early maturation and prolifically breeding lead to overcrowd in ponds. The Chitralada strain of Nile tilapia (O. niloticus), a far superior farmed tilapia (faster growing and more manageable than the Mozambique tilapia), was then introduced to Bangladesh from Thailand by the UNICEF in 1974 (ADB, Asian Development Bank 2005). Nevertheless, Nile tilapia farming was slow to develop as most farmers were interested to grow carps (the most popular species in Bangladesh). Gradually, the red tilapia (hybrid of O. mossambicus x O. niloticus) was imported to Bangladesh from Thailand. The BFRI reintroduced Nile tilapia and red tilapia from Thailand in 1987 and 1988 (Gupta et al. 1992). GIFT was introduced to Bangladesh by International Centre for Living Aquatic Resource Management (ICLARM, currently WorldFish Center) and BFRI in 1994 (Hussain et al. 2000). Performance of GIFT was proved to be significantly superior to that of tilapia previously introduced. Technology is also developed to produce all male tilapia or sex-reversed GIFT locally known as mono-sex tilapia, because the male tilapia grow faster than females, and the unwanted reproduction, overcrowding and harvest of undersized fish are avoided (ADB, Asian Development Bank 2005).

The most small-scale tilapia farming use extensive to improved-extensive technology and therefore have low per unit productivity ranging from 1.5 to 2.0 tons per ha per year. On the contrary, many farmers in the urban periphery are practising commercial tilapia farming in several districts of the country. Productivity of these ponds is considerably high and the concerned are making a very good profit out of it. Rahman (2005) in his study in Mymensingh district showed productivity of tilapia pond operators is 8.82 tons per ha, and net return per Taka (Bangladesh currency) invested on tilapia farming is 1.25, which is very high compared to carps and pangas farming.

The peak season for tilapia farming is April–December, a culture period of around 9 months. Farmers stock their ponds from as early as April to May and harvest tilapia after 4 months, usually two crops per year. The most common supplementary feed for small-scale tilapia farming is a mixture of rice bran, wheat bran and mustard oil cake, those are readily available on-farm or in local markets (Ahmed and Ahmed 2009). Nevertheless, intensive or semi-intensive tilapia farming is primarily dependent upon industrially manufactured pelleted feed. In general, feed is given twice a day in the morning and evening. Framers also use fertilisers mainly cow-dung, urea and triple super phosphate for grow-out of tilapia.

Methodology

The stochastic production frontier and technical inefficiency model

Frontier techniques have been widely used in determining the farm-level efficiency in developing countries’ agriculture since the publication of a seminal article of Farrell (1957) on efficiency measurement and subsequent development of several approaches to efficiency and productivity measurement. The most basic method of technical efficiency (TE) estimation is to map a production frontier (statistically or non-statistically, parametrically or non-parametrically), find the locus of maximum output levels associated with given input levels and estimate farm-specific TE as a deviation from the fitted frontier. Among different major approaches followed to measure and estimate efficiency, the stochastic frontier production function (SFPF) approach involving econometric estimation of parametric function (Aigner et al. 1976, 1977; Meeusen and van den Broeck 1977) and non-parametric programming, known as data envelopment analysis (DEA) (Charnes et al. 1978), are the most popular. The stochastic frontier is considered more appropriate for assessing TE in developing countries’ agriculture, where the data are often heavily influenced by measurement errors and other stochastic factors such as weather conditions, diseases, etc. (Fare et al. 1985; Kirkly et al. 1995, 1998; Jaforullah and Devlin 1996; Coelli et al. 1998; Dey 2000; Dey et al. 2005). Several recent studies have applied stochastic frontier technique for determining efficiency in aquaculture in the developing Asian countries (Gunaratne and Leung 1996, 1997; Jayaraman 1998; Sharma and Leung 1998, 2000a, b; Iinuma et al. 1999; Sharma 1999; Sharma et al. 1999; Bimbao et al. 2000; Dey et al. 2005; Irz and McKenzie 2003; Chiang et al. 2004; Singh et al. 2009) and African countries (Ekunwe and Emokaro 2009; Kareem et al. 2008).

