Abstract

We developed a method of interfacing microfluidics with mass spectrometry (MS) using a robotic spotting system to automate the contact spotting process. We demonstrate that direct and automated spotting of analyte from multichannel microfluidic chips to a custom microstructured MALDI target plate was a simple, robust, and high-throughput method for interfacing parallel microchannels using matrix-assisted laser desorption/ionization mass spectrometry (MALDI-MS). Using thermoplastic cyclic olefin copolymer (COC) polymer microfluidic chips containing eight parallel 100 μm × 46 μm microchannels connected to a single input port, spotting volume repeatability and MALDI-MS signal uniformity are evaluated for a panel of sample peptides. The COC microfluidic chips were fabricated by hot embossing and solvent bonding techniques followed by chip dicing to create open ends for MS interfacing. Using the automatic robotic spotting approach, microfluidic chip-based reversed-phase liquid chromatography (RPLC) separations were interfaced with electrochemically etched nanofilament silicon (nSi) target substrate, demonstrating the potential of this approach toward chip-based microfluidic separation coupled with matrix-free laser desorption/ionization mass spectrometry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The ability to perform high-throughput bioanalysis in a single integrated platform is a substantial benefit offered by microfluidics technology. Arrays of multiplexed microchannels allowing large numbers of simultaneous on-chip analyses have been demonstrated in numerous applications including chemical reaction screening (Wang et al. 2006a), immunoassays (Wang et al. 2006b), enzymatic processing (Su et al. 2005), biomolecular separations performed by zone electrophoresis (Chen et al. 2002; Shen et al. 2006), gel electrophoresis (Li 2004; Medintz et al. 2001), denaturing gradient electrophoresis (Buch et al. 2005), and isoelectric focusing (Cui et al. 2005). A common challenge in many bioanalytical systems is the need for accurate identification of biopolymers on the basis of their molecular weights. For applications that require analyte detection with high mass accuracy, interfacing microfluidics with mass spectrometry (MS) is necessary. However, microfluidic chip interfacing to mass spectrometry is not a straightforward process and requires further development to effectively transport sample from the chip to mass spectrometer. A number of microfluidic-mass spectrometry interfacing devices have demonstrated. Generally, microfluidic chips are commonly interfaced with mass spectrometry by either through electrospray ionization mass spectrometry (ESI–MS) or through matrix-assist laser desorption/ionization mass spectrometry (MALDI-MS).

Electrospray directly from microfluidic chip surface is the most straightforward and most frequent approach for interfacing microfluidic with mass spectrometry. The first microfluidic chip based mass spectrometry interfacing was demonstrated in 1997 by Xue et al. (1997a, 1997b) and Ramsey and Ramsey (1997) through electrospray sample from the flat edge of a glass microfluidic chip to mass spectrometer orifice. However, several issues limit its application, for example: sample spreading at the hydrophilic interface causes large dead volumes on the flat edge and flat edge is not ideal to establish strong electrical field thus does not create efficient and stable electrospray. Following developments of ESI–MS interfacing including mating microchannels to conventional capillary tips (Chan et al. 1999; Lazar et al. 1999; Pinto et al. 2000; Zhang et al. 2001), incorporating with hydrophobic membrane (Wang et al. 2004), photolithography fabricated emitters (Freire et al. 2008) and microfabricated tapered electrospray tips (Dahlin et al. 2005; Mery et al. 2008; Schilling et al. 2004; Yin et al. 2005). These methods have present as potential solutions to minimizing liquid spreading at the channel orifice, minimizing dead volumes and providing better stability for mass spectrometry interfacing application. Some examples of microfluidic systems containing multiplexed microchannels interfaced to electrospray ionization (ESI) tip arrays for ESI–MS analysis have been previously demonstrated (Le Gac et al. 2003; Tang et al. 2001; Xue et al. 1997b). The multiplexed electrospray process is performed sequentially from channel to channel instead of simultaneously which limit the analysis throughput. In practice, ESI–MS interfacing systems are not well suited to parallel analysis. Coupling multiple electrospray tips with parallel MS analysis would thus require multiple MS tools, substantially limiting the practicality of this approach.

MALDI-MS is an alternative commonly used mass spectrometry interfacing method that presents a superior solution to high-throughput applications in multiplex format than ESI–MS. MALDI-MS is typically performed by transferring the sample and matrix solution onto the target substrate followed by air-drying the deposited spots leaving co-crystallized UV-absorbing organic matrix sample on the target substrate for the following mass spectrometry analysis (Karas and Hillenkamp 1988). A variety of approaches for interfacing microfluidic systems to MALDI-MS have been demonstrated which including employ a rotating ball to transfer sample form a polymer microfluidic chip to MALDI-MS system (Musyimi et al. 2005), deposition through tube fitting (Lee et al. 2008), and directly transfer from enclosed channels to target plate for MALDI-MS analysis (Brivio et al. 2005). A commercialized microfluidic device from Gyros Inc. uses centrifugal fluidic propulsion for sample preparation and MALDI-MS interfacing (Gustafsson et al. 2004). One approach called spot-on-a-chip platform uses microfabricated piezoelectric-actuated dispensers to transfer picoliter size droplet for MALDI-MS analysis (Ekstrom et al. 2001a; Laurell et al. 2001). The piezoelectric membrane was operated at 500 Hz to deposit the droplets onto the MALDI target with droplet volume varied from 30 to 200 pL. Electrospray deposition of sample/matrix solution has also demonstrated by Wang et al. (2005). Uniform sample deposition with spots as small as 170 μm were readily produced from the tiny electrospray mists. A widely known digital microfluidic technique, called electrowetting, was also demonstrated in MALDI-MS interfacing (Moon et al. 2006; Wheeler et al. 2004, 2005). This technique uses electric voltage to manipulate the droplet for generating sample/matrix solutions for MALDI-MS detection. Overviews of these and other related approaches are discussed in several recent review papers (DeVoe and Lee 2006; Foret and Preisler 2002; Jeonghoon et al. 2009).

