Abstract

To simulate debris flow run-out, the governing equations for free-surface shallow flow are corrected by setting the basal flow resistance coefficients with the quadratic rheological friction model. A well-balanced numerical scheme is developed for its run-out simulation over irregular topography. A linear reconstruction is adopted for improving the spatial accuracy of the numerical scheme. Considering the complex friction terms of governing equations of debris flow, they are estimated with a full implicit scheme for ensuring stability of the numerical scheme. The validity check of run-out simulation is implemented based on general knowledge of fluid, and a well-studied case occurred in the Xiezi Gully in Yingxiu Town, Sichuan Province of China. For practical purpose, the present numerical scheme is used for run-out prediction of debris flow in Xiaojia Gully of Panzhihua City, Sichuan Province of China. Our work aims to present a well-balanced numerical scheme for debris flow run-out simulation prediction, which can be applied quite conveniently to solve other kinds of debris flow models and helpful to promote the development in debris flow numerical calculation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Debris flow often exists in the mountainous area with irregular topography, which is assumed conventionally as a free-surface shallow flow due to that the depth of the flow is small relative to the tangential length scale of the flow (George and Iverson 2014). Currently, many engineering and environmental issues involve the flow type of shallow flow over irregular topography, such as dam-break flow, open channel flow and flood (Pongsanguansin et al. 2016). It is very helpful for run-out prediction of debris flow over irregular topography with recent numerical schemes developed in these fields.

When applying numerical scheme for modelling free-surface shallow over highly irregular topography, it is very necessary to ensure it at a steady state, where the flux gradient is needed to be balanced with the bottom slope of the topography. A numerical scheme that could make it is named as a well-balanced scheme, which can better control numerical oscillations in solving governing equations (Liu et al. 2013). The kind of scheme was first proposed by Bermudez and Vazquez (1994). In recent years, the well-balanced scheme has been further developed for simulating flood or dam-break flow over irregular topography (Song et al. 2011; Liu et al. 2013).

Considering that the initial simulation domain of debris flow is usually dry, a good numerical scheme solver should be needed to deal with the wet/dry problem in numerical calculation. Many Riemann solvers have been developed at the basis of a Godunov-type finite volume scheme, which are introduced in the two books of Toro (2001) and LeVeque (2002). Presently, the HLLC Riemann solver is widely employed to simulate free-surface shallow flow because it can deal well with wet/dry problem in numerical calculation (Zia and Banihashemi 2008).

To simulate debris flow run-out with the well-balanced numerical scheme, differences between debris flow and flood or dam-break flow must be distinguished. As we know, debris flow is the water-saturated mass which is usually composed of soil and rock. The physical and mechanical property of it should fall in between rock avalanche and flash flood (Iverson 1997). The basal flow resistance coefficients of governing equations of flood or dam-break flow should be corrected in order to simulate debris flow run-out. Various friction models for calculating the basal flow resistance coefficients of debris flow have been proposed based on different study ideas, such as Voellmy model, Coulomb model and quadratic rheological model (O’Brien et al. 1993; Hungr 1995; Rickenmann et al. 2006; George and Iverson 2014).

In this work, we study the well-balanced scheme, which have been widely applied for simulating flood or dam-break flow over irregular topography in recent years. The motivation for using it is that it shows a good capacity in simulating them over irregular topography, as shown in Liang (2010). Before applying the scheme to simulate debris flow run-out, we first correct the basal flow resistance coefficients of free-surface shallow flow equations with the quadratic rheological friction model. Then, we improve the spatial accuracy of numerical result by applying a linear reconstruction method (Liang and Borthwick 2009; Liang 2010). Considering the complex friction terms of governing equations of debris flow, we adopt a full implicit scheme to deal with it for ensuring the stability of numerical scheme (Liang and Marche 2009). By combining all of these techniques, the present numerical scheme for debris flow run-out simulation is efficient as it has been shown by our numerical validation. Furthermore, the present numerical scheme is used for run-out prediction of debris flow in Xiaojia Gully of Panzhihua City, Sichuan Province of China, considering different hydrological designs.

Debris flow run-out simulation

Governing equations

Movement of debris mixtures can be simulated by solving free-surface shallow equations, which include the depth-averaged mass conservation equation and the momentum conservation equations (Wu et al. 2016). The vector format of these equations is expressed as

where t denotes time, x and y are Cartesian coordinates, and q, f, g and s are vectors representing the conserved variables, fluxes in the x-direction and y-direction and source terms, respectively. These vectors are given by

where h is the water depth; z b is defined as the bed elevation above the datum; g refers to the acceleration due to gravity; q x (=uh) and q y (=vh) denote the unit width discharge in the x-direction and y-direction, respectively; and S fx and S fy represent the flow frictional resistance coefficients in the x-direction and y-direction, respectively.

