Abstract

Vitamin B12 plays a very important role in human body and its deficiency can be detrimental to the production of red blood cells, anemia, memory loss, low immunity to infection, and permanent and severe damage in the nervous system and brain. In the present work, vitamin B12 sensing has been accomplished using two Electrochemiluminescence (ECL) platforms, one with Bipolar Electrode (BPE), while the second one Single Electrode (SE). The electrodes were fabricated on polyimide (PI) substrate by creating optimized Laser-Induced Graphene (LIG). With optimized speed and power of CO2 Laser, non-conducting portion of PI gets converted into conducting zone (electrodes) for ECL imaging. A 3D-printed miniaturized portable system was developed to detect and monitor the ECL signals. Android smartphone was effectively used to provide dual functions such as to drive the DC to DC buck-boost converter and to capture the ECL images. The sensing of vitamin B12 was accomplished in the linear range 0.5–700 nM and 0.5–1000 nM with a limit of detection (LOD) 0.107 nM (R2 = 0.98, n = 3) and 0.094 nM (R2 = 0.977, n = 3), respectively, for BPE and SE-based ECL platforms correspondingly. Therefore, proposed ECL platforms can be selectively used in various domains such as point of care testing (POCT) and biomedical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent era, microfluidic-based analytical devices have gathered huge attention of the researchers as they provide numerous advantages such as cost-effectiveness, easy accessibility, simple in fabrication and operation, small in size, rapid analysis, portability and easily inheritability with the point-of-care testing devices. Due to these virtues, the microfluidic devices have been used for environmental detection, food quality control, molecular analysis, and health monitoring (Ge et al. 2012; Li et al. 2012; Nery and Kubota 2013). Several analytical detection methods compatible with microfluidics-based POCT, including chemiluminescence (CL), electrochemistry, Electrochemiluminescence (ECL), fluorescence, etc., have been reported. Among these Electrochemiluminescence (ECL)-based microfluidic platforms are recognized as an important and highly sensitive detection strategy for fabrication and development of point of care testing (POCT) devices (Liu et al. 2015; Gao et al. 2017; Xiao et al. 2016; Wang 2013). ECL provides unique advantages over other detection techniques which include, (1) it does not require any excitation light, which leads to provides high selectivity, sensitivity, and low background signal, (2) small volumes of analytes are required for the analysis, (3) provides wide linear range and good control of light emission, etc. (Zanut 2020). Recently, paper-based ECL systems was effectively used for the detection of some biomolecules including H2O2, glucose (Chen et al. 2016; Liu et al. 2015), lactate, choline and cholesterol (Xiao et al. 2016; Wang et al. 2018) etc.

Vitamin B12, also called cobalamin or cyanocobalamin, is soluble in water and cobalt-containing vitamin (Parvin et al. 2018), making it the most prevalent and complex vitamin. As it is involved in the production of red blood cells, maintaining the normal level of vitamin B12 is essential for the healthy immune system and synthesis of DNA; therefore, it acts as an important nutrient in the human body for the maintenance of neurological functions (Reddy et al. 2020). Eggs, meat, fish, milk poultry, etc. are the natural sources of vitamin B12. Vitamin B12 plays a very important role in human metabolism and its deficiency can cause fatigue, memory loss, restlessness, hair loss, mood swing, anemia, low immunity to infection, and permanent or severe injury in the nervous system and brain. The normal values of vitamin B12 in human body (blood serum) ranges from 160 to 950 picograms per milliliter (pg/ml) or 0.118 to 0.7 nM (Watanabe 2007; Akshaya et al. 2019; Mwafy and Afana 2018). Hence, the development of a portable, sensitive, and reliable detection system with a simple approach is crucial to sense and monitor vitamin B12. Therefore, in the present work, for the first time, attempt has been made to sense vitamin B12 without using any enzymes with the help of LIG-based ECL platform.

