Abstract

The effects of the humic acid (HA) nature and the activated carbon (AC) surface chemistry on the effectiveness of HA removal were investigated. Brown (BHA) and gray (GHA) humic acid fractions of different structure and physicochemical properties were tested in the adsorption process using mesoporous ACs. The modification of chemical structure and surface properties of AC was achieved by ammonization (AC/N) and hydrogen treatment (AC/H). Both approaches led to a decrease in the oxygen content followed by an increase in the carbon basicity, maintaining the porous texture of AC nearly unaltered. Over twice higher removal degree of BHA and GHA was observed for the modified ACs. The kinetics of adsorption of HA fractions have been discussed using the pseudo-second-order model and the intraparticle diffusion model. All ACs showed a higher adsorption capacity toward BHA compared to GHA, which is mainly attributed to the lower molecular weight of BHA. The shape of the equilibrium isotherms indicates a strong competition between water and HA molecules for adsorption sites of the carbon surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The humic acid (HA) constitutes the major fraction of natural organic matter in water supplies, decreasing considerably water quality. It contains both hydrophilic and hydrophobic moieties with functional groups such as carboxylic, phenolic, carbonyl and hydroxyl groups (Stevenson 1994). The various fractions of humic substances are known to show different interactions with the adsorbent due to their polydispersive nature. The molecular fractionation of HA carried out according to the different solubility of the molecules under specific conditions of pH and ionic strength allowed to distinguish different HA fractions. Among them there are the gray humic acids (GHA) and brown humic acids (BHA), which differ essentially in their characteristics in terms of structure and physicochemical properties (Baigorri et al. 2007, 2008). Since some fractions of HA are not removed by conventional water purification methods, they remain in treated water and reach the disinfection stage of water treatment. This, via reaction with chlorine, leads to the formation of carcinogenic and mutagenic disinfection-by products (Huang and Yeh 1999; Watt et al. 1996).

Regardless of the water source, one of the recommended methods for HA removal is adsorption on activated carbon (AC). The adsorption of HA is affected by many factors, including porous texture and surface chemistry of AC (Bjelopavlic et al. 1999; Cheng et al. 2005; Dastgheib et al. 2004; Lorenc-Grabowska and Gryglewicz 2005; Pelekani and Snoeyink 1999), macromolecular size and chemical structure of HA (Karanfil et al. 1996a, b) and solution parameters like ionic strength and pH (Duan et al. 2002; Han et al. 2003; Illés and Tombácz 2004; Newcombe and Drikas 1997). Various forces, electrostatic and non-electrostatic ones, are considered in the adsorption process of natural organic matter from water (Newcombe and Drikas 1997). Electrostatic attraction and repulsion between the carbon surface and HA molecule, lateral repulsion between adsorbed HA molecules and repulsive interaction between adsorbed HA and HA in solution can determine the extent of adsorption. In some cases, non-electrostatic forces such as hydrophobic interactions, the π–π dispersion interactions and hydrogen bonding between the carbon surface and HA molecule are mainly responsible for the uptake. Despite many investigations performed in the field of the removal of HA, the reported sorption capacities of AC are relatively low. Most of commercial ACs used for water treatment are microporous and their internal surface cannot be reached by high-molecular organics. The mesoporous ACs with wider pores are more appropriate for HA removal (Bjelopavlic et al. 1999; Dastgheib et al. 2004; Lorenc-Grabowska and Gryglewicz 2005). A promising method of upgrading the adsorption capacity of AC, is the modification of chemical character of the surface (Cheng et al. 2005; Dastgheib et al. 2004). The HA molecules are negatively charged at a typical water treatment condition, i.e. neutral pH of solution. Hence for enhanced uptake of HA the activated carbon used should be characterized by positively charged surface.

