Abstract

A novel and simple coating method was developed by coating bovine serum albumin (BSA) onto the inner surface of a fused-silica capillary, to avoid the adsorption of analytes during CE. The advantage presented here was that the coating process is more simple, fast, stable, and reproducible. The coated capillary avoided the adsorption of analytes onto the inner surface of a fused-silica capillary and might be a promising candidate for separation of complex biological samples with further development. Meanwhile, the efficiencies of the coated capillary were evaluated by EOF, chromatographic peak shape, and theoretical plate number (N m−1) of RNase A. The optimal coating conditions were obtained from the results. The pH value of coating buffer PB was 4.2, the standing time was 12 h at 4 °C, and the coating concentration of BSA was 1.5 mg mL−1. The stability of the coating on the inner wall of the capillary and the reproducibility of the coated capillaries were good. The theoretical plate number values of RNase A were over 1.3 × 105 (N m−1) in the coated capillary. After successive electrophoresis for 48 h using the coated capillary, the RSD values of EOF and the theoretical plate number were 4.14 % and 9.14 %, respectively. In addition, the RSD values of EOF and the theoretical plate number (N m−1) in the coated capillaries were 13.19 % and 8.96 %, respectively. Finally, the coated capillary was successfully applied to separate the mixture of four basic proteins (RNase A, lysozyme, trypsin and myoglobin).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Capillary electrophoresis (CE) has been developed into a powerful analytical technique for separations of peptides, proteins, and nucleic acids. It can provide a variety of advantages, such as high efficiency, short analysis time, ease of automation, and low sample consumption. Though CE possesses is of so many advantages, there still exists the adsorption between sample and the wall, which was induced by the anionic nature of the silanol groups on the inner surface of the capillary. As we all know, proteins can be easily adsorbed to many different kinds of surfaces, containing the inner wall of the fused-silica capillary. To be exact, the adsorption mainly originates from the strong electrostatic interaction between proteins, especially basic proteins and the inner wall. For CE analysis, the adsorption will lead to poor peak shape, irreproducible migration times, and irregular electro-osmotic flow (EOF). So one of the main objective for CE analysis is to minimize protein–wall interactions by masking or modifying the silanol groups on the inner wall of the capillary [1, 2].

Over the past years, several methods have been applied to reduce the adsorption of proteins on the inner wall of the capillary. Like extreme pH values [3, 4], high salt concentrations [5], or coating the inner wall of the capillary. However, under the conditions of extreme pH and high salt concentrations, proteins might undergo conformational changes, even denaturation [6, 7].

Coating is the most common method to avoid protein adsorption onto the inner wall of the capillary. Such coatings can be classified as covalently bonded polymers and physically adsorbed polymers coatings. Covalent coatings have often been used in separation of proteins due to its high effectivity. Barron et al. [8] covalently attached tri (ethylene glycol)-terminated alkyltrichlorosilane to create a very thin coating on the inner surface of a fused-silica capillary, and the coating displayed good resistance to the adsorption of cationic proteins, providing clean separations of a mixture of lysozyme, cytochrome c, RNase A, and myoglobin for more than 200 consecutive runs. Xiao et al. [9] developed a novel covalent coupling method for coating of capillaries with liposomes. The intra- and inter-capillary variations in EOF were 4.02 % RSD (n = 30) and 6.72 % RSD (n = 4), respectively, and the coated capillaries can be used to perform analysis at least for 1 month without any performance deterioration when stored at 4 °C. It should be noted that the production of covalent coatings is tedious, which requires multiple time-consuming steps; moreover, this covalent coating is not reproducible and uses the expensive or toxic organic solvents.