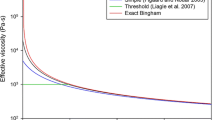

For calculating the basal flow resistance coefficients, the quadratic rheological friction model that combines frictional, viscous and turbulent effects is adopted in this study. The formulas are expressed as follows (Chen et al. 2017):

where τ is the yield stress, ρ m denotes the solid density of debris flow mixture, K refers to the resistance coefficient, β is the viscosity of debris flow and n td represents the equivalent Manning resistance coefficient, which accounts for both turbulent boundary friction and internal collisional stresses and is expressed as follows:

where n represents the Manning resistance coefficient and C v is the sediment concentration by volume.

Well-balanced numerical scheme

In this study, a well-balanced numerical scheme with first-order accuracy in time and second-order accuracy in space is presented to calculate the above governing equations for debris flow run-out simulation based on the non-staggered rectangular grids as shown in Fig. 1.

First, using a finite volume Godunov-type scheme, the flow variables (q) are updated to a new time step based on the following time-marching formula:

where ∆t represents a time step; ∆x and ∆y refer to cell size in the x-direction and y-direction, respectively, and subscripts i and j are the cell indices.

Next, to obtain a second-order accurate in space, a linear slope-limited reconstruction method introduced by Liang and Borthwick (2009) and Liang (2010) is adopted (see Fig. 1). Using this method, the face values of the flow variables are first reconstructed with the available flow data at the cell centres. Then, the face values of the bed elevations are obtained by finding differences between the water surface elevations and the corresponding water depths. For instance, on the left-hand side of the cell interface (i + 1/2, j) (see Fig. 1), the face values are given by

where η denotes the water surface elevation above the datum and Ψ is a slope limiting function evaluated at cell (i,j) for different flow variables (Pongsanguansin et al. 2016). For instance (η),

where

Similar reconstructions can also be used to obtain the face values on the right-hand side of the cell interface (i + 1/2, j) (see Fig. 1):

where Ψ is a slope limiting function evaluated at cell (i + 1,j). The associated face values of velocities are then calculated by

In dry cells (defined by h < 10−3 in this study), the velocities directly take the value of zero and are not computed by Eq. (10). The slope-limited linear reconstruction method is applied to all wet cells away from the dry-wet front. In dry cells or in wet cells directly adjacent to dry cells, the face values of the flow variables and bed elevations directly take those of the cell centres. This is a natural behaviour since the slope-limiting procedure essentially reduces the numerical accuracy near the flow discontinuities, including shocks and dry/wet fronts (Liang and Borthwick 2009).

Next, in order to obtain the well-balanced scheme, the new face value of the bed elevation at the cell interface i + 1/2 can be expressed based on the above face values after linear reconstruction (Zhang 2014):

The components on either side of the cell interface (i + 1/2,j) are then rewritten by

Next, the HLLC Riemann solver is employed to compute the interface f i + 1/2,j (Liu et al. 2013). The other cell interfaces (f i − 1/2,j , g i,j + 1/2, g i,j − 1/2) can also be computed with the same way.

Finally, the bed slope and friction source terms are treated separately. The bed slope source terms are approximated by a central differentiation approach, and the friction source terms are evaluated with a full implicit scheme (Liang and Marche 2009).

Implementation of debris flow run-out calculation

In numerical calculation, the computational domain and boundary conditions are first allocated based on the actual situation in the study area as in the method introduced by Hu et al. (2000) and Ouyang et al. (2013), as illustrated in Fig. 2. Then, the inflow hydrology of debris flow entering a research region is set as the inflow boundary condition. Finally, the present well-balanced scheme is applied to solve the governing equation of debris flow for run-out simulation. The implementation process of the numerical calculation is depicted in the flow chart illustrated in Fig. 3.

Numerical validation

Flow test over irregular topography

An irregular topography with a bulge in the channel is used to verify the effectiveness of numerical calculation with the present numerical scheme. The test result is shown in Fig. 4. The computational domain consists of a 98 m × 92 m (width × height) region that is divided into 46 × 49 rectangular grids. For the initial inflow condition, the debris flow inflow flux is set to 30 m3/s. The inflow duration is set to 50 s. From the simulation result, a natural debris flow scene over irregular topography is shown with the present numerical scheme.