There are many different methods proposed to prepare ACs with basic surface characteristics (Dastgheib et al. 2004; Jansen and van Bekkum 1995; Mangun et al. 2001; Menendez et al. 1996). However, the high temperature treatment of AC in inert, hydrogen or ammonia atmosphere is believed to be the easiest way of producing porous carbons with basic surface properties (Jansen and van Bekkum 1995; Mangun et al. 2001; Menendez et al. 1996; Lorenc-Grabowska et al. 2010). The heat treatment at 800–900 °C results in elimination of acidic groups, that leads to enhanced π electron density of graphene layers. The hydrogen treatment additionally stabilize the carbon surface by forming C–H bonds that prevents from resorption of oxygen when the carbon is exposed to the air (Menendez et al. 1996) whereas the basic nitrogen functionalities are incorporated into carbon structure when the treatment of AC with ammonia at 400–900 °C is applied (Jansen and van Bekkum 1995).

The objective of this work was to determine the effect of HA nature and surface chemistry of mesoporous AC on the kinetics and adsorptive interactions between HA and AC in aqueous solution. We developed a method of preparation of highly mesoporous AC from bituminous coal for the removal of large molecules of organic pollutants from water (Lorenc-Grabowska et al. 2004). In the present paper the starting mesoporous AC was subjected to ammonization and high-temperature hydrogen treatment to enhance the basic character of the carbon surface.

The various fractions of humic substances BHA and GHA fractions of HA, were selected as adsorbates. Three assumptions have been made for designing the sorption system: (i) all adsorbents have a comparable porous texture, which excludes any differences in the adsorption extent caused by diversified porosity of adsorbent, (ii) ionic strength of the solution is close to zero, which implies no screening interaction resulting from the presence of electrolyte in the adsorption system and (iii) pH of the solution is slightly higher than neutral, as typical for water treatment plants on the stage of AC bed. Such a configuration of the sorption system parameters, allows for determining which interactions between AC and HA are of the key-meaning for the adsorption process and further, how the contribution of those interactions changes depending on HA and AC characteristics. We consider such knowledge to be very useful for the design and selection of porous materials for effective removal of HA.

2 Materials and methods

2.1 Humic substances

BHA and GHA were isolated and fractioned from a young brown coal obtained from the Czech Republic, following the procedure described elsewhere (Stevenson 1994). 12 g/L of HA was dissolved in KCl (2 M, pH 7) overnight and centrifuged subsequently. The solution containing BHA and the precipitate containing GHA were purified until the ash was lower than 2 wt%. For the purpose of adsorption tests, a stock solution of 50 mg/L concentration was prepared by dissolving 50 mg of HA in 30 mL of deionized water containing 1.2 mL of 0.1 M NaOH. The solution was shaken till the maximum dissolving was achieved, and filtered on a vacuum filtration set with the nitrate-cellulose filters 0.45 µm. Finally, the filtrate was diluted with deionized water to achieve the required concentration.

2.2 Adsorbents

The starting mesoporous AC (AC0) was produced by catalytic gasification of a high volatile bituminous coal. Briefly, the process includes the following stages: (i) generation of ion-exchangeable groups on the coal surface by oxidation with nitric acid, (ii) calcium and iron loading by ion-exchange, and finally, (iii) carbonization and activation with steam at 850 °C up to 50 % of burn-off (Lorenc-Grabowska et al. 2004). Prior to the surface modification, the carbon was treated with diluted hydrochloric acid.

2.3 Surface modification

The AC0 sample was modified by heat treatment with hydrogen and ammonia. Heat treatment under hydrogen was carried out in a horizontal tube furnace with a heating rate of 5 °C/min and a hydrogen flow of 5 L/h. After reaching the final temperature of 900 °C, the sample was heated for 2 h. Ammonization was conducted in a vertical furnace in a fluidized bed. The AC0 sample was heated up to 700 °C in the nitrogen flow with a heating rate of 10 °C/min. Afterwards, ammonia was introduced to the reaction system and the sample was heated in the ammonia flow of 9 L/h for 2 h. The samples for adsorption tests were stored in vacuum desiccators.