In the present work, a miniaturized, portable and sensitive Electrochemiluminescence (ECL) system with Laser-Induced Graphene (LIG)-based Bipolar (BPE) and Single Electrode has been discussed to sense vitamin B12. Polyimide (PI) material was used for the fabrication of the ECL device with electrodes. PI provides several advantages like reliability, more stability, one step fabrication, and rapid prototyping (Jayapiriya et al. 2020; Lin 2014). With the optimized speed and power, LIG, with enhanced conductivity, can be formed on PI by ablation of the CO2 laser (Kothuru et al. 2020; Rahimi et al. 2016). Herein, for the fabrication of BPE ECL and SE ECL, LIG-based approach was used as it provides several key advantages over other conductive material such as carbon, stainless steel etc. These advantages include low resistivity, high surface area, high carrier mobility, high thermal conductivity and excellent mechanical properties (high Young’s modulus and intrinsic strength) (Wang 2018). Various characterizations of LIG on PI, such as SEM, Raman, and XPA spectra, were carried out in the previous work published by our group, providing admirable formation of LIG on PI (Kothuru et al. 2020; Rewatkar et al. 2020).

2 Experimental section

2.1 Materials and equipment

For the fabrication of a portable 3D-printed black box, PLA filament was purchased from the Nova beans, India. Polyimide sheet with 250 μm thickness was purchased from Dali Electronics India. A CO2 infrared laser system (VLS 2.30 from Universal Laser, USA) was used to develop LIG SE and BPE electrode-based ECL systems. To power, the ECL image-sensing device, step-up step-down DC to DC buck-boost (5 V to 1.2–24 V) USB converter was used. Android smartphone was effectively used to provide two functions such as to power the ECL system through the buck-boost (DC to DC) converter and to captured the ECL signals.

Vitamin B12 (with > = 98% purity), Hydrogen Peroxide (H2O2) 35%, Luminol 97% were purchased from Sigma Aldrich, India. NaOH and acetone was procured from SRL Chemicals, India. DI water was used to prepared different analytes with different molar concentrations.

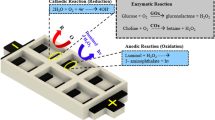

2.2 Device principle of BPE and SE LIG-ECL

The working principle of Laser-Induced Graphene (LIG)-based bipolar (BPE) and single (SE) electrode-based ECL systems is illustrated in Fig. 1a, b, respectively. Two rectangular shape driving electrodes (DEs) were connected to the edge of the channel. As illustrated in Fig. 1a, BPE was immersed into the channel and placed in between two DEs. An external potential was applied to DEs with the help of a buck-boost converter. As the applied external potential was sufficient, a strong electric field was generated across the channel leading to initiate the redox (oxidation and reduction) phenomenon at BPE. The oxidation and reduction happened simultaneously on the opposite poles of BPE which led to generating ECL signal at the edge of the anode, as shown in Fig. 1a. The relation between the change in electric field and applied external voltage is given in the following equation (Liu et al. 2016, 2017):

where \(\Delta {\mathrm{E}}_{\mathrm{lect}}\)= change in electric field across the bipolar electrode, Etot = total external applied voltage, Lchannel = length of the channel, LBPE = Length of the bipolar electrode.

In a similar manner, when the external potential was applied to the single electrode (SE)-based ECL system, as shown in Fig. 1a, b strong electric field was generated across the channel. The magnitude of the electric field was very high at the anode of DE and it decreased linearly while moving towards cathode of DE. When applied voltage was sufficient, the strong electric field was generated across the channel which initiated oxidation and reduction at anode and cathode, respectively, leading to generate ECL signal at the anode. The relation between the driving voltage and the potential difference between driving electrodes is given in the following equation (Gao et al. 2018; Ma 2019):

where \({\Delta \mathrm{E}}_{c}\)= potential difference between two driving electrodes, VTOT = total applied external voltage, Lc = length of channel, Le = length of driving electrodes.

2.3 Device fabrication

Fabrication of LIG-based BPE and SE ECL system has been accomplished by inducing a CO2 laser on a polyimide (PI) sheet. With the optimized speed and power, LIG was formed by ablation of CO2 infrared laser over PI sheet (Jayapiriya et al. 2020; Kothuru et al. 2020). All the optimized parameters (speed and power) and fabrication flow were taken from the literature for the fabrication of LIG-based BPE and SE ECL system (Bhaiyya et al. 2020). The fabrication process is illustrated in Fig. 2 for the LIG-based BPE ECL system.