The ESI–MS method of data acquisition is performed in real-time together with the on-chip analytical process. In contrast, LDI-MS is an off-line ionization method providing advantages over ESI–MS for interfacing microfluidic devices with mass spectrometry. Samples deposited on the LDI target substrate can be preserved so that MS experiments can be conducted without time constraints. In addition, for high-throughput multichannel microfluidic devices, parallel deposition of samples from multichannel onto the target plate for off-line LDI-MS analysis is feasible while simultaneous electrospraying sample to MS orifice for on-line ESI–MS analysis is not practical due to the equipment limitation. Knapp and co-workers demonstrated that a multichannel cyclic olefin copolymer (COC) microfluidic chip could be used for parallel multiplex reversed-phase liquid chromatography (RPLC) analysis (Ro et al. 2006). The chip was interfaced with a MALDI target through an electrically mediated deposition technique (Ericson et al. 2003) in the case of a 2-channel.

Through off-line LDI-MS analysis, the performance of this technique can be further enhanced by modifying the LDI target substrate. Microfabrication technologies have been widely used to modify LDI target plate surfaces to improve detection sensitivity. LDI-MS can detect femtomol or less when the target substrate is modified. For conventional stainless steel MALDI target plate, due to the liquid sample spreading on the metal surface, only small portion of deposited sample is present during the mass spectrometry scan under approximately 100–200 μm diameter size. Several microfabricated MALDI target plates have been demonstrated to physically constrain lateral sample spreading; these modifications have included anisotropically bulk etching on silicon target plate to create vials (Ekstrom et al. 2001a; Little et al. 1997) or directly milling to create vials on polymer-based target plate to increasing local concentration (Ekstrom et al. 2001b). The most common approach is done by either coating hydrophobic layer as sample support like poly(tetrafluoroethylene) (Hung et al. 1999) and propyltrimethoxysilane (Xiong et al. 2003) or by coating hydrophilic gold pad on hydrophobic Teflon background (Schuerenbeg et al. 2000) to constrain lateral spreading of analyte during deposition and matrix cocrystallization. In a recent research demonstration, galvanic etching techniques have also been used to produce nanoscale porous or filament-like structure on silicon surfaces as matrix-free, high sensitivity LDI-MS target substrate for bioanalysis. The nanostructure on this silicon surface serves to efficiently absorb UV laser energy during LDI-MS analysis to ionized small biomolecules without adding organic matrix solution with high sensitivity down to femtomole or attomole range (Tsao et al. 2008a; Wei et al. 1999).

In this study, we present a simple approach for interfacing microfluidics with microstructured MALDI-MS and nSi-MS target plate based on hydrodynamic contact spotting through an automatic robotic spotting system. Compared to other MS interfacing methods, contact spotting provides a generic approach for LDI-MS interfacing which is straightforward to implement and integrate by fixing microfluidic chip and LDI-MS target plate on their respective robotic stages. The microfluidic chip technology presented here combines a fully integrated flow splitter and parallel microchannels for contact spotting onto a LDI-MS target substrate. This configuration enabled all spotting tips in the array to be operated from a single pump. This approach is suitable for highly multiplexed systems and also compatible with a wide dynamic range of flow rates, where the use of independent pumps for each channel would be impractical. In addition, the single inlet port configuration is also amenable to applications in high-performance liquid chromatography (HPLC) separation. Further integration of microfluidic chip-based separations interfacing with the electrochemically etched matrix-free LDI-MS silicon target substrate, nanofilament silicon (nSi), is also discussed in this study.

2 Experimental section

2.1 Materials and sample preparation

Cyclic olefin copolymer (COC) sheets used for microfluidic chip fabrication (Zeonor 1020R) were procured from Zeon Chemicals (Louisville, KY). 10 cm diameter p-type <100> silicon wafers with resistivity of 0.005–0.02 Ω-cm for nanofilament silicon target substrate preparation were purchased from Customized Communication Inc (La Center, WA). Teflon AF solution was purchased from DuPont Fluoroproducts (Wilmington, DE). The MassPREP peptide consisting of 9 model peptides was purchased from Waters (Milford, MA). Butyl methacrylate (BMA, 99%), ethylene dimethacrylate (EDMA, 99%), ethylene diacrylate (EDA, 90%), methyl methacrylate (MMA, 99%), 1,4-butanediol (99%), 1-propanol (≥99.5%), cyclohexane (99%), acetonitrile (ACN, reagent grade), 2,2′-dimethoxy-2-phenylacetophenone (DMPA, 99%), benzophenone (BP, 99%), neurotensin (98%), bradykinin acetate (98%), [leu5]-enkephalin (96%), angiotensin II acetate, α-cyano-4-hydroxycinnamic acid (CHCA), and 0.1% trifluoroacetic acid (TFA) solution were purchased from Sigma–Aldrich (St. Louis, MO). Methanol, 2-propanol (IPA) and HPLC water were obtained from Fisher Scientific (Pittsburg, PA). Trimethylolpropane trimethacrylate (TMPTMA) was received as a gift from Sartomer (Warrington, PA). Ethyl alcohol was purchased from Pharmco-AAPER (Shelbyville, KY). 49% hydrofluoric acid (HF), 30% hydrogen peroxide, acetic acid, sodium carbonate, and sodium bicarbonate were purchased from J.T. Baker (Phillipsburg NJ)

