Abstract

This study presents a new microfluidic chip that generates micro-scale emulsion droplets for gene delivery applications. Compared with conventional methods of droplet formation, the proposed chip can create uniform droplets (size variation <7.1%) and hence enhance the efficiency of the subsequent gene delivery. A new microfluidic chip was developed in this study, which used a new design with a pneumatic membrane chamber integrated into a T-junction microchannel. Traditionally, the size of droplets was controlled by the flow rate ratio of the continuous and disperse phase flows, which can be controlled by syringe pumps. In this study, a pneumatic chamber near the intersection of the T-junction channel was designed to locally change the flow velocity and the shear force. When the upper air chamber was filled with compressed air, the membrane was deflected and then the droplet size could be fine-tuned accordingly. Experimental data showed that using the new design, the higher the air pressure applied to the active tunable membrane, the smaller the droplet size. Finally, droplets were used as carriers for DNA to be transfected into the Cos-7 cells. It was also experimentally found that the size of the emulsion droplets plays an important role on the efficiency of the gene delivery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Emulsion techniques have been widely used in a variety of industries such as toiletries, cosmetics, food, and pharmaceuticals (Wibowo et al. 2001; Friberg et al. 1997). Traditionally, emulsions are prepared using large-scale equipment like blenders (Vladisavljevic et al. 2002) and ultrasonic homogenizers (McClements et al. 1999). However, it is challenging to control particle sizes and distribution by using these large-scale stirring processes. Control of the size of emulsion droplets to raise the performance of the emulsion droplet is in great need. Hence the use of microfluidic devices has attracted considerable interest since they have the advantage of generating more uniform droplets. Membrane emulsification methods, an alternative to the use of microfluidic devices, were first reported in the early 1990s (Nakashima et al. 1991). In this approach, one phase is dispersed in the other phase after being pressed through the pores of a membrane. The detachment of the droplets from the membrane surface produces an emulsion with a narrow droplet size distribution at mild processing conditions. Multiple membranes were used to distribute the droplets in the emulsion as the entire emulsion was pushed through the pores, allowing for a higher production rate (Suzuki et al. 1996). However, it must have a narrow pore size distribution and the structure should be strong enough to prevent being deformed. Alternatively, the rapid development of microfabrication technologies has enabled the development of custom-designed microchannels in emulsification technology (Kawakatsu et al. 1997). Emulsion droplets were created when a disperse phase was forced into a continuous phase through channels in the microchannel emulsification system. Oil-in-water emulsions with a coefficient of variation (CV) of less than 5% and a droplet size from 3 to 100 μm have been successfully prepared using this control of microchannel geometry technique (Sugiura et al. 2000, 2002a, b, c; Kobayashi et al. 2007). Several types of emulsions including oil-in-water emulsions, water-in-oil emulsions, lipid micro-particles, and polymer micro-particles can be prepared with this approach (Sugiura et al. 2004). It has been reported that droplet formation based on the spontaneous transformation of an oil–water interface occurs when the dispersed-phase velocity inside a microchannel is lower than a critical dispersed-phase velocity (Sugiura et al. 2002a, b, c). The formation mechanism of the droplet was also reported by the same group (Sugiura et al. 2001). Though this method provides better droplet size uniformity, droplet size is limited by the microchannel structures because of the difficulty in their adjusting size.

Recently, significant advancement has been made on the design of emulsification chips which use microfluidics and emulsion techniques to produce uniform droplets in liquids. One of the most popular geometries for the production of droplets is a T-junction microchannel, which is constructed with a cross-junction design connected to a large opening (Thorsen et al. 2001; Nisisako et al. 2002; Tice et al. 2003, 2004; Garstecki et al. 2006; Menech et al. 2008; Teh et al. 2008). When mixing two immiscible liquids in the T-junction microchannel, an interface formed at the junction of the inlet and main channel. The stream of the disperse phase penetrates into the main channel and the formation of emulsion droplets can be observed. The formation of the droplets is due to the shear force exerted by the continuous fluid and the surface tension force caused by the disperse fluid. The formation of the droplets is mainly dominated by the surface tension force when the capillary numbers are low, typically smaller than 10−2 (Ca = μu/γ, where μ is the viscosity, and u is the mean speed of the continuous phase, and γ is the interfacial tension). As the capillary numbers are increased, there is a transition to a dripping regime caused by the balance between the viscous force and the interfacial forces. However, the shear force starts to play an important part in the production of droplets when Ca > 10−2 and can easily lower the diameter of the droplets to smaller ones in the jetting regime (Menech et al. 2008). It was reported that droplet diameter depends only on the capillary number for the unconfined case (the continuous phase channel is much greater than the dispersed phase channel) (Christopher et al. 2007). In the confined case, droplet length depends only on the flow rate ratio. By using the T-junction layout in our study, the size of the droplets could be adjusted by controlling the flow rate ratios. As the continuous-phase flow rate increases, the diameter of the droplets decreases. It was reported that the diameter of the droplets can be well controlled in a range from 100 to 380 μm as the flow velocity of the continuous phase ranges from 0.01 to 0.15 ms−1 (Nisisako et al. 2002). It is expected that much smaller droplets can be generated at a higher velocity of continuous phase flow.

