Abstract

Turmeric farming in slash and burn areas of Bangladesh plays an important role for generating cash income. This paper estimates technical efficiency of turmeric farmers in the slash and burn areas of Bangladesh and identifies sources of inefficiency using survey data obtained from 150 farmers over 6 villages throughout 2014/2015 growing season. Turmeric farming displayed much variability in technical efficiency ranging from 18 to 96% with mean technical efficiency of 84%, which suggested a substantial 16% of potential output of turmeric can be recovered by removing inefficiency. Besides improving technical efficiency, potential also exists for raising turmeric production through intensive training and extension services. For a land scarce country like Bangladesh this gain could help increase income and ensure better livelihood for the hilly farmers. The key policy implication of the analysis is that investment in training and extension service would greatly improve technical efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Shifting cultivation (Jhum) used to be a special kind of agricultural practice on sloppy hills. In the Chittagong Hill Tracts (CHT) of Bangladesh, shifting cultivation has been practiced from long time. Seventy-three percent of the land of CHTs is used only for forest (Forestal 1966) in which shifting cultivation is practiced. It involves clearing of forest land by slashing and burning followed by cultivation of crops about 15–20 years before shifting to another forest patch. Due to high population pressure the fallow period is reduced 3–4 years and the practice is no longer viable for sustainable agriculture as allowing very little time for soil regeneration (Riessen 2000).

Shifting cultivation and its associated fires destroyed about two-third of the existing forests of CHTs (Farid and Husain 1988), which accelerated soil erosion (Shoaib et al. 1998). This technique not only affects the soil of the cultivated land but also surrounding environments of such cultivated land. As a result, it is considered as primitive, backward, wasteful, unproductive, and exploitative as well as cause of widespread environmental degradation (Thomas 1956).

But shifting cultivation is not as alarming as often posed (Hossain 2011). Because it causes least disturbance to soil, build up natural fertility through remains of mixed cropping (rice, maize, sesame, cotton, beans, cucumber, chilies, yam, turmeric, ginger, banana, etc.) on moderate to steep slopes with minimum tillage under rained condition depending on local resources (Sharma 1976). Ramakrishna (1992) studied economics and efficiency of shifting agriculture and argued that the economic and energetic efficiency of shifting cultivation is higher than alternative forms of agriculture such as terrace and valley cultivation.

Therefore, shifting cultivation is an adaptive forest management practice predicated on sound scientific principles that productively uses hill and mountain lands, conserves forest, soil and water resources, and is ecologically preferable to alternative agricultural and forestry activities. Bangladesh is among the countries with least forest areas (only 11.2% of the total land area) (Asian Development Bank 2016). But this forest area is shrinkage day by day due to high population pressure and demand for food. Therefore, shifting cultivation can be considered as alternative technique to produce crops in forest area by preserving forest and increasing crop productivity.

In traditional shifting cultivation, land is denuded and exposed to degradation forces like water erosion, land slide, etc. In new planting approach keeps the land covered and obstructs speedy run off and thereby restricts water erosion and landslide. Therefore, new shifting cultivation is environmental friendly and it is started by slashing vegetation during January–February. The dry vegetation is burnt and the hill is cleaned for sowing seeds in April–May. After the start of the first rains in April–May, they dibble different crop seeds in holes, while simultaneously using the hoe.

Turmeric can be a good source to generate cash income for shifting cultivation areas people of Bangladesh as its production requires low technology, less capital investment, and it can be grown with comparatively less use of fertilizer which conserve ecosystem. The sloppy topography of hilly region and the nature of soil are optimal for turmeric cultivation. The sustainability of hill agriculture depends on promoting productivity by improving management practices and conserving hill resources. Alongside researchers and policy makers have greatly emphasized on adoption of new technologies for increasing farm productivity and income (Hayami and Ruttan 1985; Kuznets 1966). However, during the last decade, attention to productivity gains arising from a more efficient use of existing technology is justified (Bravo-Ureta and Pinheiro 1993, 1997; Squires and Tabor 1991).

