Abstract

Spray drying biologics into a powder can increase thermal stability and shelf-life relative to liquid formulations, potentially eliminating the need for cold chain infrastructure for distribution in developing countries. In this study, process modelling, microparticle engineering, and a supplemented phase diagram were used to design physically stable fully amorphous spray-dried powder capable of stabilizing biological material. A greater proportion of anti-Campylobacter bacteriophage CP30A remained biologically active after spray drying using excipient formulations containing trehalose and a high glass transition temperature amorphous shell former, either trileucine or pullulan, as compared to the commonly used crystalline shell former, leucine, or a low glass transition temperature amorphous shell former, pluronic F-68. Particle formation models suggest that the stabilization was achieved by protecting the bacteriophages against the main inactivating stress, desiccation, at the surface. The most promising formulation contained a combination of trileucine and trehalose for which the combined effects of feedstock preparation, spray drying, and 1-month dry room temperature storage resulted in a titer reduction of only 0.6 ± 0.1 log10(PFU mL−1). The proposed high glass transition temperature amorphous formulation platform may be advantageous for stabilizing biologics in other spray drying applications in the biomedical engineering industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Spray drying is a one-step continuous process for converting liquid containing dissolved or suspended solids into a dry powder by solvent evaporation of the atomized liquid in a hot drying gas. The removal of the solvent, typically water, decreases water-mediated degradation, improves thermal stability, and decreases weight and volume.5 These improvements allow for more effective shipping, handling, and storage.30 For these reasons, spray drying is widely used in the food, pharmaceutical, chemical, and mining industries, among others.1,2,17 In comparison, the main alternative process for generating dry powder, lyophilization, is a batch process that requires more time, is higher cost, and typically requires a secondary milling step if particle size adjustment is needed.22,23 Improvements to spray drying techniques for stabilizing biological materials are of increasing interest for applications in the biopharmaceutical industries, where stabilized biologics are widely used as vaccines and for the treatments of common chronic illnesses such as arthritis and diabetes.29

We recently applied spray drying to stabilize bacteriophages (phages) active against Campylobacter jejuni,3 a leading cause of foodborne illness worldwide and a relatively major source of childhood mortality in Kenya.19 A limitation of the study was the extent of phage inactivation that occurred due to desiccation during spray drying.3 Biological inactivation by desiccation may be due to loss of hydrogen bonds, resulting in irreversible protein denaturation. The desiccation effect is strongest at the surface of the drying droplets, which is where biologics tend to concentrate during spray drying and exposure to drying gas occurs during particle formation.3,5 Therefore, it is hypothesized that excipients that increase viscosity and solidify into an amorphous solid phase early during the drying process may be capable of limiting the exposure of the biologic to the drying gas and may allow for hydrogen bond replacement to counter desiccation stress. However, under normal spray drying conditions, the commonly used shell forming excipient, leucine, crystallizes,8 and therefore is incapable of providing stabilization in an amorphous glass. Thus, testing the ability of shell forming excipients that can provide glass stabilization to spray-dried biologics is of interest. Two such excipient options are trileucine and pullulan.

Trileucine is a tripeptide that has been used to produce low-density and non-cohesive particles.15 It does not crystallize under typical spray drying conditions and has a sufficiently high dry glass transition temperature, ~ 104 °C, a low solubility in water, and a high surface activity,15,27 typically resulting in early solidification during the evaporation of aqueous solution droplets. These are favourable properties for minimizing exposure of phages to the drying gas.

Pullulan is an extracellular linear polysaccharide that has been used to produce respirable microparticles.4 It has a very high dry glass transition temperature of ~ 261 °C and a high molecular mass.4,7,24,25 Since pullulan diffuses slowly due to its high molecular mass, it tends to quickly enrich and increase viscosity near the surface of drying droplets,4 leading to early shell formation and potentially the prevention of phages from exposure to desiccation stress at the surface of the forming microparticles.

In this study, trileucine and pullulan, as amorphous shell formers, were compared to leucine and a polymeric surfactant, for improving the biological stability of spray-dried phages. This was tested using anti-Campylobacter phage CP30A as a model biologic and trehalose as a bulk stabilizing agent. The inactivation during processing and the short-term biological and physical storage stability of the powder without refrigeration were tested. The latter is important for use in developing countries without cold chain infrastructure. A process model and a supplemented phase diagram were applied to select spray drying parameters suitable for producing stable phage powder. Microparticle engineering models were used in particle design and particle formation models assisted in explaining the mechanisms of biological stabilization.