In addition, there are many other ways for generating droplets using the flow focusing method, the dielectrophoretic (DEP) force method, and the electrowetting-on-dielectrics (EWOD) method (Teh et al. 2008). The droplet production using a flow focusing device under an electric field was also reported (Kim et al. 2007). Recently, an approach of picoliter or nanoliter droplets generation driven by piezoelectric actuators has also been reported (Xu et al. 2008). However, these methods require a complicated fabrication and a delicate control system. In our previous work (Lee et al. 2007), a “vertical moving walls” was proposed to form a dynamic chopper such that a pre-focused stream can be dynamically chopped into droplets. The vertical moving-wall structures were located parallel to the microchannel. When we pressured the moving walls, they deflected to squeeze the microchannel and finally caused the break-up of the pre-focused stream. The size of the droplets was majorly determined by the chopping frequency. In the current study, we adopted a pneumatic membrane chamber located above the main channel downstream (but in the proximity of) the T-junction channel. The membrane chamber can be deflected to cause the constriction of the cross-section. The size of the droplets was majorly determined by the applied pressure. The higher the pressure applied to the chamber, the lower the cross-sectional-area of the main channel and the smaller the droplets produced.

Gene transfection through cationic liposomes is convenient and highly efficient when compared with other non-viral gene carriers (Gao et al. 1991). Despite the fact that many cationic liposomes show good gene delivery activity in vitro, their use in vivo has been limited due to their instability in serum (Reimer et al. 1999). Lipid emulsions also have been investigated in the medical field for use as DNA and drug carriers. To be applied as parenteral formulations, emulsions have to be physically stable and non-toxic (Davis et al. 1985; Floyed et al. 1999). There is a great potential for its use in gene delivery systems by using different natural oils for emulsion droplets. Even though the in vitro gene transfection activity of emulsions were lower than that of liposomes in the absence of serum, the activity of squalene emulsions, for example, was higher than that of liposomes in the presence of 80% (v/v) serum (Chung et al. 2001). In vitro, cationic lipid emulsions were even reported to be capable of facilitating the transfer of DNA in the presence of up to 90% serum (Yi et al. 2000). It was experimentally found that DNA can be successfully delivered into the cells with this approach. Recent studies suggest that cationic emulsion may have some advantages over the currently used cationic liposomes such as high physical and biological activity (Yi et al. 2000; Serikawa et al. 2000). There is low toxicity from cationic lipid-based emulsion, which shows great potential as an alternative candidate for efficient low-toxicity gene transfer (Choia et al. 2004). Consequently, emulsions can be used as a vehicle for gene transfection.

However, the non-uniform size distribution of the emulsion droplets produced through large-scale processes limit their activity in transfection of DNA. Microfluidic chips offer a way to improve the quality of emulsification and generate more uniform droplets. In this study, a pneumatic membrane chamber placed near the intersection of the T-junction channel was used to generate uniform droplets and was designed to control the continuous phase flow speed, thus increasing the shear force. Thus, droplets with different sizes can be generated by fine-tuning the deflection of the membrane. DNA attached to water-in-oil (squalene) droplets produced by the microfluidic chip can be then successfully transfected into cells. The suitability of the emulsion droplet for gene transfection can be systematically explored with this approach.

2 Materials and methods

2.1 Design

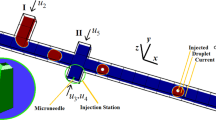

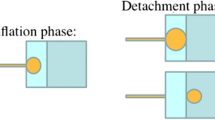

The proposed device provides a new design using a pneumatic upper chamber placed onto a continuous phase channel to deform the membrane of the microchannel for the purpose of creating uniform droplets and controlling the size of the droplets. The operation of the microfluidic chip is shown in Fig. 1. Figure 1a shows the top and the cross-sectional schematic illustrations of the emulsification chip, which has a tunable membrane at the downstream of the T-junction channel. Two different liquids, one each for the continuous phase and for the disperse phase are used to form droplets. The balance between the shear force and the surface tension generates uniform droplets in this T-junction layout. Continuous phase liquids and disperse phase liquids are driven into the microfluidic chip to form the specific droplets at different flow rates. Then a pneumatic upper chamber is placed downstream of the intersection of the T-junction channel and a deformation of the tunable membrane structure occurs while compressed air is applied to the pneumatic upper chamber (as shown in Fig. 1b). Without adjusting the syringe pump flow rates, one can use the tunable membrane to squeeze the liquid to locally generate a higher shear force. With this approach, the tunable membrane can modify the width of the microchannel and, consequently, locally change the flow velocity. Therefore, the size of the droplets can be decreased by activating the tunable membrane at the same continuous and disperse phase flow rate ratio. For comparison, a tunable membrane structure placed upstream of the intersection of the T-junction channel was also designed (as represented in Fig. 1c).