Production gain can be achieved without requiring additional conventional inputs and without the need for new technologies. In that case, empirical measures of efficiency are necessary in order to determine the magnitude of the gain that could be obtained by improving performance in production with a given technology. Policy implication stemming from significant levels of inefficiency is that it might be more cost effective to achieve short run increases in farm output, and thus income, by concentrating on improving efficiency rather than introducing new technologies (Belbase and Grabowski 1985; Shapiro and Muller 1977).

Developing economy of Bangladesh can benefit a great deal from inefficiency studies, which shows that it is still possible to raise productivity by improving efficiency. It is important to know how well the resources are being utilized and what possibilities exist for improving the production using the existing resources and technology (Ahluwalia 1996). The present study sets out to analyse technical efficiency of turmeric farmers in the slash and burn region of Bangladesh, and to identify farm specific characteristics that explain variation in efficiency of individual farmers. An understanding of these relationships could provide the policy makers with information to design progress that can contribute to measures needed to expand the productivity potential of the nation.

Methodology

Analytical framework

Farrell (1957) seminal paper has brought new avenue in methodologies and their applications to efficiency measurement. The early methodologies were based on deterministic models that attribute all deviations from the maximum production to efficiency. The recent methodologies have made it possible to separately account for factors beyond and within the control of firms that cause inefficiency. The popular approach to measure the technical efficiency components is the use of frontier production function (Wadud and White 2000; Sharma et al. 1999; Battese and Coelli 1995). Aigner et al. (1977) and Meeusen and Van Den Broeck (1977) independently applied the stochastic frontier production function to account for the presence of measurement errors and other noise in the data, which are beyond the control of firms. Stochastic frontiers have two errors: the presence of technical inefficiencies in production and the measurement errors in output, weather, etc. and the combined effects of unobserved inputs in production.

In the literature of the efficiency measurement, the predicted efficiency indices were regressed against a number of farm characteristics, in an attempt to explain the observed differences in efficiency among farms, using a two stage procedure. Although this exercise has been recognized as a useful tool, it has also been recognized as an inconsistent in its assumptions regarding the independence of the inefficiency effects.

Coelli (1996) and Battese and Coelli (1995) extended the stochastic production frontier model by suggesting that the inefficiency effects can be expressed as a linear function of explanatory variables, reflecting farm specific characteristics. The advantage of this model is that it allows estimation of the farm specific efficiency scores and the factors explaining efficiency differentials among farmers in a single stage estimation procedure (Rahman 2003) which is utilized in this paper.

Data collection

The study was carried out in Khagrachhari district which is one of the major turmeric growing districts in Bangladesh. It accounted for 8.9% of the total turmeric area. A stratified random sample was constructed by dividing the district into Upazila and village. Among the eight Upazilas of Khagrachhari district, Khagrachhari Sadar, Matiranga and Panchhari were selected as strata. In 2010–2011, a total of 2039 acres of land was cultivated for turmeric in these Upazilas which is around 41% of cultivated area of turmeric in Khagrachhari district (BBS 2013). Within each of these three Upazilas, two villages were randomly selected based on a complete list of villages. Within each village 25 households were randomly selected from the list. This procedure gave a total sample of 150 households involved in turmeric production in Khagrachhari district.

The data for this study were collected both from primary and secondary sources. The primary data were collected from the selected farmers for the whole year of 2014. The formal data, however, were collected during January 2015 by using face to face interview technique.

A summary values of the variables used in the analysis is presented in Table 1. The table shows that considerable variation exists among the farmers in terms of production practices and the socioeconomic attainments. The average farm size was 1.39 ha ranging from 0.11 to 9.07 ha.

Seed (rhizome) has a major impact on production and the profitability of turmeric farm. Farmers hand-pick the best turmeric and preserve it as seeds for the next season. They also purchase from other farmers if they need additional seeds to available own stocks. Since farmers produce turmeric as a mixed crop in Jhum lands they do not take into account the exact size of the land to determine the volume of seeds required. The average annual application of seed of turmeric was 634.08 kg/ha which has considerable variation of turmeric farmers used. This finding is in line with the findings by Karna et al. (2010).

Fertilizer application is not based on the need of the soil, but rather on common practice. Except for some commercial production, most of the turmeric is produced by traditional farming practices where the farming knowledge derived from forefathers is used with no or less application of chemical fertilizer. On average, annual fertilization rate was 177.97 kg/ha ranging from nil to 975.03 kg/ha in turmeric farm.

