Abstract

Polyethylenimine (PEI) and 2,4,6,8-tetramethyl-2,4,6,8-tetrakis(propyl glycidyl ether)cyclotetrasiloxane (POSS–epoxy) were used as precursors for the preparation of organic-silica hybrid monolithic columns (PEI–POSS monolith) via epoxy–amine ring-opening polymerization (ROP). The high density of amine groups in PEI provides rich chromatographic interaction sites for the polar or acidic analytes in hydrophilic interaction (HILIC) and weak anion exchange (WAX) mechanisms. The column preparation conditions, such as the porogens, solvent and reaction temperature, were systematically investigated according to the morphology, permeability and column efficiency. The separation mechanisms of HILIC and WAX were evaluated with neutral polar compounds and halogen benzoic acids. Owing to the existence of reactive amine groups on the matrix surface, the PEI–POSS monolith is also an ideal starting material for the preparation of HILIC or strong anionic exchange (SAX) stationary phases by modification. The modification of PEI–POSS monoliths with iodomethane or bromoacetic acid via the nucleophilic substitution reaction could achieve the retention mechanisms of SAX or zwitterionic HILIC, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Monolithic columns have played a significant role in micro-scale separation science, such as micro/nano liquid chromatography (µ/nano-LC), capillary electrochromatography (CEC), solid phase micro-extraction and so on, because they are inherently easy to prepare and have a better permeability and faster mass transfer rate compared to conventional particle-packed columns [1–6]. Generally, the monoliths could be classified into three types according to the chemical nature of the matrix: organic polymer-based [7–9], inorganic (silica) [10–13] and hybrid organic–inorganic monoliths [14–16]. For the preparation of polymer-based monoliths, in addition to the free radical polymerization [8, 17], several “new” approaches, such as the thio-ene reaction [18–21] and epoxy–amine ring-opening polymerization (ROP) [22–28], were introduced because of their high column efficiency compared to conventional free radical polymerization. In these new methods, the precursors and reactions are dramatically different, and satisfying column efficiency could be achieved without extensive optimization in column preparation.

In the epoxy–amine ROP, two precursors will become involved, one containing multiple epoxy moieties and the other with multiple primary amines. The polar primary amine functionalized monomers were transformed to the secondary amine groups. Theoretically, the reaction between epoxy and amine is at equal molar ratio, which is more controllable compared to the free radical polymerization among the double carbon bonds. If the amount of amine precursors is above the equal molar ratio, the extra primary amine groups will lead to a monolith with a weak anion exchange (WAX) and hydrophilic interaction (HILIC) mechanism. In virtue of the high reactivity of amine group via the nucleophilic substitution reaction, the chemical properties of the monolith could be tuned with modifications. PEI is a polymer containing multiple primary amine groups, which will be involved in the crosslinking reaction [29]. The high density of amine groups (including primary, secondary and tertiary amines) in PEI provides extensive chromatographic interaction and post-modification sites.

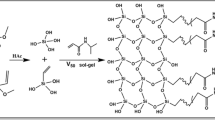

Polyhedral oligomericsilsesquioxanes (POSS) as crosslinkers in monolithic column preparation have been widely employed because of their unique property of improving the mechanical stability of organic polymer monoliths by incorporating fine nano-scale inorganic particles into the final monoliths [24, 30]. In this work, we used 2,4,6,8-tetramethyl-2,4,6,8-tetrakis(propyl glycidyl ether)cyclotetrasiloxane (POSS–epoxy), which is similar to POSS in structure, and PEI as the precursors to prepare an anion exchange/HILIC monolith via the ROP reaction (PEI–POSS monoliths). The chromatographic performances of the prepared PEI–POSS were systematically evaluated in capillary liquid chromatography (CLC). PEI–POSS monoliths were also applied as the starting material for further modification with iodomethane (IM) and bromoacetic acid (BAA) to obtain strong anion exchange (SAX) and zwitterionic HILIC stationary phases, respectively.