There are two approaches to analyse determinants of technical efficiency or inefficiency. A number of authors (Pitt and Lee 1981; Kalirajan 1981) have first estimated stochastic frontiers to predict firm-level efficiencies and then regressed these predicted efficiencies upon farm-specific variables (such as managerial experience, ownership characteristics and production conditions) in an attempt to explain variations in output between firms in an industry. This is usually referred to as a two-stage procedure. Several economists have, however, criticised this procedure (Battese et al. 1989; Kumbhakar et al. 1991; Reifschneider and Stevenson 1991; Battese and Coelli 1995) arguing that the socio-economic variables should be incorporated directly into the estimation of production frontier model because such variables may have a direct influence on the production efficiency. To overcome inconsistencies in the assumptions regarding the independence of inefficiency effects in this two-stage estimation procedure, Kumbhakar et al. (1991) and Reifschneider and Stevenson (1991) proposed a single-stage stochastic frontier model in which the inefficiency effects (u i ) are expressed as an explicit function of a vector of farm-specific variables and a random error. Nevertheless, in spite of the criticisms, many studies have used two-stage approach; Simar and Wilson (2007) have mentioned that about 800 published articles and working papers that have followed two-stage approach for measuring efficiency.

The SFPF for cross-sectional data can be specified as follows:

where Y i denotes the production for the ith farm (i = 1, 2, 3, …, n); X i is a (1 × k) vector of functions of input quantities used by the ith farm; β is a (k × 1) vector of unknown parameters to be estimated; the V i ’s are random variables assumed to be independently and identically distributed N(0, σ 2 v ) and are independently distributed of the technical inefficiencies U i ’s ; the U i ’s are non-negative random variables associated with technical inefficiency in production and are assumed to be independently distributed as truncations of the N(Z i δ, σ 2 u ) distribution.

Following Battese and Coelli (1995), U i ’s can be expressed as:

where Z i is a 1 × p vector of variables that may influence efficiency of a farm; δ is an p × 1 vector of parameters to be estimated; and W i ’s are the random variables defined by the truncation of the normal distribution with mean 0 and variance, σ 2 u , such that the point of truncation is −Z i δ, i.e. W i ≥ −Z i δ. These assumptions are consistent with U i being a non-negative truncation of the N(Z i δ, σ 2 u ) distribution (Battese and Coelli 1995).

The technical efficiency of production for the ith farm (TE i ) is defined as:

The prediction of the technical efficiencies is based on conditional expectation of expression in Eq. 3, given model assumptions.

Study areas and data

Cross-section data are used in the present study. A pre-tested questionnaire is used to collect information on tilapia farming. The data are generated from Jessore district of Bangladesh. A trained graduate student under the supervision of the first author conducted the survey. Fifty GIFT tilapia farmers are randomly selected from the list of farmers prepared by the first author in collaboration with the fisheries officer of the Department of Fisheries, Jessore district. Survey method is followed to collect information from the tilapia farmers. The survey was conducted during June 2008.

Sample characteristics

Table 1 presents the summary statistics of the relevant variables for the tilapia farmers and GIFT production. The table reveals that considerable variation exists among the farmers in terms of production practices and the socioeconomic attainments of the farmers. Stocking density (number of fingerling released per ha) and feed application are, respectively, 51,495 pieces and about 18 tons per ha, which appear to be quite high. The supplementary feed used for GIFT production is mostly a mixture of rice bran, wheat bran and mustard oil cake. However, use of industrially manufactured pelleted feed is also used in addition to the home made mixture The mean annual income of the GIFT farmers is 2,377 US$, ranging from a minimum of 526 US$ to as high as US$ 8,759. Education is in general very low. The mean yield of tilapia is 7.37 tons per hectare per annum (two cycles comprising 217 days) ranging from a minimum of 1.68 tons to as high as 19.09 tons. The average size of fingerling is 1.71 inch. Average pond size is 51 decimal (0.21 ha) ranging from 14 (0.06 ha) to 130 decimals (0.53 ha). It is to be mentioned that 16% and 22% ponds are of ≤20 and 21 ≤ 40 decimal sizes, respectively. Although intensity of inputs use varies across ponds, the overall technology practice is largely improved extensive (relying more on naturally food produced in the water body and some degree of supplementary inputs) to semi-intensive (relying mostly on supplementary feed and fertilizer).

The empirical model

Two of the most popular functional forms in the economics literature correspond to Cobb-Douglas (C-D) and the transcendental logarithmic (TL) functions. The first one is easy to interpret and estimate but imposes important restrictions on the technology such as scale and output elasticities that do not vary with input or output levels and substitution elasticities among inputs are all equal to unity. The translog on the other hand is a flexible form in the sense that it can provide a local, second order approximation to any function, but it is more difficult to estimate due to the large number of parameters and the attendant problem of multicollinearity among the regressors (Irz and Mckenzie 2003). We first specified a translog (TL) stochastic frontier model in this study that is then tested for Cobb-Douglas (CD) form to decide about the functional specification that best suits the data on the tilapia farming.