2.4 Analysis

A Vario EL III analyzer was applied for elemental composition analysis (CHNS) of HA and ACs studied. Oxygen content was determined directly using a Carlo Erba analyzer. The porous texture parameters of the ACs were determined from adsorption and desorption of N2 at 77 K by a gas sorption analyzer (NOVA 2200, Quantachrome). Samples were degassed overnight at 300 °C prior to the adsorption analysis. Nitrogen sorption isotherms were analyzed to obtain the information about: (i) the surface area by the BET method (SBET), (ii) the total pore volume (VT) as calculated from N2 adsorption at relative pressure of p/p0 = 0.96, (iii) the micropore volume (VDR) by applying the Dubinin-Radushkevich equation up to p/p0 < 0.05, (iv) the micropore size distribution by means of the Quenched Solid Density Functional Theory (QSDFT) method and (v) the mesopore size distribution by the BJH method. The mesopore volume (Vmes) was determined as the difference between VT and VDR. The mesopore fraction was expressed as the ratio of Vmes/VT.

The pHPZC of ACs [(point of zero charge (PZC)] was determined according to the procedure described elsewhere (Moreno-Castilla et al. 2000).

In order to determine the molecular size distribution of HA, ultrafiltration method was applied. The BHA and GHA samples were fractionated using an UF cell (Amicon model 8200) under inert atmosphere (N2). Five UF membranes (Millipore) of molecular weight cutoff (MWCO) of 100 [poly(ether sulfone)], 50 [poly(ether sulfone)], 10 [poly(ether sulfone)], 5 [poly(ether sulfone)], and 1 (cellulose) kDa were used. First, the solutions were filtered through a membrane with the largest pore size. The process was halted when the volume of the retained solution decreased to 5–10 % of the initial solution volume. The filtrate was introduced in the UF cell and filtered through another membrane of lower MWCO. This operation was repeated for each membrane. The mass percentages of the different fractions were evaluated by measuring absorption differences at 400 nm between the consecutive filtrates.

The acidity of HA fraction were determined elsewhere (Baigorri et al. 2008).

2.5 Adsorption experiments

The adsorption processes of HA from aqueous solution were carried out in a static system at room temperature. For the adsorption isotherm determination, 0.003–0.1 g of AC was placed into flasks and 0.05 L of the adsorbate solution (50 mg/L) was added to each of the flasks. The set of flasks included two additional flasks containing blank solution with the purpose of checking the adsorption of sorbate on the walls. The stoppered flasks were shaken for 5 days to reach steady-state conditions. Before and after contact, the pH of solution was measured by a digital pH meter (Mettler Toledo) using a glass electrode.

To establish the equilibrium time, 0.05 g of carbon sample was placed into a set of Erlenmeyer flasks, containing 0.05 L of adsorbate solution (50 mg/L), and the suspension was then shaken until the equilibrium was achieved. Samples were collected in time intervals and the concentration of solute remaining in the water phase was quantified using a Hitachi U-2800A spectrophotometer at a wavelength of 254 nm.

3 Results and discussion

3.1 Characteristics of HA

The structural features of BHA and GHA used in this study have been already described (Baigorri et al. 2007; 2008). The main differences in the chemical nature of HA fractions lie in their acidity as well as H/C and O/C ratios. A lower H/C ratio of BHA compared to GHA (0.058 vs. 0.073) indicates a more aromatic character of the former fraction. Nearly twice higher O/C ratio observed for BHA (1.25 vs. 0.73) proves its more hydrophilic character compared to GHA. The total acidity, determined by potentiometric titration, was 3.54 and 2.25 mmol/g for BHA and GHA, respectively. This corresponds to the contribution of carboxylic groups, amounting to 2.22 mmol/g in BHA and 1.42 mmol/g in GHA (Baigorri et al. 2008).

Figure 1 shows that BHA is mainly composed of molecules of low molecular weights with dominant species of 5–50 kDa. No molecules of sizes greater than 100 kDa are observed for BHA fraction, whereas in case of GHA these molecular patterns constitute nearly 40 % of the total fraction (Baigorri et al. 2007).

3.2 Characteristics of adsorbents

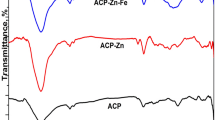

The initial AC subjected to surface modification was characterized by very low ash content due to the hydrochloric acid treatment. The applied surface modifications hardly have changed the ash content. The characteristics of ACs studied, including the elemental composition, porous texture parameters and pHPZC, are summarized in Table 1. The nitrogen adsorption–desorption isotherms for the studied ACs are shown in Fig. 2. The isotherms are almost identical and represent type IV in the BDDT classification, indicating a mesoporous character of the carbons.