Result test of numerical calculation

The validity of calculation result with the present numerical scheme must be validated before engineering and scientific application. For this reason, we consider a well-studied case occurred in the Xiezi Gully in Yingxiu Town, Sichuan Province of China, which emanated from the paper of Chen et al. (2017). We compare our debris flow run-out calculation result with their result with the FLO-2D model. The results of them are shown in Fig. 5. Figure 5a shows the calculation result of flow depth of debris flow using the FLO-2D model, and Fig. 5b describes our calculation result using the same simulation domain and parameters as those in the FLO-2D model. Through the comparison between them, some differences between the two results can be found. In flow height, the maximum flow depth obtained by our numerical calculation is smaller than those in the FLO-2D model. In flow type, some debris moves upstream, which is different to those obtained with the FLO-2D model. The similarities between them are larger flow depth, similar inundation region and same location of maximum flow depths that are consistent with the field survey. Thus, the numerical calculation with the present numerical scheme can be used to run-out calculation of debris flow.

Case study

Background of Xiaojia Gully

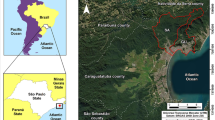

The Xiaojia Gully is on the right bank of the Jinsha River, which belongs administratively to Panzhihua City of Sichuan Province (see Fig. 6a). It has a catchment area of 0.92 km2 and a height range from 1004 to 1754 m. Based on its slope information, the gully can be divided into two subdomains (see Fig. 6b). Subdomain 1 (=0.22 km2) has a steep slope, and its longitudinal gradient is approximately 69.6%. Subdomain 2 (=0.70 km2) has a slow slope, and its longitudinal gradient is approximately 25.9%. The bedrock in subdomain 1 is mainly syenite with structural characteristics including high strength, jointed fissures and strongly weathered layers at the surface (see Fig. 7a, b). In subdomain 2, the drainage channel is more wide and rough, and some deposited debris has been found in the drainage channel (see Fig. 7c, d). Moreover, at the mouth of the gully, the deposited debris is also seen in the field, and its granularity is less than that of the deposited debris in the drainage channel (see Fig. 7e). Additionally, the average annual rainfall in the study region is 853.4 mm; the maximum monthly rainfall is 316 mm (July 1986), and the maximum daily rainfall is 155 mm (18 June 1986). Precipitation is unevenly distributed over the year. It is mainly concentrated between June and September, which accounts for 80% of the total annual precipitation (see Fig. 8). Such climate characteristics can prompt the highly weathering rock materials into the channel when meeting with heavy rainfall.

Debris flow triggering hydrographs

Debris flow is exclusively related to heavy rainstorm, which can cause either shallow landslides or superficial soil erosion into channel (Cuomo et al. 2015). Rainfall intensity and duration greatly influence debris flow volume. However, it is a complex process that has yet to be not well solved (Abancó and Hürlimann 2014). Thus, a practical triggering model based on the empirical hydrograph designs under different recurrence intervals in the study region and the empirical formula of triggering discharge of debris flow is adopted to predict the volume of debris flow. Based on slope information and field survey, subdomain 1 of the gully is determined as the triggering area where debris materials are initiated. The run-off hydrographs for the triggering area are designed under 20, 50, 100 and 200-year recurrence intervals, which are calculated using “The Rainstorm and Flood Calculation Manual of Medium and Small Basin in Sichuan Province” (Liu et al. 2014) (see Fig. 9). Maximum discharges and run-off confluence times under different recurrence intervals are listed in Table 1. The shape of these run-off hydrographs is determined with the empirical triangle method.

The run-off only partly contributes to the debris flow. Herein, all parts of the hydrograph larger than the triggering discharge are considered to contribute it (Gregoretti et al. 2016). Because few expressions between flood discharge and particle diameter have been proposed in China, the critical discharge as the triggering discharge is estimated in this study by the formula proposed by Takahashi (2014):

where Q CRIT (m3/s) denotes the critical discharge, d m (m) is the mean debris diameter (here, 0.08 m is selected based on the deposited sediment in the drainage channel of subdomain 2) and W (m) refers to the average width of the valley incision (=8 m in the study). After calculation, the corresponding triggering discharge Q CRIT is equal to 1.13 m3/s.

