Abstract

Because of the micromachining characteristic of excimer laser ablation, the microchannels ablated with this technique on poly(methyl methacrylate) (PMMA) substrate have definite surface roughness. Utilizing this characteristic, the hydrophilicity of PMMA microchannels could be directly modified during fabrication process both by the mechanism of photochemical ablation and the effect of surface roughness. The contact angle is inversely proportional to the surface roughness under ablation with same fluence and could be reduced to 25° by choosing ablation parameters reasonably (7.38 J/cm2, 20 Hz, 10 mm/min). Excimer laser irradiation of PMMA substrates for different irradiation times at fluence below the ablation threshold also results in the surfaces becoming more hydrophilic without any marked change in the surface topography. The contact angle decreases with the increase of irradiation times and finally reaches the saturated status after irradiation for 2,500 times. Under same irradiation times, higher fluence led to PMMA substrates more hydrophilic.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bio-micro-electro-mechanical systems (BioMEMS) have attracted more interests in recent years due to their potential applications in biological analysis, drug development and medical diagnostics. Most of the early BioMEMS devices were made of glass, quartz or silicon because of well-established microfabrication techniques, and materials’ surface chemical and optical properties. The use of polymer substrates in the construction of BioMEMS devices has become increasingly important because they are less expensive and microstructures can be easily fabricated (Wei et al. 2005). As one primary kind of thermoplastic polymer, poly(methyl methacrylate) (PMMA) has been used for fabrication of BioMEMS devices using various techniques, such as laser ablation (Costela et al. 1995), injection molding (Lee et al. 2006) and hot embossing with microchannels sealed with some processes (Thomson et al. 2004).

However, the surface characteristics of BioMEMS devices based on PMMA, such as hydrophilicity, surface topography or interactions between substrate and reagent can cause undesired, non-specific analyte adsorption onto the microstructure walls leading to inaccurate reaction analysis and sample loss (Liu et al. 2004). The non-specific adsorption of proteins to surface of device is a significant problem encountered in a variety of biomedical applications. Since hydrophobic surface absorbs proteins more strongly than hydrophilic surface (Prime and Whitesides 1991), surface modification for PMMA is needed. There have been many reports on surface modification techniques of PMMA, such as vacuum ultraviolet (VUV) irradiation with excimer lamp (Hozumi et al. 2002), UV/ozone graft polymerization (Shah et al. 2006), water-vapor plasma treatment (Long et al. 2006), vapor-phase deposition of organic films (Hiratsuka et al. 2004), aminolysis (Henry et al. 2000) and surface-initiated atom transfer radical polymerization (Liu et al. 2004).

Comparing with other surface modification techniques, excimer laser ablation and irradiation have been shown to be very effective methods because of special fabrication characteristics. The hydrophilicity of PMMA microchannel and substrate could be modified during ablation and irradiation process without accessional modification step. Many researches have been carried out to study the effect of excimer laser irradiation on the surface characteristics of polymers (Lawrence and Li 2001). The surface of microchannel can be modified with pulsed UV excimer laser irradiation by studying the surface charge distribution on the sidewalls of hot embossed PMMA microchannels (Johnson et al. 2001). Yet, no published literature to date systematically studies the influence of excimer laser ablation and irradiation parameters on the surface hydrophilicity modification of PMMA microchannel and substrate.

In this work, we investigated the hydrophilicity modification of microchannel ablated on PMMA substrate with fluence above the ablation threshold of PMMA (typically 500 mJ/cm2) and utilized the irradiation of excimer laser with fluence below the ablation threshold to directly modify the surface hydrophilicity of PMMA substrate to study the influence of irradiation parameters on the hydrophilicity modification effect. Contact angle measurements were performed in this study to quantify the change in hydrophilicity of PMMA. Surface topographies of PMMA microchannels and irradiated substrates were also investigated to understand the correlation between the surface roughness and the hydrophilicity.