The changes observed in the chemical composition and the pHPZC value of ACs reflect a different type of carbon surface modification applied. The effect of surface modification can be seen in the increase of pHPZC value of AC/N (pHPZC 7.5) and AC/H (pHPZC 8.5) compared to AC0 (pHPZC 6.7). Ammonization results in the nitrogen content increasing from 0.3 to 0.9 wt% accompanied by a decrease in the oxygen content from 2.7 to 1.0 wt%. The latter observation can be explained by both the elimination of less stable oxygen groups and the participation of surface oxygen groups in the reaction with NH3 to form nitrogen surface functionalities (Jansen and van Bekkum 1995; Jansen and Bekkum 1994). At 700 °C, pyridine-type structures occur which improve the basicity of carbon surface (Raymundo-Pinero et al. 2003). Due to hydrogen treatment, a considerable amount of oxygen, from 2.7 to 0.9 wt%, was removed. This causes an increase in the electron density of the graphene layers, improving basicity of carbon. It can be observed that the heteroatom content (O+N), decreases in the direction: AC0 < AC/N < AC/H.

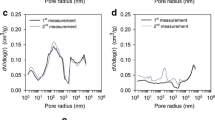

The ACs are characterized by a similarly developed mesoporosity (Table 1). The mesopore fraction in the total pore volume is the same, amounting to 0.66. The mesopore volume is comparable, between 0.336 and 0.355 cm3/g. Only a small difference in the BET surface area only can be observed. The pore size distribution is also similar for all carbons studied. Figure 3 shows the micropore size distribution determined by QSDFT (a) and the mesopore size distribution determined by BJH (b). For the mesopore range, two maxima occur which are centered at 3.5 and 27 nm for all carbons. This is a clear evidence that the applied modifications did not alter the porous texture of the initial AC (AC0). Therefore, the differences observed in the HA uptake for the tested adsorbents could be explained almost entirely by the carbon surface chemistry.

3.3 Comparison of BHA and GHA adsorption on modified ACs

The adsorption tests were carried out at neutral pH value, which is typical for water treatment plant in the stage of AC bed. The initial HA solution pH was in the range of 7.5–8. During the adsorption process, pH remained around 7.2–7.5, without any buffer addition. At such solution pH, the HA molecule carriers a negative charge that causes starching out of the HA molecules (Stevenson 1994). It is well known that due to amphoteric character, the surface of AC can be positively or negatively charged depending on the solution pH. Taking into account pHPZC values determined, the surface of AC0 is negatively charged (pHPZC 6.7), AC/N charge is around zero (pHPZC 7.5) and AC/H is charged positively (pHPZC 8.5) under the adsorption conditions tested in our work. Hence, significant differences between ACs in terms of adsorption of HA are expected.

The results of the adsorption test for BHA and GHA on modified ACs vs. time are shown in Fig. 4. All ACs studied show a higher removal degree for BHA compared to GHA. It is presumably due to the differences in molecular weight between both HA fractions. BHA, which exhibits lower molecular weight and molecular size than GHA (Fig. 1), can reach a higher number of adsorption sites of the carbon surface (Karanfil et al. 1996a; Newcombe et al. 1997).

It can be clearly observed that the applied modifications of the carbon surface lead to an enhanced adsorption of HA from aqueous solution. The uptake of BHA and GHA changes as follows: AC0 < AC/N < AC/H. In case of non-modified AC0 the removal of BHA and GHA amounts to 26 and 20 %, respectively. Nearly twice higher removal degree of BHA (46 %) and GHA (42 %) can be observed for AC/N compared to AC0. These findings can be explained by both the electrostatic interactions and the dispersive forces. The electrostatic repulsion occurring between the negatively charged HA and AC0 surface (pHPZC < pHsolution) can lead to the lower extent of adsorption of both BHA and GHA. In case of AC/N the dispersive forces play the main role in the HA adsorption. The contribution of electrostatic interactions in the uptake of HA is insignificant because pHPZC ~ pHsolution. Hence, a higher adsorption extent of AC/N compared to AC0 can explained by a lack of negative repulsion forces between the HA and AC/N.

