Abstract

A simple, external in-line valve for use in microfluidic devices constructed of polydimethylsiloxane (PDMS) is described. The actuation of the valve is based on the principle that flexible polymer walls of a liquid channel can be pressed together by the aid of a permanent magnet and a small metal bar. In the presence of a small NdFeB magnet lying below the channel of interest, the metal bar is pulled downward simultaneously pushing the thin layer of PDMS down thereby closing the channel stopping any flow of fluid. The operation of the valve is dependent on the thickness of the PDMS layer, the height of the channel, the gap between the chip and the magnet and the strength of the magnet. The microfluidic channels are completely closed to fluid flows ranging from 0.1 to 1.0 μL/min commonly used in microfluidic applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microfluidic devices (MDs) have emerged as novel analytical tools in many areas of science and industry. Their inherent qualities including low power requirements, low sample consumption, rapid and parallel analysis, and automation provide unique opportunities to create novel and more powerful devices with a myriad of applications. In recent years poly(dimethylsiloxane) (PDMS) has been widely used for microfluidic, optical, and nanoelectromechanical structures and in low-cost replication processes such as replica molding and templating. Research on microfluidics has focused on the development of the microfluidic components, and specifically micropumps, micromixers, world-to-chip microfluidic interfaces and microvalves. One of the most important elements of a successful MD is reliable microvalves since they make possible the manipulation of liquid flow in the channels, on/off switching of fluid flow, and injection of minute volumes of solution into the separation channel. To address the issue of sample loading and manipulation a number of valve-type techniques have been developed. A recent review detailed several types of microvalves and classified them as active or passive employing mechanical, non-mechanical and external systems (Oh and Ahn 2006).

Quake’s group developed a microfluidic valving system based on a technique called multilayer soft lithography (MSL) (Unger et al. 2000). They combined soft lithography with the capability to bond multiple patterned layers of elastomer. Layered structures are constructed by binding two layers (fluid and control) of elastomer each of which is separately cast from a micromachined mold. The upper layer (control channel) is placed on top of the lower layer (fluid channel) where a irreversible seal is formed due to reactive molecules at the interface between the two layers. When the air is passed through the control channel the fluid channel is getting pressed and a valve is formed.

Some magnetically controlled microvalves have been detailed. Miniaturized electromagnetic microvalves were first developed for gas chromatography (Terry et al. 1979). Later, movable silicon membranes were integrated with solenoid coils (Bosch et al. 1993) or mounted with permanent magnets for glaucoma implants (Bae et al. 2002, 2003). Others used a micro ball valve in polymer tubing driven by an external solenoid using a metal bar (Oh et al. 2001; Fu et al. 2003). Some authors created magnetic layers of elastomer by loaded fine iron powder (Unger et al. 2000; Jackson et al. 2001) or fabricated electromagnets with micron-scale dimension into PDMS chips (Siegel et al. 2006). Oh et al. (2002) showed a microvalve consisting of an integrated inductor, deflectable silicon membrane with a NiFe thin film and a stationary inlet/outlet valve seat. In this system the leakage flow rates were several μL/min in the kPa range. The magnetic microvalves published to date have not been applied in microfluidic lab-on-a-chip devices, where channels of only a few tens of microns could be closed/opened without leakage at flow rates in the μL/min range. A common disadvantage of many of these methods is that they all integrate either an electromagnet or contain a metal part of the valve on a movable membrane, which prevents the chips from being disposable.

Herein, we report a simple, external in-line valve for manipulation of fluid flow in microfluidic channels. The actuation of this valve is based on the principle that flexible polymer walls in a liquid channel can be pressed together by the aid of magnets, thereby, opening and closing the microfluidic channels. The proper operation of the magnetically controlled valve is largely due to the high flexibility of the thin layer of PDMS membrane. In the magnetically controlled valve, the deformation of the thin PDMS layer is the key element. In our approach the deformation depends on the attractive forces between the magnet and the metal bar and the rubber-elastic nature (spring constant of the layer) of the thin layer of PDMS.