The TL SFPF model is specified as follows:

where subscript i refers to the ith tilapia farmer in the sample; X ji represents the amount of input j used by the tilapia farmer, Y is output variable; ln represents natural logarithm; β’s are unknown parameters to be estimated; V i’s and U i’s are random variables as defined earlier. Maximum-likelihood estimation of Eq. (4) provides the estimation for β’s and variance parameters, σ2 = σ 2 u + σ 2 v and \( \gamma = \frac{{\sigma_{u}^{2} }}{{\sigma^{2} }}. \) There is symmetry in input cross-effects by assuming β jk = β kj . Following Battese and Coelli (1995), it is further assumed that the technical inefficiency distribution parameter, U i , is a function of various operational and farm-specific variables hypothesised to influence technical inefficiencies as:

where, Z’s (Z A , Z E , Z I , Z L , Z G , Z D , Z W , Z T ) represents, respectively, age, education, annual gross income, length of tilapia farming, age of tilapia pond, depth of tilapia pond, water colour and pond tenure status of the farmer. The later two are dummy variables. δ’s are unknown parameters to be estimated. W i is a random variable as defined earlier. Different variables of the SFPF and the inefficiency function along with their definitions are presented in Table 2.

It should be noted that the technical inefficiency model in Eq. 5 can only be estimated if the technical inefficiency effects, U i ’s, are stochastic and have particular distributional properties (Coelli and Battese 1996). Therefore, it is of interest to test the null hypothesis that the technical inefficiency effects are absent, γ = δ 0 = δ A = ⋯ = δ T = 0, that technical inefficiency effects are non-stochastic, γ = 0, and that farm-specific factors do not influence the inefficiencies, δ A = ⋯ = δ T = 0; γ = 0; the stochastic frontier model reduces to traditional average function in which the explanatory variables in the technical inefficiency model are included in the production function. H0: γ = 0 implies the existence of a stochastic frontier. Similarly, γ = 1 implies that all the deviations from the frontier are due entirely to the technical inefficiency (Coelli et al. 1998).

These hypotheses as well as other related hypotheses are tested using the generalised likelihood-ratio statistic, λ, given by:

where L(H0) and L(H1) denote the values of likelihood function under the null (H0) and alternative (H1) hypotheses, respectively. If the null hypothesis is true, λ has approximately χ2-distribution or mixed χ2-distribution when the null hypothesis involves γ = 0 (Coelli 1995a, b).

Given the model specification, the technical efficiency index for the ith farm in the sample (TE i ), defined as the ratio of observed output to the corresponding frontier output, is given by:

The prediction of technical efficiencies is based on the conditional expectation of expression in Eq. 7, given the values of V i − U i evaluated at the maximum-likelihood estimates of the parameter of the SFPF (Battese and Coelli 1988). The frontier production for the ith farm can be computed as the actual production divided by the technical efficiency estimate. The parameters for the SFPF in Eq. 4 and those of the technical inefficiency model in Eq. 5 are estimated simultaneously using the maximum-likelihood (ML) estimation method, using the computer programme, FRONTIER 4.1 (Coelli 1994).

Results and discussion

Parameter estimates of the SFPF

The functional specification is tested first. Log-likelihood ratio test is applied to test the null hypothesis that the translog SFPF can be reduced to a C-D SFPF. The test statistic H0: β jk = 0, H1: β jk ≠ 0 has a likelihood-ratio value of 108.95, which implies a rejection of the null hypothesis at the 5% significance level. In other words, the TL is more suitable to the farm survey data that adequately captures the production behaviour of GIFT farmers of Bangladesh.