The average labour use is 156.76 man-days/ha ranging from 26.67 man-days/ha to 475.31 man-days/ha. For the land preparation male labour were used. Mostly female labours were working for hoeing and weeding.

The average age of farmers is 40 years ranging from 20 to 83 years in turmeric farming. Average general education level is seemed to be level of primary ranging from illiterate to 14 years. The average experience of farmers is 11 years ranging from 1 to 42 years in turmeric farming.

Empirical model

Despite its limitations, this paper uses a Cobb–Douglas functional form to specify the stochastic production frontier. In fact, Taylor et al. (1986) argued that as long as interest rests on efficiency measurement and not on the analysis of the general structure of the production technology, the Cobb–Douglas production function provides an adequate representation of the production technology. For this reason Cobb–Douglas functional form has been widely used in farm efficiency analysis both in developing and developed countries (Battese 1992; Bravo-Ureta and Pinheiro 1993). The specific model estimated is given by:

where \(Y\) denotes production level, \(X_{i}\) is input level and \(\beta\) is a vector of unknown parameters to be estimated. \(\varepsilon_{i}\) is the composed error term and \(f\) is the Cobb–Douglas function form. \(V_{i}\) are independently and identically distributed random errors, having \(N\) (0, \(\delta v^{2}\)) distribution while \(U_{i}\) are non-negative stochastic variables, called technicalin efficiency effect, associated with the technical inefficiency of production of farmers involved. According to Battese and Coelli (1995), technical inefficiency effects are defined by

where Zi is a vector of explanatory variables associated with technical inefficiency effects, \(\delta\) is a vector of unknown parameters to be estimated, \(W_{i}\) are unobservable random variables, which are assumed to be identically distributed, obtained by truncation of the normal distribution with mean zero and unknown variance \(\sigma^{2}\), such that \(U_{i}\) are non-negative.

The stochastic frontier technique can only handle one single output. The following model specifications were used in the analysis

where \({ \ln }\) represents the natural logarithm (i.e., to the base e) and i refers to the ith farm in the sample; \(Y_{i}\) represents yield kg/ha; \(X_{1i}\) represents the farm size in hectares; \(X_{2i}\) represents the total quantity of labour employed in man-days per hectare per year; \(X_{3i}\) represents total number of turmeric seed (rhizome) per hectare per year; \(X_{4i}\) represents quantity of fertilizer used in kg per hectare per year; \(V_{i}\) represents the random variations in output due to factors outside the control of the farm operator such as: natural disaster, disease of turmeric etc. \(\beta_{1} - \beta_{4}\) are parameters to be estimated;

Following Battese and Coelli (1995), it is further assumed that the technical inefficiency distribution parameter, Ui is a function of various operational and farm specific variables hypothesized to influence technical inefficiencies as:

where \(Z_{1i}\) denotes the age of the ith farmer (in year); \(Z_{2i}\) denotes the education (year of schooling) of the ith farmer; \(Z_{3i}\) denotes experience in turmeric farming of the ith farmer (in years) \(Z_{4i}\) denotes the training received by the ith farmer (1 if received, 0 otherwise); \(Z_{5i}\) denotes farm visits by extension officers (1 if yes, 0 otherwise); \(\delta_{1}\), \(\delta_{2}\), \(\delta_{3}\), \(\delta_{4}\), and \(\delta_{5}\) are unknown parameters to be estimated.

Results and discussion

The maximum likelihood estimates (MLE) of the parameters of Cob–Douglas stochastic frontier function defined by Eq. (4), given the specifications for the inefficiency effects defined by Eq. (5), estimates of the model were obtained using maximum likelihood procedures by using FRONTIER 4.1 (Coelli 1996). The estimates of the stochastic frontier which measures the proportional change in output when all inputs included in the model are changed in the same proportion is presented in Table 2. The function coefficient for the MLE is about 0.57, which indicates that returns to scale is decreasing. The null hypothesis of constant return to scale was tested by using restricted least squares regression model. The computed F statistic is 4.31 which exceed the critical F value of 3.84 at 5% level of significance. The result indicates that the null hypothesis constant return to scale was rejected.