Compared with the covalent coatings, the physically adsorbed polymer coating shows several advantages [1, 10, 11]: easily prepared, no use of organic solvents, and reproducible, for instance. Physical coating can be obtained by either a dynamic or a static approach [12]. Dynamic coating is done by adding additives to the BGE, such as amines, surfactants, and some neutral polymers [13], and can be quite effective to avoid protein adsorption. For example, five additives, potassium chloride, morpholine, cetyltrimethylammonium bromide (CTAB), poly(vinyl alcohol), and polyethyleneimine were used by Cifuentes et al. [14] to reduce the adsorption of the proteins onto the capillary inner wall. But when CE is coupled with mass spectrometry (MS), the dynamic coating may deteriorate the ionization of the analyte. Haselberg et al. [15] used polybrene and dextran sulfate to form a semi-permanent and non-covalent triple-layer coating, and was used to efficiently separate basic proteins by coupling the triple-layer coated capillaries with time-of-flight mass spectrometry (TOF-MS). Peng et al. [16] coated the inner wall of capillary with the hydroxyethylcellulose-graft-poly (N,N-dimethylacrylamide), which was used to separate basic proteins successfully and were also used as a sieving matrix to separate 11 fragments of the double-strand DNA (dsDNA) sample. Wang et al. [17] developed another quite stable non-covalent coating, poly (1-vinylpyrrolidone-co-2-dimethylaminoethyl methacrylate), for the separation of four basic proteins: lysozyme, cytochrome C, ribonuclease A, and α-chymotrypsinogen A.

Apart from the above-mentioned coatings, there is still another kind of physical coating—protein coating, but only few reported. Coating one characteristic protein easily adsorbed onto the inner surface of the capillary to inhibit the adsorption of protein sample. VanTassel et al. [18] placed a thermally treated monolayer of adsorbed fibrinogen on the internal surface of the fused silica capillary, and the measured capillary surface potential and electro-osmotic mobility are reduced roughly 30 % by the adsorbed layer and are shown to be stable over the course of several runs. Janssens et al. [19] used the proteins, such as albumin or hemoglobin. to form a polycation coating to saturate the sites of adsorption on the inner surface of the capillary to prevent adsorption of cationic species. Bonvent et al. [20] used one characteristic protein, ferritin (Ft), which was adsorbed to fused-silica capillaries, to prove the binding of proteins to the capillary wall using atomic force microscopy.

The aforementioned studies demonstrate that it is imperative to find a simple coating method to avoid the adsorption of analytes during capillary electrophoresis. Here we introduce a simple coating of BSA to inhibit the adsorption of protein samples during CE. BSA is the most abundant proteins in the blood, and the BSA coating can decrease the non-specific adsorption of proteins. A physical adsorption process was used to coat the BSA onto the inner wall of the capillary. The pH of coating buffer, the standing time of coating, and the coating concentration of BSA were optimized. Moreover, the stability of the coating on the inner wall of the capillary and the reproducibility of the coated capillaries were evaluated. Finally, the performance of the capillary coated with BSA in the inner wall was validated by separation of four mixed proteins (RNase A, lysozyme, trypsin and myoglobin).

Materials and Methods

Materials and Chemicals

Fused-silica capillary (375 μm o.d. × 75 μm i.d.) with a polyimide outer coating was purchased from Hebei province Yongnian County Ruipu Chromatogram Equipment CO., LTD (Hebei, China). Bovine serum albumin (BSA, purity ≥98 %), ribonuclease A (bovine pancreas), myoglobin (equine skeletal), lysozyme (chicken egg white), trypsin, and dimethyl sulfoxide (DMSO) were ordered from Amresco Reagent Company (Cleveland, OH, USA). Methanol, hydrochloric acid (HCl), and disodium hydrogen phosphate dehydrate (NaH2PO4·2H2O) were produced by Beijing Chemical Works (Beijing, China). Sodium hydroxide (NaOH) and disodium hydrogen phosphate (Na2HPO4·12H2O) were bought from Beijing Chemical Reagent Company (Beijing, China). All of the chemicals were of analytical grade. The pH value of phosphate buffer (PB) was measured with microprocessor pH meter (HNANA instruments, Woonsocket, RI, USA). The water was purified and deionized with a Milli-Q system (Millipore, France). All the solution was filtered with 0.45 μm syringe filter (MEMBRANA, Wuppertal, Germany) before use.

The Procedure of Capillary Coating

Prior to the coating, about a 2 mm optical detection window was prepared on the fused-silica capillaries by burning. The detection window was protected by a plastic pipe (o.d. is about 375 μm).The effective length of the capillary is 385 mm.