Maximum-likelihood (ML) estimates of the parameters in the TL SFPF model and those in the inefficiency model are presented in Table 3. Most of the first degree terms of the SFPF show positive algebraic signs. Fingerling size, labour, feed and fertilizers have not only positive signs but are also statistically significant at 5% level. Stocking density shows negative sign and is statistically significant, which is usually unexpected. It might behave otherwise if the number of fingerling stocked exceeds the biomass holding capacity of the ponds due to congestion. As we see, number of fingerling stocked per hectare is 51,495, which is fairly high. Rahman (2005) found the average tilapia stocking density to be 21,404 pieces per hectare. On the other hand, Chowdhury et al. (2007) found average annual stocking density of tilapia to be 24,700 per ha. Dey (2001) obtained higher production of tilapia at a stocking density of 20,000 per ha during 6 months culture period. On the basis of the profit, the optimum stocking density for GIFT is 30,000 per ha (Hussain et al. 2004). All these figures support that fingerlings in the GIFT ponds are overstocked. Some farmers have their own sources of fingerlings from where they might have stocked tilapia ponds. Therefore, the possibility of dumping more fingerlings cannot be ruled out. Under that circumstance, stocking density might show a different and unexpected sign.

Pond size may have some influence on production of output. We encountered a negative sign for the pond size, which is significant. Whether small ponds are more productive or not is still in dilemma. No definite answer is established as yet. Rahman (2005) found the medium sized pond having the highest yield. The small ponds get intensively input-fed since addition of a small quantity of inputs adds very little to the overall cost that is not usually felt burdened. However, this small addition of inputs might get proportionately higher than the pond size requires. It is likely that this might have happened beyond the knowledge of the farmers. On the contrary, larger pond owners/operators also seldom add inputs proportionately with the pond size because costs associated with the inputs application for bigger ponds are high. Therefore, they are likely to add proportionately less than the pond size requires. This feeling often results in proportionately higher input feeding for smaller ponds and lower for larger ponds. This is the general scenario in particularly the improved-extensive pond fish culture system under the existing economic setting of the farmers. Appearance of a negative sign for the coefficient of pond size is therefore not surprising.

Parameter estimates of the inefficiency function

Since the dependent variable of the inefficiency model, Eq. 5, is defined in terms of technical inefficiency, a farm-specific variable associated with the negative (positive) coefficient will have a positive (negative) impact on technical efficiency. Age of operator, culture length and green water colour of the pond water appear as significant factors and have positive impact on technical efficiency (negative impact on technical inefficiency). Pond tenure, water depth, pond age and education do not seem to have any effect on technical efficiency individually as they are all statistically insignificant. Income has a negative and significant effect on technical efficiency (positive effect of technical inefficiency) of the operators suggesting that inefficiency is higher for those pond owners/operators who have higher income. This might be so because of their preference to invest in non-aquaculture or to non-tilapia species.

The γ-parameter associated with the variance in the stochastic production frontier model is estimated to be close to one and highly significant. Although the γ-parameter cannot be interpreted as the proportion of the total variance explained by the technical inefficiency effects, the result indicates that technical inefficiency effects do make a significant contribution to the level and variation of tilapia production in Bangladesh.

Hypotheses tests for γ and δ-parameters

Generalised likelihood-ratio tests of various null hypotheses involving restrictions on variance parameter, γ in the stochastic production frontier and δ-coefficients in the technical inefficiency model are presented in Table 4. The first null hypothesis H0: γ = δ 0 = δ A = ⋯ = δ8T = 0 is regarding the existence of inefficiency factor. If H0: γ = δ 0 = δ A = ⋯ = δ T = 0 is accepted, then there is no inefficiency in the tilapia production. However, a significant log-likelihood ratio test value of 40.84 with 10 degrees of freedom rejects the H0 and implies the existence of inefficiency across the tilapia farmers establishing that average response function estimated by OLS that assumes all growers are technically efficient is not an adequate representation of data, given the specification of TL stochastic frontier and inefficiency model (Table 4). This leads to conclude that indeed there is an inefficiency effect associated with the tilapia production.

The second null hypothesis H0: δ A = ⋯ = δ T = 0 implies that technical inefficiency effects follow a standard truncated normal distribution (Stevenson 1980) as the null hypothesis is rejected at 5% level of statistical significance. The rejection of null hypothesis indicates that the farm-specific variables involved in the technical inefficiency model contribute significantly as a group to the explanation of the technical inefficiency effects in tilapia production although, based on asymptotic t ratios, some slope coefficients are not significant individually. Dey et al. (2000b) and Sharma and Leung (1998) also observed similar findings in their studies. The third null hypothesis, H0: δ 0 = δ A = ⋯ δ T = 0, suggests on the other hand that technical inefficiency follow a half-normal distribution originally proposed by Aigner et al. (1977). Both these hypotheses are rejected at 5% significance level suggesting that, given the stochastic frontier with the model for technical inefficiency effects, the standard stochastic error component model is not appropriate for both half-normal and truncated normal distribution. The fourth null hypothesis calls for testing if stochastic technical inefficiency exists. This test is also rejected at 5% level of significance establishing that stochastic inefficiency does exist (Table 4). Hypothesis five to twelve are for testing the individual effect on the inefficiency function. And all of these individual tests are rejected at 5% statistical significance level (Table 4).