Materials and Methods

Phage CP30A

Phage CP30A is a Myoviridae that infects Campylobacter jejuni. The phage generation and assay were described in detail in a previous study.3 In this study, after the amplified lysate was 0.22 µm filtered, it was further purified by centrifugation and pellet resuspension in water, and 1:100 dilution into formulation, which was found to improve biological stability in our previous study.3

Formulation

To achieve the stabilization of biologics by amorphous shell formation, the dissolved solids concentration of trileucine in the feed solution was chosen to be near the solubility limit15 of ~ 6.8 mg mL−1. This allows for the development of rugose microparticles that solidify early in the drying process to encapsulate the phages. For pullulan, the dissolved solids concentration was chosen to be high enough to ensure early solidification, but not so high that it would increase viscosity to the point that atomization was affected.4 Pluronic F-68 surfactant, which has a low glass transition temperature of − 63 °C,12 was tested at the same dissolved solids concentration as trileucine, as it has a similar surface activity at this concentration, and the mass fraction is the same, making results comparable. Leucine and trehalose were tested at the same dissolved solids concentration used previously to examine shipping stability without cold chain infrastructure.3

Accordingly, the following aqueous formulations were prepared and tested with phages: (1) 4 mg mL−1 trileucine (Product no. L0879, lot BCBP2254V; Sigma-Aldrich, St. Louis, MO, USA) and 100 mg mL−1d-(+)-trehalose dihydrate (Cat. no. BP2687; Fisher BioReagents, NH, USA); (2) 20 mg mL−1 pullulan (Product no. J66961, lot N21D031; Alfa Aesar, Tewksbury, MA, USA) and 100 mg mL−1 trehalose; (3) 4 mg mL−1 pluronic F-68 (Product no. P7061, lot 70M011718V; Sigma-Aldrich, St. Louis, MO, USA) surfactant and 100 mg mL−1 trehalose; (4) 20 mg mL−1l-leucine (Code 125121000, lot A0269620; Acrös Organics, NJ, USA) and 100 mg mL−1 trehalose. Control measurements were performed using 100% pullulan at 20 mg mL−1 and 100% trehalose at either 30 mg mL−1 or 100 mg mL−1.

Spray Dryer Process Modelling

The spray dryer used in this study was a Büchi B-191 (Büchi Labortechnik AG, Flawil, Switzerland) with a custom twin-fluid atomizer that has been described in detail previously.3 A mechanistic process model based on steady state heat and mass balances on the spray dryer, similar to previous work,5 was used to determine suitable conditions for processing and storing the phage powder. First, the inlet processing conditions were used to predict the outlet conditions. Then, the moisture content in the powder at the outlet was predicted. The plasticized glass transition temperature was then predicted and compared to the storage target.

At constant pressure, the change in enthalpy, \(h\), between two locations, ‘in’ and ‘out’, for an incompressible liquid or ideal gas, is given by,5

where \(T\) is temperature and \(c_{\text{p}}\) is specific heat capacity.

Steady state conditions were assumed. Figure 1 shows a control volume around the spray dryer with process model parameters used for the energy balance.

The energy change of the atomizing gas, \(\dot{m}_{\text{ag}} \left( {h_{{{\text{ag}},{\text{out}}}} - h_{{{\text{ag}},{\text{in}}}} } \right)\), was found to be negligible. Additionally, the sensible heat change of the solvent was negligible; thus, only the latent heat of evaporation, \(\Delta h_{{{\text{w}},{\text{evap}}}}\), was considered for the solvent. The effects of energy changes of the solute and the formed solid were also neglected. Applying an energy balance on the control volume with these assumptions gives,

where \(\dot{m}\) is mass flow rate, the subscript ‘\({\text{dg}}\)’ refers to drying gas and ‘\({\text{w}}\)’ to the solvent: water here. The term \(\dot{E}_{\text{loss}}\) refers to energy (heat) loss from the spray dryer, which is not adiabatic.

Thermodynamic control volume around the spray dryer and associated process model parameters. \(\dot{E}_{\text{loss}}\) = energy (heat) loss from the spray dryer, \(\dot{m}_{\text{dg}}\) = drying gas mass flow rate, \(\dot{m}_{\text{ag}}\) = atomizing gas mass flow rate, \(\dot{m}_{\text{w}}\) = solvent (water) mass flow rate, \(h_{\text{dg}}\) = enthalpy of drying gas, \(h_{\text{ag}}\) = enthalpy of atomizing gas, \(h_{\text{w}}\) = enthalpy of solvent, \(P_{\text{out}}\) = outlet pressure, \(T_{\text{in}}\) = inlet temperature, \(T_{\text{out}}\) = outlet temperature.

Rearranging Eq. (2) and using Eq. (1) gives,

An empirical linear relation for heat loss is given by,

where the constants \(\alpha\) and \(\beta\) were experimentally determined by fitting data obtained using different inlet temperatures (range 50–80 °C), liquid feed flow rates (range 0–3.3 × 10−5 kg s−1), and drying gas flow rates (range 4.5 × 10−3–1.0 × 10−2 kg s−1).

Substituting and isolating for outlet temperature gives,5

The water activity at the outlet, \(a_{\text{out}}\), is given by,

where the saturation vapour pressure, \(p_{{{\text{w}},{\text{sat}}}}\), was found for different outlet temperatures by the empirical Antoine equation,21 and the water vapour partial pressure, \(p_{\text{w}}\), is,5

where \(p_{\text{out}}\) is the outlet pressure and \(M\) refers to molecular mass.