The discharge of the debris flow can be estimated using the triggering discharge of run-off and multiplying by the bulking factor (1-C V )−1. The volumetric sediment concentration (C V = 0.45) of the solid-liquid mixture is suggested according to the “Specification of geological investigation for debris flow stabilization” (the Chinese geological mineral industry standard, DZ/T0220-2006). The triggering hydrographs of debris flow including 20, 50, 100 and 200-year recurrence intervals are shown in Fig. 9. Based on the above process, the designed inflow volume of debris flow is from 1128.1 to 7531.3 m3, and the corresponding debris is from 506.7 to 3389.1 m3.

Run-out calculation of debris flow

The simulation calculation is conducted based on a MATLAB platform. Subdomain 2 is set as the simulation domain identified with an 8-m mesh size. The input parameters for debris flow and simulation domain are listed in Table 2. The solid density (ρ m ) of the debris mixture is suggested to be 2700 kg/m3 (Zhou et al. 1991). Based on published researches (O’Brien and Julien 1988; Rickenmann et al. 2006; Bisantino et al. 2010; Liu and Wu 2012), Chen et al. (2013) proposed a simple classification for the yield stress (τ) and viscosity (η) of debris flow (see Table 3). In our study, the rheological properties of debris flow in the study region are considered to be low yield stress (τ = 1500 kPa) and middle viscosity (β = 10 Pa s). Besides, a relatively large resistance coefficient (K = 2500) and pseudo-Manning’s resistance coefficient (n = 0.05) are selected for the run-out simulation (Chen et al. 2013; Zhang et al. 2014). The simulation calculation results are shown in Fig. 10.

Run-out prediction of debris flow

The simulation result in Fig. 10a is in accordance with the field survey (see Fig. 7d). Over there, the deposited debris is found, and its deposition depth is estimated to be less than 0.2 m. Again, at the mouth of the gully, the deposited sediment is also seen in the field, and its granularity is less than that of the deposited debris in Fig. 7d (see Fig. 7e). This phenomenon is considered as the result of run-off erosion subsequent to the debris flow. To predict the run-out of debris flow at Xiaojia Gully in the future, the designed debris flow hydrographs under 50, 100 and 200-year recurrence intervals are also simulated in this study (see Fig. 10b–d). These results show a smaller average flow depth under different debris flow run-off hydrographs. The effect of debris flow in the future is minuscule.

Discussion

Debris flow inflow volume and rheological parameters

One important aspect of numerical simulation calculation is to predict run-out region of debris flow. Accurate assessment of the debris flow volume is of great concern. However, the debris flow volume entering a reach is usually difficult to estimate. A reasonable calculation of the volume is a key. Thus, a feasible design is made by considering hydrological run-offs with different recurrence intervals and an empirical triggering debris flow mechanism in this study.

In debris flow run-out simulation calculation, selection of the rheological parameters of debris flow has a significant impact on the simulation result. The yield stress controls the inundation region, and the viscosity largely influences the flow velocity because it increases viscous friction (Chen et al. 2013). Based on field investigation combined with published relevant researches, the two parameters are adjusted to meet the knowledge of the current situation of Xiaojia Gully.

Debris flow numerical model

Many numerical models have been developed for debris flow simulation calculation, which can be divided into three categories: (1) debris flow run-out model without entrainment, (2) debris flow run-out model with entrainment and (3) debris flow run-out model including debris material initiation process. In the first kind of model, such as the FLO-2D model (O’Brien et al. 1993), the governing equations are obtained based on the free-surface shallow equations. The basal flow resistance coefficients of them are corrected with the debris flow friction model. In the second kind of model, such as the Kanako-2D model (Nakatani et al. 2008) and the EDDA model (Chen and Zhang 2015), the governing equations of debris flow are further corrected in consideration of channel erosion which is likely to occur in many real situations (Iverson et al. 2011; Cuomo et al. 2014; Frank et al. 2015). Some extra parameters and formulas are added in this kind of model. In the third kind of model, such as the D-Claw model (Iverson and George 2014; George and Iverson 2014), the debris material initiation process is added into the model. In order to make it, the governing equations of debris flow are further enhanced. Some parameters, such as pore fluid pressure parameter, are brought into the governing equations for setting the threshold from statics to dynamics for the initially stable debris materials. Based on the above-mentioned fact, it could be seen that the capacity of debris flow run-out model develops more and more strongly. However, the input parameters into the model also became greater in number. Thus, to an extent, the model application condition is also limited.