2.2 Polymer microfluidic chip fabrication

The polymer microfluidic chip fabrication employed hot embossing from a deep reactive-ion etching (DRIE) silicon micromold. The patterns on the DRIE micromold were initially defined by standard UV lithography process followed by transferring to deep reactive ion etcher (Surface Technology Systems, Newport, UK) to create a 45 μm deep silicon micromold. 2.0 mm thick COC sheet was cut into 3 × 8 cm pieces using tabletop dicing saw (Micro-Mark, Berkeley Heights, NJ) and cleaned with IPA and DI water, dried with N2, and dehydrated in a vacuum oven at 85°C for 2 h. COC replicas were generated upon the DRIE micromold by hot embossing using commercial hydraulic hot press (AutoFour/15, Carver, Wabash, IN). The press platens were preheated to 125°C, followed by application of a fixed pressure of 2.0 MPa. After 10 min, pressure was released, the platens were cooled to 95°C, and the imprinted COC plate was released from the silicon micromold. The imprinted substrate was then solvent bonded to a second COC plate pre-drilled with a 1.5 mm diameter reservoir prior to bonding. A small volume of cyclohexane was placed in a glass beaker and the pre-drilled COC plate was fixed on a glass cover which sealed the beaker. After 5.5 min of cyclohexane vapor deposition at room temperature, the COC substrates were aligned and bonded at 3.5 MPa for 10 min in the hot press.

2.3 Automated spotting system

A robotic spotting system was developed to automate the spotting process and coupling the polymer microfluidic chip with LDI-MS target substrate which was shown in Fig. 1. The 5 μm positioning resolution was achieved using micro-stepper motors (Parker Hannifin, Rohnert Park, CA) to drive three independent linear stages (Mitutoyo, Aurora, IL). A 3-axis (X, Y and Z) stage was used for microfluidic chip positioning, and a 2-axis (X and Y) stage was used to position the LDI-MS target. A manual rotation stage attached to the chip positioner provided initial angular alignment between the spotting array and the target surface. Using custom LabView (National Instrument, Austin, TX) code for motor control, the system provided precise chip-to-target alignment and allowed automated positioning during the spotting process.

2.4 Monolith preparation

The monolith inside the microchannel was fabricated according to the process described by Frechet et al. (Stachowiak et al. 2003) The COC microchannel surface was initially modified to enhance monolith/wall adhesion through photografting method. Subsequently, the reversed-phase monolith was fabricated in situ using a UV photolithography process resulting in a monolith with a morphology well suited for application to liquid chromatography applications. The COC microchannel was first thoroughly rinsed with methanol, dried in a vacuum oven at room temperature, and filled with a reaction solution containing 49.5 wt% EDA, 49.5 wt% MMA, and 1.0 wt% BP, which has been sonicated for 30 min. The device was then exposed to UV generated from a PRX-1000 UV source (Tamarack Scientific, Corona, CA) with a radiation power of 24.0 mW/cm2 for 630 s. Following UV grafting, the channel was again rinsed with methanol and dried in the vacuum oven. The reversed-phase monolithic stationary phase was synthesized using a photolithography method. First, a reaction solution containing 24.5 wt% BMA, 14.5 wt% TMPTMA, 30.0 wt% 1-propanol, 30.0 wt% 1,4-butanediol, and 1.0 wt% DMPA was degassed through 30 min sonication, then introduced to the surface-treated COC channel. In order to selectively photopolymerize the solution in the separation channel, the entire channel except for the separation channel section was covered with a photomask. After 240 s UV exposure using the PRX-1000 UV source, the resulting 150 mm long monolith was rinsed with methanol at 1 μl/min for 12 h before use.

2.5 LDI-MS measurements

The LDI-MS tests were performed on a Kratos Amixa time-of-flight (TOF) mass spectrometer (Kratos Analytical, Manchester, UK). All LDI-MS spectra were acquired in linear, positive ion mode using between 25 and 50 laser pulses from a 337 nm nitrogen laser with a 3 ns pulse width. Laser power was optimized based on signal-to-noise (S/N) ratio using a test sample spot, and held constant during all experiments.

3 Results and discussion

3.1 Multiplex microfluidics microstructured MALDI-MS interfacing

3.1.1 Design and fabrication of multiplex microfluidics chip and the microstructured MALDI-MS target

It is generally desirable to use parallel multiplex microchannels on an integrated microfluidic chip platform. High throughput can be achieved by performing multiple functions within each microchannel. Connecting each microchannel to a single input channel is a functionally simple approach. In contrast, connecting each single channel to its individual input is impractical for large channel number and potentially increases system complexity. A single input multiplex microfluidic chip design was employed in this study. As shown in Fig. 2a, the system consisted of a symmetric 3-stage splitter connecting a single input port to an array of 8 parallel microchannels. Each channel was nominally 100 µm wide and 46 µm deep, with geometric variances of less than 1.5% measured across all channels prior to chip bonding. The overall microchannel network was 50 mm long from input port to spotting tips. And a micrograph of an individual spotting tip from this chip is also shown in Fig. 2b.