Pretreatment

New fused-silica capillaries were initially pretreated by the following steps: first of all, the capillary was rinsed in sequence with flowing HCl (1 mol L−1) for 90 min and deionized water for 30 min. Second, they were flushed with NaOH (1 mol L−1) for 120 min, deionized water for 40 min, and nitrogen gas for 30 min, sequentially.

Coating

A physical coating procedure was employed. BSA was dissolved in 10 mM PB (pH 4.2). First, the capillary was flushed with BSA solution for 15 min and then was stored at 4 °C for 120 min with two ends capped. Second, the capillary was flushed with the same BSA solution for another 15 min and then was stored at 4 °C 12 h with two ends capped. After this, the capillary was dried with flowing nitrogen for 30 min. Finally, the capillary was equilibrated with 10 mM PB (pH 7.0) for 30 min and stored with two ends capped analysis at 4 °C. For the regeneration, the capillary was easily redone following the pretreatment procedure and the coating procedure mentioned above.

Capillary Electrophoresis System

Experiments were employed on the HP3D capillary electrophoresis instrument (Agilent Technologies, Wilmington, DE, USA) equipped with a diode array UV detection. The total length of the fused-silica capillary was 470 mm, and the effective separation length (from the inlet to the detection window) was 385 mm. The capillary of CE was installed in the cartridge, and the temperature was set at 25 °C during all the experiments. The protein sample was injected at 50 mbar for 3 s. The separation voltage was set at 15 kV, and the absorbance wavelength of the UV detector was set at 200 nm. The protein sample used in the experiment contained 0.6 mg mL−1 RNaseA, 0.6 mg mL−1 lysozyme, 1 mg mL−1 trypsin, and 1 mg mL−1 myoglobin, which were all dissolved in PB (pH 7.0). DMSO was chosen as the EOF mobility neutral marker with the concentration of 1:7000 (v/v) in PB. Between runs, the capillary was flushed for 3 min (50 mbar) with the PB (pH 7.0), and the PB buffer of separation vials (the inlet and outlet vials) were changed every four runs. Electropherograms were analyzed using Agilent Chemstation B.02.01. The number of theoretical plates (N m−1) was calculated based on peak width at half height.

Results and Discussion

In order to achieve the optimal effectiveness of coating, the coating conditions, such as the pH value of the buffer, the concentration of BSA, and the standing time were optimized in our study. The stability of the coatings on the inner wall of the capillary and the reproducibility of the coated capillaries were evaluated. Finally, four basic proteins were successfully separated using the new capillary with BSA coating under the optimal conditions. The performance of the BSA coated capillary was validated.

Optimizing the pH Value of Coating Buffer (PB) and the Concentration of BSA

In this section, pH 4.2, and pH 7.0 of the coating buffer were chosen according to properties of protein; meanwhile, a series of different coating concentrations of BSA (0.1, 0.75, 1.5, 3, 6, 10, and 20 mg mL−1) were set. The sample containing RNase A and DMSO was used as analysis target. The chromatographic peak shape and theoretical plate number (N m−1) of RNase A and the migration times of DMSO were used to evaluate the efficiency of the coated capillary. The computational formula of theoretical plate number (N m−1) is \( N = 5.54\left( {\frac{{t_{R} }}{{W_{\frac{1}{2}} }}} \right)^{2} \), where t R is the migration time of RNase A (min); W 1/2 is the peak width at half height (cm).

All the results were shown in Fig. 1 including the control result. The capillary of the control was the non-coated capillary.