Materials and Methods

Chemicals and Materials

Polyethylenimine (PEI, Mw = 600), 2,4,6,8-tetramethyl-2,4,6,8-tetrakis(propyl glycidyl ether)cyclotetrasiloxane (POSS–epoxy), PEG (Mw = 10,000) and (3-aminopropyl)-triethoxysilane (APTES) were purchased from Aldrich (Milwaukee, WI, USA). Analytical standards such as toluene, thiourea, N,N-dimethylformamide (DMF) and formamide were purchased from Sigma (St. Louis, MO, USA). The 4-methylbenzoic acid (4-MBA), benzoic acid (BA), 4-fluorobenzoic acid (4-FBA), 4-chlorobenzoic acid (4-CBA), 4-bromobenzoic acid (4-BBA), 4-iodobenzoic acid (4-IBA), iodomethane (IM) and bromoacetic acid (BAA), and acetonitrile (ACN) of HPLC grade were all purchased from Aladdin (Shanghai China). The fused-silica capillaries were purchased from Ruifeng Chromatographic Devices (Yongnian, Hebei, China). Doubly distilled water was further purified by a Milli-Q system and used in all experiments (Millipore, Milford, MA, USA).

Preparation of Monolithic Columns

The pretreatment of the fuse silica capillary was similar to the reported method [24]. In detail, the capillary was flushed by 0.1 M NaOH for 12 h, water for 30 min, 0.1 M HCl for 12 h and water for another 30 min in series and dried with nitrogen. Primer amine groups were covalently introduced onto the inner capillary wall by reaction with APTES solution in methanol (50 %, v/v) for 12 h. Finally, the modified capillary was flushed with methanol and dried with a nitrogen stream for further use.

To prepare the PEI–POSS monolithic columns, POSS–epoxy (50 µL), PEI (20 mg), PEG 10000 (20 mg), PEG 200 (120 µL) and ACN (180 µL) were first mixed in a 1.5-ml centrifugation tube. After vibration and sonication for 15 min to obtain a homogeneous pre-polymerization solution, the mixture was introduced in a APTES-pretreated capillary with a syringe. After both ends had been sealed with rubber stoppers, the capillary was immersed in a water bath at 55 °C for polymerization for 12 h. Finally, the resulting hybrid PEI–POSS monolithic columns were extensively flushed with methanol and water to remove the porogens and unreacted residuals. The microscale morphologies of the monoliths were characterized by scanning electron micrographs (SEM, Nova NanoSEM 450, FEI, Hillsboro, OR, USA) after gold sputter deposition.

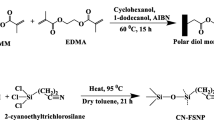

The modification of the PEI–POSS monolithic columns with IM or BAA was followed with the reported methods via the nucleophilic substitution reaction [31]. In particular, the IM ethanol solution (20 %, v/v) was pumped into the PEI–POSS monolithic columns using a manual syringe pump. Then, a modification reaction was performed at 50 °C for 12 h. Finally, the resulting IM-modified PEI monolithic columns (IM–PEI–POSS monolith) were washed with methanol. For the modification with BAA, the procedure was the same as that of IM except modifier was replaced by BAA. The BAA-modified monolith (BAA-PEI–POSS) was expected to be zwitterionic with carboxyl and amine groups, and the hydrophilic interaction could be increased compared to the PEI–POSS columns. The schematic synthesis of the PEI–POSS monoliths and the following modification with IM or BAA are illustrated in Fig. 1.

CLC System

A CLC system was set up in the laboratory, consisting of a conventional LC pump, a UV detector (Unimicro, Shanghai, China), a chromatography workstation (Unimicro, Shanghai, China) and an injection valve (model 7125, Rheodyne). A T-joint used as splitter was connected between the injection valve the capillary column, with one end to the capillary monolithic column and the other to a section of open capillary (50 μm i.d. and 375 μm o.d., 80 cm length). The outlet of the column was connected to an open silica capillary (75 μm i.d. and 375 μm o.d.) with a detection window located at a position 5 cm away from the column outlet end.

Results and Discussion

Preparation and Characterization of PEI–POSS Monolithic Columns

The appearance under optical microscopy is closely related to the performances of the column; for instance, when it is transparent, the permeability is poor or non-permeable [16]. Therefore, in the preparation of the PEI–POSS monolith, the conditions involved, such as the porogen, solvent and reaction temperature, were systematically investigated based on their morphology under the optical microscopy. As show in Table 1, the morphology was significantly affected by PEG 10000, which was used as porogen. The monoliths became transparent under microscopy when the PEG 10000 content was too low (column A, 15 mg), but slack when it was too high (column C, 25 mg). The ratio of PEG 200 to ACN, which could impact the column permeability, was optimized by keeping the total volume at 400 µL. With the increase of PEG 200 content, the permeability decreased in the test range. For the polymerization temperature, raising the temperature leads to a denser monolith (transparent under microscope) with poorer permeability (column G, 55 °C). Conversely, low temperature causes the detachment of the monolith from the inner capillary wall (column F, 50 °C). After optimization, the conditions used for column B were adapted for the preparation of PEI–POSS monolithic columns (Table 1).