2 Experimental

2.1 Excimer laser ablation of PMMA microchannels at laser fluence above the threshold fluence

PMMA substrates were purchased from China Anhui Shuguang Chemical Group and cut with commercial CO2 laser machine to definite-sized pieces (30 × 25 × 0.5 mm3). Before any type of experimental procedure was carried out, PMMA substrates were sonicated in deionized water for 10 min, and subsequently dried under pressurized air.

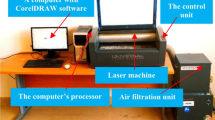

The microchannels were ablated with self-developed excimer laser micromachining direct-writing system as shown in Fig. 1. This system comprises an excimer laser machine (LPX305iF, Lambda Physik, Germany) and a precise 3D working platform. The excimer laser has 248 nm of wavelength, 1.2 J per pulse of maximum energy, and 50 Hz of maximum pulse frequency with state pulse duration of 30 ns.

The ablation of PMMA microchannel was controlled by the movement of working platform. The translational velocity of working platform can be adjusted between 1.5 and 60 mm/min. During ablation, the ablation area was being blown with compressed air (0.2 MPa) to drive away the generated impurity in microchannels.

In this study, a square mask (2 × 2 mm2) was chosen such that the laser beam after being focused on the surface of PMMA substrate exposes a 200 × 200 μm2 area. The pulse frequency was set as 20 Hz, and the translational velocity of working platform was set as 6–14 mm/min. The excimer laser fluence was adjusted between 5.28 and 7.38 J/cm2.

Because microchannel is too narrow to conveniently measure the contact angle of its bottom surface, large-area ablation was taken to be as reference considering their comparability in the microstructure quality (mainly surface roughness and ablation depth). The excimer laser large-area ablation processing comprises the focused laser beams being triggered back and forth across the surfaces of the PMMA substrates to ablate a large area (about 10 × 10 mm2) by movement of working platform.

2.2 Excimer laser irradiation of PMMA substrates at laser fluence below the threshold fluence

Excimer laser was used to directly irradiate the surface of PMMA substrate at fluence below the ablation threshold to modify the hydrophilicity. PMMA substrates were placed in front of the laser-emitting window of excimer laser machine to be irradiated for different times (500–3,000 times). The pulse frequency was set to 5 Hz to avoid substrate distortion caused by heat accumulation of laser, and the fluence was adjusted between 60 and 150 mJ/cm2. All the substrates were irradiated in atmosphere and being blown with compressed air (0.2 MPa) during irradiation.

2.3 Contact angle measurements

After excimer laser ablation and irradiation under appropriate parameters, static water-contact angles of the PMMA microchannels and substrates were measured based on the sessile drop method, to investigate the effect of excimer laser ablation and irradiation on the hydrophilicity modification of PMMA.

Contact angle values were measured immediately with a video-supported contact angle measuring instrument (OCA 20, DataPhysics Instruments GmbH, Germany) and the software provided by the manufacturer, utilizing approximately 2 μL drop of deionized water, at 25°C in air with humidity of 50%. The measurements were repeated at least five times at separate positions on a given microchannel or substrate.

In this work, general definition of contact angle (θ) was adopted without consideration of any amendment in Wenzel equation (Wenzel 1936) or Cassie-Baxter equation (Cassie and Barter 1944) for convenient measurement.

2.4 Surface topography characterization

The surface topographies of the pristine and excimer laser-modified PMMA microchannels and substrates were viewed and measured with non-contact 3D optical profiling system (Wyko NT1100, Veeco Instrument Inc. USA), and the data were analyzed and simulated using WYKO Vision32 software provided by the manufacturer.

3 Results and discussion

3.1 Hydrophilicity modification of ablated PMMA microchannels

Surface topography (surface roughness) is an important issue for substrate support materials used in applications such as BioMEMS devices. Surface roughness can strongly affect the hydrophilicity of polymer materials and the values of contact angles. By understanding the correlation between surface roughness and hydrophilicity of PMMA microchannels ablated under different excimer laser parameters, it may be possible to determine the influence of surface roughness on the contact angle, and help us to choose optimal ablation parameters to make hydrophilicity modification.