Fabrication flow for the Laser-Induced Graphene (LIG)-based Bipolar Electrode (BPE) Electrochemiluminescence (ECL) system, a PI sheet was glued to glass substrate, b CO2 infrared laser was directed over PI sheet with optimized speed (10%) and power (50%) to create a channel, c creation of channel over PI sheet after pulling out black portion (carbon) from the ablated PI sheet, d ablation of CO2 infrared laser over PI sheet to form laser-induced graphene (LIG)-based driving (DEs) and bipolar (BPE) electrode with optimized speed (80%) and power (50%)

2.4 Assay procedure of LIG BPE and SE ECL device

After the fabrication of LIG BPE and SE ECL devices, an assay was performed to validate the performance of the fabricated devices. For the present work, the detection of vitamin B12 was carried out without using any enzymes. The following procedure was adopted for the detection of vitamin B12 using luminol-based chemical reaction. First, the luminol and vitamin B12 were pipetted into the channel and the power supply was turned on for the optimized period (120 s in case of LIG-BPE and 60 s for LIG-SE) with optimized voltage (7 V for both LIG-BPE and LIG-SE devices) followed by steering operation to generate H2O2 (Garcia-Manyes and Beedle 2017). To initiate the chemical reaction steering operation was performed. With optimized voltage and period, H2O2 was produced using oxygen and reduced graphene oxide (Kim et al. 2018; Nurhafizah et al. 2019; Faucett 2016). After steering operation, to observe the ECL signal, once again power supply was turned on and the generated ECL signal was successfully captured with the help of android smartphone. The relation between Time (s) vs ECL Intensity (RLU) for the LIG BPE and LIG SE ECL device is illustrated in Fig. 3a, b, respectively.

Time (s) vs ECL intensity (RLU); a optimization of time for the generation of H2O2 in case of BPE, Time: 30, 60, 90, 120 and 150 s, applied voltage: 7 V, luminol = 4 mM, vitamin B12 = 500 nM; b optimization of time for the generation of H2O2 in case of SE, Time: 15, 30, 45, 60 and 90 s, applied voltage: 7 V, luminol = 5 mM, vitamin B12 = 500 nM; n = 3

2.5 Assembly of LIG ECL device, data acquisition and analysis

Herein, a 3D-printed portable miniaturized assembly was fabricated for the detection of ECL signal generated by LIG-based BPE and SE system. A low cost, compact DC to DC buck-boost converter was used to drive the ECL system. The output of DC to DC buck boost converter was given to LIG ECL device through switch. To obtained different voltage values DC to DC buck boost converter has been effectively used. An android smartphone was effectively used to capture the ECL images and to drive the DC to DC buck-boost converter. 3D-printed assembly with an android smartphone and DC to DC buck-boost converter is shown in Fig. 4.

After the detection of the ECL signal, for data acquisition and analysis, ImageJ software was used. Following steps were followed to calculate the ECL signal intensity using ImageJ software. First, captured ECL image was uploaded in ImageJ. Second, high intensity area around (2000 pixels) was chosen for the calculation of ECL intensity and then mean grey value was calculated. The same process was followed throughout to calculate the ECL intensity. Calculation of ECL signal intensity using ImageJ software is illustrated in Fig. 4b.

3 Results and discussion

3.1 Device design and fabrication

Polyimide (PI) sheet was used to fabricate the ECL devices including electrodes. To realize BPE and SE electrodes over PI sheet, all the optimized parameters of universal CO2 infrared laser system (speed and power) and the fabrication flow was taken from the article published by our group (Bhaiyya et al. 2020), wherein BPE and DEs were fabricated using CO2 laser for the sensing of glucose and H2O2. The final fabricated device with device dimensions is revealed in Fig. 5.

3.1.1 Parameters optimization of LIG BPE and SE ECL device

The performance of the device depends significantly on the width and length of BPE not too much on the dimensions of the driving electrode (width and length of the DE were selected to be 6 and 7 mm, respectively) (Chen et al. 2016). Several experiments were performed, wherein the width of BPE varied from 0.5 to 1.5 mm and it was observed that from 0.5 to 1 mm the ECL intensity was increased and then no significant change was observed in the ECL intensity. Therefore, the optimized width of BPE was chosen as 1 mm.