The outlet water activity was used to predict moisture content in the powder using literature data,20 giving the following approximation for trehalose moisture uptake,

where \(w_{2}\) is the mass fraction of water in the trehalose powder. The moisture content was used to predict the glass transition temperature for a trehalose-water system, \(T_{{{\text{g}},{\text{mix}}}}\), to develop a plasticization curve using the Gordon–Taylor equation,5

where the glass transition temperature of trehalose, \(T_{{{\text{g}},1}}\) = 387 K, and the glass transition temperature of water,\(T_{{{\text{g}},2}}\) = 138 K, were used with a constant \(K\) = 7.5, according to literature data.6 The mass fraction of trehalose was assumed to be w1= 1 − w2. Pullulan and trileucine were neglected for solid phase modelling. This is a conservative assumption as their inclusion would increase the glass transition temperature and theoretically lead to even better physical stability than predicted. The glass transition temperature and moisture content were plotted vs. outlet water activity.

Supplemented Phase Diagram

A non-equilibrium supplemented phase diagram (refer to Fig. 4) was developed using a method described previously5 and the equations given above. Briefly, the phase of a trehalose-water system at different temperatures and mass fractions of water was supplemented with process modelling predictions of moisture content and temperature of the droplets and produced powder throughout an approximation of the drying and storage process. The plasticization data of glass transition temperature for different moisture contents obtained using Eq. (9) was also included. This diagram is useful for choosing processing, packaging, and stability testing conditions to ensure adequate manufacturability and physical stability, which may be related to biological stability, as trehalose crystallization has been shown to inactivate biologics.26

Regarding the drying and storage process, the droplets were assumed to remain near the wet bulb temperature17 and then dry into particles that quickly reach the temperature of the drying gas in their vicinity, which was approximated in the diagram. As the particles proceed through the dryer to the outlet and collection bottle, heat loss occurs from the dryer and correspondingly the powder moisture content increases because cooler air has a lower saturated vapour pressure. The outlet conditions were predicted using process model Eqs. (5) and (8). The storage conditions were designed to be at least 50 °C below the glass transition temperature at the final moisture content,10 and the packaging was designed to protect against humidity intrusion.

Raman spectroscopy was performed using a custom Raman spectrometer31 after the powder was stored at room temperature for 4 months in a previously developed packaging system3 to confirm physical stability predictions from the supplemented phase diagram.

Microparticle Engineering Models and Particle Morphology

Microparticle engineering models were used to predict the evaporation time until solidification at the surface begins, the corresponding outer shell diameter, and the resulting particle morphology. Atomization causes droplets to be dispersed in hot drying gas resulting in solvent evaporation that leads to recession of the droplet surface and redistribution of solute or suspended matter in the droplet by diffusion. Unless the solute or suspended matter is capable of quickly diffusing to the interior of the droplet, it will tend to increase in concentration at the surface. A common approach to model this process is to use a non-dimensional Péclet number developed under the assumptions of 1-D spherical symmetry and no convection except Stefan flow.28 The effects of surface activity, shell deformation, change of droplet viscosity, and non-constant evaporation rates were not considered. The non-dimensional Péclet number is given by,28

where \(D_{i}\) is the diffusion coefficient of solute or suspended matter, \(i\), in the droplet solvent and \(\kappa\) is the evaporation rate taken as 4.0 × 10−9 m2 s−1 for the chosen drying conditions.28 The diffusion coefficient of pullulan in water was approximated to be 2.8 × 10−11 m2 s−1 for a typical molecular mass of 115 kDa.18 The diffusion coefficients of trehalose and trileucine were both approximated to be 5.0 × 10−10 m2 s−1.28 The diffusion coefficient of pluronic F-68 was approximated to be 1.0 × 10−10 m2 s−1 based on data for pullulan at the same molecular mass, 8.35 kDa.18

Dissolved or suspended solids with a high Péclet number diffuse slowly relative to the surface recession rate resulting in an increase in their concentration near the surface.27 A low Péclet number, i.e. less than 1, results in a relatively homogeneous distribution of the dissolved or suspended solids.27

The surface enrichment is defined as the ratio of surface concentration to mean concentration. A numerical model fit to the solution of Fick’s second law with the previous assumptions indicated that the surface enrichment of component \(i\) may be accurately approximated by,28

Due to this surface enrichment, dissolved solids with a high Péclet number will tend to first solidify at the droplet surface, where their concentration is highest, while the interior will not solidify until later in the drying process. For multi-component amorphous systems, co-solidification will occur at the surface of the drying droplet after evaporating for the characteristic time, \(t_{{{\text{t}},{\text{mix}}}}\), given by,4

where \(\tau_{\text{D}}\) is the droplet lifetime defined as \(\tau_{D} = d_{0}^{2} /\kappa\), in which \(d_{0}\) is the initial droplet diameter, which was assumed to be 9 µm based on data of mass median diameter for the twin-fluid atomizer and air–liquid ratio settings used,13 giving a droplet lifetime of 20 ms with the previously given evaporation rate, \(\kappa\). The non-dimensional number \(P_{i}\) is the ratio of initial solute concentration, i.e. dissolved solids concentration of solute \(i\) in the feedstock solution, to its solid true density. This model assumes co-solidification occurs when the true density of the mixture is reached at the surface.4 The true densities of trehalose, pullulan, and trileucine were assumed to be 1580 kg m−3,9 1850 kg m−3,4 and 1250 kg m−3, respectively. Pluronic F-68 was assumed to have the same true density as trehalose. Leucine was not modelled in this way as it crystallizes and separates from the other excipients.