Technical efficiency distribution

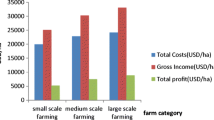

The mean technical efficiency of the tilapia farmers in Bangladesh is 78% ranging from 45.76 to 99.98%. Surprisingly, not a single farm appears as fully technically efficient. This level of mean TE score implies that GIFT farmers are operating 22% below the frontier production given the level of technology. About 32% farmers have technical efficiency scores ranging between 70 and 80% while 28% operate between 90 and 99% level. About 10% farmers operate at less than 60% level of technical efficiency level (Fig. 1). This mean TE level of GIFT farmers appears to be higher than some other species in Bangladesh. Sharma and Leung (2000a) found the TE of carp polyculture to be 47.5% for extensive culture and 73.8% for semi-intensive culture. ICLARM (2001) estimated the TE of carp polyculture at 70% while that of Arjumanara et al. (2004) found TEs of 61, 69 and 86% for different groups of carp farmers. However, TE of tilapia farming in other countries appeared to be higher than that found in Bangladesh. Studies on Philippines conducted by Dey et al. (2000b) and Bugarin and Bayacag (2007) estimated the TE of tilapia to be 83%, while the same conducted in Taiwan found the TE to be 81% (Chiang and Huang 2008).

Conclusions and policy implications

Tilapia farming has not yet widely spread in Bangladesh. The general practice is largely dominated by extensive to improved-extensive method particularly in the rural ponds. However, improved extensive to semi-intensive practices are common in culture method in urban areas and commercial farms. The culture practice of the sampled farm is largely improved extensive to semi-intensive. The mean culture period of GIFT is 216 days in two cycles. Average yield of tilapia is 7.3 tons per ha. Fingerling size, labour, feed and fertilizers are significant factors contributing positively to the production of tilapia. Age of operator, education, income, culture length, green water colour, culture length, pond age, pond depth and pond tenure, as a group, are significant determinants of technical inefficiency. Although the mean TE of the tilapia farmers is 78%, it implies that per hectare yield can be increased by 22% with the existing technology. Thus, given the levels of existing technologies and resource use, the sample farms could increase their average yield from the existing 7.36 to 8.98 ton/ha by using their existing resources more efficiently.

The study reveals that level of understanding of GIFT technology is different across farmers particularly in terms of inputs application. The decision to add or not to add inputs must not be arbitrary. It has to be judicious. Monetary and psychological factor must not constrain the decision to allocate inputs. Rather, the philosophy should be to add input if it is needed. This fact needs to be disseminated to the fish farmers. The farmers need to know more about the GIFT production technology. Department of fisheries can play a very vital role in improving technical efficiency of the GIFT farmers through better extension on stocking, feeding and fertilising ponds. Demonstrations showing effect of variable stocking, feeding, and fertilising may make many wrong beliefs/practices clear, which may help improve fish production. To enable the farmers to make intensive use of inputs, quality fish feed and seed need to be provided at affordable prices.

References

ADB, Asian Development Bank (2005) An impact evaluation of the development of genetically improved farmed tilapia and their dissemination in selected countries. Operations Evaluation Department, Asian Development Bank, Manila, p 124

Ahmed N, Ahmed S (2009) Development of tilapia marketing systems in Bangladesh: potential for food supply. Final report CF#8/07. National Food Policy Capacity Strengthening Programme of the FAO, Dhaka

Ahmed M, Bimbao MP, Gupta MV (1996) Economics of tilapia aquaculture in small water bodies in Bangladesh. In: Pullin, RSV, Lazard J, Legendre M, Amon Kothias JB, Pauly D (eds) The third international symposium on Tilapia in aquaculture. ICLARM conference proceedings, vol 41, pp 471–475

Aigner DJ, Amemiya T, Porier DJ (1976) On the estimation of production frontiers: maximum likelihood estimation of the parameters of a discontinuous density function. J Econom 17(2):377–396

Aigner DJ, Lovell CAK, Schimidt P (1977) Formulation and estimation of stochastic frontier production models. J Econom 6:21–37