a Top view and cross-sectional view of the emulsification chip with an active tunable membrane downstream of a T-junction channel, b deformation of the tunable membrane occurs when compressed air is applied, decreasing the size of the droplets, c when the tunable membrane is placed upstream of the T-junction channel, the droplet size cannot be significantly adjusted

Figure 2 is a representation of the three-layer structure of the microfluidic chip. The PDMS 2 and PDMS 3 layers are bonded and used as the liquid channels. The pneumatic upper chamber is formed on the PDMS 1 layer. When compressed air is supplied, the membrane can be deflected to squeeze the liquid channel. Different applied pressures can precisely control the deflection of the membrane. Please note that the operation of the membrane is controlled by a single electromagnetic valve (EMV) switch device and a compressor.

2.2 Fabrication process

The microfluidic chip was fabricated using a micro-electro-mechanical-systems (MEMS) fabrication process by constructing the elastic PDMS membrane structure onto the liquid microchannels. For the PDMS microfluidic structures, SU-8 negative thick photoresist (MicroChem Corp., MA, USA) was used to form master molds on silicon substrates. Using standard lithography and a two-step baking processes, the SU-8 master mold was formed and used to replicate the PDMS structure (Chen et al. 2006). Figure 3 shows a simplified fabrication process using the SU-8 master mold and the replication process of the PDMS structure. The thickness of the pneumatic chamber (SU-8 master mold) was measured to be 232.5 μm with a rotation speed of 500 rpm. The dimensions of the chip were measured to be 20 and 25 mm in width and length, respectively (as shown in Fig. 4). The distance between the intersection of the T-junction channel and the continuous phase inlet, the disperse phase inlet, and the collection reservoir were 7.5, 5.4, and 5.0 mm, respectively. A close-up view shows that the depth and width of the continuous phase flow channel was 100 and 150 μm, respectively. The disperse phase flow channel was 100 μm deep and 100 μm wide. The pneumatic side chamber was 650 μm in length.

2.3 Experimental setup

Figure 5 illustrates the experimental setup for the formation of droplets. The setup consists of an optical microscope (TE300, Nikon, NY, USA), a charge-coupled device (CCD, model TE/CCD512TKM, Roper Scientific, Princeton, NJ, USA), two syringe pumps (KD Scientific Inc., KDS200, MA, USA), and a compressed air control system including a compressed air source (JUN-AIR Inc., MDR2-1A/11, Japan), an EMV (SMC Inc., S070M-5BG-32, Taiwan), and a control circuit. Two syringe pumps injected immiscible liquids into the microfluidic chip to form the continuous phase and the disperse phase. The compressor supplied compressed air to the pneumatic upper chamber to squeeze the liquid microchannel. The compressed air control system was used to fine-tune the size of the droplets. The micro droplets collected in the collection reservoir were observed through an optical microscope and recorded by a computer equipped with a CCD device. The droplet CCD images were digitally processed by image analysis software (Compix Inc., Imaging systems). After collecting the droplets in an Eppendorf tube, transfection assay procedures were then performed.

2.4 Sample preparation

For generating emulsion droplets using the tunable membrane structure at the T-junction channels, a deionized (DI) water solution with the surfactant Tween20 (Sigma Chemical, USA) at 2.5% (v/v) was used as the disperse phase with a viscosity of around 10−3 (Pa s). Please note that Tween20 has good biocompatibility (Pisal et al. 2004). A surfactant cationic lipid material, dimethyldioctadecylammonium bromide (DDAB, 5 mg, Sigma Chemical, USA) which has positive charges and a hydrophobic chain to provide electrostatic attraction between the positive-charged lipid droplet and the negative-charged DNA modules (Feitosa et al. 2006), was added to a squalene oil with the density of 0.855 gw/cm3 (1.5 ml, Sigma, St. Louis, MO, USA) and with a viscosity of 0.028 (Pa s), to form a solution with a concentration of 3.3 mg/ml as the continuous phase, so that, water-in-oil droplets can be prepared and used as the vectors for transfection. Please note that the unused squalene oil was refrigerated at 4°C to maintain its freshness.

2.5 Zeta-potential and agarose gel electrophoresis

The DDAB droplets were primarily produced by ultrasonic agitation. And the zeta-potentials of the DNA/DDAB droplet complexes were measured and gel electrophoresis of these droplet complexes were performed by using the methods reported in the literature (Yooa et al. 2004). The measurement of zeta-potential was used to validate that the DDAB droplet was positively charged and negative-charged DNA can be attached onto it. Agarose gel electrophoresis was also used to demonstrate that DNA/DDAB droplets were successfully formed so that we could use the material DDAB in the following step. First, the zeta-potentials of the DNA/DDAB droplet complexes were determined with Malvern Zetasizer (Malvern Instruments, England) without dilution in water. About 1.0 and 0.5 μg of plasmid DNA mixed with different amounts of DDAB droplets were used to measure the zeta-potentials and perform agarose gel electrophoresis.