In this work, our primary focus was to fabricate miniaturized portable handheld low-cost ECL platform. When the length of the BPE increases too much (beyond 10 mm), it leads to increase the size of the LIG-ECL device and more reagents are consumed. Furthermore, there is no significant improvement in the ECL intensity. Hence optimization of the length of BPE was also performed and it was found that the ECL intensity did not changed more than 5% as the length of BPE varied from 10 to 15 mm. The dependency of ECL intensity on width and length of BPE is shown in Fig. 6a, b, respectively. Similarly, in case of LIG SE-based ECL device, the ECL signal intensity is mainly depending on the length and not that much on width of driving electrodes (DEs). At 6 mm DEs length, maximum ECL intensity was observed. Hence, length of DEs was chosen to 6 mm for the sensing of vitamin B12. To provide proper electrical contacts the width of DEs was chosen to 8 mm. Therefore, in case of LIG SE ECL device width and length of the DEs were chosen to 8 and 6 mm, respectively.

a Width of BPE (mm) vs ECL Intensity (RLU); width of BPE: 0.5, 0.7, 1, 1.3 and 1.5 mm; (H2O2: 1 mM); (Applied Voltage: 7 V); (Luminol: 4 mM); b Length of BPE (mm) vs ECL Intensity (RLU); Length of BPE: 8, 10, 13 and 15 mm; (Applied Voltage: 7 V); (Luminol: 4 mM); (H2O2: 1 mM); (Error bars for n = 3)

The ECL signal intensity is also depends on the length of the channel (Liu et al. 2017; Chen et al. 2016). As the length of the channel increases too much which leads to consumes more reagent and if the length of the channel is too short then it is difficult to get a stable ECL signal. By considering this, several experiments have been performed, where channel length was varied from 16 to 24 mm, and concerning every value of channel length, ECL intensity was calculated which is shown in Fig. 7. For the presented work it was observed that when channel length was less than 20 mm, an unstable ECL signal was obtained. Standard deviations of ± 15 and ± 6.8 were calculated for the channel length 16 and 18 mm, respectively, at the optimized driving voltage of 7 V. At 20 mm channel length, stable ECL intensity signal was obtained with standard deviation ± 1.5 at the optimized voltage. As the channel length increased above 20 mm, consumption of reagent increased. Stable ECL intensities were obtained for the channel length 22 and 24 mm at applied voltage 9 and 11 V with standard deviations ± 2.52 and ± 5.34, respectively. Hence, it is clearly evident that with increasing the length of channel the consumption of reagent and applied voltage increased. Hence for LIG BPE-ECL system optimized channel length was kept as 20 mm when the ECL signal began to get stabilized. In continuation, similar analysis has been carried out for the LIG SE ECL device and optimized channel length was chosen as 12 mm.

3.2 Assay optimization for LIG BPE and SE ECL device

To improve the analytical performance of the device, it is important to optimize the parameter over which ECL signal intensity is highly dependent. The dependable factors on ECL signal include applied external voltage, concentration of luminol and concentration of pH. For sensing of vitamin B12 using LIG BPE ECL device, all the optimized parameters were taken as it is from the previous work from our group (Bhaiyya et al. 2020). In a similar way, optimization process was carried out for the LIG SE ECL-based ECL device and optimized parameters were used to sense vitamin B12 using LIG SE ECL. Table 1 shows the optimized parameter values used by LIG BPE and SE ECL devices to sense vitamin B12.

3.3 Analytical performance on LIG BPE and SE ECL

After realizing the LIG BPE and SE-based ECL device optimization was carried out and then to validate the performance of the ECL device, sensing of vitamin B12 has been done. Background ECL signal (only because of luminol) was subtracted from each obtained ECL signal (ECL signal because of luminol and vitamin B12) values for different concentration of vitamin B12 and then resultant graph showing the relation between vitamin B12 and ECL signal intensity was plotted which is shown in Fig. 8. With miniaturized portable 3D-printed platform sensing of vitamin B12 was accomplished by LIG BPE and SE ECL device for the linear range 0.5–700 nM and 0.5–1000 nM with a limit of detection (LOD) 0.107 nM (R2 = 0.98, n = 3) and 0.094 nM (R2 = 0.977, n = 3), respectively. Hence, it was clear evidence that the proposed device can be effectively used for the detection of vitamin B12 as it ranges from 0.118 to 0.7 nM in human body (Watanabe 2007).