The SEM images confirmed that the synthesized monolith with uniform macro-pores was well attached to the inner capillary wall (Fig. 2a). The porous monolith was formed with a narrow skeleton diameter of about 0.5 μm and large cross-connections through pores at 3–5 μm, which could provide a fast mass transfer rate and good permeability. Such morphology was different from that prepared from traditional free radical polymerization, which consisted of large clusters with small spheres and were formed through pores between these large clusters [32, 33].

The mechanical stability was evaluated by measuring the back pressure at different flow rates. When the flow rate increased from 0.43 to 1.85 mm/s, the back pressure increased linearly from 4.2 up to 26 MPa (Fig. S1), which indicated that no crash happened to the monolith within the tested pressure range. The permeability of the PEI–POSS hybrid monolithic columns was measured following Darcy’s law of permeability, B = FηL/(πr 2ΔP) [34], where F is the flow rate (m3/s), η is the viscosity of the mobile phase (Pa s), L is the column effective length (m), r is the inner radius of the column (m), and ΔP is the pressure drop (Pa). The permeability of the PEI–POSS hybrid monolithic column was calculated as 7.1 × 10−14 m2 and 2.4 × 10−14 m2 for water (η = 0.89 cP) and ACN (η = 0.38 cP), respectively, indicating the good permeability of these columns [24, 35].

The Separation of Neutral Polar Analytes

To investigate the hydrophilic properties of the prepared monolithic columns, neutral polar compounds were used as analytes. For the PEI–POSS column, with 90 % ACN (v/v) as the mobile phase, the strong polar solutes formamide and thiourea were eluted after the nonpolar toluene (Fig. 3), which is consistent with the HILIC mechanism [36, 37]. However, the weak polar DMF was not separated from toluene. After modification with IM or BAA, the hydrophilic retentions for the polar compounds were both increased, and the DMF and toluene were fully separated. The reason is that after modification with IM, some of the amine groups (probably the secondary and the tertiary amines) on the matrix surface turned into ionized quaternary amines, which increased the hydrophilicity, and led to stronger retention against polar analytes. For the BAA modified columns, the retention of thiourea was further strengthened compared to IM–PEI–POSS columns because of introducing polar carboxyl groups onto the matrix surface. We also observed that the separation of DMF and toluene on the BAA-PEI–POSS column was inferior to that on the IM–PEI–POSS column, which pointed out that different functional groups possess different selectivities. The change of the retention behavior of polar solutes also confirmed that the modification procedure was successful.

Comparison of the PEI–POSS monolith and modified PEI–POSS monoliths on the separation of neutral polar solutes. Experimental conditions: effective column length, 30 cm; mobile phase, ACN/water (90/10, v/v); injection volume, 1.0 μL in split mode; detection wavelength, 214 nm. Analytes: 1 toluene, 2 DMF, 3 formamide, 4 thiourea

The effect of ACN content on the retention factors (k) was investigated by using different ACN contents from 50 to 98 % (v/v) in the mobile phase. Figure 4 shows the retention factor for toluene keeping constant at ACN concentrations from 70 to 98 %, which indicates that the column shows little retention to nonpolar compounds at high ACN concentration. In contrast, the k of the polar solutes increased with the increase of the ACN content in the test range from 50 to 98 %. These results were consistent with the HILIC retention mechanism, which confirmed that the desired monolithic columns were successfully prepared via the epoxy–amine ROP and post modification. For the IM–PEI–POSS column, the highest column efficiency of over 56,000 N/m (plate height about 17.5 μm) could be achieved for neutral polar analytes (Fig. 5).