2.6 Transfection

Endocytosis with subsequent destruction of an endosome within the cell and direct fusion with the cellular membrane are two major pathways to cause the DNA–lipid complex to enter the cell (Zhdanov et al. 2002). The latter one was used as the transfection mechanism in this study. The droplets were used as carriers to take DNA into Cos-7 cells. We chose the luciferase reporter plasmid, pGL3-CMV-luciferase, as our DNA in this study. After transfection, cell lysates were harvested for measuring the luciferase activities by adding luciferin and adenosine triphosphate (ATP) to the lysates. Figure 6 illustrates schematically the transfection procedure. Cos-7 cells were seeded in a 24-well plate (1 × 105 cells/well) and grown for 24 h in Dulbecco’s modified minimal essential medium (DMEM) supplemented with 10% cosmic calf serum (Hyclone, Logan, Utah, UK), 2 mM l-glutamine and 50 μg/ml gentamicin. About 2 μg of totfil plasmid DNA was added in 100 μL of serum free DMEM (A tube) and incubated for 5 min. Similarly, 1.4 mg of the droplets (with a concentration of 28%) was added to 100 μL of serum free DMEM (B tube) and incubated for 5 min at room temperature, such that DNA and droplets could be uniformly distributed in each tube. The two solutions were then well mixed together and incubated for 20 min to bind negative-charge DNA with positive-charge surface of droplets. The mixed solution was added to the well of Cos-7 cells and incubated at 37°C for 2 h. Since the density of the carrier is quite high, the DNA/carrier complexes precipitate to the bottom of the wells, thus increasing the contact between the complexes and adherent cells. Then DNA/droplet complexes were uptaken into cells, increasing in vitro transfection efficiencies of adherent cells (Yooa et al. 2004). After incubation, the supernatant was removed and cells were washed with serum free DMEM. 10% CCS DMEM was added and the plate was then incubated for 22 h for gene expression. After incubation, medium was aspirated and cells were washed with PBS two times. The luciferase activities were analyzed after the transfection procedure using a luciferase assay kit that includes lysis solution, ATP (substrate A) and luciferin (substrate B) (TROPIX, USA). About 120 μL of lysis solution was added to each well and set on ice for 10 min. The final solution was collected in a 1.5 ml Eppendorf tube and centrifuged at 12,000 rpm for 10 min at 4°C. Supernatant was transferred to a new tube, and 50 μL of substrate A and substrate B were added to it. And the luciferase activity was measured using an ATP Luminometer (Berthold technologies, Lumat 9507). With this approach, the transfection efficiency can be determined easily through measuring the luciferase activity from the reporter plasmid insides cells.

3 Results and discussion

In this study, we proposed a new design with an upper tunable membrane on a T-junction channel. The size of the droplets can be actively controlled by the deformation of the membrane structure without changing the flow rate ratio between the continuous and the disperse flow through the syringe pumps. Images of the microfluidic chip with this structure are shown in Fig. 7. It is notable that the original continuous/disperse flow ratio was 3 (the continuous flow rate was 300 μl/h and the disperse flow rate was 100 μl/h). When the membrane was off, emulsion droplets were produced using the T-junction mechanism (as shown in Fig. 7a). T-junction microfluidic chips were reported to be capable of generating emulsion droplets in the previous literature (Thorsen et al. 2001; Nisisako et al. 2002; Tice et al. 2003, 2004; Garstecki et al. 2006; Menech et al. 2008; Teh et al. 2008). The shear stress and surface tension forces produced flow instabilities and were used to control the formation of the emulsion droplets. When the shear stress is increased, the size of the droplets can be decreased accordingly. By controlling the flow rates of the two phases in immiscible liquids with two syringe pumps, the size of the droplets can be well tuned. However, this approach requires the adjustment of the syringe pumps. It usually requires a transition time interval for achieving a stable droplet formation process. Sometimes, the precision of the syringe pump rate also affects the uniformity of the generated droplets. Therefore, we adopted another approach in this study to fine-tune the size of the droplets. Without adjusting the syringe pumps, smaller droplet sizes can be produced by activating the upper membrane, thus locally increasing the continuous/disperse phase flow ratios. It is presented in Fig. 7b that the microchannel was reduced in depth with the deformation of the membrane and that the size of the droplets was decreased when 0.1 MPa (15 psi) of the compressed air was injected into the membrane chamber. The flow velocity measured downstream of the intersection is 1,364.2 μm/s. The method that we used was to measure the time that a droplet took to pass through a fixed distance from the front to the end of the membrane chamber (650 μm) using the high-speed CCD device. Experimental data show that the size of the droplets can be successfully changed by locally changing the flow velocity and the resulting shear stress.