The efficiency effects jointly estimated with the production frontier function are not simply random errors. This is shown by the γ = σμ2/(σν2 + σμ2) which ranged the value between zero and one, where if γ = 0, inefficiency is not present and if γ = 1, there is no random noise (Battese and Coelli 1995). The estimated value is close to 1 and is significantly different from zero, thereby, establishing the fact that a high level of inefficiencies exists in turmeric farming systems of the slash and burn agriculture in Bangladesh. Furthermore, the corresponding variance ratio parameterFootnote 1 γ* imply 44.21 of the difference between observed and the maximum production frontier for turmeric farming system, is due to the existing differences in efficiency levels among farmers.

Further, a set of hypothesis on different inefficiency specifications using Likelihood ratio (LR) test statisticFootnote 2 was tested. The null hypothesis that γ = 0 is rejected at the 5% level of significance confirming that inefficiencies exists and are indeed stochastic (LR statistic 44.32 > χ21,0.95 = 3.84).

The estimate coefficients for four variables: farm size, labour, seed and fertilizer are shown in upper portion of Table 2. Labour, seed and fertilizer are significant at 1 and 10% levels, while farm size did not give a significant figure. The estimated Maximum Likelihood (ML) coefficient of farm size showed positive value of 0.007. Similarly, the estimated ML coefficient for labour showed positive and significant value at 0.337. Therefore, a 1% increment of labour will increase output by 0.337% which is reasonable as slash and burn area needs more labour for preparing land for cultivation. The estimate coefficient for seed and fertilizer showed positive and significant values of 0.203 and 0.019 respectively.

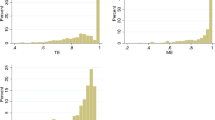

The results also indicate that technical efficiency (TE) indices range from 18 to 96% for the turmeric farming system, which an average of 84% (Table 3). Unfortunately, not a single farm appears as fully technical efficient. The implication is that, on average, turmeric farming could generate 16% of the potential return by eliminating technical inefficiency, which is substantial. If the average farmer in the sample was to achieve the TE level of its most efficient counterpart, then the average farmer could realize 13% cost savings (i.e., [1 − 84/96]). Similarly, the most technically inefficient turmeric farmers could realize an 81% [1 − (18/96)], if he/she could increase the level of TE to his/her most efficient counterpart. These cost saving will increase their overall income and ensure better livelihood for the farmers.

About 5%, of the turmeric farmers are producing at an efficiency level of less than 60% while 81% of the turmeric farmers are producing at an efficiency level of 80% and above, which are encouraging. As existing empirical studies in Bangladesh show the 84% means technical efficiency found in this study is in the line with the findings reported by Bravo-Ureta et al. (2007), Coelli et al. (2002), Wadud and White (2000).

Factors explaining inefficiency

The parameter estimates of the inefficiency effects stochastic production frontier model employed to identify the factors influencing farmers’ levels of technical inefficiency are listed in the lower panel of Table 2. The results show that, the age, family size, training and farm visits of the extension workers have a significant impact on technical inefficiency of farmers in the slash and burn agriculture in Bangladesh.

Results indicate that training significantly improves technical efficiency of turmeric farming, consistent with Karthick et al. (2013). The trained farmers are expected to follow the turmeric management practices properly, which might have led to higher efficiency for them.

The age coefficient is positive and significant with technical inefficiency in turmeric farming which indicates that older farmers are less capable to take risky decisions regarding farm management practices. This confirms to the results obtained by Begum et al. (2013).

Family size is negative and significant with technical efficiency, consistent with Irz and Meckenzie (2003), which indicates that those farmers that have a large size family are less efficient. This might be result of all family members are worked in the turmeric farms which in turn excess labour use which is usually happen in the case of Bangladesh.

The coefficient for number of farm visits by extension officers have negative impact on technical inefficiency which indicates that an increase in the number of farm visits by extension officers decreases the inefficiency level of farmers in the study area. Thus, with the increase in farm visits their efficiency increases. This could be due to the fact that farmers that actively communicate with extension officer usually get information and benefits regarding input use and market prices of inputs and outputs.