Vitamin B12 vs ECL Intensity (RLU), a sensing of vitamin B12 using LIG BPE ECL, (vitamin B12: 0.5, 100, 200, 300, 500 and 700 nM); (Applied Voltage: 7 V); (Luminol: 4 mM), b sensing of vitamin B12 using LIG SE ECL, (vitamin B12): 0.5, 100, 200, 300, 500, 700 and 1000 nM), (Applied Voltage): 7 V; (Luminol): 5 mM, (Error bars for n = 3)

4 Conclusion

In summary, with optimized parameters (speed and power) of CO2 infrared Laser, LIG-based BPE and SE ECL platform were fabricated over polyimide sheet for the detection of vitamin B12. In the presented work major focused was given to develop a miniaturized portable system to captupe and analyze ECL images. The external bulky power supply was replaced by a compact and low-cost DC to DC buck-boost converter to drive the ECL system. Android smartphone was perfectly placed over a 3D-printed black box to capture ECL images as well as to provide power to DC to DC buck-boost converter. Sensing of vitamin B12 was accomplished by LIG BPE and SE ECL device for the linear range 0.5–700 nM and 0.5–1000 nM with a limit of detection (LOD) 0.107 nM (R2 = 0.98, n = 3) and 0.094 nM (R2 = 0.977, n = 3), respectively. This makes the platforms amenable to detect vitamin B12 even in humans. Future work will include testing real samples for vitamin B12 sensing and evaluating the specificity of the device-sensing capabilities.

References

Akshaya KB, Anitha V, Nidhin M, Sudhakar YN, Louis G (2020) Electrochemical sensing of vitamin B12 deficiency marker methylmalonic acid using PdAu-PPy tailored carbon fiber paper electrode. Talanta 217:121028. https://doi.org/10.1016/j.talanta.2020.121028

Bhaiyya M, Rewatkar P, Salve M, Pattnaik PK, Goel S (2020) Miniaturized electrochemiluminescence platform with laser-induced graphene electrodes for multiple biosensing. IEEE Trans Nanobioscience. https://doi.org/10.1109/TNB.2020.3036642

Chen L, Zhang C, Xing D (2016) Paper-based bipolar electrode-electrochemiluminescence (BPE-ECL) device with battery energy supply and smartphone read-out: a handheld ECL system for biochemical analysis at the point-of-care level. Sensors Actuators, B Chem 237:308–317. https://doi.org/10.1016/j.snb.2016.06.105

Faucett AC (2016) Voltage-induced reduction of graphene oxide by submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in Physics in the Graduate School of Binghamton University State University of New York https://doi.org/10.13140/RG.2.2.25520.76801

Gao W, Saqib M, Qi L, Zhang W, Xu G (2017) Recent advances in electrochemiluminescence devices for point-of-care testing. Curr Opin Electrochem 3(1):4–10. https://doi.org/10.1016/j.coelec.2017.03.003

Gao W, Muzyka K, Ma X, Lou B, Xu G (2018) A single-electrode electrochemical system for multiplex electrochemiluminescence analysis based on a resistance induced potential difference. Chem Sci 9(16):3911–3916. https://doi.org/10.1039/c8sc00410b

Garcia-Manyes S, Beedle AEM (2017) Steering chemical reactions with force. Nat Rev Chem. https://doi.org/10.1038/s41570-017-0083

Ge L, Yan J, Song X, Yan M, Ge S, Yu J (2012) Three-dimensional paper-based electrochemiluminescence immunodevice for multiplexed measurement of biomarkers and point-of-care testing. Biomaterials 33(4):1024–1031. https://doi.org/10.1016/j.biomaterials.2011.10.065

Jayapiriya US, Rewatkar P, Goel S (2020) ScienceDirect Miniaturized polymeric enzymatic biofuel cell with integrated microfluidic device and enhanced laser ablated bioelectrodes. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2020.06.133

Kim HW et al (2018) Efficient hydrogen peroxide generation using reduced graphene oxide-based oxygen reduction electrocatalysts. Nat Catal 1(4):282–290. https://doi.org/10.1038/s41929-018-0044-2

Kothuru A, Rao CH, Puneeth SB, Salve M, Amreen K, Goel S (2020) “Laser-induced flexible electronics (LIFE) for sensing applications. IEEE 20(13):7392–7399

Li X, Ballerini DR, Shen W (2012) A perspective on paper-based microfluidics: current status and future trends. Biomicrofluidics. https://doi.org/10.1063/1.3687398

Lin J et al (2014) Laser-induced porous graphene films from commercial polymers. Nat Commun 5:5–12. https://doi.org/10.1038/ncomms6714

Liu R, Zhang C, Liu M (2015) Open bipolar electrode-electrochemiluminescence imaging sensing using paper-based microfluidics. Sensors Actuators, B Chem 216:255–262. https://doi.org/10.1016/j.snb.2015.04.014

Liu M, Liu R, Wang D, Liu C, Zhang C (2016) A low-cost, ultraflexible cloth-based microfluidic device for wireless electrochemiluminescence application. Lab Chip 16(15):2860–2870. https://doi.org/10.1039/c6lc00289g