Emulsion droplets are produced using a T-junction channel, a when the membrane is not actuated under a flow rate ratio of 3 (the continuous flow rate is 300 μl/h, and the disperse flow rate is 100 μl/h), and b when the microchannel is reduced in depth with the deformation of the membrane; the size of droplets decreases when 15 psi of compressed air is injected into the chamber

The relationship between the average diameter of the droplets and the applied pressure is shown in Fig. 8a. When the upper air chamber is filled with compressed air, the PDMS membrane is deflected and the droplet size can then be fine-tuned accordingly. From the figure, it can be clearly seen that the changes of size from 0 to 0.07 MPa is not prominent because the membrane requires an initial force to deflect from its original location. However, the deflection cause by applied pressures from 0.07 to 14 MPa (10–20 psi) changes significantly indicating that the deflected membrane varies greatly in the channel. For applied pressures from 0.14 to 0.24 MPa (20–35 psi), the deflection reaches a plateau since the membrane of the chamber has been already deflected to the substrate of the channel. The images captured in Fig. 8b–f show the different droplet sizes by using different applied air pressures under a fixed syringe pump continuous/disperse flow ratio of 3. The average diameters are 75.9, 37.2, 23.1, 27.9 and 13.9 μm, for corresponding applied air pressures of 0.10 (15 psi), 0.14 (20 psi), 0.17 (25 psi), 0.21 (30 psi), and 0.24 MPa (35 psi), respectively. It can be clearly seen that the larger the applied pressure, the smaller the droplet size under the same continuous/disperse flow rate ratio. Another case with a fixed continuous/disperse flow rate ratio of 1 (the continuous flow rate was 100 μl/h, and the disperse flow rate was 100 μl/h) is also shown in this figure. The average diameters are 161.3, 151.7, 139.9, 86.4, 57.9, 41.8, 33.9, and 23.5 μm, respectively, for corresponding applied air pressures of 0, 0.07, 0.10, 0.14, 0.17, 0.21, and 0.24 MPa (0–35 psi, at increments of 5 psi). Experimental results confirm that the deflection of the upper membrane structure can be efficiently used to fine-tune the size of the droplets. It indicates that we can change the flow rate ratio of continuous/disperse phase flows locally using the proposed device without changing the setup of the syringe pumps. In addition to fine-tuning the size of the droplets, the other major objective of the current study is to generate uniform droplets. The size distributions of the generated droplets were then measured. When the membrane was placed at the downstream channel (as shown in Fig. 8g), the coefficients of variation were measured to be less than 6.3 and 7.1% under fixed continuous/disperse phase flow ratios of 3 and 1, respectively. The variations in droplets size are comparable with the ones generated by other microfluidic technologies (Benita and Levy 1993). It shows that the static pneumatic squeezing can generate uniform emulsion droplets successfully. It has been observed that variation of the droplet sizes is much higher if it is controlled by syringe pumps. Since the flow rate ratio can be adjusted by locally activating the membrane, the generation of the uniform droplets is much more stable.

a The relationship between the average diameter of the droplets and the applied air pressure. Images of the different droplet sizes: b 75.9 μm, c 37.2 μm, d 23.1 μm, e 27.9 μm, and f 13.9 μm, for the applied pressures of 15 psi to 35 psi, g the coefficients of variation for droplets at different applied pressures when the membrane is placed at downstream

On the other hand, the relationship between the average diameter of the droplets and the pressure applied to the membrane chamber when placed upstream of the T-junction channel is presented in Fig. 9a. It was found that the size of the droplets cannot be efficiently fine-tuned using this layout. The average diameters were 202.3, 197.3, 197.5, 190.2, 203.3, 192.9, 206.2, and 194.4 μm, at applied air pressures of 0, 0.07, 0.10, 0.14, 0.17, 0.21, and 0.24 MPa (0–35 psi, in increments of 5 psi), respectively, at a global flow rate ratio of 3. Similarly, at a flow rate ratio of 1, the droplet diameters are 315.1, 313.1, 320.6, 313.3, 321.3, 316.3, 312.4, and 313.4 μm, at the same respective applied air pressures from the same aforementioned value. The emulsion droplet sizes were not significantly affected because the continuous flow speed was recovered from the original value at the intersection area so the relationship between the shear force and the interfacial force were not significantly changed. And the coefficients of variation were measured to be less than 6.9 and 4.9% under the same flow ratios of 3 and 1, respectively (as shown in Fig. 9b).