While the primary steps for fabricating the multichannel COC spotting chips were based on commonly employed hot embossing methods, a critical step in the fabrication of these devices is the final dicing of the exit surfaces to expose the fluid exit points by using a semiconductor wafer dicing saw (DAD321, Disco Hi-Tec America, Santa Clara, CA). Before dicing, the regions around the spotting tips were shaped using a CNC milling machine to reduce the amount of COC material required to be removed by the dicing saw. This step resulted in an improved surface finish and enhanced uniformity of spotting tip geometry, while allowing the use of higher feed rates during dicing. Higher water contact angles on the chip exit surfaces were desirable to prevent droplets from wetting the chip outlets during spotting. Stronger hydrophobic exit surfaces could also encourage easier droplet transfer to the MS target, particularly for smaller droplets, by reducing the contact forces between droplets and spotting tips. Deposition of Teflon AF offers a simple approach to produce hydrophobic layers with good mechanical property and chemical resistance. In this study, low-temperature-baked Teflon AF layer was used to prevent overheating COC chip above its glass transition temperature (T g), which would have caused the distortion of polymer-based microchannels. A film of Teflon AF was coated on the tip exit surfaces by blotting from a glass slide, and the chip was heated to 90°C for 2 h to densify the Teflon AF layer. As shown in Fig. 3, the deposition of densified Teflon AF film on the exit surface resulted in a water contact angle of 98° rendering the surface substantially more hydrophobic than native COC exit surface of 67° before coating.

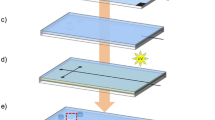

In conventional MALDI-MS analysis, the liquid sample deposited on the stainless steel target plate spread on the stainless steel target plate and resulted in large sample spots typically measuring from 5 to 10 mm2. For an approximately 200 μm diameter laser spot size, only a small portion of deposited sample was analyzed during the mass spectrometry test, limiting the detection performance. For the off-line LDI-MS interfacing approach, detection performance can be further improved by target plate modification. Schuerenbeg et al. (2000) shown that the detection sensitivity can be greatly enhanced simply by spotting a gold anchor on a Teflon film. In this study, the microstructured MALDI target plates were fabricated by first spin-coating a thin Teflon AF layer onto an optically smooth stainless steel plate. The Teflon AF film, approximately 1 µm thick, was baked at high temperature of 250°C for 2 h to produce a highly densified hydrophobic layer over the entire stainless steel surface. A 300 nm thick gold film was then deposited by e-beam evaporation using a shadow mask to pattern four 8 × 8 arrays of 250 µm diameter gold pads on top of the Teflon AF film. Each gold anchor was 2 mm away from the other anchors, corresponding to the 8 channel spotting chip.

3.1.2 Characterization of multiplex microfluidics microstructured MALDI-MS interfacing

The 8 channel microfluidic chip and microstructured MALDI target were fixed on their respective robotic stages, with the spotting array tips initially aligned 2 mm from the gold anchor pads on the target. Lyophilized MassPREP peptide used for evaluating the interfacing performance were reconstituted with 0.1% aqueous TFA solution to an initial concentration of 1 pmol/μl for each of RASG-1 (MW:1000.49), Amgiotensin frag.1-7 (MW:898.47), Angiotensin II (MW:1045.53), Bradykinin (MW:1059.56), Angiotensin I (MW:1295.67), Renin Substrate (MW:1757.92), Enolase T35 (MW:1871.9604), Enolase T37 (MW:2827.28), and Melittin (MW:2845.74) peptide sample. The samples were pre-mixed with MALDI matrix to avoid the need for adding matrix solution to the target surface after peptide deposition, thereby eliminating this potential source of experimental variability. The MALDI matrix solution consisted of 10 µg/μl CHCA mixed into acetonitrile, DI water, and acetic acid 5:4:1 v/v/v. The matrix solution was mixed 1:1 v/v/with the peptide sample, for final peptide concentrations of 0.5 pmol/μl. The premixed matrix sample was introduced into the microfluidic chip using a syringe pump (PHD2000; Harvard Apparatus, Holliston, MA) connecting through a 100 μm i.d. silica capillary (Polymicro, Phoenix, AZ) couple with a Nanoport (Upchurch Scientific, Oak Harbor, WA) bonded to the chip at the single input reservoir.

