Abstract

A gradient HPLC method coupled with diode array detection was developed and fully validated for the analysis of impurities in ropinirole using a Kromasil® C8 100 Å (250 × 4.6 mm, 5 μm) column with a flow rate 1.0 mL min−1 and detection at 250 nm. The mobile phase component A consisted of a mixture of 19.6 mM aqueous potassium dihydrogen phosphate–acetonitrile (98:2 v/v), pH adjusted to 7.0 with triethylamine and the mobile phase component B consisted of acetonitrile. The method was validated in terms of linearity, sensitivity, precision, accuracy and stability. The calibration curves for ropinirole and its five impurities showed good linearity (r > 0.998) within the calibration ranges tested. The intra- and inter-day RSD values were <3.9 %, while the relative percentage error E r was <5.8 % for all compounds. Accelerated stability studies performed under various stress conditions including oxidation, hydrolysis and UV light irradiation at 254 nm proved the selectivity of the procedure. Long-term stability studies performed on blistered tablets and under various conditions of heat and humidity indicate the presence of four of the studied impurities in less than 0.07 %. The method was applied successfully to the detection and determination of ropinirole impurities in pharmaceutical formulations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ropinirole hydrochloride, 4-[2-(dipropylamino)ethyl]-l,3-dihydro-2H-indol-2-one, belongs to a class of non-ergoline dopamine agonists which bind specifically to D2 and D3 receptors with a selectivity similar to that of dopamine, and it is approved for the treatment of the signs and symptoms of Parkinson’s disease both as initial therapy and as an adjustment therapy with levodopa [1–3]. In addition, ropinirole is efficacious in the management of more advanced Parkinson’s disease in patients experiencing motor complications after long-term use of levodopa [4, 5] and it is administered for the treatment of restless legs syndrome [6].

Very few analytical techniques have been published for the determination of ropinirole in biological fluids, including high-performance liquid chromatography [7, 8] and liquid chromatography-mass spectrometry [9–11]. Reversed-phase HPLC [12] and spectrophotometric methods [13] have been reported for the determination of ropinirole in tablets. Capillary liquid chromatography [14], capillary zone electrophoresis [15] and UPLC [16] methods have been used for the separation and quantification of ropinirole HCl and some potential impurities. Recently, a stability-indicating high-performance thin-layer chromatography (HPTLC) method was reported for the analysis of ropinirole in the presence of its degradation products [17]. HPLC methods with UV [18, 19] and diode array detection (HPLC–DAD) [20] have been developed for the determination of some of the impurities of ropinirole. A chemometric evaluation of the chromatographic behavior of ropinirole and its impurities (4-[2-(dipropylamino)ethyl]-1H-indol-2,3-dione) has also been reported [21]. None of the above HPLC methods deals with the determination of all the five impurities of ropinirole in pharmaceutical dosage forms.

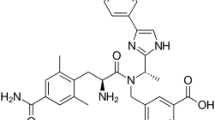

According to the ICH Topic Q3A [22], the selection of impurities in a new drug substance specification should be based on the impurities found in batches manufactured by the proposed commercial process. The impurities in this study were selected according to the Drug Master file (DMF) that was obtained from the manufacturer of the bulk substance (Vitalife Chemipharma Pvt. Ltd.). To the best of our knowledge, up until now only one official report in USP refers to the determination of ropinirole in tablets including impurity testing, yet this method does not include the chromatographic separation of 4-[2-(dipropylamino)ethyl] indoline-2,3-dione hydrochloride (impurity 2), 6-[2-(dipropylamino)ethyl]-2-nitrophenyl-acetic acid (impurity 4) and N-[2-(2-methyl-3-nitrophenyl)ethyl]-N-propylpropan-1-amine hydrochloride (impurity 5) [23]. Thus, we thought that it would be of particular interest to develop and validate an improved stability-indicating HPLC–DAD method for the quality control of the five impurities namely impurity 1, impurity 2, impurity 3, impurity 4 and impurity 5 (Fig. 1) in pharmaceutical preparations containing ropinirole as the parent compound. Although isocratic HPLC systems have been used often for the determination of impurities in bulk drug, a gradient method offered a better ability to resolve and detect low-level impurities over an isocratic system [24]. Because the design emphasis of the impurity test is in the detection and accurate quantitation of impurities, a gradient RP-HPLC procedure was developed in this study and it was fully validated according to ICH guidelines [25, 26].