As mentioned earlier, the size of the droplets can be fine-tuned by changing the local flow velocity by activating the upper membrane. The velocity near the intersection of the T-junction channel was measured. The relationship between the diameter of the droplet and the velocity of the fluid (measured at a point 650 μm downstream of the intersection using the similar method mentioned above) is shown in Fig. 10. Under a fixed continuous/disperse phase flow ratio of 3, the droplet velocities were measured to be 1,475.4, 1,579.9, 3,529.4, 4,090.9, 5,000.0, and 6,666.7 μm/s for the corresponding diameters of 201.3, 161.7, 112.3, 85.2, 59.1, 28.2 μm under the applied pressure from 0 psi to 25 psi, in increments of 5 psi, respectively. At a flow ratio of 1, the velocities were measured to be 1,153.8, 1,417.3, 1,935.5, 2,903.2, 4,186.0 and 5,714.3 μm/s for the corresponding diameters of 250.3, 200.3, 152.9, 92.4, 75.1, 46.8 μm, respectively, at the same applied pressure ranging from 0 psi to 25 psi. This was obtained by measuring the time that one droplet passed through a fixed distance in the downstream portion of the microchannel. The results show that the smaller the droplet was formed, the faster the speed of the fluid flow can be achieved. It is notable that the higher frequency of the droplet generation is observed when larger pressure is applied into the chamber. The reason is that the local velocity has been increased due to the deflection of the chamber. Formation of droplets can be characterized by the dimensionless capillary number, (Ca = μu/γ), where μ (Pa s) is the viscosity of the continuous phase, and u (m/s) is the mean velocity of the continuous phase which is the flow velocity measured downstream of the intersection the velocity in our study, and γ (N/m) is the interfacial tension). The capillary numbers for each case can be primarily calculated to be 0.0012, 0.0013, 0.0029, 0.0034, 0.0041, and 0.0055 at a fixed flow rate ratio (V 1/V 2) of 3. At a flow rate ratio (V 1/V 2) of 1, the capillary numbers are 0.0010, 0.0011, 0.0016, 0.0024, 0.0035, and 0.0047, respectively. (The velocity is the above measured value; the viscosity μ of the squalene is 0.028 Pa s (Smet et al. 1998); the interfacial tension for water/squalene is 0.0339 N/m (Chung et al. 2001). Since the surfactants are not included in the calculation, the interfacial tension for water/squalene should be much smaller so that Ca can be larger than the calculated results, indicating that the production of the droplets is determined by the shear force as mentioned in literatures (Garstecki et al. 2006).

Finally, droplets were used as carriers for plasmid DNA to be transfected into the Cos-7 cells. Monodisperse droplets are needed in this study because of two reasons. First, the droplets have to be “dispersed” such that they can have more probability to transfect genes into the cells. Second, if the size of the droplets is not uniform, it is hard to characterize their size effect on the gene transfection efficiency since more than two sizes of droplets exist in the solution. In this study, squalene oil was chosen for its biocompatibility (Chung et al. 2001). A lipid DDAB was dissolved in the squalene in order to charge the emulsion droplets so that they could be bound with the negatively charged plasmid DNA in the outer surface and therefore used as vectors. The zeta-potentials and agarose gel electrophoresis of the DNA/DDAB droplet complexes were measured by using the methods in the literature to confirm the statement (Yooa et al. 2004). As shown in Fig. 11a, 1.0 μg of naked plasmid DNA was served as a control case. Droplet solution (the concentration of water and DDAB was 89.3 and 0.5%, respectively) measuring 0, 2.45, 4.90, 9.80, 14.70, and 19.60 mg DDAB was mixed with plasmid DNA, for testing. Then, the zeta-potentials of the DNA/DDAB droplet complexes were measured to be −48.0, −26.2, −13.3, −0.8, 7.4, and 12.5 mV, respectively. The values were changed positively with the increasing DNA/DDAB droplet complexes. Besides, the agarose gel electrophoresis of DNA/DDAB droplet complexes was represented in Fig. 11b. Similarly, 0.5 μg of naked plasmid DNA was used as a control case. DDAB droplet solution measuring 0, 2.45, 4.90, 9.80, 14.70, and 19.60 mg was mixed with plasmid DNA, respectively (lane 1–6). DNA bands disappeared gradually when the DDAB droplets were increasingly added, indicating the absence of free DNA. The results clearly demonstrated that the lipid DDAB with the positive charges was bound with the negatively charged plasmid DNA. Therefore, the DNA/DDAB droplets formation was confirmed.

At last, in the transfection process, when adding luciferin and ATP to the Cos-7 cell lysates, the light emission could be measured as an indicator of gene transfection. The relationship between the intensity of light emission and emulsion droplet size is represented in Fig. 12. Four droplet samples with different droplet sizes (57.9, 41.8, 33.9, and 13.9, respectively) were tested. The corresponding reactive light units (RLU) measured were 120,000, 150,000, 250,000, and 410,000, respectively. The mock control is a sample of Cos-7 cells transfected with the plasmid DNA alone without droplets. Its RLU value was about 300. The increase of light emission in droplets-DNA-transfected cells suggested that these emulsion droplets could be used as a carrier for cell gene delivery. Our results showed that smaller droplets had better transfection efficiency. The smaller the droplets were, the higher the intensity measured. This was consistent with our expectation that smaller droplets have a higher surface-to-volume value, and therefore could carry more DNA. With traditional methods using liposomes as carriers in the large-scale system, liposomes can be taken up into cells by endocytosis, and DNA wrapped by the liposomes can be released into the cytoplasm for gene expression. In this study, DNA plasmids were bound to the positive-charge surface of the droplets. The high-density DNA/droplets complexes used as the carriers will sink to the bottom of the cell culture plate, subsequently increasing their contact with COS-7 cells. Then DNA plasmids can be fused with the cellular membrane and released into cells for gene transfection (Zhdanov et al. 2002). Therefore, the cells are not needed to uptake the droplet. As a result, higher transfection efficiency was observed and smaller droplets with a higher surface-to-volume value may allow DNA to be delivered into cells more efficiently.