The metal bar of the valve can be considered as a soft ferromagnetic iron core. By inserting a soft ferromagnetic iron core into the magnetic field of the hard permanent magnet the core becomes polarized and produces an induced magnetic dipole momentum \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{m}. \) In an inhomogeneous field the magnitude of the force \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{F} \) can be expressed as the product of the magnetic moment and the gradient of the external magnetic field \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{B} \) (Eq. 1).

If the direction of \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{m} \) and \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{B} \) are parallel with the x-axis of the used coordinate system (direction of the bar), according to Eq. 2, the acting force (F) increases with an increase in m.

In the case of polymers a large elastic deformation can be achieved due to the partial orientation of polymer chains. This orientation causes a negative entropy change (ΔS) during the deformation. A detailed statistical analysis of the entropy change leads to the following expression for the elastic strain σ (σ = F/A) in case of small deformations (ε is very small).

Here, ρ is the uniaxial stress, R is the molar gas constant, T is the absolute temperature and M c is the molar mass of polymer chain between two adjacent crosslinks, ε is the strain of deformation (the relative length change ε = ΔL/L0).

2 Experimental section

2.1 Microchip fabrication

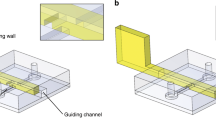

The microfluidic chip with magnetically controlled microvalve includes two PDMS layers stacked to each other and sealed on to a thin microscope cover glass. The upper thick PDMS layer is used to hold the metal bar and the liquid connections (and electrode connections if it is needed). The lower thin PDMS layer (membrane) contains the microfluidic channels.

Fabrication of the PDMS layers (Fig. 1a). The lower PDMS layer that contains the channels was prepared by using a mold created by photolithography (Duffy et al. 1998). The pattern of 100 μm wide channels was designed using AutoCAD software (San Rafael, CA) and printed as a high-resolution (20,000 dpi) photo-mask (CAD/Art Services, Inc., OR). Negative type photoresist (SU-8 2025, Microchem, Newton, MA) was spin-coated onto a 3′′ silicon wafer at 3,000 rpm for 60 s to a thickness of 25 μm. Photoresist coated wafer was baked for 15 min. at 95°C. The pattern on the mask was transferred to the wafer through UV exposure for 2 min. The exposed wafer was baked at 95°C for 5 min and unexposed areas were removed by rinsing with SU-8 developer (Microchem, Newton, MA). The PDMS layers with different thicknesses were fabricated by cast molding of a 10:1 mixture of PDMS oligomer and cross-linking agent. The proper thickness (50 μm) of the thin layer containing the microchannel pattern was obtained by spin coating PDMS on to the mold at 1,200 rpm for 60 s (Zhang et al. 2004). The thick layer was prepared by simply pouring the PDMS mixture into a petri dish. Each layer was degassed and baked for 30 min in an oven at 80°C. The PDMS replicas were peeled off from the mold and the petri dish.

Aligning and sealing the PDMS layers (Fig. 1b). The upper thick layer was punched for the hole(s) for the metal bar(s). The diameter of the holes is ∼1 mm, slightly larger than the diameter of the bars. The holes containing the upper PDMS layer was aligned with the thin lower PDMS layer and sealed irreversibly using an Ar plasma (Duffy et al. 1998). Holes (300 μm) were punched through the combined PDMS layers for the liquid and electrode connections (Fig. 1c) to the chip. The PDMS chip was irreversibly sealed onto a clean cover glass of 150 μm thickness (VWR micro cover glass, VWR, USA) (Fig. 1d).

For the operation of the magnetic valve a small NdFeB magnet (1/8′′ × 1/8′′ × 1/16′′ thick, K&J Magnetics, Inc., Jamison, PA, USA), and a cylindrical shape of metal (0.7 mm × 5 mm) (paper clip stub) as the metal bar (Fig. 2a) were used. To actuate the valve the metal bar is inserted into the valve-hole and upon moving the magnet the metal is attracted towards it from the opposite side (Fig. 2b, c). To simultaneously actuate more than one valve a larger magnet can be used. A peristaltic pump was used to flow liquids at the rates of 0.1–1 μL/min through out all experiments.