Alam MF (2011) Measuring technical, allocative and cost efficiency of pangas (Pangasius hypophthalmus: Sauvage 1878) fish farmers of Bangladesh. Aquac Res 42:1487–1500

Alam MF, Jahan KM (2008) Resource allocation efficiency of the prawn-carp farmers of Bangladesh. Aquac Econ Manag 12(3):188–206

Arjumanara L, Alam MF, Rahman MM, Jabber MA (2004) Yield gaps, production losses and technical efficiency of selected groups of fish farmers in Bangladesh. Ind J Agric Econ 59(4):806–818

Battese GE, Coelli TJ (1988) Prediction of firm-level technical efficiencies with a generalized frontier production function and panel data. J Econom 38(3):387–399

Battese GE, Coelli TJ (1995) A model of technical inefficiency effects in a stochastic frontier production function for panel data. Empir Econ 20:325–332

Battese GE, Coelli TJ, Colby TC (1989) Estimation of frontier production functions and the efficiencies of Indian farms using panel data from ICRISAT’s village level studies. J Quant Econ 5:327–348

Bimbao GB, Paraguas FJ, Dey MM, Eknath AE (2000) Socio-economics and production efficiency of tilapia hatchery operations in the Philippines. Aquac Econ Manag 4(1&2):31–46

Bugarin JB, Bayacag PG (2007) Production Efficiency and marketing practices of Tilapia in lake Sebu, South Cotabato, Philippines. Res Je USM Grad School 9:62–70

Charnes A, Cooper WW, Rhodes E (1978) Measuring the efficiency of decision-making units. Eur J Oper Res 2(4):429–444

Chiang F-S, Huang W-R (2008) A technical efficiency analysis of tilapia production in Taiwan using log book data. World aquaculture society meeting abstract, 2008

Chiang F-S, Sun C-H, Yu J-M (2004) Technical efficiency analysis of milkfish (Chanos chanos) production in Taiwan—an application of the stochastic frontier function. Aquaculture 230:99–116

Chowdhury MAK, Bureau DP, Bose ML, Dey MM (2007) Relevance of a rapid appraisal approach to identify locally available feed ingredients to small-scale Nile tilapia (Oreochromis niloticus L.) aquaculture. Aquac Econ Manag 11:151–169

Coelli TJ (1994) A guide to FRONTIER version 4.1: a computer programme for stochastic frontier production and cost function estimation. Department of Econometrics, University of New England, Armidale

Coelli TJ (1995a) Recent development in frontier modelling and efficiency measurement. Aust J Agric Econ 39(3):215–245

Coelli TJ (1995b) Estimators and hypothesis tests for a stochastic frontier function: a Monte Carlo analysis. J Prod Anal 6:247–268

Coelli TJ, Battese GE (1996) Identification of factors which influence the technical efficiency of Indian farmers. Aust J Agric Econ 40(2):103–128

Coelli TJ, Rao DSP, Battese GE (1998) An introduction to efficiency and productivity analysis. Kluwer, Boston, p 275

Dey MM (2000) The impact of genetically improved farmed Nile tilapia in Asia. Aquac Econ Manag 4(1&2):107–124

Dey MM (2001) Tilapia production in South Asia and Far East. In: Subasinghe S, Singh T (eds) Tilapia: production, marketing and technological development. International technological and trade conference on Tilapia, 28–30 May 2001, Kuala Lumpur, Malaysia, pp 17–26

Dey MM, Bimbao GB, Yong L, Regaspi P, Kohinoor AHM, Pongthana N, Paraguas FJ (2000a) Current status of production and consumption of tilapia in selected Asian countries. Aquac Econ Manag 4(1):13–31

Dey MM, Eknath AE, Sifa Li, Hussain MG, Thien TM, Hao NV, Aypa S, Pongthana N (2000b) Performance and nature of genetically improved farmed tilapia: a bioeconomic analysis. Aquac Econ Manag 4(1):83–106

Dey MM, Paraguas FJ, Bimbao GB, Regaspi PB (2000b) Technical efficiency of tilapia grow-out pond operations in the Philippines. Aquac Econ Manag 4(1&2):49–63

Dey MM, Paraguas FJ, Sricantuk N, Xinhua Y, Bhatta R, Dung LTC (2005) Technical efficiency of freshwater pond polyculture production in selected Asian countries: estimation and implication. Aquac Econ Manag 9(1&2):39–63