4 Conclusions

We have demonstrated the successful operation of a microfluidic chip capable of forming uniform emulsion droplets using a new design consisting of an active tunable membrane and a T-junction channel. Using MEMS technology, rapid and reliable fabrication techniques involving SU-8 standard lithography and PDMS replication processes were employed for the fabrication of the prototype microfluidic chip. Experimental results showed that droplet sizes can be fine-tuned by applying different air pressures to the pneumatic chamber. The size of the emulsion droplets can also be actively controlled using the size-tunable membrane without changing the continuous/disperse flow rate ratio. The higher the air pressure applied to the membrane chamber, the smaller the emulsion droplets generated. Furthermore, the experiments also showed that the droplets can be successfully used as carriers for gene transfection. The smaller the droplets, the higher the transfection activity. The development of a microfluidic device capable of generating uniform and size-tunable droplets will be of great use for DNA and drug delivery applications.

Abbreviations

- CCD:

-

Charge-coupled device

- DEP:

-

Dielectrophoretic

- DI:

-

Deionized

- EMV:

-

Electromagnetic valve

- EWOD:

-

Electrowetting-on-dielectrics

- PDMS:

-

Polydimethylsiloxane

- V 1 :

-

Flow velocity of continuous phase

- V 2 :

-

Flow velocity of disperse phase

- DMEM:

-

Dulbecco’s modified eagle medium

- ATP:

-

Adenosine triphosphate

- DDAB:

-

Dimethyldioctadecylammonium bromide

- DNA:

-

Deoxyribonucleic acid

- CV:

-

Coefficient of variation

- CCS:

-

Cosmic calf serum

- Ca:

-

Capillary number

References

Benita S, Levy MY (1993) Submicron emulsions as colloidal drug carders for intravenous administration: comprehensive physicochemical characterization. J Pharm Sci 82:1069–1079

Chung H, Kim TW, Kwon M, Kwon LC, Jeong SY (2001) Oil components modulate physical characteristics and function of the natural oil emulsions as drug or gene delivery system. J Control Release 71:339–350

Choia WJ, Kima JK, Choia SH, Parka JS, Ahnb WS, Kima CK (2004) Low toxicity of cationic lipid-based emulsion for gene transfer. Biomaterials 25:5893–5903

Chen CT, Lee GB (2006) Formation of micro-droplets in liquids utilizing active pneumatic choppers on a microfluidic chip IEEE/ASME. J Microelectromech Syst 15:1492–1498

Christopher GF, Anna SL (2007) Microfluidic methods for generating continuous droplet streams. J Phys D Appl Phys 40:R319–R336

Davis SS, Hadgraft J, Palin KJ (1985) Medical and pharmaceutical applications of emulsions. Encycl Emuls Technol 2:159–238

Friberg SE, Larsson K (1997) Food emulsions. Marcel Dekker Inc., NY, pp 189–233

Floyed AG (1999) Top ten considerations in the development of parenteral emulsions. Pharm Sci Technol Today 24:134–143

Feitosa E, Alves FR, Niemiec A, Oliveira MCDR, Castanheira EMS, Baptista ALF (2006) Cationic liposomes in mixed didodecyldimethylammonium bromide and dioctadecyldimethylammonium bromide aqueous dispersions studied by differential scanning calorimetry, nile red fluorescence, and turbidity. Langmuir 22:3579–3585

Garstecki P, Fuerstman MJ, Stone HA, Whitesides GM (2006) Formation of droplets and bubbles in a microfluidic T-junction––scaling and mechanism of break-up. Lab Chip 6:437–446

Gao X, Huang L (1991) A novel cationic liposome reagent for efficient transfection of mammalian cell. Biochem Biophys Res Commun 179:280–285

Kawakatsu T, Kikuchi Y, Nakajima M (1997) Regular-sized cell creation in microchannel emulsification by visual microprocessing method. J Am Oil Chem Soc 74:317–321

Kim H, Luo D, Darran Link, Weitz DA, Marquez M, Cheng Z (2007) Controlled production of emulsion drops using an electric field in a flow-focusing microfluidic device. Appl Phys Lett 91:133106

Kobayashi I, Uemura K, Nakajima M (2007) Formulation of monodisperse emulsions using submicron-channel arrays. Colloids Surf A 296:285–289

Lee CH, Hsiung SK, Lee GB (2007) A tunable microflow focusing device utilizing controllable moving walls and its applications for formation of micro-droplets in liquids. J Micromech Microeng 17:1–9

McClements DJ (1999) Food emulsions: principles, practice, and techniques. CRC Press, Boca Raton