Experimental

Materials and Reagents

All solvents used were of analytical-reagent grade and purchased from E. Merck (Darmstadt, Germany). Water was deionised and further purified by means of a Milli-Q Plus Water Purification System (Millipore, Waters Milford, MA, USA). E. Merck (Darmstadt, Germany) supplied triethylamine, potassium dihydrogen phosphate and phosphoric acid 85 % v/v. Millex®-LCR hydrophilic PTFE filters 0.2 μm, were obtained from Merck-Millipore (Darmstadt, Germany).

Ropinirol hydrochloride of pharmaceutical purity grade, 4-[2dipropylamino)ethyl]-1-hydroxyindoline-2-one hydrochloride (impurity 1), 4-[2dipropylamino)ethyl] indoline-2,3-dione hydrochloride (impurity 2), 4-[2-(propylamino)ethyl]- indoline-2-one hydrochloride (impurity 3), 6-[2-(di-n-propylamino) ethyl]-2-nitrophenyl-acetic acid hydrochloride (impurity 4) and N-[2-(2-Methyl-3-nitrophenyl)ethyl]-N-propylpropan-1-amine hydrochloride (impurity 5) were purchased from Vitalife Chemipharma Pvt. Ltd (Mumbai, Maharashtra, India) [16].

Ropinirol tablets are pilot products of Pharmathen SA (Pallini, Attiki, Greece); each tablet contains 2 mg of ropinirole. Inactive ingredients consist of Eudragit® RS100, hypromellose, vinylpyrrolidone–vinyl acetate copolymer (Kollidon® VA-64), sodium lauryl sulphate, magnesium stearate and ethanol.

Requib XL® extended-release tablets are products of GlaxoSmithKline and were used for comparison. The tablets are formulated as a three-layered tablet with a central, active-containing, slow-release layer, and two placebo outer layers acting as barrier layers which control the surface area available for drug release. Each biconvex, capsule-shaped tablet contains 2 mg of ropinirole, respectively. Inactive ingredients consist of carboxymethylcellulose sodium, colloidal silicon dioxide, glyceryl behenate, hydrogenated castor oil, hypromellose, lactose monohydrate, magnesium stearate, maltodextrin, mannitol, povidone, and one or more of the following: FD&C Yellow No. 6 aluminum lake, FD&C Blue No. 2 aluminum lake, ferric oxides (black, red, yellow), polyethylene glycol 400, titanium dioxide.

Equipment and Chromatographic Conditions

All experiments were performed on a Prominence Series (Shimadzu Co.) LC system, equipped with a vacuum degasser, a DGU-20A5 quaternary pump, an autosampler, a column compartment, an SPD-M20A diode array detector, controlled by LC Solutions software ver. 1.23 SP1, Shimadzu Co.

Separation was achieved under gradient elution on a spherical silica-based Kromasil® C8 analytical column 100 Å, 250 × 4.6 mm, particle size 5.0 μm from AkzoNobel (USA) with a flow rate of 1.00 mL min−1. The mobile phase component A consisted of a mixture of 19.6 mM aqueous potassium dihydrogen phosphate–acetonitrile (98:2 v/v), pH adjusted to 7.0 with triethylamine and the mobile phase component B consisted of acetonitrile. The gradient program started at 100 % component A for 5 min and then component B was increased linearly from 0 to 70 % for a 45-min period. A 5-min return ramp to mobile phase component A was followed by a 15-min re-equilibration at 100 % component A. The elution profile was monitored over the wavelength range 190–800 nm and peaks were identified by UV absorbance at 250 nm. The column temperature is maintained at 45 °C. The injection volume was 20 μL.

Stock and Working Standard Solutions

A stock standard solution of ropinirole at 0.10 mg mL−1 was prepared by dissolving an appropriate amount of the drug in methanol. Stock standard solutions of impurity 1 at 0.10 mg mL−1, impurity 2 at 0.10 mg mL−1, impurity 3 at 0.10 mg mL−1, impurity 4 at 0.10 mg mL−1 and impurity 5 at 0.10 mg mL−1 were prepared by dissolving appropriate amounts of the compounds in methanol. A mixed working solution containing ropinirole and its five impurities at 0.001 mg mL−1 was prepared in methanol by the appropriate dilution of the above-mentioned stock solutions. These solutions were stable for several weeks when stored in the dark and under refrigeration at 4 °C.