Numerical scheme for debris flow run-out calculation

Debris flow numerical models have become viable tools in run-out analysis of debris flows. However, one challenge in applying them is to develop robust numerical schemes that can well simulate them over highly irregular topography with complex geometry (Ouyang et al. 2013). In our work, we study the well-balanced scheme which has been widely applied for simulating free-surface shallow flow over irregular topography in recent years. It shows its good capacity in simulating free-surface shallow flow over irregular topography, as shown in Liang (2010). Our work aims to present a well-balanced numerical scheme for debris flow run-out simulation prediction, which can be applied quite conveniently to solve other kinds of debris flow run-out models and helpful to promote the development in debris flow numerical calculation.

Conclusions and remarks

This paper presents a well-balanced numerical scheme for debris flow run-out prediction in Xiaojia Gully. The values of our work are listed as follows:

-

1.

Bring a well-balanced numerical scheme into debris flow numerical simulation for run-out prediction of it.

-

2.

Effective techniques, such as the linear reconstruction method and the full implicit scheme to deal with the complex friction terms of governing equations of debris flow, are employed to improve the spatial accuracy of numerical result and to ensure the stability of numerical scheme over irregular topography.

-

3.

The current present numerical scheme could be easily applied to other kinds of debris flow models, which can be helpful to promote the development of debris flow numerical calculation.

In our study of debris flow run-out prediction in Xiaojia Gully, the first kind of model is adopted considering the application condition and the current situation in Xiaojia Gully: clearly identifiable source area and broad channel with little loose material. To enhance and strengthen application ability of the present numerical scheme in debris flow numerical calculation, further work in the future should consider some additional factors, such as the channel erosion and debris material initiation process.

References

Abancó C, Hürlimann M (2014) Estimate of the debris-flow entrainment using field and topographical data. Nat Hazards 71(1):363–383

Bermudez A, Vazquez ME (1994) Upwind methods for hyperbolic conservation laws with source terms. Comput Fluids 23:1049–1071

Bisantino T, Fischer P, Gentile F, Liuzzi GT (2010) Rheological properties and debris-flow modeling in a southern Italy watershed. WIT Trans Eng Sci 67:237–248

Chen HX, Zhang LM (2015) EDDA: integrated simulation of debris flow erosion, deposition and property changes. Geosci Model Dev 8:829–844

Chen HX, Zhang LM, Zhang S, Xiang B, Wang XF (2013) Hybrid simulation of the initiation and runout characteristics of a catastrophic debris flow. J Mt Sci 10(2):219–232

Chen HX, Zhang LM, Gao L, Yuan Q, Lu T, Xiang B, Zhang WL (2017) Simulation of interactions among multiple debris flows. Landslides 14(2):1–21

Cuomo S, Pastor M, Cascini L, Castorino GC (2014) Interplay of rheology and entrainment in debris avalanches: a numerical study. Can Geotech J 51(11):1318–1330

Cuomo S, Sala MD, Novità A (2015) Physically based modelling of soil erosion induced by rainfall in small mountain basins. Geomorphology 243:106–115

Frank F, Mcardell BW, Huggel C, Vieli A (2015) The importance of entrainment and bulking on debris flow runout modeling: examples from the Swiss Alps. Nat Hazards Earth Syst Sci 15(11):2569–2583

George DL, Iverson RM (2014) A depth-averaged debris-flow model that includes the effects of evolving dilatancy. II. Numerical predictions and experimental tests. Proc R Soc A Math Phys Eng Sci 470(2170):20130820–20130820

Gregoretti C, Degetto M, Boreggio M (2016) GIS-based cell model for simulating debris flow runout on a fan. J Hydrol 534:326–340

Hu K, Mingham CG, Causon DM (2000) Numerical simulation of wave overtopping of coastal structures using the non-linear shallow water equations. Coast Eng 41(4):433–465

Hungr O (1995) A model for the runout analysis of rapid flow slides, debris flows and avalanches. Can Geotech J 32:610–623

Iverson RM (1997) The physics of debris flows. Rev Geophys 35:245–296

Iverson RM, George DL (2014) A depth-averaged debris-flow model that includes the effects of evolving dilatancy. I. Physical basis. Proc R Soc A Math Phys Eng Sci 470(2170):20130819–20130819

Iverson RM, Reid ME, Logan M, Lahusen RG, Godt JW, Griswold JP (2011) Positive feedback and momentum growth during debris-flow entrainment of wet bed sediment. Nat Geosci 4:116–121