The effect of the pH value of coating buffer (PB) and the coating concentration of BSA on the separation of RNase A and DMSO. a The chromatogram of RNase A and DMSO in different coating concentrations of BSA in the pH value of coating buffer PB 7.0. b The chromatogram of RNase A and DMSO in different coating concentrations of BSA in the pH value of coating buffer PB 4.2. The coating concentrations of BSA from a–h were 0, 0.1, 0.75, 1.5, 3, 6, 10, and 20 mg mL−1, respectively. The standing time was 12 h. c The theoretical plate number (N m−1) of RNase A in different coating concentrations of BSA in the pH value of PB 7.0 and 4.2, respectively

The Optimal Coating Buffer pH

From the results of control group, shown in Fig. 1 sample a it can be concluded that the separation efficiency of the RNase A and DMSO was not good according to the poor peak shape of RNaseA. The results of CE separation using the capillary coated with BSA under pH 7.0 of the coating buffer were shown in Fig. 1a. Although RNase A and DMSO were not well separated in most of different concentrations of BSA, there did exist two exceptions like samples d and e. It should be noted that the baseline was not stable because of adsorption; besides that, the peak shape of RNase A of samples f, g, and h was poor, and the migration time of DMSO was irregular. All these prove that it was not reasonable for CE separation and to coat onto the inner surface under pH 7.0. But for CE separation using the capillary coated with BSA under pH 4.2 of the coating buffer was different, as unambiguously described in Fig. 1b, RNase A and DMSO represented by peak 1 and peak 2 were already separated thoroughly. And all of the peak shape of RNase A was much better than that in Fig. 1a. We had temporarily ignored the problems of baseline induced by adsorption, only from the shape of peak, it can be easily concluded that pH 4.2 was much more proper than that of pH 7.0 in the process of separation.

In order to better understand the influence of pH value to the separation, the theoretical plate numbers of RNase A separated in capillaries coated under different pH value of coating buffer were calculated, and the results are shown in Fig. 1c. When the pH value of coating buffer was 7.0, the theoretical plate number of RNase A can be only calculated at the concentrations of BSA of 1.5 and 3 mg mL-1, because the theoretical plate number of RNase A at the other concentrations of BSA can’t be calculated due to the poor shape of the peaks. It was not difficult to find that the theoretical plate numbers of RNase A at the pH value of 4.2 was at least 3 times higher than that of pH 7.0.

The separation result of the coated capillary under the coating buffer with pH value of 4.2 was much better than that of 7.0, mainly because its inner wall of the pretreated capillary possesses negative charge. As we know, the pI of BSA is 4.7, so in the buffer of pH 4.2, BSA possesses positive charge, but it possesses negative charge in the buffer of pH 7.0. So using the pH 4.2 of coating buffer, BSA and the inner wall of capillary can intensely interact with each other by strong electrostatic.

The Optimal Coating Concentration of BSA

As shown in Fig. 1b, in the optimal coating buffer of pH 4.2, the result of CE separation in the capillary coated with different concentrations of BSA, the peak shape of RNase A with BSA concentrations of 0.75, 1.5, and 3 mg mL−1 were better than the other BSA concentrations. Combining the results of theoretical plate numbers in Fig. 1c, it can be clearly found that when the coating concentration of BSA was 1.5 mg mL−1, under the optimal coating buffer pH 4.2, the theoretical plate number reaches 1.3 × 105, which is higher than that of the other concentration of BSA. So we took 1.5 mg mL−1 as the optimum coating concentration of BSA.

The Standing Time of BSA Coating

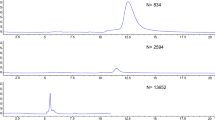

The standing time of coating was optimized under the optimal condition of coating BSA at the concentration of 1.5 mg mL−1 and coating buffer pH value of 4.2. We used three same capillaries with different standing times of coating (2, 5, and 12 h), respectively. Then the performance of the three BSA coated capillaries was evaluated by CE. The mixture of RNase A and DMSO was used as targets. The results are shown in Fig. 2.

As shown in Fig. 2a, from the chromatographic peak shape of RNase A, it can be found that 12 h was the optimal standing time of coating. Simultaneously, the theoretical plate number of RNase A was calculated (Fig. 2b). It is clear that the theoretical plate number of standing time of 2 h was only about 7500 (N m−1). When the standing time up to 5 h, the theoretical plate number attained to 9.2 × 104 (N m−1), and when the time extended to 12 h, the theoretical plate number was up to 1.1 × 105 (N m−1). We can see that the standing time changes from 5 h to 12 h, via a long standing time interval, but the theoretical plate number increased very little. The theoretical plate number increased very little, that is to say, the coating has reached the better adsorption status. So the standing time of 12 h was enough for optimal coating.

