Abstract

A conformal load-bearing antenna structure (CLAS) combines the antenna into a composite structure such that it can carry the designed load while functioning as an antenna. Novel microstrip antennas woven into the three dimensional orthogonal woven composite were proposed in our previous study. In order to determine the effect of the space between the conductive wires on the antenna performance, different space ratios of 1.7, 2.3 and 4.6 were considered in the design. Simulation results showed that when the space ratio increased, the frequency shift and return loss of the corresponding antenna became larger. And the antenna had relatively good performance when the space ratio reached 1.7. Two types of antennas were designed and fabricated with the ratio of 1.7 and 1 respectively and both of them obtained agreeable results. It was also demonstrated by the experimental that the orthogonal structure patch antenna had similar radiation pattern with the traditional copper foil microstrip antenna. However, the interlaced patch antenna had large back and side lobes in the radiation pattern because the existence of the curvature of copper wires in interlaced coupons lowered the reflective efficiency of the ground.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

How to create high level of conformability of multifunctional structures is a big issue in aerospace crafts design for next generation [1]. It is desirable to integrate the electronic devices into load-bearing structures since the integral element can function as both an efficient electronic component and that can withstand considerable load [2]. In this case, innovative improvement can be made to realize smart structures [3]. The most effective way to realize smart structures is to embed the active element into the structures like the wings and airframes to enhance the structure efficiency [4]. Significant advances have been made in embedding antennas in load-bearing structures since 1990s; these advances are crucial to enhance system and structural efficiency for spacecraft design that eliminates chassis, cables, connectors and folds the electronics into the walls of the spacecraft [1, 5].

Antennas are most widely used in wireless mobile telecommunication and satellite communication for vehicles, which can be attached to aerospace structures to transmit or receive electromagnetic waves [6]. However, traditional antenna structures attached to aircrafts have protruding aerials, which will have negative impact on aerodynamic properties of the aircrafts as causing air drags. In addition, the protruding components are not conformal with the airframes thus are mechanically weak from a structural point of view. The installation of the structure requires local reinforcements and cause changes in the load path, leading to increase in overall weight and reduction in structural efficiency [7].

The most popular smart skin technology is CLAS (conformal load-bearing antenna structures), in which a multi-arm spiral antenna was embedded in the fuselage which is composed of the sandwich laminated composites [8]. Based on the concept of CLAS, You and his co-workers have developed a mechanically and electrically effective antenna structure termed as SAS (surface antenna structure) and CSS (composite smart structure) [9–12]. In these structures, microstrip antennas were embedded into the sandwich laminated composite structures. However, laminated composites, as the basic structures of these smart antennas, have such drawbacks as delamination, complicate manufacturing process and uneven structures, which limit the real conformability of the antenna and composite and also the function of the antenna. As described in [7], when the antenna structure was impacted at 2 J energy, the antenna did not work any more due to the delamination of the basic structure. Therefore, it is of great importance to develop new conformal load-bearing antenna structures to realize the real integration.

In our previous study, a new load-bearing antenna structure named as 3DIMA (Three dimensional integrated microstrip antenna) was firstly proposed in [13], in which a microstrip antenna was woven into the three dimensional woven composites. The 3DIMA shows excellent integrity due to the existence of through-thickness reinforcements and superior conformability because the radiating patch and the ground plane are both composed of woven conductive wires. Up to now, 3DIMAs with both coaxial and microstrip feeding were successfully fabricated. 3DIMA with coaxial feeding showed proper radiation patterns even after 15 J impact energy, indicating 3DIMA has superior integrity to the CLAS [14]. However, how to obtain better antenna properties by adjusting weaving parameters has not been investigated in those studies. Therefore, in this study, the effect of the wire spaces and weaving patterns on the antenna properties were investigated.

2 Simulation Work

2.1 Design Concept

The basic structure of the 3DIMA has been introduced in our previous publication [13, 14]. The fundamental design concept of the 3DIMA is an integral composite structure in which a microstrip antenna is woven into a 3D woven composite. This study was to consider a resonant λ/2-patch antenna operating at radar L-band frequency of 1.5 GHz. The upper conductive wire fabricated patch was fed by a coplanar probe, and the input impedance was transformed into a 50 ohm feedline when fabricated. The practical width W and length L of the patch should be adjusted with small extension considering the fringing fields at the edges of the patch.

2.2 Simulation Analysis

For a traditional microstrip antenna, the conductive foils are usually attached to each side of the dielectric substrate functioning as the patch and ground plane respectively. While in the 3DIMA, both the patch and ground plane are composed of conductive copper wires, so there is inevitably space existing between the copper wires. Therefore, to investigate the effect of space between copper wires on the antenna performance, simulations need to be done using the software Ansoft HFSS for mesh grid pattern antennas that resemble the real woven antennas.