Spotting was performed by moving the microfluidic chip to 200 μm away from the target surface to transfer droplets to the gold pads, then returning to the initial 2 mm gap and indexing the stage for the next row. The hydrophilic anchor pads were found to be effective in encouraging the efficient transfer of droplets from the hydrophobic chip spotting tips and also served to maintain the positions of the deposited droplets once transferred to the MALDI target. Sequential images of the robotic spotting process are shown in Fig. 4a. Each of the 8 channels deposited droplets in parallel onto the MALDI target plate, with a total of 8 spotting events to fill the array. For each experiment, peptide sample premix with matrix solution was deposited onto 64 target spots in an 8 × 8 array. A total flow rate of 12 μl/min was imposed by a syringe pump, with a 6 s interval between each spotting event resulting in a 150 nl theoretical droplet volume for each spot. In practice, due to variations in hydraulic resistance and surface hydrophobicity between each channel in the array, corresponding variations in spotted droplet volumes were observed. At total flow rate of 12 μl/min, spotting droplet volumes varied from 104 to 190 nl droplet volume between spotting events from individual channels. The measured variability in droplet volumes was expected based on a previously reported analytic and numerical model of the multichannel spotting process (Tsao et al. 2008b). It should be noted that the model also predicts that tighter control of droplet volume repeatability can be obtained by using higher flow rates, or by increasing the hydraulic resistance of the channels. Following spotting, the array of droplets was air dried, leaving co-crystallized sample and matrix on the gold anchors. With deposition volume between 104 to 190 nl and 52 to 95 fmol model peptides was deposited on the target substrate. Figure 4b shows sequential images of the solvent evaporation and sample/matrix co-crystallization process on a single gold anchor pad. The Teflon hydrophobic background was found to constrain lateral sample spreading leaving the crystallized sample/matrix on the hydrophilic gold anchor. This resulted in a higher local concentration than hydrophobic layer on the prestructured MALDI target plate.

a Consecutive images of the automated contact spotting process using a 12 μl/min total flow rate and 6 s interval between spotting events, resulting in an 8 × 8 array of 150 nl droplets deposited on the microstructured MALDI target surface. b Sequential images showing the solvent evaporation and sample/matrix co-crystallization process on a single gold anchor

The target plate with sample deposition is then affixed to a custom machined substrate holder for MALDI-TOF MS measurements. Figure 5 shows the mass spectra from all 8 channels during a single spotting event. The MALDI-MS spectra acquired from the 64 sample spots provided repeatable identification for 8 model peptides across all spotting events. Except for the m/z value at 1000.5 (RASG-1) presents relatively low average signal intensity of 58 mV with signal-to-noise (S/N) value less than 3 for peptide identification, all other 8 model peptides present high average signal intensity of 720 mV. Figure 6 displays the resulting uniformity of MALDI-MS signal intensities.

MALDI-MS spectra for peptide sample deposited from all 8 channels form 1st spotting event (Sp1) to 8th spotting event (Sp8) for m/z value 1–4000 with interference from matrix components below 500 m/z value shows in the right. In the top image, the mass spectra (Sp6) with m/z value of 500–4000 event shows identification of angiotensin fragment 1 (MW 898.7), angiotensin II (MW 1045.5), bradykinin (MW 1059.6), angiotensin I (MW 1295.7), renin substrate (MW 1758.0), enolase T35 (MW 1872.0), enolase T37 (MW 2827.3), and melittin (MW 2845.7)

Figure 6a shows the deviation of intensity values between different spotting events averaged over all channels with average RSD of 48%, while Fig. 6b reveals deviations between each channel averaged over all spotting events with an average RSD of 44%. The measured RSD values shows good MALDI-MS signal uniformity with an overall average RSD of 46% across all 64 spots for all observed peptides. This result compares favorably with an RSD of 50% in MALDI-MS signal intensities reported for multiple peptide spots generated by sequential depositions from a single capillary using an optimized matrix seed layer technique (Onnerfjord et al. 1999) and is significantly lower than the variations observed between spotting volumes. The reason for this latter observation is that MALDI-MS analysis was performed by acquiring data with the MALDI laser positioned on the region of highest sample concentration, as determined by visual inspection of the target under the MALDI imager. Thus, the influence of molar variations in deposited sample on MALDI-MS signal intensity was reduced.

3.2 Microfluidic LC chip/nSi-MS interfacing

3.2.1 Design and fabrication of microfluidic LC chip and nSi LDI-MS target

Previous multiplex microfluidics MALDI-MS characterizations were generated using a microstructured stainless steel MALDI target for sample deposition and analysis. Our research demonstrates that this process may be performed through a reverse-phase liquid chromatography (RPLC) microfluidic chip interfaced with a high sensitivity matrix-free nanofilament silicon (nSi) LDI-MS target substrate through direct spotting. The matrix-free nSi target substrate were fabricated using procedures identical to our previously reported process (Tsao et al. 2008a). A 3 nm thick gold layer was first deposited onto silicon wafer by e-beam evaporation followed by immersion into a solution of HF, H2O2, and EtOH (1:1:1 v/v/v) mixture in a Teflon beaker for 32 s to create ~2.8 μm deep and ~10 nm diameter filament-like nanostructures on silicon surface. The RPLC chip design used in this study shown in Fig. 7 consists of one injection port for water and acetonitrile injection and a 150 mm long serpentine separation channel regulated with double-T cross-injector. The double-T on-chip injection design precisely controls sample loading and significantly reduces the dead volume band broadening during sample injection process compared to off-line injection methods. The entire separation channel was 150 mm long from input port to spotting tips. Fabrication of the RPLC chip employed thermal embossing, solvent bonding and chip dicing using procedures identical to the 8 channel chip fabrication except that the chip inlet port was inserted by a surgical stainless steel needle as high pressure-resistance, low dead-volume interconnections (Chen et al. 2009). After microfluidic chip fabrication, porous monoliths were fabricated inside the microchannel through standard UV lithography process. Silica capillary sections with outer diameters of 360 μm and inner diameters of 100 μm were used to connect the microchip to external pumps and valves.