The highest removal degree of BHA (61 %) and GHA (51 %) observed for AC/H is attributed to electrostatic attractive interactions between positively charged carbon surface (pHPZC > pHsolution) and negatively charged HAs, which, next to dispersive forces, can be considered as the main adsorption mechanism responsible for the enhanced adsorption on AC/H.

It is worth pointing out the larger difference in the uptake of BHA and GHA in case of AC/H compared to AC0 and AC/N. As mentioned above, the electrostatic attraction is mainly responsible for the enhanced adsorption of HA fractions in case of AC/H. Therefore, the difference in uptake presumably arises from different charge of BHA and GHA molecules. Indeed, the concentration of carboxylic groups, which are dissociated in the conditions of adsorption test, is twice higher in a BHA fraction than in a GHA one (2.22 vs. 1.42 mmol/g HA of COO−) (Baigorri et al. 2008). Hence, BHA will interact stronger with the positively charged surface of AC/H, leading to a higher adsorption compared to GHA. A much higher BHA uptake compared to GHA is a confirmation for the adsorption mechanism strongly based on the electrostatic interactions.

3.4 Kinetics of adsorption

Among several models available for examination of the kinetics of adsorption and interpretation of the experimental data, the pseudo-first order Lagergren model, the pseudo-second order kinetic equation and the intraparticle diffusion model were applied in this work. The first two models are described by the Eqs. (1) and (2) as follows:

Lagergren pseudo-first order kinetic model

Pseudo-second order kinetic model

The kinetic data obtained from batch studies for the sorption of BHA and GHA using the Lagergren model and the pseudo-second order model are given in Tables 2 and 3. The correlation coefficient (R2) for the Lagergren equation is low, ranging from 0.822 to 0.957. For the pseudo-second kinetic model, the linear plots of t/qt vs. t gives R2 between 0.991 and 0.998. Moreover, the experimental qe exp values do not agree with those calculated from the Lagergren equation, while the ones calculated from the pseudo-second order equation agree with experimental data. The results obtained are in consistence with our previous results (Lorenc-Grabowska and Gryglewicz 2005) and those reported for HA (Anirudhan et al. 2008), where the pseudo-second order kinetic model gives a better fit to experimental data. An extended analysis of over 200 adsorption systems in terms of the pseudo first- and the second-order kinetics models reported in the literature have led to the conclusion (Ho and McKay 1998, 1999) that the first-order model is generally applicable only for the first 20–30 min of the sorption process. On the contrary, the pseudo second-order model was found to predict the behavior over the whole range of adsorption run. Our results fit to these findings as well. However, one has to remember that both the pseudo-second kinetic model and the Lagergren model cannot provide a definite mechanism of adsorption, but only help to predict the adsorptive behavior of the system in various system conditions.

Since Weber and Morris (Basibuyuk and Forster 2003; Vinod and Anirudhan 2003) presented an intraparticle diffusion (IPD) model, it has been widely applied to describe the kinetics of adsorption from liquids. The model is given by the following equation:

The extrapolation of the linear portion of the plot back to the axis provides intercepts which are proportional to the extent of the boundary layer thickness. The larger the intercept, the greater the boundary layer effect is.

The plots qt = f(t0.5) were fitted using the linear regression method (Fig. 5). It can be seen that for BHA and GHA, all plots consist of two linear portions, which indicates that two steps occur in the adsorption process. None of the first linear portion passes through the origin, reflecting the existence of an external mass transfer during the HA adsorption process. The first portion of the plot corresponds to the HA diffusion in macropores and wide mesopores. The second linear portion is attributed to the final equilibrium step in wide micropores and narrow mesopores, where the intraparticle diffusion starts to slow down due to a very low adsorbate concentration left in the solution. The slope of the linear portion of the plot indicates the rate of adsorption. The small differences in the slopes of the first portion of the plots can be observed. The slope of the first portion increases gently in direction AC0 < AC/H ≤ AC/N and is slightly larger for BHA compared with GHA. The first finding is attributed to an enhanced affinity of HA fractions toward the surface of the modified carbons due to removal of oxygen (AC/H) and enrichment in nitrogen (AC/N). The second finding can be explained by a smaller size of BHA molecules, which promotes their diffusion through macropores and mesopores.