The water-contact angles and surface roughness of PMMA microchannels ablated at various excimer laser fluences with stated translational velocity of working platform (10 mm/min) and pulse frequency (20 Hz) were shown in Fig. 2. From Fig. 2 we can see that the value of contact angle decreases with the increase of fluence and is inversely proportional to the surface roughness.

For excimer laser photochemical ablation of PMMA above the ablation threshold, there have been many reports offering explanations about the ablation process and mechanism. Many studies have indicated that excimer laser ablation can cause scission of various chemical bonds in chains of PMMA including C–C, C–H, C=O, and results in the formation of oxygen-containing species such as carboxylate and hydroxylate groups. Higher fluence leads to formation of much carboxylate groups and further increases the hydrophilicity of PMMA (Wochnowski et al. 2000; Johnson et al. 2001; McCarley et al. 2005). Therefore, from Fig. 2, we do not know exactly whether the contact angle is also influenced by the surface roughness of microchannel because the surface roughness of microchannel increases with the increase of fluence too (Qi et al. 2006).

For understanding the influence of surface roughness on the contact angle without consideration of change in fluence, microchannels were ablated at stated fluence (6.34 J/cm2) with various translational velocities of working platform (6–14 mm/min). The influence of surface roughness on the contact angle is shown in Fig. 3. Obviously, the contact angle is also inversely proportional to the surface roughness under ablation with same fluence. By controlling the excimer laser parameters, different contact angles could be obtained during ablation process to directly realize the hydrophilicity modification of PMMA microchannels for further BioMEMS applications. Figure 4 shows the 3D simulation image of microchannel ablated at 6.34 J/cm2 with 10 mm/min of translational velocity.

Using excimer laser to fabricate microchannel on PMMA substrate can modify the hydrophilicity of microchannel both by the mechanism of photochemical ablation and the effect of surface roughness. However, the surface roughness of microchannel should be chosen appropriately because it has certain effect on the sample flow in it.

3.2 Hydrophilicity modification by excimer laser irradiation

Besides hydrophilicity modification of PMMA microchannels during ablation, excimer laser irradiation also can be used to directly modify the hydrophilicity of PMMA substrates in theory, just like the use of excimer lamp (Hozumi et al. 2002). Irradiation of excimer laser below the ablation threshold has any marked change in the surface topography of PMMA surface, but the number of carboxylate groups slightly increased compared to the pristine substrate—a trend that increases linearly with fluence until ablation begins (Johnson et al. 2001).

In this work, excimer laser irradiation of PMMA substrates for different irradiation times at fluences below the ablation threshold resulted in the surfaces becoming more hydrophilic. Changes in the water-contact angles of PMMA substrates irradiated at various fluences below ablation threshold for different irradiation times were plotted in Fig. 5. Under different fluences, all the water-contact angles of PMMA substrates rapidly decreased from original value (76°) after first 500 times irradiation, and decreased gradually by followed irradiations. Finally, the water-contact angles reached the saturated status at around 2,500 times. Under same irradiation times, higher fluence could led to PMMA substrates being more hydrophilic.

Figure 6 shows the image of water-contact angles of pristine and irradiated PMMA substrates for different 2,500 times at 150 mJ/cm2. By controlling the excimer laser fluence and irradiation times, the pristine PMMA substrate could be modified to more hydrophilic. This is favorable for decreasing adsorption of proteinic reagent when used as support material in BioMEMS applications. However, because of relatively small cross-section of excimer laser beam, only smaller area of the substrate can be uniformly irradiated and hence excimer laser irradiation technique is not convenient for larger surface modification. The method to solve this problem is to adopt multi-area irradiation technique.

4 Conclusions

Because of the micromachining characteristic of excimer laser ablation, surface roughness of microchannel ablated using excimer laser has obvious effect on the change in contact angles. The hydrophilicity of PMMA microchannels could be successfully modified during ablation process with optimal excimer laser parameters. Excimer laser irradiation also can be used to directly modify the hydrophilicity of the pristine PMMA substrate. Irradiation of excimer laser below the ablation threshold for different irradiation times at various fluences has significant influence to reduce the contact angle. Excimer laser ablation and irradiation could be used in hydrophilicity modification of PMMA substrate. However, such differences in obtained hydrophilicity must be attributed to factual experimental conditions, such as gas pressure of excimer laser machine and sample purity.