The volume equivalent diameter at the time of shell formation, \(d_{\text{v}}\), can be predicted for multi-component fully amorphous microparticles, according to Ref. 4,

where the other variables have been described previously.

The particle density, \(\rho_{\text{p}}\), may be predicted according to a mass balance,27

where \(C_{\text{f}}\) is the total combined solute concentration in the feedstock.

The true density of a solid mixture, \(\rho_{{{\text{t}},{\text{mix}}}}\), is defined as,4

where \(Y_{i}\) is the mass fraction of component \(i\) and \(\rho_{{{\text{t}},i}}\) is the solid true density of component \(i\). If the ratio \(\rho_{\text{p}}\)/\(\rho_{{{\text{t}},{\text{mix}}}}\) is much less than one, the particle is expected to be hollow or wrinkled, or to have a smaller diameter than predicted due to particle contraction after initial solidification. If the ratio is near one, the particle is expected to be spherical and solid, and to have a diameter near the predicted value.

To examine the particle morphology, scanning electron microscopy (SEM) was performed with a field-emission SEM (Zeiss Sigma FESEM, Oberkochen, Germany) using settings of × 5000 magnification, working distance ~ 7 mm, and accelerating voltage 2 kV. An immersion lens (in-lens) detector, which is a type of secondary electron detector, was used in the SEM to provide topographical images. A sputter deposition system (Denton II; Denton Vacuum LLC, Moorestown, NJ, USA) was used prior to imaging to apply a gold coating of ~ 10 nm to minimize charging. Images were taken immediately after spray drying.

Processing Titer Reduction and Stability Testing

The processing titer reduction was defined as the titer of the initial phage lysate (divided by 100 due to the 1:100 dilution step) minus the titer of the spray-dried phage powder. The titer was measured using spot plaque assays, which are an in vitro test of biological activity because they are conducted on the pathogen. To assay the titers of the spray-dried powders, the powders were dissolved in water using a target concentration of 30 mg mL−1. The titer was also measured after room temperature storage for 1 month, in a packaging system described previously.3 For trileucine containing formulation, due to the low aqueous solubility, the formulation was allowed to dissolve for approximately 5 days prior to assay.

Statistics

Titer reduction results are given as mean ± standard deviation based on spot assays performed in triplicate. Statistical comparisons were performed using the Student’s t test at a significance level of 0.05 without assuming equal variance.

Results

Spray Dryer Process Modelling

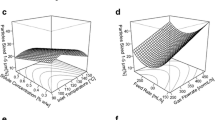

The obtained heat loss constants for use in Eq. (5) were \(\alpha\) = 4.75 × 10−3 kW K−1 and \(\beta\) = - 1.39 kW (R2 = 0.82) for the spray dryer used in this study. Using these constants, the process model predictions of outlet temperature and outlet water activity are given in Fig. 2. As expected, higher inlet temperature and drying gas mass flow rate corresponded to higher outlet temperature and lower outlet water activity. Due to evaporative cooling, higher liquid feed mass flow rate corresponded to lower outlet temperature and higher outlet water activity, as expected. An inlet temperature of 70 °C, drying gas flow rate of 8.5 × 10−3 kg s−1, and liquid feed flow rate of 1.7 × 10−5 kg s−1 were used in this study and resulted in a predicted outlet temperature of 49 °C and outlet water activity of 0.029. The measured outlet temperature during spray drying experiments matched the process model predictions to within 2 °C.

The predicted moisture content and glass transition temperature of trehalose powder for different outlet water activities are given in Fig. 3. For the chosen outlet water activity, the outlet moisture content is low enough that a sufficiently high glass transition temperature is expected to be achieved for long-term physical stability with room temperature storage.

Mass fraction of water and glass transition temperature of trehalose powder in equilibrium with different spray dryer outlet water activities. The chosen conditions are indicated by circles and are in the region for long-term physical stability, based on a glass transition temperature at least 50 °C above the 25 °C storage temperature.

Supplemented Phase Diagram

The developed supplemented phase diagram is given in Fig. 4. Long-term physical stability was predicted in terms of retention of amorphous structure for the chosen processing and storage conditions. Considering that both pullulan and trileucine have high glass transition temperatures (see “Introduction”), both were also predicted to have long-term physical stability. Good manufacturability was predicted as the glass transition temperature was not approached during processing.