3.2.2 Characterization of microfluidic LC chip and nSi LDI-MS interfacing

In order to evaluate the RPLC chip to nSi interfacing performance, model peptides consisting of [leu5]-enkephalin (MW 555.62), angiotensin II (MW 1046.18), bradykinin (MW 1060.61), and neurotensin (MW 1672.92) were dissolved in 10 mM sodium carbonate/bicarbonate buffer (pH 9.0) to a concentration of 2 mM. Equal volumes of each peptide solution were diluted 5-fold with HPLC grade water before being injected into the double-T injector. During sample injection, the 6-way selection valve (Upchurch Scientific, Oak Harbor, WA) was set at position 1 and sample was injected to the microchip at a flow rate of 4 μl/min using a PHD-2000 syringe pump (Harvard Apparatus, Holliston, MA). Water was simultaneously pumped to the microchip at a flow rate of 15 μl/min using a PU-2089 analytical LC pump (Jasco, Easton, MD). The sample was diverted to the head space of the separation channel and stacked at the front end of the RP monolith in the double-T column. Immediately after the sample was injected, the selection valve was switched to position 3 and residual sample inside channels was flushed into waste containers preventing sample from leaking from the side channels during separation.

In RPLC separation interfacing with nSi target substrate procedure, a linear ACN gradient was delivered to the RPLC chip from the LC pump to elute and separate the sample stacked at the head column. The master flow rate of LC pump was set at 1–2 ml/min and the flow rate in the monolithic column was 200–500 nl/min. During separation, the double-T channels together with the connecting capillaries served as two passive splitters to shunt a specific portion of mobile phase to waste, thus maintaining the desired flow rate in the separation channel. By selecting different capillaries lengths and diameters, control of split ratios could be readily achieved. Throughout the separation, automatic spotting was performed by moving the chip 200 μm from the target surface for eluting droplets to come into contact with the nSi substrate before returning to the initial 2 mm gap and indexing the stage for the next spot. A total of 20 droplets were eluted onto the nSi substrate, with 2 min between each spotting event over the full 40 min separation time. The microfluidic chip separated 20 droplets and a droplet of peptide mixture droplet on nSi substrate was transfer to Kratos Amixa time-of-flight (TOF) mass spectrometer for MS analysis. The resulting mass spectra measured from each of the 20 deposited spots are shown in Fig. 8.

Each of the sample peptides was observed in specific fractions deposited on the nSi surface, with [leu5]-enkephalin identified in spots #2 and #3, angiotensin II from spot #5, and bradykinin and neurotensin together from spot #10 which indicates RPLC separation eluting of [leu5]-enkephalin during 2–6 min interval, angiotensin II during 8–10 min interval and bradykinin with neurotensin together during 18–20 min interval. The co-elution of [leu5]-enkephalin across two adjacent fractions indicated a relatively large bandwidth for this peptide, while the simultaneous elution of bradykinin and neurotensin within a single fraction suggested that more fractions should be sampled to fully resolve these components with similar hydrophobicity. Compared with the LDI-MS spectra in Fig. 9 prior to LC-nSi LDI-MS interfacing showing identification of all peptide samples, the robotic spotting system presented in this study is demonstrated to be an efficient method to collect separate fractions from microfluidic RPLC chips to nSi LDI-MS substrate. This spotting system is also amenable to interface faster and higher separation resolution solid-phase extraction (SPE) column integrated RPLC chip (Liu et al. 2009) by simply adjusting spotting time interval.

4 Conclusions

Direct automatic contact spotting from multichannel microfluidic chips represents a simple, robust, and high-throughput approach for transferring samples from on-chip analyses to an target plate for LDI-MS analysis. The repeatability and robustness of the platform was demonstrated using a panel of model peptides deposited from microchannels. Spotting of analyte from parallel multiplex microchannels to MALDI target substrate revealed good uniformity in both droplet volume and MS signal intensity across all channels and between multiple spotting events. Spotting of eluting droplets from signal RPLC separation microchannel onto the nSi LDI-MS target was also successfully demonstrated through the hydrodynamic contact spotting system.

References

Brivio M, Tas NR, Goedbloed MH, Gardeniers HJGE, Verboom W, van den Berg A, Reinhoudt DN (2005) A MALDI-chip integrated system with a monitoring window. Lab on a Chip 5:378–381

Buch JS, Rosenberger F, Highsmith WE, Kimball C, DeVoe DL, Lee CS (2005) Denaturing gradient-based two-dimensional gene mutation scanning in a polymer microfluidic network. Lab on a Chip 5:392–400

Chan JH, Timperman AT, Qin D, Aebersold R (1999) Microfabricated polymer devices for automated sample delivery of peptides for analysis by electrospray ionization tandem mass spectrometry. Anal Chem 71:4437–4444

Chen X, Wu H, Mao C, Whitesides GM (2002) A prototype two-dimensional capillary electrophoresis system fabricated in poly(dimethylsiloxane). Anal Chem 74:1772–1778

Chen CF, Liu J, Hromada LP, Tsao CW, Chang CC, DeVoe DL (2009) High-pressure needle interface for thermoplastic microfluidics. Lab on a Chip 9:50–55