Except for BHA-AC/H, all remaining adsorption systems are characterized by a similar slope of the second portion of the plot, indicating that the rate of adsorption in wide micropores and small mesopores is comparable. The different behavior observed for BHA-AC/H arises from the fact that BHA, possessing a significant negative charge due to a larger amount of carboxylic groups, interacts strongly with a positively charged AC/H surface, which results in a decrease of diffusion resistance in the pores of the adsorbent. The slope of the second portion of the plot for all the ACs is considerably lower compared with the first portion. This indicates that the intraparticle diffusion of BHA and GHA molecules into wide micropores and small mesopores is a rate-limiting step.

3.5 Equilibrium isotherms

The experimental equilibrium isotherms for the adsorption of BHA and GHA on the AC0, AC/N and AC/H carbons are shown in Fig. 6. The concave alignments of the isotherms indicate the heterogeneity of compounds composed of HA fractions. For all ACs, a strong competition between the solute and the adsorbate molecules for active sites on the carbon surface can be observed. Presumably, water molecules form hydrophilic coating cluster, hindering therefore the adsorption of HA molecule. In order to overcome the formation of water clusters on the carbon surface and to allow the adsorption of HA molecules, a sufficiently high concentration of the adsorbate is required. Molecules of a more hydrophilic character will displace water more easily compared to the ones of a more hydrophobic character, hence, a significant shift of adsorption isotherm in the direction of higher equilibrium concentrations observed for GHA compared with BHA (Fig. 6). It can be observed that a partial removal of oxygen functional groups by heat treatment of AC0 with hydrogen and ammonia leads to an enhanced carbon affinity for both BHA and GHA. However, HA molecule once adsorbed favors the adsorption of another one. This leads to a multilayer formation in the mesopores, which reflects the shape of the equilibrium isotherm. The effect of such “induced” adsorption is stronger in case of more hydrophobic GHA which can be deduced from more vertical course of the isotherm. Molecule of GHA adsorbed on the surface of AC enhances the affinity of another GHA molecule for the carbon surface by increasing its hydrophobicity and displacement of water molecules from the surface in their close proximity. Such a strong “inducing” effect is not observed in case of BHA. The presence of an enhanced amount of hydrophilic oxygen functionalities, i.e. carboxylic and phenolic groups, in the BHA structure promotes covering of adsorbed BHA molecule by water coating-cluster, which decreases “induced” effect of adsorption. This allows to conclude that the preferential adsorption observed for various HA fractions arises not only from the size of molecules, but also from their chemical structure and the chemistry of carbon surface.

4 Conclusions

The differences in the molecular structure between BHA and GHA determine their behavior during adsorption on mesoporous AC from aqueous solution. Regardless of the chemical structure and the surface charge of AC, the higher removal degree was achieved for BHA compared to GHA. The higher uptake of BHA can be explained by its lower molecular weight and smaller molecule size.

Depending on the pHPZC of AC, different interactions between the carbon surface and the HA molecules were responsible for the HA removal at pH solution of 7.2–7.5. A series of ACs with different pHPZC of 6.7–8.5, was prepared by modification of mesoporous AC0 with hydrogen and ammonia treatment at high temperature. Due to the modifications applied a decrease in the oxygen content and an increase in the carbon aromaticity were observed which leads to enhanced hydrophobicity of the carbon surface. The highest BHA and GHA uptake observed for AC/H resulted from the occurrence of both dispersion forces and electrostatic interactions between the positively charged carbon surface of AC/H and HA molecules. In case of AC/N, mainly dispersive interactions were responsible for the uptake of BHA and GHA. On the contrary, electrostatic repulsive interactions between AC0 and HA molecules were the reason of the lowest efficiency of AC0 in the HA removal.