As expected, Raman spectroscopy confirmed at least 4 months of physical stability for each tested fully amorphous powder, with trileucine, pullulan, pluronic F-68, and trehalose each retaining their amorphous structure.

Microparticle Engineering Models and Particle Morphology

The Péclet number was 1.0 for trehalose, leucine, and trileucine, 4.8 for pluronic F-68, and 18 for pullulan. Consequently, the predicted surface enrichment was 1.2 for trehalose, leucine, and trileucine, 2.2 for pluronic F-68, and 6.3 for pullulan. The microparticle engineering parameter predictions are given for the fully amorphous formulations in Table 1.

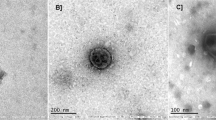

SEMs of the spray-dried powders containing phage CP30A are presented in Fig. 5. The leucine trehalose microparticles appeared to have small leucine crystals near the surface. Raman spectroscopy confirmed leucine was partially crystalline, while trehalose was fully amorphous. The trileucine trehalose microparticles were wrinkled. A previous study demonstrated that trileucine tends to form wrinkled microparticles when spray-dried with different actives and excipients.15 Trileucine tends to control the morphology of microparticles as it is typically designed to solidify at the surface prior to the other excipients by using it at a higher saturation level in the liquid feed solution than the other excipients. The pluronic F-68 trehalose microparticles were small and spherical. The pullulan trehalose microparticles were semi-wrinkled, in agreement with the literature for the tested mass fractions,4 and appeared to have a smaller diameter than predicted, potentially associated with the low \(\rho_{\text{p}}\)/\(\rho_{{{\text{t}},{\text{mix}}}}\) value, indicating particle contraction occurred after initial solidification. The pullulan-only microparticles had a very low \(\rho_{\text{p}}\)/\(\rho_{{{\text{t}},{\text{mix}}}}\) value and were accordingly very collapsed, in agreement with the literature.4 The trehalose microparticles were spherical, as expected.4

SEMs of phage CP30A powders spray-dried with different excipients. Notation: L leucine, T trehalose, LLL trileucine, S pluronic F-68 surfactant; P pullulan; preceding number denotes feedstock dissolved solids concentration in mg mL−1. 20T microparticles (not shown) were small (< 2 µm) and spherical. Images were taken of the powder immediately after processing. A change in particle morphology is not expected after 1 month of room temperature storage for the formulations containing trileucine or pullulan based on the high glass transition temperatures of the excipients used. The same magnification was used in all images.

Processing Titer Reduction and Stability Testing

The results of processing phage CP30A by spray drying and storing for 1 month in packaging protecting against humidity intrusion are given in Table 2. The use of trileucine resulted in the least overall titer reduction after processing and 1-month room temperature storage, with a total of only 0.6 ± 0.1 log10(PFU mL−1) titer reduction, which is a relatively low titer reduction for a biological powder production process.14 The use of pullulan with trehalose also outperformed the standard formulation of leucine with trehalose. The use of pluronic F-68 surfactant resulted in much worse stabilization than the use of trileucine, despite the same solids concentration and surface activity, and also resulted in very low manufacturing yield, potentially due to the glass transition temperature being exceeded during the spray drying process. Formulations with trehalose or pullulan alone performed poorly. The use of pullulan alone matched the use of trehalose alone when they were designed to have approximately the same evaporation time until solidification at the surface (see Table 1). The use of a higher solids concentration of trehalose outperformed a lower solids concentration in terms of titer reduction and manufacturing yield.

Discussion

The objective of this research was to develop a stable anti-Campylobacter phage powder with minimal titer reduction due to spray drying and room temperature storage through the use of process modelling, a supplemented phase diagram, and microparticle engineering. Generally, processing losses of greater than 1 log10(PFU mL−1) would lead to more expensive products which could make them unsuitable for developing countries. In order to protect against desiccation stress and the corresponding phage inactivation, the use of amorphous glass stabilizers trileucine and pullulan was tested and compared to the commonly used crystalline shell former leucine.

Leucine was shown to be partially crystalline and thus could not provide adequate glass stabilization to counter desiccation stress. Indeed, there is no glass stabilization within a crystal, and phages located within a forming crystal may be broken apart or expelled.

The stabilization achieved with amorphous shell formers pullulan or trileucine with trehalose outperformed leucine with trehalose, as hypothesized, and produced flowable powders. This was a novel finding as, to the authors’ knowledge, neither pullulan nor trileucine have been spray-dried with phages before. The use of pullulan or trehalose alone did not provide the same extent of biological stabilization as did their combination. This is perhaps related to better stabilization occurring with a core–shell microparticle structure, or with the earlier co-solidification at the surface when used in combination, which would decrease the fraction of phages that would otherwise be exposed to the drying gas and associated desiccation stress as the droplet shrinks. The latter was supported by the results showing that using trehalose at a higher initial dissolved solids concentration (100 mg mL−1), for which solidification was predicted to occur earlier and may prevent as many phages from reaching the surface, provided better, albeit insufficient, biological stabilization than using trehalose at a lower initial dissolved solids concentration (20 mg mL−1). This was also supported by results showing that the same level of biological stabilization was provided by pullulan-only as by trehalose-only when they experienced approximately the same predicted evaporation time until solidification at the surface (see Table 1) and hence approximately the same predicted diameter and predicted phage surface concentration at initial shell solidification. This happened despite different solids concentrations, i.e. biologic-to-glass stabilizer ratios. The proposed particle formation mechanisms and their relation to biological stabilization are described in more detail in Fig. 6 and in the footnote.Footnote 1