LeVeque RJ (2002) Finite volume methods for hyperbolic problems. Cambridge University Press, Cambridge

Liang QH (2010) Flood simulation using a well-balanced shallow flow model. J Hydraul Eng 136(9):669–675

Liang Q, Borthwick AGL (2009) Adaptive quadtree simulation of shallow flows with wet–dry fronts over complex topography. Comput Fluids 38(2):221–234

Liang Q, Marche F (2009) Numerical resolution of well-balanced shallow water equations with complex source terms. Adv Water Resour 32(6):873–884

Liu KF, Wu YH (2012) Comparison between FLO-2D and Debris-2D on application of assessment of granular debris flow. Kyoto Conference Proceeding (The Tenth International Symposium on Mitigation of Geo-disasters in Asia) http://hdl.handle.net/2433/180432

Liu Y, Zhou J, Song L, Zou Q, Liao L, Wang Y (2013) Numerical modelling of free-surface shallow flows over irregular topography with complex geometry. Appl Math Model 37(23):9482–9498

Liu J, You Y, Chen X, Liu J, Chen X (2014) Characteristics and hazard prediction of large-scale debris flow of Xiaojia gully in Yingxiu town, Sichuan Province, China. Eng Geol 180:55–67

Nakatani K, Wada T, Satofuka Y, Mizuyama T (2008) Development of “Kanako 2D (Ver.2.00)”, a user-friendly one- and two-dimensional debris flow simulator equipped with a graphical user interface. Int J Erosion Control Eng 1(2):62–72

O’Brien JS, Julien PY (1988) Laboratory analysis of mudflow properties. J Hydraul Eng 114(8):877–887

O’Brien JS, Julien PY, Fullerton WT (1993) Two-dimensional water flood and mudflow simulation. J Hydrol Eng 119(2):244–261

Ouyang C, He S, Xu Q, Luo Y, Zhang W (2013) A MacCormack-TVD finite difference method to simulate the mass flow in mountainous terrain with variable computational domain. Comput Geosci-UK 52(1):1–10

Pongsanguansin T, Maleewong M, Mekchay K (2016) Shallow-water simulations by a well-balanced WAF finite volume method: a case study to the great flood in 2011, Thailand. Comput Geosci 20:1269–1285

Rickenmann D, Laigle D, Mcardell BW, Hübl J (2006) Comparison of 2d debris-flow simulation models with field events. Comput Geosci 10(2):241–264

Song L, Zhou J, Guo J, Zou Q, Liu Y (2011) A robust well-balanced finite volume model for shallow water flows with wetting and drying over irregular terrain. Adv Water Resour 34(7):915–932

Takahashi T (2014) Debris flow: mechanics, prediction and countermeasures, 2nd edn. CRC Press, London

Toro EF (2001) Shock-capturing methods for free-surface shallow flows. John Wiley & Sons Press, Chichester

Wu NJ, Chen C, Tsay TK (2016) Application of weighted-least-square local polynomial approximation to 2D shallow water equation problems. Eng Anal Bound Elem 68:124–134

Zhang H (2014) Research on mathematical model and hydrodynamic characteristics of flow field in lakes. Hydraulic and hydro-power engineering department. Huazhong University of Science & Technology, Wuhan (in Chinese)

Zhang P, Ma J, Shu H, Han T, Zhang Y (2014) Simulating debris flow deposition using a two-dimensional finite model and soil conservation service-curve number approach for Hanlin gully of southern Gansu (China). Environ Earth Sci 73(10):6417–6426

Zhou BF, Li DJ, Luo DF (1991) Guide to prevention of debris flow. Science Press, Beijing (in Chinese)

Zia A, Banihashemi MA (2008) Simple efficient algorithm (SEA) for shallow flows with shock wave on dry and irregular beds. Int J Numer Methods Fluids 56(11):2021–2043

Acknowledgements

This work was supported by the State Key Program of the National Natural Science Fund of China (Grant No. 41330636), the National Natural Science Fund of China (Grant Nos. 41302218 and 41402243) and Special Fund for Scientific Research of China Ministry of Lands and Resources (CMLR) (Grant No. 201211095).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, X., Chen, J., Xu, P. et al. A well-balanced numerical scheme for debris flow run-out prediction in Xiaojia Gully considering different hydrological designs. Landslides 14, 2105–2114 (2017). https://doi.org/10.1007/s10346-017-0850-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10346-017-0850-7