A series of mixed calibration standard samples were prepared by the appropriate dilutions of the mixed working solution in aqueous potassium dihydrogen phosphate–methanol (10:90 v/v) to reach concentration ranges of 0.10 to 0.40 μg mL−1 for ropinirole and its five impurities. Mixed quality control (QC) samples containing the parent drug at 0.1 mg mL−1 and the five impurities at three concentration levels (0.24, 0.30 and 0.36 μg mL−1) were also prepared in aqueous potassium dihydrogen phosphate–methanol (10:90 v/v). Separate stock standard solutions of the analytes were used for the preparation of calibration standard solutions and quality control samples. Calibration standard and quality control samples were prepared freshly every day and found to be stable during the analysis time.

Assay of Pharmaceutical Preparations: Preparation of the Test Solution

Twenty tablets were used to calculate the table weight and then were finely powdered. An accurately weighed portion of this powder, equivalent to 2 mg of ropinirole was transferred into a 20-mL volumetric flask and diluted to volume with aqueous potassium dihydrogen phosphate–methanol (10:90 v/v) to obtain nominal concentration of 0.1 mg mL−1 of ropinirole. The mixture was introduced into a magnetic stirrer for 20 min. Aliquots 20 μL of this test solution were injected into the chromatographic system for the impurities studies. We followed the same procedure for Requib XL® extended-release tablets.

Validation Procedure

Mixed calibration standards samples in the concentration ranges of 0.10 to 0.40 μg mL−1 for ropinirole and its five impurities, were prepared and analyzed in duplicate in three different analytical runs. The peak area signal of each analyte was regressed against the corresponding concentrations to create the calibration curves, and its closeness of fit was calculated as the regression coefficient, r. Three calibration curves were constructed over a period of 1 month.

Mixed quality control (QC) samples at three concentration levels for each impurity while the concentration of ropinirole remain constant at 0.1 mg mL−1 were prepared in aqueous potassium dihydrogen phosphate–methanol (10:90 v/v). The QC samples were processed in five replicates at each concentration level for three different analytical runs in order to evaluate the intra- and inter-assay accuracy and precision. The accuracy was assessed by the relative percentage error, E r%, and the precision was assessed by the relative standard deviation (RSD %).

Forced Degradation Studies

Forced degradation studies were performed in ropinirole tablets under various stress conditions where degradation was stimulated by UV light, acidic, basic and oxidative conditions. Thus, the stability-indicating capability of the HPLC–DAD method was determined by subjecting the tablets to accelerated degradation studies with 0.01 M HCl, 0.01 M NaOH at 60 ± 2 °C for 3 h, 2 % v/v H2O2 at 65 ± 2 °C for 3 h and UV light at 254 nm for 24 h. During each degradation study and at predetermined time intervals, 20-μL aliquots were neutralized with base or acid, and analyzed according to the proposed method. The purity of peaks obtained from stressed samples was checked by use of the PDA detector. The final concentration of ropinirole for all stability samples was 0.1 mg mL−1.