Schematic of the particle formation mechanisms for the different tested formulations and their relationship to phage distribution and stabilization. The best performing to worst performing formulations are from top to bottom. Descriptions of the particle formation processes are available in the footnote. Full resolution colour image available online.

To our knowledge, this is the first study in which phages have been spray-dried with trileucine, and excellent biological stabilization was observed, with an overall titer reduction of 0.6 ± 0.1 log10(PFU mL−1) due to formulation, spray drying, 1-month dry room temperature storage, and dissolving the powder in water for plaque assay. Based on microparticle formation calculations, trileucine is expected to form a very thin amorphous shell at the surface early in the drying process that provides glass stabilization to the phages and prevents the phages from reaching the surface and being exposed to desiccation stress. The shell may fold because it is thin and has a high flexibility11,32 in a rubbery, deformable state when initially formed at a high moisture content; after drying further the trileucine will progress to a glassy phase. Despite a similar surface activity, the pluronic F-68 surfactant did not provide the same level of stabilization as trileucine. This is perhaps due to poor biologic stabilization provided by the surfactant, which may be associated with its low glass transition temperature resulting in a suitable glassy phase not being formed after drying. The better stability using trileucine rather than surfactant indicated the importance of using a high glass transition temperature amorphous shell former rather than a low glass transition temperature amorphous shell former. The greater stabilization with trileucine as compared to pullulan may be related to the smaller molecular mass of trileucine, allowing the glass to more closely interact with the biologic, or to the surface activity, better preventing the phages from reaching the surface during drying.

Phages have previously been stabilized in pullulan trehalose films.16 To our knowledge, this is the first time pullulan trehalose microparticles have been used to stabilize biologics. This combination showed excellent biologic stabilization potential, outperforming the standard leucine trehalose combination that is commonly proposed for spray drying phages. Other high glass transition temperature polysaccharides than pullulan may also be suitable for glass stabilization near the surface of spray-dried microparticles.

Both novel successful spray-dried formulations, trileucine with trehalose, and pullulan with trehalose, were fully amorphous as opposed to the traditional crystalline shell-amorphous core system, leucine with trehalose. The amorphous shell platform for stabilizing biologics developed in this work consists of the use of a high glass transition temperature excipient that solidifies to an amorphous phase at the surface early in the spray drying process due to any combination of high initial dissolved solids concentration, high surface activity, or high molecular mass (associated with slow diffusion and hence high surface enrichment). In this study, the best stabilization was obtained using trileucine as an amorphous shell former, an excipient with intermediate molecular mass, high surface activity, and low solubility.

In summary, the use of processing modelling, microparticle engineering, and a supplemented phase diagram allowed for expedited design of physically stable spray-dried powder capable of stabilizing biological material with no iterations necessary to find suitable processing conditions. Based on data presented here, the use of a high glass transition temperature amorphous shell former that solidifies at the surface early in the drying process is recommended for glass stabilization of spray-dried phage CP30A against the main inactivating factor, desiccation at the surface of the drying microparticles. Indeed, fully amorphous formulation using trileucine (dry glass transition temperature ~ 104 °C) or pullulan (dry glass transition temperature ~ 261 °C) as shell-forming excipients and trehalose as a bulk glass stabilizer are promising alternatives to the standard crystal leucine shell and amorphous trehalose interior formulation for the development of stable spray-dried phage powders. With the fully amorphous approach, at least 1-month dry room temperature storage stability of active anti-Campylobacter phage CP30A in a flowable powder was achieved. The proposed amorphous shell platform is expected to be useful for the stabilization of other biologics that generally tend to concentrate on the surface of spray-dried microparticles and may have a variety of applications in the biomedical engineering and other industries.