The Stability of Coating on the Inner Wall of the Capillary

We used the EOF and the theoretical plate number (N m−1) of RNase A to evaluate the stability of the BSA coating on the inner wall of the capillary. The computational mobility of the EOF is \( \mu = \left( {\frac{{L_{\text{a}} }}{{t_{\text{R}} }}} \right)\left( {\frac{{L_{\text{b}} }}{V}} \right) \), where t R is the migration time of DMSO (s); L a is effective length of the capillary (cm); L b is the total length of capillary (cm); and V is the separation voltage (V). Electrophoresis with the coated capillary was run successively for 48 h, and every 12 h as an interval. The results are shown in Table 1. At the beginning, the coated capillary was applied in CE, the EOF was 2.56 ± 0.04 (×10−4 cm2 V−1 s−1), and the theoretical plate number (N m−1) was 1.34 ± 0.03 (×105). After that, the coated capillary has been applied successively for 48 h, the EOF was 2.65 ± 0.04 (×10−4 cm2 V−1 s−1), and the theoretical plate number (N m−1) was 1.25 ± 1.61 (×105). In addition, the RSD values of EOF and the theoretical plate number after successive electrophoresis for 48 h were 4.14 % and 9.14 %, respectively. The obtained results were enough to prove that the coating had a high stability.

The Reproducibility of the Coated Capillaries

The reproducibility of the coated capillaries was evaluated by comparing the separating results of RNase A and DMSO using three same coated capillary. The theoretical plate number of RNase A and EOF were evaluated, and the results were shown in Table 2. The EOF values of the three capillaries were 2.93 ± 0.07, 2.41 ± 0.01, and 2.30 ± 0.08 (×10−4 cm2 V−1 s−1), respectively. The theoretical plate number values of RNase A were 1.34 ± 0.03, 1.16 ± 0.22, and 1.14 ± 0.06 (×105N m−1), respectively. We can see that as for three same coated capillaries, the values of the EOF and theoretical plate number (N m−1) also changed a little. Moreover, the RSD values of EOF and the theoretical plate number were 13.19 % and 8.96 %, respectively. So it can be easily concluded that the reproducibility of the coated capillaries was good.

Application on Protein Separation

Basic proteins turned out to be easier to attachment with the inner wall of the capillary. Therefore, these basic proteins, such as cytochrome C, trypsin, lysozyme, RNase A, myoglobin and so on, have been proposed by researchers as model proteins to evaluate the shielding efficiency of the coating agents [21–23]. In this study, four proteins (lysozyme, pI 11.0, Mr 14.3 kDa; trypsin, pI 8.7, Mr 23.7 kDa; RNase A, pI 9.4, Mr 13.5 kDa, and myoglobin, pI 7.3, Mr 17.5 kDa) were randomly chosen from those basic proteins and used as the targets to evaluate the performance of the coated capillary. As shown in Fig. 3, the mixtures of four standard basic proteins (0.6 mg mL−1 RNaseA, 0.6 mg mL−1 lysozyme, 1 mg mL−1 trypsin, and 1 mg mL−1 myoglobin) were separated using the BSA coated capillary. The BSA-coated capillary (Fig. 3b) showed all peaks of four proteins and provided a good separation, whereas there was no peak showed in Fig. 3a when the non-coating capillary was employed. The baseline went up at the retention time of 5 min was observed, but non-significant loss of BSA was found in our repeated use for 5 days. These results indicated that the BSA coating can significantly reduce the adsorption of proteins in the CE.