Results and Discussion

Optimization of the Chromatographic Procedure

For HPLC analysis of ropinirole and its five impurities, several types of analytical columns have been tested during the early development of this study. Early chromatographic work was done using a BDS Hypersil C8 (250 × 4.6 mm, 3 μm particle size), an ODS Hypersil C18 (250 × 4.6 mm, 5 μm particle size) and a Symmetry Shield RP18 (250 × 4.6 mm, 5 μm particle size). However, using BDS Hypersil C8 column it was not possible to achieve consistent resolution of the parent drug from impurity 2. Adequate resolution for ropinirole and impurity 2 was achieved by the use of an ODS Hypersil C18 or a Symmetry Shield RP18 column, though the detection of impurities D and E at trace levels was not successful. It was found that a spherical silica-based Kromasil® C8 analytical column 100 Å (250 × 4.6 mm, 5 μm particle size) column was the best choice for the chromatographic separation of closely eluting impurities and the parent drug. The gradient HPLC procedure described in “Experimental” was chosen as the optimum so as to obtain a good separation, stable baseline and sharp peaks for the analytes. The pH in the mobile phase component A, which consisted of a mixture of 19.6 mM aqueous potassium dihydrogen phosphate–acetonitrile (98:2 v/v), was adjusted to 7.0 with triethylamine. Acetonitrile (mobile phase component B) was used as organic modifier and preferred to methanol as it gave better peak resolution and shorter chromatographic run times. Column temperature was maintained at 45 °C and the analytes were detected at 250 nm. The selectivity of the proposed chromatographic procedure is illustrated in a representative chromatogram obtained from the analysis of a mixed QC sample containing the parent drug at 0.1 mg mL−1 and the five impurities at 0.30 μg mL−1 (Fig. 2a), a chromatogram obtained from the analysis of powdered tablets (Fig. 2b), along with a chromatogram obtained from the analysis of placebo tablets according to the sample preparation procedure (Fig. 2c). Under the current chromatographic conditions, ropinirole is eluted around 26.8 min and all impurities were well resolved from each other and from ropinirole peak. The relative retention times for impurity 1, impurity 2, impurity 3, impurity 4 and impurity 5 are 0.81, 1.04, 0.58, 0.75 and 1.79, respectively. It was observed that many solvent peaks were eluted mainly at the end of the chromatogram. The resolution between ropinirole and the closely eluted impurity 2 is 3.89. The evaluation of the system suitability parameters was based on five replicate determination of the test solution spiked with the five impurities at 0.3 μg mL−1. Specificity data presented in Table 1 indicate that under the current chromatographic conditions ropinirole impurities are well separated from the parent drug.

a HPLC–DAD chromatogram obtained from the analysis of a mixed QC sample containing ropinirole at 0.1 mg mL−1 and the five impurities at 0.30 μg mL−1; b HPLC–DAD chromatogram obtained from the analysis of a processed powdered tablets sample containing 0.1 mg mL−1 ropinirole; c HPLC–DAD chromatogram obtained from the analysis of a processed powdered placebo tablet sample. Chromatographic conditions: reversed-phase HPLC on a Kromasil® C8 analytical column 100 Å (250 × 4.6 mm, 5 μm particle size) with gradient elution; flow rate, 1.00 ml min−1; detection wavelength, 254 nm

Statistical Analysis of Data

Mixed calibration standard samples containing ropinirole and its five impurities in the concentration ranges of 0.10–0.40 μg mL−1 were analyzed for the calibration procedure. Concentration levels for impurities correspond to 0.1–0.4 % of the test solution concentration for ropinirole (0.1 mg mL−1). Linear relationships between the peak area signal of each analyte and the corresponding concentrations were observed as shown by the results presented in Table 2. Back-calculated concentrations in the calibration curves were less than 1.8 % of the nominal for ropinirole and <7.5 % of the nominal for the impurities, which are in agreement with international guidelines. The insignificance of intercepts that was proven by Student’s t tests indicates that there is no effect from the tablet’s excipients. The relative detector response factor, commonly referred as response factor (RRF), expresses the sensitivity of the PDA detector for each impurity relative to the parent drug and is also presented in Table 2.

The limits of detection, LOD, and the limits of quantitation, LOQ, for ropinirole and each impurity were determined according to the definitions of ICH Topic Q2R1 [26]. In particular, the LOD was calculated using the equations y − α = 3.3 × S α and y − α = b × LOD, while the limit of quantitation, LOQ, was attained using the equations y − α = 10 × S α and y − α = b × LOQ (where b is the slope and S α is the standard deviation of the intercept of the regression line). In particular, LOD and LOQ were calculated taking under consideration data obtained from the calibration equations. The LODs were found to be at the level of 19, 8, 3.4, 2, 23 and 2.5 ng mL−1 for ropinirole, impurity 1, impurity 2, impurity 3, impurity 4 and impurity 5, respectively, while the LOQs were found to be at the level of 58, 24, 10, 6.5, 72 and 7 ng mL−1 for ropinirole, impurity 1, impurity 2, impurity 3, impurity 4 and impurity 5, respectively.

The specificity of the proposed method was further established by analyzing mixed QC samples prepared by spiking the parent drug at 0.1 mg mL−1 with appropriate levels of impurities. One-way analysis of variance was used to evaluate the intra- and inter-assay precision. Results presented in Table 3 indicate that ropinirole impurities can be determined by appropriate precision and accuracy. In particular, intra-assay relative standard deviation values, %RSD, were between 1.4 and 3.9 % for all impurities while inter-assay %RSD was no more than 7.1 %. The overall accuracy was assessed by the relative percentage error, %E r, which ranged from −5.4 to 5.8 for all the analytes.