Notes

A droplet emitted from the atomizer is assumed to initially be well-mixed in terms of the excipients being evenly distributed within the droplet, while the phages are assumed to be randomly distributed. “A”: trileucine is surface-active and near saturation initially and forms an amorphous shell with small amounts of trehalose early, before all phages are present at the surface. The mainly trileucine shell folds, potentially since it is thin and rubbery; the mainly trehalose interior has yet to solidify. The shell potentially maintains the same surface area upon folding and prevents phages from reaching the surface. “B”: the crumpled appearance is controlled by the folded shell. The interior later solidifies into a glass from a highly viscous solution due to further desiccation. “C”: pullulan enriches at the surface due to high molecular mass and forms a viscous amorphous shell that contains small amounts of trehalose; the shell contracts, causing phages to recede with the surface, and desiccates until a glassy mixture of pullulan and trehalose is present at the surface. “D”: the surface is mainly pullulan, with some trehalose that may have prevented shell deformation. The interior is mainly trehalose with some pullulan. “E”: nucleation at the surface results in small leucine crystals that eventually become close enough and large enough to form a shell. Trehalose and remaining leucine eventually solidify. “F”: phages could be expelled from crystals, be damaged by inter-crystal forces, or inhibit crystallization. Small crystals are at the surface of the microparticles. The interior is primarily trehalose and may contain voids. “G”: pullulan enriches near the surface and solidifies there. The thin shell is moderately rigid due to a high glass transition temperature and may easily deform and contract as it is not hindered by a trehalose interior. “H”: there is no trehalose glass stabilizer or void space in the interior. “I”: surfactant may form a film that recedes but does not adequately stabilize the phages. “J”: small cohesive spherical microparticle with phages near or on the surface where they are not adequately stabilized by the low glass transition temperature surfactant. “K”: small cohesive solid spherical microparticle formed. There is a high chance that phages reside on the surface. “L”: same as “K” except that a very small microparticle results and there is a very high chance that phages reside on surface. Void space is not shown in the schematic and may be possible in many cases. Note that there is likely a radial distribution of each excipient within the drying droplet rather than complete separation of excipients.

References

Anandharamakrishnan, C., and S. Padma Ishwarya. Spray Drying Techniques for Food Ingredient Encapsulation. Chichester: Wiley, 2015.

Broadhead, J., S. K. Edmond-Rouan, and C. T. Rhodes. The spray drying of pharmaceuticals. Drug. Dev. Ind. Pharm. 18:1169–1206, 1992.

Carrigy, N. B., L. Liang, H. Wang, S. Kariuki, T. E. Nagel, I. F. Connerton, and R. Vehring. Spray-dried anti-Campylobacter bacteriophage CP30A powder suitable for global distribution without cold chain infrastructure. Int. J. Pharm. 569:118601, 2019.

Carrigy, N. B., M. Ordoubadi, Y. Liu, O. Melhem, D. Barona, H. Wang, L. Milburn, C. A. Ruzycki, W. H. Finlay, and R. Vehring. Amorphous pullulan trehalose microparticle platform for respiratory delivery. Int. J. Pharm. 563:156–168, 2019.

Carrigy, N. B., and R. Vehring. Engineering stable spray-dried biologic powder for inhalation. In: Pharmaceutical Inhalation Aerosol Technology (3rd ed.), edited by A. J. Hickey and S. da Rocha. Boca Raton: CRC Press, 2019, pp. 291–326.

Chen, T., A. Fowler, and M. Toner. Literature review: supplemented phase diagram of the trehalose-water binary mixture. Cryobiology 40:277–282, 2000.

di Stefano, F. Pullulan as release enhancer for controlled release capsular device: performance assessment and preparation methods. M.Sc. Thesis, Department of Chemistry, Materials and Chemical Engineering, Politecnico di Milano, Milan, Italy. 2017.

Feng, A. L., M. A. Boraey, M. A. Gwin, P. R. Finlay, P. J. Kuehl, and R. Vehring. Mechanistic models facilitate efficient development of leucine containing microparticles for pulmonary drug delivery. Int. J. Pharm. 409:156–163, 2011.

Grasmeijer, N., H. W. Frijlink, and W. L. J. Hinrichs. Model to predict inhomogeneous protein-sugar distribution in powders prepared by spray drying. J. Aerosol Sci. 101:22–33, 2016.

Hancock, B. C., S. L. Shamblin, and G. Zografi. Molecular mobility of amorphous pharmaceutical solids below their glass transition temperatures. Pharm. Res. 12:799–806, 1995.

Hasegawa, T., J. Umemura, and N. Yamada. Characterization of thin cast films of a trileucine-induced lipid by infrared multiple-angle incidence resolution spectrometry. J Mol. Struct. 735–736:63–67, 2005.

He, X., L. Pei, H. H. Y. Tong, and Y. Zheng. Comparison of spray freeze drying and the solvent evaporation method for preparing solid dispersions of baicalein with pluronic F68 to improve dissolution and oral bioavailability. AAPS PharmSciTech. 12:104–113, 2011.

Hoe, S., J. W. Ivey, M. A. Boraey, A. Shamsaddini-Shahrbabek, E. Javaheri, S. Matinkhoo, W. H. Finlay, and R. Vehring. Use of a fundamental approach to spray-drying formulation design to facilitate the development of multi-component dry powder aerosols for respiratory drug delivery. Pharm. Res. 31:449–465, 2014.

Hoe, S., D. D. Semler, A. D. Goudie, K. H. Lynch, S. Matinkhoo, W. H. Finlay, J. J. Dennis, and R. Vehring. Respirable bacteriophages for the treatment of bacterial lung infections. J. Aerosol Med. Pulm. Drug Deliv. 26:317–335, 2013.