2.2 Valve actuation

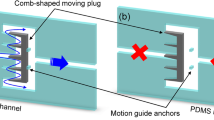

The operation of the magnetically controlled valve is based on the deformation of a thin (25 μm), flexible layer of PDMS that covers the top wall of the microfluidic channel (height: 25 μm, width: 100 μm) due to the downward movement of the metal bar caused by a permanent magnet which is placed below the chip. In the presence of a magnet, the metal bar is pulled downward simultaneously pushing the thin PDMS membrane down thereby closing the entire channel to fluid flow (Fig. 3). In order to open the valve the magnet must be pulled 5 mm away from the closure position. At present the magnet is manipulated manually. We are in the process of automating the valve technique. The use of a magnet with smaller magnetic field, thicker layer of PDMS, or larger gap between magnet and bar, only partially closes the microfluidic channel. The distance between the magnetic valves should be at least 4 mm due to possible interference of the magnetic fields of induced by small magnets.

2.3 Flow visualization and detection

For visualization of the valve movement, food dyes (FD&C Blue#1, McCormick&Co., Inc, MD, USA) (0.025 M) were injected and transported by peristaltic pump into the microfluidic channels. The movement of the liquid streams was monitored using an inverted microscope (Nikon Eclipse TE2000-S) equipped with a color CCD camera (Panasonic GP-KR222). Movies and the images were captured by Pinnacle Studio 9 (Mountain View, CA) software. The intensities of the RGB colors against pixels on a specified area of the snapshot were determined and evaluated with Imagej 1.37v software (National Institutes of Health, USA). These data were transported to Microsoft Excel program for integration. On the basis of the change of the color intensity the flow rate of dye plug could be determined.

In some experiments, after fluid manipulation is accomplished in the chip, the injected dye plugs were detected by UV–Vis (Spectro-100, Thermo Separation, Waltham, MA, USA) that was connected externally to the chip via a short fused silica capillary of 50 μm ID.

3 Results and discussion

3.1 Study of deformation of PDMS layers by magnetic force

We studied the highest degree of deformation that can be achieved from the permanent magnet. As shown in Fig. 4 a 30 μm thick PDMS membrane was layered onto two vertically placed glass slides spaced 2 mm apart. A metal bar was placed on one side of the membrane and a magnet was gradually brought closer to the membrane from the opposite side. Due to the attractive forces, the metal bar and PDMS membrane is pulled towards the approaching magnet. The movement of the metal bar and membrane are easily visualized under a microscope, and the extent of stretching (deformation) of the membrane measured. As the distance between the metal bar and the magnet decreases the deformation increases due to increased attraction forces between the two objects. The magnet will be in contact with the metal bar (membrane) when the distance becomes below 2 mm.

Microscopic photograph of deformation of a thin PDMS layer (d = 30 μm) due to the movement of metal bar towards the approaching magnet monitored under the microscope [distance between the magnet and the PDMS layer is 2 mm; deformation (distance of the highest deformed point from its original position) is 7 mm]

The deformation of the PDMS layer also depends on the thickness of the PDMS layer. Layers with different thicknesses can be prepared by spincoating PDMS onto silicon wafers at different spinning speeds. PDMS thickness is inversely propotional to the spinning speed (ω0.945) (Zhang et al. 2004). Figure 5 shows that the deformation of the layer dramatically increases with a decrease of the thickness below 100 μm. These results demonstrate that an efficient magnetically controlled valve can only be fabricated in chips when the thickness is about or less than 50 μm. Hence, the thinner the PDMS layer, the more efficient the valve will be. Since in practice we could not peel layers with thickness of smaller than 50 μm from the mold, the 50 μm thickness of the layer is a compromise to in order to obtain a thin layer with adequate mechanical stability.

The degree of deformation of the PDMS layer can be increased, by increasing the strength of the magnet. The PDMS layers between the magnet and the metal bar are quite durable. No significant changes in repeated actuations were observed. Unger et al. (2000) reported that they could deflect PDMS layers with the thickness of 30 μm more than 4 million times without any significant of wear or fatigue.