In order to evaluate the robustness of the proposed method, the influence of small deliberate variations of the method parameters in the retention times, the capacity factors and the peak asymmetry of the analytes and the ISTD was thoroughly investigated. The factors selected to examine were the pH of the mobile phase component A, the flow rate and the column temperature. Each factor was changed at three levels (−1, 0 and 1), while one factor at the time was changed to estimate the effect. Replicate injections (n = 3) of a mixed standard solution containing 0.1 mg mL−1 ropinirole and the five impurities at 0.30 μg mL−1 were performed under small changes of the aforementioned parameters (factors). Results presented in Table 4 indicate that the analytes were adequately resolved and elution orders remained unchanged in all the deliberately varied chromatographic conditions.

The statistical evaluation of the proposed HPLC method revealed its good linearity and reproducibility and led us to the conclusion that it can be used for the reliable determination of ropinirole impurities in tablets.

Forced Degradation Studies

To assure the selectivity of the proposed method, forced degradation studies have been performed under various stress conditions. Thus, appropriate amounts of powdered tablets equivalent to 2 mg of ropinirole were stressed with 0.01 M HCl and 0.01 M NaOH at 60 ± 2 °C for 3 h, 2 % v/v H2O2 at 65 ± 2 °C for 3 h. Moreover, samples of powdered tablets were exposed to UV light at 25 ± 2 °C for 24 h. After the degradation treatments were completed, the samples were analyzed according to assay sample preparation, after being neutralized with acid/base, when necessary.

In stability studies the calculation of the percentage content for impurities (% w/w) was based on peak area measurements taking under consideration the appropriate response factor; for unknown impurities the response factor is 1.0. The reporting threshold for ropinirole impurities is 0.05 % w/w, while identification and qualification thresholds are 0.15 and 0.2 % w/w, respectively [24, 25]. Ropinirole impurities have been identified in these studies using the relative retention time (RRT) and spectral library search using the photo-diode array detector. Peak purity tests have also been performed for all the analytes and the unknown impurities.

The degradation of ropinirole under basic hydrolysis conditions leads to the formation of impurity 2 (0.05 % w/w), impurity 3 (0.06 % w/w) and three unknown degradation products with concentration greater than the reported threshold (0.05 % w/w) at 22.14, 38.76 and 51.69 min. In the acid-stressed samples in 0.01 M HCl, stability data for ropinirole indicate the formation of impurity 2 (0.06 % w/w), impurity 3 (0.06 % w/w), impurity 5 (0.28 % w/w). The oxidative degradation of ropinirole in 2 % v/v H2O2 leads to the formation of impurity 2 (0.06 % w/w) and impurity 5 (0.28 % w/w) along with two unknown degradation products at 22.14 and 45.6 min. After 24 h under UV light at 254 nm impurity 3 (0.11 % w/w) is present along with one unknown degradation product at 19.09 min.

Figure 3 shows typical chromatograms obtained from the analysis of processed powdered tablet samples, under basic-stressed conditions with 0.01 M NaOH for 3 h, under acid-stressed conditions with 0.01 M HCl for 3 h and under stressed conditions with 2.0 % v/v, Η2Ο2 for 3 h, the concentration of ropinirole in the analyzed samples is 0.3 mg mL−1.

HPLC–DAD chromatograms obtained from the analysis of processed powdered tablets sample containing 0.3 mg mL−1 ropinirole: a under basic-stressed conditions (0.01 M NaOH) for 3 h at 60 °C; b under acid-stressed conditions (0.01 M HCl) for 3 h at 60 °C, and c under oxidative stressed conditions in 2.0 % v/v, Η2Ο2 for 3 h at 65 °C. The retention time of ropinirole is 26.65 min

Long-term stability studies have also been performed on blistered tablets containing 2 mg ropinirole per tablet. Ropinirole tablets, Pharmathen SA and Requib XL® extended-release tablets were stored for three months at 25 ± 2 °C and 60 ± 2 % relative humidity, at 30 ± 2 °C and 65 ± 2 % and at 40 ± 2 °C and 75 ± 2 % relative humidity. Long-term stability data presented in Table 5 indicate that the proposed HPLC–DAD method is able to separate and identify ropinirole impurities.