The adsorption process of BHA and GHA on mesoporous ACs with different surface characteristics follows the pseudo-second order kinetic model. Application of the intraparticle diffusion model for interpretation of the kinetic data revealed that the diffusion resistance in the wide micropores and small mesopores is the lowest for the AC/H-BHA system, which explains the greatest removal of BHA by AC/H.

The concave alignment of the equilibrium isotherms indicates that the BHA and GHA fractions are heterogeneous in their composition. An enhanced hydrophobicity of AC leads to a greater affinity of the HA fractions for the carbon surface. Nevertheless, the competition for the adsorption sites between the water molecules and the GHA and BHA molecules is still meaningful; it weakens with increasing carbon surface hydrophobicity in the direction: AC0 > AC/N > AC/H.

The proposed mechanism of “induced” adsorption explains the different behavior of BHA and GHA during adsorption on AC, which is a consequence of different molecular structure of the studied HA fractions.

Abbreviations

- t:

-

Time (min)

- qt :

-

Amount of HA adsorbed by carbon at time t (mg/g)

- qe exp :

-

Amount of HA adsorbed at equilibrium − experimental data (mg/g)

- qe,c :

-

Amount of HA adsorbed at equilibrium − calculated data (mg/g)

- kads :

-

The first-order rate constant of adsorption (1/min)

- k2ads :

-

The second-order rate constant of adsorption [g/(mg min)]

- ki :

-

IPD rate constant [mg/(g min0.5)]

- C:

-

Constant for a given experiment (mg/g)

References

Anirudhan, T.S., Suchitra, P.S., Rijith, S.: Amine-modified polyacrylamide-bentonite composite for the adsorption of humic acid in aqueous solutions. Colloids Surf. A 326, 147–156 (2008)

Baigorri, R., Fuentes, M., González-Gaitano, G., García-Mina, J.M.: Simultaneous presence of diverse molecular patterns in humic substances in solution. J. Phys. Chem. B 111, 10577–10582 (2007)

Baigorri, R., Zamarreño, A.M., Fuentes, M., González-Gaitano, G., García-Mina, J.M., Almendros, G., González-Vila, F.J.: Multivariate statistical analysis of mass spectra as a tool for the classification of the main humic substances according to their structural and conformational features. J. Agric. Food Chem. 56, 5480–5487 (2008)

Basibuyuk, M., Forster, C.F.: An examination of the adsorption characteristics of a basic dye (Maxilon Red BL-N) on to live activated sludge system. Process Biochem. 38, 1311–1316 (2003)

Bjelopavlic, M., Newcombe, G., Hayes, R.: Adsorption of NOM onto activated carbon: effect of surface charge, ionic strength, and pore volume distribution. J. Colloid Interface Sci. 210, 271–280 (1999)

Cheng, W., Dastgheib, S.A., Karanfil, T.: Adsorption of dissolved natural organic matter by modified activated carbons. Water Res. 39, 2281–2290 (2005)

Dastgheib, S.A., Karanfil, T., Cheng, W.: Tailoring activated carbons for enhanced removal of natural organic matter from natural waters. Carbon 42, 547–557 (2004)

Duan, J., Wilson, F., Graham, N., Tay, J.H.: Adsorption of humic acid by powdered activated carbon in saline water conditions. Desalination 151, 53–66 (2002)

Han, S., Kim, S., Lim, H., Choi, W., Park, H., Yoon, J., Hyeon, T.: New nanoporous carbon materials with high adsorption capacity and rapid adsorption kinetics for removing humic acid. Micropor. Mesopor. Mater. 58, 131–135 (2003)

Ho, Y.S., McKay, G.: A comparison of chemisorption kinetic models applied to pollutant removal on various sorbents. Inst. Chem. Eng. Trans. IChemE B 76, 332–340 (1998)

Ho, Y.S., McKay, G.: Pseudo-second order model for sorption processes. Process Biochem. 34, 451–465 (1999)

Huang, W.J., Yeh, H.H.: Reaction of chlorine with NOM adsorbed on powdered activated carbon. Water Res. 33, 65–72 (1999)

Illés, E., Tombácz, E.: The role of surface charge and surface complexation in the adsorption of humic acid on magnetite. Colloids Surf. A 230, 99–109 (2004)