Lechuga-Ballesteros, D., C. Charan, C. L. M. Stults, C. L. Stevenson, D. P. Miller, R. Vehring, V. Tep, and M. C. Kuo. Trileucine improves aerosol performance and stability of spray-dried powders for inhalation. J. Pharm. Sci. 97:287–302, 2008.

Leung, V., A. Szewczyk, J. Chau, Z. Hosseinidoust, L. Groves, H. Hawsawi, H. Anany, M. W. Griffiths, M. M. Ali, and C. D. M. Filipe. Long-term preservation of bacteriophage antimicrobials using sugar glasses. ACS Biomater. Sci. Eng. 4:3802–3808, 2018.

Masters, K. Spray Drying: An Introduction to Principles, Operational Practice and Applications. London: Leonard Hill Books, 1972.

Nishinari, K., K. Kohyama, P. A. Williams, G. O. Phillips, W. Burchard, and K. Ogino. Solution properties of pullulan. Macromolecules 24:5590–5593, 1991.

O’Reilly, C. E., P. Jaron, B. Ochieng, A. Nyaguara, J. E. Tate, M. B. Parsons, C. A. Bopp, K. A. Williams, J. Vinjé, E. Blanton, K. A. Wannemuehler, J. Vulule, K. F. Laserson, R. F. Breiman, D. R. Feikin, M. A. Widdowson, and E. Mintz. Risk factors for death among children less than 5 years old hospitalized with diarrhea in rural western Kenya, 2005–2007: a cohert study. PLoS Med. 9:e1001256, 2012.

Roe, K. D., and T. P. Labuza. Glass transition and crystallization of amorphous trehalose-sucrose mixtures. Int. J. Food Prop. 8:559–574, 2005.

Rumble, J. R. CRC Handbook of Chemistry and Physics (98th ed.). Boca Raton: CRC Press, 2018.

Schwartzbach, H. Achieving aseptic drying with spray drying technologies. Pharm. Technol. Eur. 23:90–92, 2011.

Siew, A. Exploring the use of aseptic spray drying in the manufacture of biopharmaceutical injectables. Pharm. Technol. 40:24–27, 2016.

Singh, R. S., and G. K. Saini. Biosynthesis of pullulan and its applications in food and pharmaceutical industry. In: Microorganisms in Sustainable Agriculture and Biotechnology, edited by T. Satyanarayana, B. N. Johri, and A. Prakash. Dordrecht: Springer, 2012, pp. 509–553.

Teekamp, N., Y. Tian, J. C. Visser, P. Olinga, H. W. Frijlink, H. J. Woerdenbag, and W. L. J. Hinrichs. Addition of pullulan to trehalose glasses improves the stability of β-galactosidase at high moisture contents. Carbohydr. Polym. 176:374–380, 2017.

Vandenheuvel, D., J. Meeus, R. Lavigne, and G. van den Mooter. Instability of bacteriophage in spray-dried trehalose powders is caused by crystallization of the matrix. Int. J. Pharm. 472:202–205, 2014.

Vehring, R. Pharmaceutical particle engineering via spray drying. Pharm. Res. 25:999–1022, 2008.

Vehring, R., W. R. Foss, and D. Lechuga-Ballesteros. Particle formation in spray drying. J. Aerosol Sci. 38:728–746, 2007.

Walsh, G. Biopharmaceutical benchmarks 2014. Nat. Biotechnol. 32:992–1000, 2014.

Walters, R. H., B. Bhatnagar, S. Tchessalov, K. I. Izutsu, K. Tsumoto, and S. Ohtake. Next generation drying technologies for pharmaceutical applications. J. Pharm. Sci. 103:2673–2695, 2014.

Wang, H., M. A. Boraey, L. Williams, D. Lechuga-Ballesteros, and R. Vehring. Low-frequency shift dispersive Raman spectroscopy for analysis of respirable dosage forms. Int. J. Pharm. 469:197–205, 2014.

Yamada, N., T. Komatsu, H. Yoshinaga, K. Yoshizawa, S. Edo, and M. Kunitake. Self-supporting elastic film without covalent linkages as a hierarchically integrated β-sheet assembly. Angew. Chem. Int. Ed. 42:5496–5499, 2003.

Acknowledgments

NC thanks the Killam Trusts, the Natural Sciences and Engineering Research Council of Canada, Alberta Innovates, and the University of Alberta for scholarship funding. This work was financially supported by the Biotechnology and Biological Sciences Research Council [Grant Number BB/P02355X/1] (United Kingdom). The funding source had no role in study design, collection, analysis, or interpretation of data, writing the article, or in decision to submit the article for publication.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editor Emmanuel Opara oversaw the review of this article.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carrigy, N.B., Liang, L., Wang, H. et al. Trileucine and Pullulan Improve Anti-Campylobacter Bacteriophage Stability in Engineered Spray-Dried Microparticles. Ann Biomed Eng 48, 1169–1180 (2020). https://doi.org/10.1007/s10439-019-02435-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10439-019-02435-6