Application of the Proposed Method to the Analysis of Commercial Formulations

The proposed method for ropinirole impurities was evaluated in the analysis of commercially available tablets containing 2 mg of ropinirole per tablet. Ten replicate determinations were carried out on an accurately weighed amount of the pulverized tablets equivalent to 2 mg of ropinirole. Ropinirole tablets pilot product of Pharmathen SA and Requib XL® extended-release tablets were used for the application of the method. Data presented in Table 5 indicate that the proposed HPLC–DAD method is suitable for the separation of ropinirole impurities from the parent drug and can accurately determine their content (% w/w) in commercially available tablets.

Conclusions

A high-performance liquid chromatography method with diode array detection was developed and fully validated for the determination of ropinirole impurities in tablets. The method shows a good performance with respect to linearity, accuracy, precision, specificity and robustness and it offers a simple and precise way for the determination of the analytes in pharmaceutical preparations. Forced degradation studies revealed that possible unknown degradation products are well separated from the parent drug. Stability data and routine batch analysis indicated that there is no other degradation product (possible impurity) present at the level above the reported threshold for ropinirole which is 0.1 %.

References

Müller T (2012) Transl Neurodegener 1:1–12

Jost WH, Angersbach D (2005) Drug Rev 11:253–272

Ravikumar K, Sridhar B (2006) Acta Cryst 622:265–267

Matheson AJ, Spencer CM (2000) Drugs 60:115–137

Maratos EC, Jackson MJ, Pearce RKB, Jenner P (2001) Mov Disord 16:631–641

Bogan RK, Fry JM, Schmidt MH, Carson SW, Ritchie SY (2006) Mayo Clin Proc 81:17–27

Swagzdis JE, Gifford R, Mco BA (1985) J Chromatogr 345:203–208

Ramji JV, Keogh IP, Blake TJ, Broom C, Chenery RJ, Citerone DR (1999) Xenobiotica 29:311–325

Beattie IG, Blake TJA (1989) J Chromatogr 474:123–138

Bhatt J, Jangid A, Shetty R, Shah B, Kambli S, Subbaiah G, Singh S (2006) J Pharm Biomed Anal 40:1202–1208

Bharathi DV, Jagadeesh B, Kumar SS, Lakshmi RN, Hotha KK (2009) Biomed Chromatogr 23:557–562

Onal A (2006) Chromatographia 64:459–461

Aydogmus Z (2008) Spectrochim Acta 70:69–78

Coufal P, Stulik K, Claeessens HA, Hardy MJ, Webb M (1999) J Chromatogr B 732:437–444

Coufal P, Stulık K, Claessens HA, Hardy MJ, Webb M (1998) J Chromatogr B 720:197–204

Krishnaiah C, Murthy MV, Reddy AR, Kumara R, Mukkantib K (2010) J Chin Chem Soc 57:348–355

Mustafa G, Baboota S, Ali J, Ahuja A (2012) J Pharm Innov 7:47–55

Parmar G, Sharma S, Singh K, Bansal G (2009) Chromatographia 69:199–206

Sahasrabuddhey B, Nautiyal R, Acharya H, Khyade S, Luthra PK, Deshpande PB (2007) J Pharm Biomed Anal 43:1587–1593

Zissis KD, Brereton RG, Escott R (1997) Analyst 122:1007–1033

Jancic-Stojanovic B, Malenovic A, Ivanovic D, Rakic T, Medenica M (2009) J Chromatogr A 1216:1263–1269

International conference on harmonisation (ICH) Topic Q3A, Impurities in new drug substances, June 2008, Revision 2, http://www.ich.org

USP 36/NF 31 (2013), pp. 5080

B’Hymer C (2006) J Chromatogr Sci 44:200–204

International conference on harmonisation (ICH) of technical requirements for registration of pharmaceuticals for human use, Topic Q2 (R1): validation of analytical procedures: text and methodology (2005). http://www.ich.org

ICH Harmonised tripartite guideline validation of analytical procedures: Text and Methodology, Topic Q2(R1), November 2005. http://www.ich.org

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kakouris, A., Samara, V., Kalaskani, A. et al. Simultaneous Determination of Impurities in Ropinirole Tablets by an Improved HPLC Method Coupled with Diode Array Detection. Chromatographia 77, 447–457 (2014). https://doi.org/10.1007/s10337-013-2617-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-013-2617-1