3.2 Efficiency studies of closure of the valve (leakage test)

The operation of the valve and its efficiency in a microfluidic chip was studied using a cross shaped microchannel (Fig. 6). Deionized water was introduced from the left arm (A) of the microchannel and dye was introduced from the top arm (B) at the rate of 0.5 μL/min. The bottom arm (D) contained the magnetically controlled valve (Fig. 6a). When the valve is closed the laminar flow characteristic in microfluidic systems was observed in the right arm (C). When the valve is opened by moving the magnet 5 mm away from the chip, the dye and water flow through the valve (Fig. 6b) and the laminar flow was observed in the bottom arm. When the valve is closed the flow changed the direction towards the right arm where a lower backpressure exists. It is apparent that dye did not escape through the valve and dispersion of the trapped dye is evident from Fig. 6c where the bottom arm becomes uniformly dark 10 min after closure of the valve.

The closure of the valve was also studied in a simple straight channel. The dye was manipulated toward the valve and the magnetic valve closed before the dye pass the valve. Any leakage of the dye could not be observed over the valve at pressure less than 100 kPa applied for 30 min.

As the flow rate increases high pressure builds up near the valve and eventually causing the valve to partially or fully collapse. Leakage of solution can be detected by monitoring the decrease in the color intensity of the trapped dye. We observed that flow rates up to 1.7 μL/min (250 kPa) can be used without collapsing the valve. Above this critical value a slight increase in flow rate can result in significant leakage of the valve. The leakage will not be a major issue as the flow rates in many microfluidic systems are very low (0.1–1.0 μL/min) thus 100% closure can be easily achieved. Increasing the size of the magnet increases the pulling force [1.06 lbs for the used magnets (1/8′′ × 1/8′′ × 1/16′′ thick)], however, the size of the magnet cannot be considerably enlarged when more valves are intended to use on the chip.

Using a simple cross-shaped microchannel, plugs of dye were injected to a main carrier fluid by closing (100% closure) and opening a valve in time intervals. The size of the plugs can be varied by changing the frequency of valve opening and closure. The obtained dye plugs were detected (410 nm) externally to the chip via a capillary connected to the chip and a spectrophotometer (Fig. 7). The injections were accomplished manually, that is, the magnet was moved back and forth from the chip by hand.

A temporary taper (>100% closure) of the flexible microfluidic channel can easily be achieved by the use of the externally operated magnetic valve (manipulating the magnet toward the metal bar causes the metal bar to move downward thereby deforming the PDMS and tapering the fluid channel). An about 60% taper (closure) was found to be suitable for trapping 10 μm-size particles (C18 chromatographic beads) and thus this taper allows for flow of liquid through the tapered region. Figure 8 shows the channel in front of the magnetic valve where the chromatographic beads are trapped. These results prove that the magnetic valve is well suited for manipulating liquids and beads in chips. It is apparent that a sophisticated automation system is required to obtain reproducible and reliable operation of the valve especially when repeated injections with exact sample volumes are needed. Automation can be achieved by mechanical instrumentation that is capable of moving the magnet back and forth quickly or by replacing the magnet with an external electromagnet.

4 Conclusion

A novel form of microvalve actuation employing magnets for fluid manipulation in a MD has been described. Instead of using pressure, vacuum, thermal or electrical systems to control the valves, a small, NdFeB magnet is placed underneath the section of a microfluidic channel opposite a wire bar located above the channel. The microfluidic channels can be completely closed in flow rates ranging from 0.1 to 1.0 μL/min commonly used in microfluidic systems. The moving part of the valve is the upper wall of the channel itself, hence, this technique yields zero dead-volume.