Jansen, R.J.J., Bekkum, H.V.: Amination and ammoxidation of activated carbons. Carbon 32, 1507–1515 (1994)

Jansen, R.J.J., van Bekkum, H.: XPS of nitrogen-containing functional groups on activated carbon. Carbon 33, 1021–1027 (1995)

Karanfil, T., Kilduff, J.E., Schlautman, M.A., Weber, W.J.: Adsorption of organic macromolecules by granular activated Carbon. 1. Influence of molecular properties under anoxic solution conditions. Environ. Sci. Technol. 30, 2187 (1996a)

Karanfil, T., Schlautman, M.A., Kilduff, J.E., Weber, W.J.: Adsorption of organic macromolecules by granular activated carbon. 2. Influence of dissolved oxygen. Environ. Sci. Technol. 30, 2195–2201 (1996b)

Lorenc-Grabowska, E., Gryglewicz, G., Gryglewicz, S.: Development of mesoporosity in activated carbons via coal modification using Ca- and Fe-exchange. Micropor. Mesopor. Mater. 76, 193–201 (2004)

Lorenc-Grabowska, E., Gryglewicz, G.: Adsorption of lignite-derived humic acids on coal-based mesoporous activated carbons. J. Colloid Interface Sci. 284, 416–423 (2005)

Lorenc-Grabowska, E., Gryglewicz, G., Machnikowski, J.: p-Chlorophenol adsorption on activated carbons with basic surface characteristics. Appl. Surf. Sci. 256, 4480–4487 (2010)

Mangun, C.L., Benak, K.R., Economy, J., Foster, K.L.: Surface chemistry, pore sizes and adsorption properties of activated carbon fibers and precursors treated with ammonia. Carbon 39, 1809–1820 (2001)

Menendez, J.A., Phillips, J., Xia, B., Radovic, L.R.: On the modification and characterization of chemical surface properties of activated carbon: in the search of carbons with stable basic properties. Langmuir 12, 4404–4410 (1996)

Moreno-Castilla, C., López-Ramón, M.V., Carrasco-Marín, F.: Changes in surface chemistry of activated carbons by wet oxidation. Carbon 38, 1995–2001 (2000)

Newcombe, G., Drikas, M., Hayes, R.: Influence of characterized natural organic material on activated carbon adsorption: II Effect on pore volume distribution and adsorption of 2-methyisoborneol. Wat. Res. 31, 1065–1073 (1997)

Newcombe, G., Drikas, M.: Adsorption of NOM onto activated carbon: electrostatic and non-electrostatic effects. Carbon 35, 1239–1250 (1997)

Pelekani, C., Snoeyink, V.L.: Competitive adsorption in natural water: role of activated carbon pore size. Water Res. 33, 1209–1219 (1999)

Raymundo-Pinero, E., Cazorla-Amoros, D., Linares-Solano, A.: The role of different nitrogen functional groups on the removal of SO2 from flue gases by N-doped activated carbon powders and fibers. Carbon 41, 1925–1932 (2003)

Stevenson, F.J.: Humus Chemistry: Genesis, Composition Reactions. Wiley, New York (1994)

Vinod, V.P., Anirudhan, T.S.: Adsorption behavior of basic dyes on the humic acid immobilized pillared clay. Water Air Soil Pollut. 150, 193–217 (2003)

Watt, B.E., Malcolm, R.L., Hayes, M.H.B., Clark, N.W.E., Chipman, J.K.: Chemistry and potential mutagenicity of humic substances in water from different watersheds in Britain and Ireland. Water Res. 30, 1502–1516 (1996)

Acknowledgments

The work was financed by a statutory activity subsidy from the Polish Ministry of Science and Higher Education for the Faculty of Chemistry of Wrocław University of Technology.

Conflict of interest

None.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kołodziej, A., Fuentes, M., Baigorri, R. et al. Mechanism of adsorption of different humic acid fractions on mesoporous activated carbons with basic surface characteristics. Adsorption 20, 667–675 (2014). https://doi.org/10.1007/s10450-014-9610-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-014-9610-3

) and desorption(

) and desorption( ) isotherms at 77 K for the studied ACs

) isotherms at 77 K for the studied ACs