Separation of four basic proteins by capillary electrophoresis with BSA coated capillary. The conditions of BSA coating: 1.5 mg mL−1 BSA; PB buffer, 10 mM, pH 4.2; standing time, 12 h; The conditions of capillary electrophoresis: fused-silica capillary (375 μm o.d. × 75 μm i.d.), the total length is 470 mm, and the effective length is 385 mm; the sample of four standard basic proteins (0.6 mg mL−1 RNase A, 0.6 mg mL−1 lysozyme, 1 mg mL−1 trypsin, and 1 mg mL−1 myoglobin); inject, 50 mbar for 3 s; UV detection wavelength, 200 nm; temperature, 25 °C; background electrolyte, 10 mM PB, pH 7.0; voltage, 15 kV. Peaks: A lysozyme, B trypsin, C RNase A, D myoglobin

Conclusions

A novel and simple method to create BSA coating onto the inner surface of a fused-silica capillary was used to avoid the adsorption between analyte and the inner surface of capillary during CE was developed. Compared with the covalent, in our work, the process of BSA coating is simpler, with no use of the expensive or toxic organic solvents; moreover, the coating possesses good stability and reproducibility, and high column efficiencies [>1.3 × 105 (N m−1)]. With further development, this novel, simple, and efficient coating method is promising for separation of proteins, peptides, and the other biological samples.

References

Horvath J, Dolník V (2001) Electrophoresis 22:644–655

Kostal V, Katzenmeyer J, Arriaga EA (2008) Anal Chem 80:4533–4550

Lauer HH, McManigill D (1986) Anal Chem 58:166–170

McCormick RM (1988) Anal Chem 60:2322–2338

Green JS, Jorgenson JW (1989) J Chromatogr A 478:63–70

Schwartz H, Pritchett T (1994) Beckman instruments, Inc, Fullerton

Doherty EAS, Meagher RJ, Albarghouthi MN, Barron AE (2003) Electrophoresis 24:34–54

Meagher RJ, Seong J, Laibinis PE, Barron AE (2004) Electrophoresis 25:405–414

Mei J, Xu J, Xiao Y, Liao X, Qiu G, Feng Y (2008) Electrophoresis 29:3825–3833

Chiari M, Cretich M, Stastna M, Radko SP, Chrambach A (2001) Electrophoresis 22:656–659

Doherty EAS, Berglund KD, Buchholz BA, Kourkine IV, Przybycien TM, Tilton RD, Barron AE (2002) Electrophoresis 23:2766–2776

Nehme′ R, Perrin C, Cottet H, Blanchin MD, Fabre H (2009) Electrophoresis 30:1888–1898

Stutz H (2009) Electrophoresis 30:2032–2061

Cifuentes A, Rodríguez MA, García-Montelongo FJ (1996) J Chromatogr A 742:257–266

Haselberg R, de Jong GJ, Somsen GW (2009) J Sep Sci 32:2408–2415

Peng SH, Shi RH, Yang RM, Zhou D, Wang YM (2008) Electrophoresis 29:4351–4354

Wang AJ, Witos J, D’Ulivo L, Vainikka K, Riekkola ML (2009) Electrophoresis 30:3939–3946

VanTassel PR, Miras D, Hagege A, Leroy M, Voegel JC, Schaaf P (1996) J Colloid Interf Sci 183:269–273

Janssens J, Chevigne J, Louis P (1996) US Patent 5,611,903-A

Bonvent JJ, Barberi R, Bartolino R, Capelli L, Righetti PG (1996) J Chromatogr A 756:233–243

Liu Y, Fu X, Bai Y, Zhai M, Liao Y, Liao J, Liu H (2011) Anal Bioanal Chem 399:2821–2829

MacDonald AM, Bahnasy MF, Lucy CA (2011) J Chromatogr A 1218:178–184

Xu L, Dong X, Sun Y (2010) Biochem Eng J 53:137–142

Acknowledgments

This work was supported by the National Nature Science Foundation of China (No. 20905007), the Ministry of Science and Technology of China (No. 2008BAK03 A02), and the National Key Project (No. 2008AA12A218).

Author information

Authors and Affiliations

Corresponding author

Additional information

Y. Man, X. Lv contributed equally to this work.

Rights and permissions

About this article

Cite this article

Man, Y., Lv, X., Iqbal, J. et al. Adsorptive BSA Coating Method for CE to Separate Basic Proteins. Chromatographia 76, 59–65 (2013). https://doi.org/10.1007/s10337-012-2337-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-012-2337-y