Liu M, Wang D, Liu C, Liu R, Li H, Zhang C (2017) Battery-triggered open wireless electrochemiluminescence in a microfluidic cloth-based bipolar device. Sensors Actuators, B Chem 246:327–335. https://doi.org/10.1016/j.snb.2017.02.076

Ma X et al (2019) A portable wireless single-electrode system for electrochemiluminescent analysis. Electrochim Acta 308:20–24. https://doi.org/10.1016/j.electacta.2019.04.015

Mwafy SN, Afana WM (2018) Hematological parameters, serum iron and vitamin B12 levels in hospitalized Palestinian adult patients infected with Helicobacter pylori: a case–control study. Hematol Transfus Cell Ther 40(2):160–165. https://doi.org/10.1016/j.htct.2017.11.010

Nery EW, Kubota LT (2013) Sensing approaches on paper-based devices: a review. Anal Bioanal Chem 405(24):7573–7595. https://doi.org/10.1007/s00216-013-6911-4

Nurhafizah MD, Suriani AB, Mohamed A, Soga T (2019) Effect of voltage applied for graphene oxide/latex nanocomposites produced via electrochemical exfoliation and its application as conductive electrodes. Diam Relat Mater 101(November):2020. https://doi.org/10.1016/j.diamond.2019.107624

Parvin MH, Azizi E, Arjomandi J, Lee JY (2018) Highly sensitive and selective electrochemical sensor for detection of vitamin B12 using an Au/PPy/FMNPs@TD-modified electrode. Sensors Actuators, B Chem 261:335–344. https://doi.org/10.1016/j.snb.2018.01.168

Rahimi R, Ochoa M, Ziaie B (2016) Direct laser writing of porous-carbon/silver nanocomposite for flexible electronics. ACS Appl Mater Interfaces 8(26):16907–16913. https://doi.org/10.1021/acsami.6b02952

Reddy SS, Prabhakar YK, Kumar CU, Reddy PY, Reddy GB (2020) Effect of vitamin B12 supplementation on retinal lesions in diabetic rats. Mol Vis 26(April):311–325

Rewatkar P, Kothuru A, Goel S (2020) PDMS-Based microfluidic glucose biofuel cell integrated with optimized laser-induced flexible graphene bioelectrodes. IEEE Trans Electron Devices 67(4):1832–1838. https://doi.org/10.1109/TED.2020.2971480

Wang S et al (2013) 3D microfluidic origami electrochemiluminescence immunodevice for sensitive point-of-care testing of carcinoma antigen 125. Sensors Actuators, B Chem 176:1–8. https://doi.org/10.1016/j.snb.2012.08.035

Wang D, Liu C, Liang Y, Su Y, Shang Q, Zhang C (2018) A simple and sensitive paper-based bipolar electrochemiluminescence biosensor for detection of oxidase-substrate biomarkers in serum. J Electrochem Soc 165(9):B361–B369. https://doi.org/10.1149/2.0551809jes

Wang F et al (2018) Laser-induced graphene: preparation, functionalization and applications. Mater Technol 33(5):340–356. https://doi.org/10.1080/10667857.2018.1447265

Watanabe F (2007) Vitamin B12 sources and bioavailability. Exp Biol Med 232(10):1266–1274. https://doi.org/10.3181/0703-MR-67

Xiao Y, Xu L, Qi LW (2017) Electrochemiluminescence bipolar electrode array for the multiplexed detection of glucose, lactate and choline based on a versatile enzymatic approach. Talanta 165:577–583. https://doi.org/10.1016/j.talanta.2017.01.019

Zanut A et al (2020) Insights into the mechanism of coreactant electrochemiluminescence facilitating enhanced bioanalytical performance. Nat Commun 11(1):1–9. https://doi.org/10.1038/s41467-020-16476-2

Acknowledgements

The authors would like to thank the Department of Science and Technology, Science and Engineering Research Board (DST-SERB), Government of India, Grant No. CRG/2019/005468, for funding this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhaiyya, M., Pattnaik, P.K. & Goel, S. Electrochemiluminescence sensing of vitamin B12 using laser-induced graphene based bipolar and single electrodes in a 3D-printed portable system. Microfluid Nanofluid 25, 41 (2021). https://doi.org/10.1007/s10404-021-02442-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-021-02442-x