Conclusions and policy implications

The study used stochastic production frontier functions to analyze technical efficiency of turmeric farmers in the slash and burn area of Bangladesh. Using survey data obtained from 150 farmers over 6 villages throughout 2014/2015 growing season for measuring technical inefficiency among farmers. The mean level of technical efficiency is 84% suggest that substantial gains in output and or decreases in cost can be attained given existing technology.

According to a stochastic frontier production function, labour, seed and fertilizer showed significant positive effects on the turmeric production. The farm specific variables used to explain inefficiencies indicate that those farmers have more training and good contact with extension service providers trend to be more efficient. The age and family size have a negative influence in increasing technical efficiency.

The policy implications are clear. Inefficiency in turmeric farming can be reduced significantly by strengthening extension services and intensive training program. In recent years, a number of development agencies have promoted farmer field schools (FFS) as a more effective approach to extend science base knowledge and practices. The FFS training program utilizes participatory methods ‘to help farmers develop their analytical skills, critical thinking, and creativity, and help them learn to make better decisions’ (Kenmore 1997). Such an approach, in which the trainer is more of a facilitator than instructor, reflects a paradigm shift in extension work (Roling and van de Fliert 1994). The FFS concept does not require that all farmers attend FFS training. Rather, only a selected number within a village or local farmers’ group are trained in these informal schools. However, in order to disseminate new knowledge more rapidly, selected farmers receive additional training to become farmer-trainers, and are expected to organize field school replications within the community, with some support from public sources.

Notes

The parameter γ is not equal to the ratio of the variance of the efficiency effects to the total residual variance because the variance of ui is equal to [(π − 2)/π]σ2 not σ2. The relative contribution of the inefficiency effect to the total variance term (γ*) is equal to γ/[γ + (1 − γ) π/(π − 2)] (Coelli et al. 1998).

The likelihood ratio test statistic, λ = −2[log Likelihood (H0) − log Likelihood (H1)] has approximately χ2v distribution with v equal to the number of parameters assumed to be zero in the null hypothesis. To conduct the tests involving γ parameter, the critical value of the χ2 is taken from Kodde and Palm (1986, Table 1).

References

Ahluwalia MS (1996) New economic policy and agriculture: some reflections. Indian J Agric Econ 51(3):412–426

Aigner DJ, Lovell CK, Schmidt P (1977) Formulation and estimation of stochastic frontier productionfunction models. J Econ 6(1):21–37

Asian Development Bank (2016) Project completion report mission. Forestry sector project

Bangladesh Bureau of Statistics, BBS (2013) District Statistics 2011, Khagrachhari, Statistics and Informatics Division (SID), Ministry of Planning, Government of the People’s Republic of Bangladesh

Battese GE (1992) Frontier production functions and technical efficiency: a survey of empirical applications inagricultural economics. Agric Econ 7(3):187–208

Battese GE, Coelli T (1995) A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir Econ 20:325–332

Begum MEA, Hossain MI, Papanagiotou E (2013) Technical efficiency of shrimp farming in Bangladesh: an application of the stochastic production frontier approach. J World Aquac Soc 44(5):641–654

Belbase K, Grabowski R (1985) Technical efficiency in Nepalese agriculture. J Dev Areas 19(4):515–525

Bravo-Ureta BE, Pinheiro AE (1993) Efficiency analysis of developing country agriculture: a review of the frontier function literature. Agr Resour Econ Rev 22(1):88–101

Bravo-Ureta BE, Pinheiro AE (1997) Technical, economic and allocative efficiency in peasant farming: evidence from the dominican republic. Dev Econ xxxv(1):48–67

Bravo-Ureta BE, Solis D, Lopez VHM, Maripani JF, Thiam A, Rivas T (2007) Technical efficiency infarming: a meta regression analysis. J Prod Anal 27:57–72

Coelli TJ (1996) A guide to Frontier Version 4.1: a computer program for frontier production function estimation. CEPA Working Paper 96/07, Department of Econometrics, University of New England, Armidale

Coelli TJ, Prasada RDS, Battese G (1998) Introduction to efficiency and productivity analysis. KluverAcademic Publisher, Boston

Coelli TJ, Rahman S, Thirtle C (2002) Technical, allocative, cost and scale efficiencies in Bangladesh ricecultivation: a non-parametric approach. J Agric Econ 53:607–626