DoF (2003) Sharonika, Matshya Pakha 2003 (in Bengali). Department of Fisheries, Ministry of Fisheries and Livestock, Government of the People’s Republic of Bangladesh, Dhaka, p 134

DoF (2006) National fisheries strategy and action plan for the implementation of the national fisheries strategy. Department of Fisheries, Ministry of Fisheries and Livestock, Dhaka

DoF (2009) Fisheries statistical yearbook of Bangladesh 2007–08, vol 25, no 1. Fisheries Resources Survey System, Department of Fisheries, Bangladesh, Dhaka

Ekunwe PA, Emokaro CO (2009) Technical efficiency of catfish farmers in Kaduna, Nigeria. J Appl Sci Res 5(7):802–805

FAO (2000) Small ponds make a big difference: integrated fish with crop and livestock farming. Food and Agriculture Organization of the United Nations, Rome, p 142

Fare R, Grosskopf S, Lovell CAK (1985) The measurement of efficiency of production. Kluer-Nijhoff Publishing, Boston

Farrell MJ (1957) The measurement of productive efficiency. J R Stat Soc Series A 120(III):253–281 (part 30)

Gunaratne LHP, Leung PS (1996) Asian black tiger shrimp industry: a productivity analysis. Paper presented at the 2nd Biennial George productivity workshop, University of Georgia Athens, Georgia, 1–13 Nov 1996. In: Leung PS, Sharma KR (eds) (2001) Economics and management of shrimp and carp farming in Asia: a collection of research papers based on the ADB-NACA farm performance survey. Network of Aquaculture Centers in Asia pacific, Bangkok, Thailand, pp 55–68

Gunaratne LHP, Leung PS (1997) Productivity analysis of Asian shrimp industry: The case of Malaysian shrimp culture. World Aquaculture’97, Book of abstracts, World aquaculture 1997, Seattle, WA. 19–23 Feb, p 188

Gupta MV, Ahmed M, Bimbao P, Lightfoot C (1992) Socio-economic impacts and farmers’ assessment of Nile tilapia (O. niloticus) culture in Bangladesh. ICLARM technical report no. 35, p 50

Hussain MG, Kohinoor AHM, Islam MS, Mahata SC, Ali MZ, Tanu MB, Hossain MA, Mazid MA (2000) Genetic evaluation of GIFT and existing strains of Nile tilapia, Oreochromis niloticus under on-station and on-farm conditions in Bangladesh. Asian Fish Sci 13:117–126

Hussain MG, Kohinoor AHM, Islam MS, Mazid MA (2004) Status and potential of tilapia production in Bangladesh, paper presented at the Tilapia farming in Bangladesh: constraints and potentials, 4–5 Apr 2004. Mohakhali, Dhaka

ICLARM (2001) Genetic improvement of carp species in Asia: final report. Asian Development bank regional technical assistance no. 57111. WorldFish Center, Penang

Iinuma M, Sharma KR, Leung PS (1999) Technical efficiency of carp pond culture in peninsula Malaysia: an application of stochastic frontier and technical inefficiency model. Aquaculture 175:199–213

Irz X, Mckenzie V (2003) Profitability and technical efficiency of aquaculture systems in Pampanga, Philippines. Aquac Econ Manag 7:195–211

Jaforullah M, Devlin NJ (1996) Technical efficiency in the New Zealand dairy industry: a frontier production function approach. N Z Econ Paper 30:1–17

Jayaraman R (1998) Economics and technical efficiency in carp culture in Thanjavur district in Tamil Nadu, India. In: Eide A, Vassadal T (eds) Proceedings of the 9th international conference of the international institute of fisheries economic and trade, Tromso, 8–11 July, pp 77–82

Kalirajan K (1981) An econometric analysis of yield variability in paddy production. Can J Agric Econ 29:283–294

Kareem RO, Dipeolu AO, Aromolaran AB, Akegbejo S (2008) Analysis of technical, allocative and economic efficiency of different pond systems in Ogun State, Nigeria. Afr J Agric Res 3:246–254

Karim M, Ahmed M, Talukder RK, Taslim MA, Rahman HZ (2006) Dynamic agribusiness-focussed aquaculture for poverty reduction and economic growth in Bangladesh. The WorldFish Center discussion series no. 1. WorldFish Center, Penang

Kirkly JE, Squires D, Strand IE (1995) Assessing technical efficiency in commercial fisheries: the mid-Atlantic sea scallop fishery. Am J Agric Econ 77(3):686–697