The designed 3DIMA whose patch, feedline and ground plane all composed of grid patterns is shown in Fig. 1. Four S/D ratios (the ratio of space between copper wires to the diameter of the copper wire) were determined as 1.7, 2.3, 4.6 and the control. The control means the traditional microstrip antenna with the copper foil functioning as conductive parts.

To describe the performance of the antenna, the return loss and radiation pattern are the two important parameters. Return loss is the negative of the magnitude of the reflection coefficient in dB and can be expressed as

where \( \left| \Gamma \right| \) is the reflection coefficient, which is the ratio of the amplitude of the reflected wave to the amplitude of the incident wave. The plot of return loss vs. frequency usually gives the return loss value as well as the resonant frequency, and the larger positive value of the return loss indicates the less loss of the incident power. Figure 2 shows the simulated return loss variations in the 1-2 GHz range. It can be seen that with the increase of S/D ratio, the resonant frequency of the 3DIMA moves left from the central frequency due to the conductive area shrinkage of the radiation elements. In addition, the dip of the return loss floats upward as the S/D ratio increases further, which means the positive value of the return loss tends to be low. When the S/D ratio reached 1.7, the return loss and resonant frequency were similar to the control and have relatively ideal values

The radiation pattern of the antenna reflects the radiation in 360-degree direction. For a microstrip antenna, the ideal radiation generally has the largest value above the patch (in zero degree). Figure 3 shows the simulated radiation patterns of E and H planes. The designed microstrip antenna is a vertically-polarized antenna. In this case, E plane was parallel to the feedline and H plane was perpendicular to the feedline. The simulated radiation patterns of E plane and H plane showed that when the S/D ratio was increased, the gains in zero degree direction decreased. When the S/D ratio reached 1.7, the radiation patterns were similar to the control ones. Therefore, the simulated return loss and radiation pattern showed that the antenna had best performance when the S/D ratio was 1.7. This also implied that when the S/D ratio was less than 1.7, the antenna performance would also be satisfactory due to the efficient conductive part and connection points of the copper wires.

3 Experimental

3.1 Fabrication of the 3DIMA

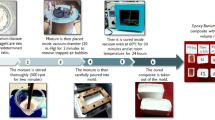

Based on the simulation results, two types of antennas were designed and fabricated. One was a single-element patch antenna with the S/D ratio of 1.7; the other was a two-element patch antenna with the S/D ratio of 1.

In the 3D integrated microstrip antenna structure, the weaving pattern of the patch could be several types. The most two practical types were interlaced woven structure and orthogonal woven structure as shown in Fig. 4. The simulation of the two types of woven structure using HFSS is difficult due to the complexity of building models. Therefore, the effect of the two types of weaving patterns on the antenna performance was investigated experimentally for the single element patch antenna.

For the single element patch antenna, Aramid fibers (Kevlar®129), with dielectric constant and dielectric loss of 4 and 0.01 respectively, were used to weave 3DIMA substrates. The resin for consolidation was vinyl ester with dielectric constant and loss of 3 and 0.01 respectively from Shanghai Resin Company, China. For the two-element patch antenna shown in Fig. 5, the substrate material for the antennas was the 3D orthogonal woven glass fiber reinforced vinyl ester composites, which have the relative dielectric constant of 4.5 and loss tangent of 0.01. The thickness of the substrate was 2.4 mm. The fabrication process of 3DIMA was very similar to that in our previous study [13, 14] and will not be introduced in detail herein.

3.2 Antenna Performance Test

Reflection coefficient was measured using an 8722ES Vector Network Analyzer in laboratory conditions. S11 and S22 were measured at ports 1 and 2 respectively, and the return loss was obtained as a measure of the mismatch of the reflected power to the incident power, which is logarithmically related to reflection coefficient. The radiation pattern was measured in the anechoic chamber using HP8510C Antenna Test System. The antenna was fixed with a termination of the section port, and then the signal of the vertical polarization was transmitted to the antenna. The radiation pattern was obtained from the signal received by the 360° rotating antenna. Gains were calculated by comparing field values of a reference-gain horn antenna.

4 Results and Discussion

The traditional antenna has the ideal return loss of less than -10 dB. Table 1 lists the measured return loss of the single-element patch woven antenna. The results showed that the antenna had relatively good return loss with proper resonant frequency in the 1-2 GHz. As the consequence of discontinuity of the patch and the existence of superstrate over the antenna, the 3DIMA has a shift from the central frequency of 1.5 GHz. For the convenience of comparison, the radiation patterns in H plane of the two types of patch configuration antennas were expressed using polar coordinates as shown in Fig. 6. The results showed that the measured radiation patterns agreed well with the simulated control one. However, the interlaced woven patch antenna presented larger side lobes and back lobe than those of the orthogonal woven patch antenna. The existence of curved copper wires caused low efficiency of reflection of the ground plane and the electromagnetic wave could not be reflected to the intended direction.