Farid ATM and Husain SMM (1988) Diagnoses of farming practices and their impact on soil resource loss and economic loss in the Hill Tract area of Bangladesh (Gazipur, Bangladesh: Bangladesh Agricultural Research Institute)

Farrell M (1957) The measurement of productive efficiency. J R Stat Soc 102(3):253–281

Foreastal, Forest and Engineering International Ltd. (1966) Chittagong Hill Tracts soil and land use survey, 1964–66. Volume 2: Geomorphology and Geology, Soil and Land Capability (Vancouver, Canada, Forestal, Forestry and Engineering International Ltd.)

Hayami Y, Ruttan W (1985) Agricultural development: an international perspective. Johns HopkinsUniversity Press, Baltimore

Hossain MA (2011) An overview on shifting cultivation with reference to Bangladesh. Sci Res Essays 6(31):6509–6514

Irz X, Mckenzie V (2003) Profitability and technical efficiency of aquaculture systems in Pampanga, Philippines. Aquac Econ Manag 7:195–211

Karna N, Sarwar R, Mccarthy G (2010) Value chains analysis final report, banana: Bandarban, Kagrachariand Rangamati Districts, Pineapple: Bandarban District Turmeric: Kagrachari District, Cht ValueChain Portfolio #1

Karthick V, Alagumani T, Amarnath JS (2013) Resource use efficiency and technical efficiency of turmeric production in Tamil Nadu—a stochastic frontier approach. Agric Econ Res Rev 26(1):109–114

Kenmore PE (1997) A perspective on IPM. Center for information on low external-input and sustainable agriculture newsletter 13

Kodde D, Palm F (1986) Wald criteria for jointly testing equality and inequality restrictions. Econometrica 54:1243–1248

Kuznets S (1966) Modern economic growth: rate, structure, and spread. Yale University Press, New Haven

Meeusen W, Van Den Broeck (1977) Efficiency estimation from Cobb–Douglas production function with composed error. Int Econ Rev 18:435–444

Rahman S (2003) Profit efficiency among Bangladesh rice farmers. Food Pol 28:487–503

Ramakrishnan PS (1992) Shifting agriculture and sustainable development: an interdisciplinary study from north-eastern India. MAB Series, Volume 10, UNESCO, Paris

Riessen AV (2000) Chittagong hill tracts region development plan, Interim Report No. 7, Sociology and Indigenous People, Asian Development Bank, Dhaka, Bangladesh

Roling N, van de Fliert E (1994) Transforming extension for sustainable agriculture: the case of integrated pest management in rice in Indonesia. Agric Hum Values 11:96–108

Shapiro KH, Muller J (1977) Sources of technical efficiency: the roles of modernnization and information. Econ Dev Cult Change 25:293–310

Sharma TC (1976) The pre-historic background of shifting cultivation in North-East India. North-East Indian Council for Social Science Research

Sharma KR, Leung P, Zalleski HM (1999) Technical, allocative, and economic efficiencies in swine production in Hawaii: a comparison of parametric and non-parametric approaches. Agric Econ 20:23–35

Shoaib JU, Mostafa G, Rahman M (1998) A case study on soil erosion hazard in hilly regions of Bangladesh, Annual report. SRDI, Dhaka

Squires D, Tabor S (1991) Technical efficiency and future production gains in Indonesia agriculture. Dev Econ 29:258–270

Taylor TG, Drummond HE, Gomes AT (1986) Agricultural credit programs and production efficiency: analysis of traditional farming in south-eastern Minas Gerais, Brazil. Am J Agric Econ 68:110–119

Thomas WL (ed) (1956) Man’s role in changing the face of the earth. The University of Chicago Press), Chicago

Wadud MA, White B (2000) Farm household efficiency in Bangladesh: a comparison of stochastic frontier and DEA methods. Apll Econ 32:1665–1673

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Begum, M.E.A., Miah, M.A.M., Rashid, M.A. et al. Factors affecting the technical efficiency of turmeric farmers in the slash and burn areas of Bangladesh. Agroforest Syst 93, 2205–2212 (2019). https://doi.org/10.1007/s10457-018-0338-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10457-018-0338-z