Kirkly JE, Squires D, Strand IE (1998) Characterizing managerial skill and technical efficiency in fishery. J Prod Anal 9(2):145–160

Kodde DA, Palm EC (1986) Wald criteria for jointly testing equality and inequality restrictions. Econometrica 54(5):1243–1248

Kumbhakar SC, Ghosh S, McGuckin JT (1991) A generalized production frontier approach for estimating the determinants of inefficiency in US dairy farms. J Bus Econ Stat 9(3):279–286

Lewis D (1997) Rethinking aquaculture for resource poor farmers: perspective from Bangladesh. Food Policy 22(6):533–546

Mazid MA (1999) Developmental needs and research priorities for fisheries in Bangladesh. In: Gupta MV, Macawaris-Ele N (eds) Priorities in aquatic resources research in the Asia-pacific region. ICLARM conference proceedings, vol 62, Manila, Philippines

Meeusen W, van den Broeck J (1977) Efficiency estimation from Cobb-Douglas production function with composed errors. Int Econ Rev 8:435–444

MoF, Ministry of Finance (2010) Bangladesh economic survey 2009. Finance Division, Ministry of Finance, Government of the People’s Republic of Bangladesh, Dhaka

MoP, Ministry of Planning (2005) Unlocking the potential: national Strategy for accelerated poverty reduction, provisional final draft. Planning Commission, Ministry of Planning, Government of the People’s Republic of Bangladesh, Dhaka

Pitt MM, Lee MF (1981) Measurement and sources of technical inefficiency viewpoint in the Indonesian weaving industry. J Dev Econ 9(1):43–64

Planning Commission (1998) Fifth-five year plan, 1997–2002. Planning Commission, Government of the People’s Republic of Bangladesh, Dhaka

Rahman MA (2005) Profit efficiency of tilapia monoculture in Trishal Upazila of Mymensingh district. Unpublished Masters thesis, Bangabandhu Sheikh Mujibur Rahman Agricultural University, Gazipur, Bangladesh

Reifschneider D, Stevenson R (1991) Systematic departures from the frontier: a framework for the analysis of firm inefficiency. Int Econ Rev 32:715–723

Sarder R (2007) Freshwater Fish Seed resources in Bangladesh, pp 105–128. In: Bondad-Reantaso MG (ed) Assessment of freshwater fish seed resources for sustainable aquaculture. FAO fisheries technical paper. no. 501, Rome, FAO, 2007, p 628

Sharma KR (1999) Technical efficiency of carp production in Pakistan. Aquac Econ Manag 3(2):131–141

Sharma KR, Leung PS (1998) Technical efficiency of carp production in Nepal: an application of the stochastic frontier production function approach. Aquac Econ Manag 2(3):129–140

Sharma KR, Leung PS (2000a) Technical efficiency of carp pond culture in south Asia: an application of a stochastic meta-production frontier model. Aquac Econ Manag 4(3&4):169–189

Sharma KR, Leung PS (2000b) Technical efficiency of carp production in India: a stochastic frontier production function analysis. Aquac Res 31(12):937–948

Sharma KR, Leung PS, Zaleski HM (1999) Technical, allocative and economic efficiencies in swine production in Hawaii: a comparison of parametric and non-parametric approaches. Agric Econ 20(1):23–35

Simar L, Wilson PW (2007) Estimation and inference in two-stage, semi-parametric models of production processes. J Econom 136(1):31–64

Singh K, Dey MM, Rabbani AG, Sudhakaran PO, Thapa G (2009) Technical efficiency of freshwater aquaculture and its determinants in Tripura, India. Agric Econ Rev 22:185–195

Stevenson RE (1980) Likelihood functions for generalized stochastic frontier estimation. J Econometrics 13(1):57–66

World Bank (1991) Bangladesh fisheries sector review. Report #8830-BD. Agriculture Operations Division, Asia country department 1, Dhaka, Bangladesh

Acknowledgments

The authors wish to thank the graduate student who collected the data from the field. We are grateful to the officers, Department of Fishery, Jessore for assisting us in preparing the list of tilapia farmers. The farmers are highly acknowledged for their cooperation in providing the data. The authors are grateful to anonymous referees for providing valuable comments and suggestions to improve the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alam, M.F., Khan, M.A. & Huq, A.S.M.A. Technical efficiency in tilapia farming of Bangladesh: a stochastic frontier production approach. Aquacult Int 20, 619–634 (2012). https://doi.org/10.1007/s10499-011-9491-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10499-011-9491-3