Cui H, Horiuchi K, Dutta P, Ivory CF (2005) Multistage isoelectric focusing in polymeric microchips. Anal Chem 77:7878–7886

Dahlin AP, Wetterhall M, Liljegren G, Bergstrom SK, Andren P, Nyholm L, Markides KE, Bergquist J (2005) Capillary electrophoresis coupled to mass spectrometry from a polymer modified poly(dimethylsiloxane) microchip with an integrated graphite electrospray tip. Analyst 130:193–199

DeVoe DL, Lee CS (2006) Microfluidic technologies for MALDI-MS in proteomics. Electrophoresis 27:3559–3568

Ekstrom S, Ericsson D, Onnerfjord P, Bengtsson M, Nilsson J, Marko-Varga G, Laurell T (2001a) Signal amplification using “spot on-a-chip” technology for the identification of proteins via MALDI-TOF MS. Anal Chem 73:214–219

Ekstrom S, Nilsson J, Helldin G, Laurell T, Marko-Varga G (2001b) Disposable polymeric high-density nanovial arrays for matrix assisted laser desorption/ionization-time of flight-mass spectrometry: II. Biological applications. Electrophoresis 22:3984–3992

Ericson C, Phung QT, Horn DM, Peters EC, Fitchett JR, Ficarro SB, Salomon AR, Brill LM, Brock A (2003) An automated noncontact deposition interface for liquid chromatography matrix-assisted laser desorption/ionization mass spectrometry. Anal Chem 75:2309–2315

Foret F, Preisler J (2002) Liquid phase interfacing and miniaturization in matrix-assisted laser desorption/ionization mass spectrometry. Proteomics 2:360–372

Freire SLS, Yang H, Wheeler AR (2008) A practical interface for microfluidics and nanoelectrospray mass spectrometry. Electrophoresis 29:1836–1843

Gustafsson M, Hirschberg D, Palmberg C, Jornvall H, Bergman T (2004) Integrated sample preparation and MALDI mass spectrometry on a microfluidic compact disk. Anal Chem 76:345–350

Hung KC, Ding H, Guo BC (1999) Use of poly(tetrafluoroethylene)s as a sample support for the MALDI-TOF analysis of DNA and proteins. Anal Chem 71:518–521

Jeonghoon L, Steven AS, Kermit KM (2009) Microfluidic chips for mass spectrometry-based proteomics. J Mass Spectrom 44:579–593

Karas M, Hillenkamp F (1988) Laser desorption ionization of proteins with molecular masses exceeding 10000 daltons. Anal Chem 60:2299–2301

Laurell T, Nilsson J, Marko-Varga G (2001) Silicon microstructures for high-speed and high-sensitivity protein identifications. J Chromatogr B 752:217–232

Lazar IM, Ramsey RS, Sundberg S, Ramsey JM (1999) Subattomole-sensitivity microchip nanoelectrospray source with time-of-flight mass spectrometry detection. Anal Chem 71:3627–3631

Le Gac S, Arscott S, Cren-Olive C, Rolando C (2003) Two-dimensional microfabricated sources for nanoelectrospray. J Mass Spectrom 38:1259–1264

Lee J, Musyimi HK, Soper SA, Murray KK (2008) Development of an automated digestion and droplet deposition microfluidic chip for MALDI-TOF MS. J Am Soc Mass Spectrom 19:964–972

Li Y, Buch JS, Rosenberger F, DeVoe DL, Lee CS (2004) Integration of isoelectric focusing with parallel sodium dodecyl sulfate gel electrophoresis for multidimensional protein separations in a plastic microfludic network. Anal Chem 76:742–748

Little DP, Cornish TJ, ODonnell MJ, Braun A, Cotter RJ, Koster H (1997) MALDI on a chip: analysis of arrays of low femtomole to subfemtomole quantities of synthetic oligonucleotides and DNA diagnostic products dispensed by a piezoelectric pipet. Anal Chem 69:4540–4546

Liu JK, Chen CF, Tsao CW, Chang CC, Chu CC, DeVoe DL (2009) Polymer microchips integrating solid-phase extraction and high-performance liquid chromatography using reversed-phase polymethacrylate monoliths. Anal Chem 81:2545–2554

Medintz IL, Paegel BM, Mathies RA (2001) Microfabricated capillary array electrophoresis DNA analysis systems. J Chromatogr A 924:265–270

Mery E, Ricoul F, Sarrut N, Constantin O, Delapierre G, Garin J, Vinet F (2008) A silicon microfluidic chip integrating an ordered micropillar array separation column and a nano-electrospray emitter for LC/MS analysis of peptides. Sens Actuators B 134:438–446

Moon H, Wheeler AR, Garrell RL, Loo JA, Kim CJ (2006) An integrated digital microfluidic chip for multiplexed proteomic sample preparation and analysis by MALDI-MS. Lab on a Chip 6:1213–1219

Musyimi HK, Guy J, Narcisse DA, Soper SA, Murray KK (2005) Direct coupling of polymer-based microchip electrophoresis to online MALDI-MS using a rotating ball inlet. Electrophoresis 26:4703–4710

Onnerfjord P, Ekstrom S, Bergquist J, Nilsson J, Laurell T, Marko-Varga G (1999) Homogeneous sample preparation for automated high throughput analysis with matrix-assisted laser desorption/ionisation time-of-flight mass spectrometry. Rapid Commun Mass Spectrom 13:315–322