Figure 7 shows the return loss vs. frequency of the two-element patch antenna. Since the S/D ratio was set as 1, the measured result was in good agreement with the simulated result except for the light shift of the resonant frequency. The measured return loss for the antenna is about -20 dB with the resonant frequency of 1.45 GHz. The return loss result showed that the antenna was working in the designed frequency range. In addition, the two-element patch antenna has proper measured far-field radiation patterns both in E and H planes as shown in Fig. 8 and also agreed well with the simulation results. The measured gain of the array antenna was 2.3 dB.

5 Conclusions

3DIMA is a new concept of constructing smart materials and structures with structurally effective elements. The main concept of this new antenna is to weave the micorstrip antenna into the three dimensional orthogonal woven composites. To investigate the effect of the space of wires and weaving patterns on the antenna properties, simulation and experimental work have been done. Simulation results uncover the trend that the larger S/D ratio is, the resonant frequency shift it has, and the greater return loss as well as lower gain there is. When the S/D ratio reaches 1.7, the simulated antenna obtains almost the same electrical performance with the regular copper foil microstrip antenna. The experimental results on the return loss and radiation patterns of the single-element and two-element patch antennas agree well with the simulation results. In addition, the fabricated antenna with orthogonal patch pattern configuration have better radiation patterns than those of the interlaced patch pattern antenna experimentally.

References

Barnett, D.M., Rawal, S., Rummel, K.: Multifunctional structures for advanced spacecraft. J Spacecraft Rockets 38, 226–230 (2001)

Kang, B.K., Park, J.S., Kim, J.H.: Analysis and optimal design of smart skin structures for buckling and free vibration. Compos. Struct. 84, 177–185 (2008)

Noor, A.K., Venneri, S.L., Paul, D.B., Hopkins, M.A.: Structures technology for future aerospace systems. Comput. Struct. 74, 507–519 (2000)

Lockyer, A.J., Alt, K.H., Coughlin, D.P., Durham, M.D., Kudva, J.N., Goetz, A.C., ‘Design and development of a conformal load-bearing smart-skin antenna: overview of the AFRL Smart Skin Structures Technology Demonstration ((STD)-T-3)’ in Smart Structures and Materials 1999: Industrial and Commercial Applications of Smart Structures Technologies, 410–424 (1999)

Barnett, D.M., Rawal, S.P.: Multifunctional structures technology experiment on Deep Space 1 mission. IEEE Aerosp. Electron. Syst. Mag. 14, 13–18 (1999)

Stutzman, W.L., Thiele, G.A.: Antenna theory and design, Second edition, John Wiley & Sons, Inc (1998)

Kim, C.K., Lee, L.M., Park, H.C., Hwang, W., Park, W.S.: Impact damage and antenna performance of conformal load-bearing antenna structures. Smart Mater. Struct. 12, 672–679 (2003)

Tuss, J., Lockyer, A.J., Alt, K.H., Uldirich, F., Kinslow, R., Kudva, J.N., Goetz, A.C.: Conformal load-bearing antenna structure. In 37th AIAA Struct Dynamics Mater Conf, Salt Lake City, UT; 836–843 (1996)

You, C.S., Hwang, W., Park, H.C., Lee, R.M., Park, W.S.: Microstrip antenna for SAR application with composite sandwich construction: Surface-antenna-structure demonstration. J. Compos. Mater. 37, 351–364 (2003)

You, C.S., Hwang, W.: Design and fabrication of composite smart structures with high electric and mechanical performances for future mobile communication. Mech. Compos. Mater. 40, 237–246 (2004)

You, C.S., Hwang, W., Eom, S.Y.: Design and fabrication of composite smart structures for communication, using structural resonance of radiated field. Smart Mater. Struct. 14, 441–448 (2005)

You, C.S., Tentzeris, M.M., Hwang, W.B.: Multilayer effects on microstrip antennas for their integration with mechanical structures. IEEE Trans. Antennas Propag. 55, 1051–1058 (2007)

Yao, L., Qiu, Y.P.: Design and fabrication of microstrip antennas integrated in three dimensional orthogonal woven composites. Compos. Sci. Technol. 69, 1004–1008 (2009)

Yao, L., Wang, X., Xu, F.J., Zhao, D., Jiang, M.W., Qiu, Y.P.: Fabrication and impact performance of three-dimensionally integrated microstrip antennas with microstrip and coaxial feeding. Smart Mater. Struct. 18 (9), 095034 (6pp) (2009)

Acknowledgement

This work was supported by the National High Technology Research and Development Program of China, (No. 2007AA03Z101), Natural Science Foundation for the Youth (No. 50803010), the Program for Changjiang Scholars and Innovative Research Team in University (No. IRT0526), the Fundamental Research Funds for the Central Universities and the Program of Introducing Talents of Discipline to Universities (No. B07024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, L., Wang, X., Xu, F. et al. Effect of Wire Space and Weaving Pattern on Performance of Microstrip Antennas Integrated in the Three Dimensional Orthogonal Woven Composites. Appl Compos Mater 19, 21–30 (2012). https://doi.org/10.1007/s10443-010-9177-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-010-9177-4