Effect of the ACN content in the mobile phase on the retention of neutral polar analytes on the IM–PEI–POSS monolith. Experimental conditions were the same as in Fig. 3 except for the ACN content in the mobile phase

The variation of column efficiency with the flow rate in the separation of neutral polar solutes on the IM–PEI–POSS monolith. Experimental conditions were the same as in Fig. 3 except for the flow rate

The Separation of Halogen Benzoic Acids (HBAs) on the PEI–POSS Monolithic Column

Owing to the existence of amine groups (including primary, secondary and tertiary amines) on the matrix surface, the anionic interaction mechanism could play part of the role in the separation of acidic compounds. The HBAs were used as the model analytes to evaluate the separation mechanism. By using 60 % ACN as the mobile phase, all the HBAs were eluted after the nonpolar toluene, which confirmed the existence of the HILIC/WAX mechanism in the separation on the PEI–POSS column (Fig. 6). Additionally, the elution order of 4-CBA, 4-BBA and 4-IBA was the same as that on the conventional C18 column (Fig. S2), which indicated that reverse phase (RP) retention was also involved in this separation. The effect of FA content on HBAs’ retention was evaluated to investigate the WAX mechanism. Figure 7 shows that the retention factor decreased with the increase of FA content from 0.1 to 2 %. The increase of FA in the mobile phase could lower the pH (from 2.5 to 1.8) and raise the ionic strength of the mobile phase, both of which could weaken the interaction between the analytes and the stationary phase and shorten the retention time. Furthermore, the separation of HBAs at different pHs (2, 3 and 4) was tested. With the increase of pH from 2 to 4, the retention factors of HBAs increased remarkably (Fig. 8, k increased from 3.2 to 8.1 for 4-IBA). These results were all consistent with the typical ion exchange mechanism, confirming the existence of the WAX mechanism in the separation of acidic compounds [35, 38].

Separation of HBAs on the PEI–POSS monolith. Experimental conditions: mobile phase, ACN/water (60/40, v/v) with 0.5 % FA; injection volume, 5 μL in split mode. Other conditions were the same as in Fig. 3. Analytes: 1 toluene, 2 4-MBA, 3 BA, 4 4-FBA, 5 4-CBA, 6 4-BBA, 7 4-IBA

Effect of FA concentration on the retention factor of HBAs on the PEI–POSS monolith. Experimental conditions were the same as in Fig. 6 except for the FA concentration (v/v)

The effect of the ACN concentration on the retention factor separation of HBAs was investigate to check whether an RP retention mechanism existed on the PEI–POSS column. Figure 9 shows that retention factors first decreased when ACN increased from 50 to 80 % and then kept constant up to 95 %. The reason is probably that under a relatively low ACN concentration, the hydrophilic interaction is weak, and the RP retention dominated the separation. At high ACN concentration (80–90 %), the hydrophilic interaction became stronger and finally compensated the decrease of RP retention, which stopped the further decrease of retention factors of these HBAs. So, for the separation of acidic compounds on the PEI–POSS column, three retention mechanisms including WAX, HILIC and RP retention were all involved. For the separation of HBAs on the IM–PEI–POSS column, the retention of analytes was extremely strong because of the SAX mechanism. The HBAs could not be fully eluted out in 60 min at the same chromatographic conditions for the PEI–POSS column (data not shown).

Effect of the ACN content on the retention factor (k) of HBAs on the PEI–POSS monolith. Experimental conditions were the same as in Fig. 6 except for the ACN content in the mobile phase

Conclusion

We prepared a set of organic-silica hybrid monolithic columns with HILIC and an ion exchange mechanism via the expoy-amine ROP. By using the PEI as the functional monomer, the amine groups with high density were incorporated into the monoliths, which provide abundant chromatographic interaction sites. The prepared columns exhibited good mechanical stability under working pressure over 25 MPa. After systematic characterization and chromatographic evaluation, the existence of mixed separation modes of WAX and HILIC were confirmed when the mobile phase contains high ACN content (>60 %). The chemical property of the PEI–POSS monolith could be easily modified via the nucleophilic substitution reaction. The modification with BAA and IM showed that the PEI–POSS monolith was an idea starting material, especially suitable for the preparation of the HILIC or SAX chromatographic stationary phase.

References

Svec F, Lv YQ (2015) Anal Chem 87:250–273

Wu RA, Hu LG, Wang FJ, Ye ML, Zou HF (2008) J Chromatogr A 1184:369–392

Tanaka N, McCalley DV (2016) Anal Chem 88:279–298

Jandera P (2013) J Chromatogr A 1313:37–53

Aggarwal P, Tolley HD, Lee ML (2012) J Chromatogr A 1219:1–14

Namera A, Nakamoto A, Saito T, Miyazaki S (2011) J Sep Sci 34:901–924

Eeltink S, Svec F (2007) Electrophoresis 28:137–147

Liu K, Aggarwal P, Lawson JS, Tolley HD, Lee ML (2013) J Sep Sci 36:2767–2781

Svec F (2004) J Sep Sci 27:1419–1430

Hara T, Kobayashi H, Ikegami T, Nakanishi K, Tanaka N (2006) Anal Chem 78:7632–7642