References

Cassie ABD, Barter S (1944) Wettability of porous surfaces. Trans Fara Soc 40:546–551

Costela A, García-Moreno I, Florido F et al (1995) Laser ablation of polymeric materials at 157 nm. J Appl Phys 77:2343–2350

Henry AC, Tutt TJ, Galloway M et al (2000) Surface modification of poly(methyl methacrylate) used in the fabrication of microanalytical devices. Anal Chem 72:5331–5337

Hiratsuka A, Muguruma H, Lee KH et al (2004) Organic plasma process for simple and substrate-independent surface modification of polymeric BioMEMS devices. Biosens Bioelectron 19:1667–1672

Hozumi A, Masuda T, Hayashi K et al (2002) Spatially defined surface modification of poly(methyl methacrylate) using 172 nm vacuum ultraviolet light. Langmuir 18:9022–9027

Johnson TJ, Waddell EA, Kramer GW et al (2001) Chemical mapping of hot-embossed and UV-laser-ablated microchannels in poly(methyl methacrylate) using carboxylate specific fluorescent probes. Appl Surf Sci 181:149–159

Lawrence J, Li L (2001) Modification of the wettability characteristics of polymethyl methacrylate (PMMA) by means of CO2, Nd:YAG, excimer and high power diode laser radiation. Mater Sci Eng A 303:142–149

Lee WJ, Lee SE, Kim CG (2006) The mechanical properties of MWNT/PMMA nanocomposites fabricated by modified injection molding. Compos Struct 76:406–410

Liu JK, Pan T, Woolley AT et al (2004) Surface-modified poly(methyl methacrylate) capillary electrophoresis microchips for protein and peptide analysis. Anal Chem 76:6948–6955

Long TM, Prakash S, Shannon MA et al (2006) Water-vapor plasma-based surface activation for trichlorosilane modification of PMMA. Langmuir 22:4104–4109

McCarley RL, Vaidya B, Wei SY et al (2005) Resist-free patterning of surface architectures in polymer-based microanalytical devices. J Am Chem Soc 127:842–843

Prime KL, Whitesides GM (1991) Self-assembled organic monolayers: model systems for studying adsorption of proteins at surfaces. Science 252:1164–1167

Qi H, Chen T, Zuo TC (2006) Surface roughness analysis and improvement of micro-fluidic channel with excimer laser. Microfluidics Nanofluidics 2:357–360

Shah JJ, Geist J, Locascio LE et al (2006) Surface modification of poly (methyl methacrylate) for improved adsorption of wall coating polymers for microchip electrophoresis. Electrophoresis 27:3788–3796

Thomson D, Hayes JP, Thissen H (2004) Protein patterning in polycarbonate microfluidic channels. BioMEMS Nanotechnol, Proc SPIE 5275:161–167

Wei Suying, Vaidya B, Patel AB et al (2005) Photochemically patterned poly(methyl methacrylate) surfaces used in the fabrication of microanalytical devices. J Phys Chem B 109:16988–16996

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28:988–994

Wochnowski C, Metev S, Sepold G (2000) UV-laser-assisted modification of the optical properties of PMMA. Appl Surf Sci 154–155:706–711

Acknowledgments

This work was supported by National Natural Science Foundation of China (50335050) and Beijing Natural Science Foundation (3031001) and Funding Project for Academic Human Resources Development in Institutions of Higher Learning under the Jurisdiction of Beijing Municipality. The authors would like to thank Dr. Qi Wei Fellowship (the College of Materials Science and Engineering of Beijing University of Technology) for measurement of contact angle.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, H., Chen, T., Yao, L. et al. Hydrophilicity modification of poly(methyl methacrylate) by excimer laser ablation and irradiation. Microfluid Nanofluid 5, 139–143 (2008). https://doi.org/10.1007/s10404-007-0234-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-007-0234-8