The operation of the magnetic valve is mainly dependent on the thickness of the PDMS layer, the height of the channel, the gap between the chip and the magnet and the strength of the magnet. The increase of the height of the channel has two opposite effects: the closure of the deeper channel requires stronger pushing-down-power from the magnetic valve, yet an increased channel height yields a thinner PDMS layer above the microfluidic channel (supposing chips with patterned layer with the same thickness) that is easier to deflect. In our experiments we used channel heights in the 25 μm range. For larger channel heights stronger (and thus larger) magnets should be used.

Since the magnetic valve does not require pumps, a high voltage power supply or other components, as in the case of other microfluidic valve systems, the magnetically controlled valve-based chips can be readily portable for injection and fluid manipulation. In addition, since the magnetic valve operates externally (without any internal manipulation, integration of wires, electrodes or other units), chips made from PDMS can be easily manufactured at low cost and are disposable.

When a weaker magnet is used, the thickness of the PDMS layer or glass slide and/or gap between magnet and chip are changed, the microfluidic channel will only partially open. We are in the process of automating the operation of the valve using miniaturized, precisely controllable electromagnets instead of permanent magnets. Future applications of the magnetic valve include their use as reversible frits for microcolumns for various micro-chromatography based applications, cell and/or bead-based applications and in manipulation of minute sample volumes in enzymatic and other chemical reactions.

References

Bae B, Kee H, Kim S, Lee Y, Sim T, Kim Y, Park K (2003) In vitro experiment of the pressure regulating valve for a glaucoma implant. J Micromech Microeng 13:613–619

Bae B, Kim N, Kee H, Kim S, Lee Y, Lee S, Park K (2002) Feasibility test of an electromagnetically driven valve. Actuator for glaucoma treatment. J Microelectromech Syst 11:344–354

Bosh D, Heimhofer B, Muck B, Seidel H, Thumser U, Welser W (1993) A silicon microvalve with combined electromagnetic/electrostatic actuation. Sensors Actuators A 37/38:684–692

Duffy DC, McDonald JC, Schueller OJA, Whitesides GM (1998) Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal Chem 70:4974–4984

Fu C, Rummler Z, Chomburg W (2003) Magnetically driven micro ball valves fabricated by multilayer adhesive film bonding. J Micromech Microeng 13:S96–S102

Jackson WC, Tran HD, O’Brien MJ, Rabinovich E, Lopez GP (2001) Rapid prototyping of active microfluidic components based on magnetically modified elastomeric materials. J Vac Sci Technol B 19:596–599

Oh KW, Ahn CH (2006) A review of microvalves. J Micromech Microeng 16:R13–R39

Oh KW, Han A, Bhansali S, Ahn CH (2002) A low-temperature bonding technique using spin-on fluorocarbon polymers to assemble microsystems. J Micromech Microeng 12:187–191

Oh KW, Rong R, Ahn CH (2001) In-line micro ball valve through polymer tubing. Proc microTAS 2001 407–408

Siegel AC, Shevkoplyas SS, Weibel DB, Bruzewicz DA, Martinez AW, Whitesides GM (2006) Cofabrication of electromagnets and microfluidic systems in poly(dimethylsiloxane). Angew Chem Int Ed 45:6877–6882

Terry SC, Jerman JH, Angell JB (1979) A gas chromatographic air analyzer fabricated on a silicon wafer. IEEE Trans Electron Devices 26:1880–1886

Unger MA, Chou H, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288:113–116

Zhang WY, Ferguson GS, Tatic-Lucic S (2004) Elastomer-supported cold welding for room temperature wafer-level bonding. In: 17th IEEE international conference on MEMS 741–744

Acknowledgments

The authors gratefully acknowledge financial support for this research by grants from the National Science Foundation (CHE-0515363 and DMR-0351848), and the National Institutes of Health (1R15AI65468-01). Additional funds were supplied by the European Community for the Marie Curie Fellowship (MOIF-CT-2006-021447) of A. Gaspar at California State University, Los Angeles.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaspar, A., Piyasena, M.E., Daroczi, L. et al. Magnetically controlled valve for flow manipulation in polymer microfluidic devices. Microfluid Nanofluid 4, 525–531 (2008). https://doi.org/10.1007/s10404-007-0204-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-007-0204-1