Xie CH, Ye ML, Jiang XG, Jin WH, Zou HF (2006) Mol Cell Proteomics 5:454–461

Malerod H, Rogeberg M, Tanaka N, Greibrokk T, Lundanes E (2013) J Chromatogr A 1317:129–137

Ikegami T, Tanaka N (2016) Annual review of analytical chemistry (Palo Alto, Calif) 9:317–342

Yan LJ, Zhang QH, Zhang H, Zhang LY, Li T, Feng YQ, Zhang LH, Zhang WB, Zhang YK (2004) J Chromatogr A 1046:255–261

Colon LA, Li L (2008) Adv Chromatogr 46:391–421

Wu MH, Wu RA, Wang FJ, Ren LB, Dong J, Liu Z, Zou HF (2009) Anal Chem 81:3529–3536

Nischang I (2013) J Chromatogr A 1287:39–58

Shen SF, Ye FG, Zhang C, Xiong YH, Su LJ, Zhao SL (2015) Analyst 140:265–271

Lin H, Ou JJ, Liu ZS, Wang HW, Dong J, Zou HF (2015) J Chromatogr A 1379:34–42

Marechal A, Laaniste A, El-Debs R, Dugas V, Demesmay C (2014) J Chromatogr A 1365:140–147

Liu ZS, Ou JJ, Lin H, Wang HW, Liu ZY, Dong J, Zou HF (2014) Anal Chem 86:12334–12340

Tsujioka N, Hira N, Aoki S, Tanaka N, Hosoya K (2005) Macromolecules 38:9901–9903

Hosoya K, Hira N, Yamamoto K, Nishimura M, Tanaka N (2006) Anal Chem 78:5729–5735

Liu ZS, Ou JJ, Lin H, Wang HW, Dong J, Zou HF (2014) J Chromatogr A 1342:70–77

Ren LB, Liu Z, Liu YC, Dou P, Chen HY (2009) Angew Chem Int Ed 48:6704–6707

Hosoya K, Sakamoto M, Akai K, Mori T, Kubo T, Kaya K, Okada K, Tsujioka N, Tanaka N (2008) Anal Sci 24:149–154

Liu Y, Lu Y, Liu Z (2012) Chem Sci 3:1467–1471

Liu Y, Liu Z (2013) Chin J Chromatogr 31:348–351

Li DJ, Li Y, Li XL, Bie ZJ, Pan XH, Zhang Q, Liu Z (2015) J Chromatogr A 1384:88–96

Wu MH, Wu RA, Li RB, Qin HQ, Dong J, Zhang Z, Zou HF (2010) Anal Chem 82:5447–5454

Wu MH, Chen YZ, Wu RA, Li RB, Zou HF, Chen B, Yao SZ (2010) J Chromatogr A 1217:4389–4394

Kip C, Erkakan D, Gokaltun A, Celebi B, Tuncel A (2015) J Chromatogr A 1396:86–97

Jiang ZJ, Smith NW, Ferguson PD, Taylor MR (2007) Anal Chem 79:1243–1250

Stanelle RD, Sander LC, Marcus RK (2005) J Chromatogr A 1100:68–75

Wang X, Zheng YQ, Zhang CY, Yang YZ, Lin XC, Huang GH, Xie ZH (2012) J Chromatogr A 1239:56–63

Ikegami T, Fujita H, Horie K, Hosoya K, Tanaka N (2006) Anal Bioanal Chem 386:578–585

Hemstrom P, Irgum K (2006) J Sep Sci 29:1784–1821

Lubbad SH, Bandari R, Buchmeiser MR (2011) J Chromatogr A 1218:8897–8902

Acknowledgments

Financial support from the National Natural Sciences Foundation of China (no. 21205058) and the starting funding from Dalian University of Technology (no. DUT15RC(3)048) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animal performed by any of the authors.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, L., Wu, M., Wang, Q. et al. Preparation of Organic-Silica Hybrid Monolith with Anion Exchange/Hydrophilic Interaction Mixed-Mode Via Epoxy–Amine Ring-Opening Polymerization Using Polyethylenimine as Functional Monomer. Chromatographia 79, 1263–1269 (2016). https://doi.org/10.1007/s10337-016-3150-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-016-3150-9