Pinto DM, Ning YB, Figeys D (2000) An enhanced microfluidic chip coupled to an electrospray Qstar mass spectrometer for protein identification. Electrophoresis 21:181–190

Ramsey RS, Ramsey JM (1997) Generating electrospray from microchip devices using electroosmotic pumping. Anal Chem 69:1174–1178

Ro KW, Liu H, Knapp DR (2006) Plastic microchip liquid chromatography-matrix-assisted laser desorption/ionization mass spectrometry using monolithic columns. J Chromatogr A 1111:40–47

Schilling M, Nigge W, Rudzinski A, Neyer A, Hergenroder R (2004) A new on-chip ESI nozzle for coupling of MS with microfluidic devices. Lab on a Chip 4:220–224

Schuerenbeg M, Luebbert C, Eickhoff H, Kalkum M, Lehrach H, Nordhoff E (2000) Prestructured MALDI-MS sample supports. Anal Chem 72:3436–3442

Shen Z, Liu XJ, Long ZC, Liu DY, Ye NN, Qin JH, Dai ZP, Lin BC (2006) Parallel analysis of biomolecules on a microfabricated capillary array chip. Electrophoresis 27:1084–1092

Stachowiak TB, Rohr T, Hilder EF, Peterson DS, Yi MQ, Svec F, Frechet JMJ (2003) Fabrication of porous polymer monoliths covalently attached to the walls of channels in plastic microdevices. Electrophoresis 24:3689–3693

Su J, Bringer MR, Ismagilov RF, Mrksich M (2005) Combining microfluidic networks and peptide arrays for multi-enzyme assays. J Am Chem Soc 127:7280–7281

Tang KQ, Lin YH, Matson DW, Kim T, Smith RD (2001) Generation of multiple electrosprays using microfabricated emitter arrays for improved mass spectrometric sensitivity. Anal Chem 73:1658–1663

Tsao CW, Kumar P, Liu JK, DeVoe L (2008a) Dynamic electrowetting on nanofilament silicon for matrix-free laser desorption/ionization mass spectrometry. Anal Chem 80:2973–2981

Tsao CW, Liu J, DeVoe DL (2008b) Droplet formation from hydrodynamically coupled capillaries for parallel microfluidic contact spotting. J Micromech Microeng 18

Wang YX, Cooper JW, Lee CS, DeVoe DL (2004) Efficient electrospray ionization from polymer microchannels using integrated hydrophobic membranes. Lab on a Chip 4:363–367

Wang YX, Zhou Y, Balgley BM, Cooper JW, Lee CS, DeVoe DL (2005) Electrospray interfacing of polymer microfluidics to MALDI-MS. Electrophoresis 26:3631–3640

Wang J, Sui G, Mocharla VP, Lin RJ, Phelps ME, Kolb HC, Tseng H-R (2006a) Integrated microfluidics for parallel screening of an in situ click chemistry library. Angew Chem Int Ed 45:5276–5281

Wang ZH, Meng YH, Ying PQ, Qi C, Jin G (2006b) A label-free protein microfluidic array for parallel immunoassays. Electrophoresis 27:4078–4085

Wei J, Buriak JM, Siuzdak G (1999) Desorption-ionization mass spectrometry on porous silicon. Nature 399:243–246

Wheeler AR, Moon H, Kim CJ, Loo JA, Garrell RL (2004) Electrowetting-based microfluidics for analysis of peptides and proteins by matrix-assisted laser desorption/ionization mass spectrometry. Anal Chem 76:4833–4838

Wheeler AR, Moon H, Bird CA, Loo RRO, Kim CJ, Loo JA, Garrell RL (2005) Digital microfluidics with in-line sample purification for proteomics analyses with MALDI-MS. Anal Chem 77:534–540

Xiong SX, Ding QX, Zhao ZW, Chen WZ, Wang GH, Liu SJ (2003) A new method to improve sensitivity and resolution in matrix-assisted laser desorption/ionization time of flight mass spectrometry. Proteomics 3:265–272

Xue QF, Dunayevskiy YM, Foret F, Karger BL (1997a) Integrated multichannel microchip electrospray ionization mass spectrometry: analysis of peptides from on-chip tryptic digestion of melittin. Rapid Commun Mass Spectrom 11:1253–1256

Xue QF, Foret F, Dunayevskiy YM, Zavracky PM, McGruer NE, Karger BL (1997b) Multichannel microchip electrospray mass spectrometry. Anal Chem 69:426–430

Yin NF, Killeen K, Brennen R, Sobek D, Werlich M, van de Goor TV (2005) Microfluidic chip for peptide analysis with an integrated HPLC column, sample enrichment column, and nanoelectrospray tip. Anal Chem 77:527–533

Zhang BL, Foret F, Karger BL (2001) High-throughput microfabricated CE/ESI–MS: Automated sampling from a microwell plate. Anal Chem 73:2675–2681

Acknowledgments

This work was supported by NIH/NIGMS grant # R01GM072512 and National Science Council, Taiwan grant # NSC 97-2218-E-008-010-MY2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsao, CW., Tao, S., Chen, CF. et al. Interfacing microfluidics to LDI-MS by automatic robotic spotting. Microfluid Nanofluid 8, 777–787 (2010). https://doi.org/10.1007/s10404-009-0510-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-009-0510-x