Menech MD, Garstecki P, Jousse F, Stone HA (2008) Transition from squeezing to dripping in a microfluidic T-shaped junction. J Fluid Mech 595:141–161

Nakashima T, Shimizu M, Kukizaki M (1991) Membrane emulsification by microporous glass. Key Eng Mater 61–62:513–516

Nisisako T, Torii T, Higuchi T (2002) Droplet formation in a microchannel network. Lab Chip 2:24–26

Pisal S, Shelke V, Mahadik K, Kadam S (2004) Effect of organogel components on in vitro nasal delivery of propranolol hydrochloride. AAPS Pharm Sci Technol 5:1–4

Reimer DL, Kong S, Monck M, Wyles J, Tam P, Wasan EK, Bally MB (1999) Liposomal lipid and plasmid DNA delivery to B16/BL6 tumors after intraperitoneal administration of cationic liposome DNA aggregates. J Pharm Exp Ther 289:807–815

Smet KD, Hellemans L (1998) Rotational relaxation of rigid dipolar molecules in nonlinear dielectric spectra. Phys Rev E 57:1384–1387

Suzuki K, Shuto I, Hagura Y (1996) Characteristics of the membrane emulsification method with preliminary emulsification for preparing corn oil-in-water emulsions. Food Sci Technol Int 2:43–47

Sugiura S, Nakajima M, Oda T, Satake M, Seki M (2000) Effect of interfacial tension on the dynamic behavior of droplet formation during microchannel emulsification. J Surf Deterg 3:295

Sugiura S, Nakajima M, Iwamoto S, Seki M (2001) Interfacial tension driven monodispersed droplet formation from microfabricated channel array. Langmuir 17:5562–5566

Sugiura S, Nakajima M, Seki M (2002a) Effect of channel structure on microchannel emulsification. Langmuir 18:5708–5712

Sugiura S, Nakajima M, Kumazawa N, Iwamoto S, Seki M (2002b) Characterization of spontaneous transformation-based droplet formation during microchannel emulsification. J Phys Chem B 106:9405–9409

Sugiura S, Nakajima M, Seki M (2002c) Preparation of monodispersed emulsion with large droplets using microchannel emulsification. JAOCS 79:515–519

Sugiura S, Nakajima M, Yamamoto K, Iwamoto S, Oda T, Satake M, Seki M (2004) Preparation characteristics of water-in-oil-in-water multiple emulsions using microchannel emulsification. J Colloid Interface Sci 270:221–228

Serikawa T, Suzuki N, Kikuchi H, Tanaka K, Kitagawa T (2000) A new cationic liposome for efficient gene delivery with serum into cultured human cells: a quantitative analysis using two independent fluorescent probes. Biochim Biophys Acta 1467:419–430

Thorsen T, Roberts WR, Arnold FH, Quake SR (2001) Dynamic pattern formation in a vesicle-generating microfluidic device. Phys Rev Lett 86:4163–4166

Tice JD, Song H, Lyon AD, Ismagilov RF (2003) Formation of droplets and mixing in multiphase microfluidics at low values of the Reynolds and the capillary number. Langmuir 19:9127–9133

Tice JD, Lyon AD, Ismagilov RF (2004) Effects of viscosity on droplet formation and mixing in microfluidic channels. Anal Chim Acta 507:73–771

Teh SY, Lin R, Hung LH, Lee AP (2008) Droplet microfluidics. Lab Chip 8:198–220

Vladisavljevic GT, Schubert H (2002) Preparation and analysis of oil-in-water emulsions with a narrow droplet size distribution using Shirasu-porous-glass (SPG) membranes. Desalination 144:167–172

Wibowo C, Ng KM (2001) Product-oriented process synthesis and development: creams and pastes. Am Ins Chem Eng J 47:2746–2767

Xu J, Attinger D (2008) Drop on demand in a microfluidic chip. J Micromech Microeng 18:06+5020

Yi SW, Yune TY, Kim TW, Chung H, Choi YW, Kwon LC, Lee EB, Jeong SY (2000) A cationic lipid emulsion/DNA complex as a physically stable and serum-resistant gene delivery system. Pharm Res 17:314–320

Yooa HS, Kwon SM, Kim YJ, Chung H, Kwon IC, Kim J, Jeong SY (2004) Cationic lipid emulsions containing heavy oils for the transfection of adherent cells. J Control Release 98:179–188

Zhdanov RI, Podobed OV, Vlassov VV (2002) Cationic lipid–DNA complexes—lipoplexes—forgene transfer and therapy. Bioelectrochemistry 58:53–64

Acknowledgments

The authors would like to thank the National Science Council in Taiwan for their financial support (NSC 96-2120-M-006-008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, HW., Huang, YC., Wu, CL. et al. Exploitation of a microfluidic device capable of generating size-tunable droplets for gene delivery. Microfluid Nanofluid 7, 45–56 (2009). https://doi.org/10.1007/s10404-008-0359-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-008-0359-4