Abstract

How to determine the quantities of acrylamide produced in foods is an important problem. Here, we report a sensitive method of high performance liquid chromatography based on a solid phase extraction using a reversed phase C18 column, which was characterized by adsorption experiments with good adsorption ability and rapid adsorption dynamic toward acrylamide. Under optimal condition, the detection limit based on three times the signal-to-noise ratio of the baseline near the analyte peak was 66.0 ng L−1. With a loading flow rate of 2.0 mL min−1 for loading 100 mL, an enrichment factor of 182 was obtained. The RSD for five replicate extractions of 50 μg L−1 acrylamide was 4.1%. Blank potato samples spiked with acrylamide at 0.125, 0.250, and 0.375 μg g−1 levels were analyzed with recoveries ranging from 88.9 to 89.5%. Moreover, this method was applied to quantitative detection of acrylamide in the crust and potato chip samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acrylamide (Fig. 1) is an industrial chemical monomer which is principally used to synthesize polyacrylamides and their copolymers, which are widely applied to wastewater treatment in the paper and textile industries, as well as to synthesize acrylamide gels for chromatography in biotechnology laboratories [1–3]. In April 2002, the Swedish National Food Administration [4] and researchers at Stockholm University announced that high acrylamide levels had been found in carbohydrate-rich foodstuffs which had been fried/baked at high temperatures. Subsequent studies have proved that acrylamide was found to occur during the browning process of starchy foodstuffs by the Maillard reaction when the temperature over 120 °C, particularly at 140–180 °C [5, 6]. It has been found in various fried, deep-fried, and oven-baked foods, and higher levels have been found in chips (French fries), crisps and bread, biscuits, crackers, and breakfast cereals [7], which has caused worldwide concerns due to its potential genetoxicity and neurotoxicity [2, 7–11]. Acrylamide has been classified as a probable human carcinogen by the International Agency for Research on Cancer [12]. Long-term exposure may cause damage to the nervous system in both humans and animals [13, 14]. Therefore, analysis of acrylamide in foods is required for both the accurate risk assessment of the carcinogenic threat it possesses and the quality control by the food industry so as to reduce acrylamide production. The development of an accurate and sensitive method is indispensable.

A great number of screening methods have been reported to quantitatively analyze acrylamide and its metabolites, such as gas chromatography (GC) with flame ionization or electron capture detectors [15–17], liquid chromatography with pulsed amperometric detector (LC-PAD) [18], enzyme-linked immunosorbent assay (ELISA) [19], and capillary electrophoresis (CE) [20]. Among them, chromatography methods lack sensitivity and require a relatively complex sample pretreatment. The ELISA method is fast and inexpensive; however, its sensitivity is lower, and the antibody production is complicated. CE has the merits of high efficiency, fast analysis, and low reagent consumption and has become an effective alternative for the analysis of a great variety of target substances, but its stability is poor. Hitherto, liquid chromatography and gas chromatography coupled to mass spectrometry (LC–MS/MS, GC–MS) appear to be acknowledged as the most useful and authoritative methods for the determination of trace acrylamide [1, 8, 15, 17, 21–28]. These methods possess high performance, but require expensive instruments and complicated sample pretreatment procedures. Therefore, efforts should be focused on the development of sensitive and low-cost screening methods that can be easily used by many laboratories [20, 29]. For GC, a tedious procedure of derivatization is usually required, and the high injection temperature may result in acrylamide production, and thus false results are obtained. Compared to GC, LC offers the advantage of being able to analyze acrylamide without derivatization, and the sample treatment is simplified [26]. Furthermore, acrylamide is present in samples at low concentration levels. So, a simple and effective pre-concentration step is needed prior to LC analysis.

The methods for extraction of acrylamide include soxhlet extraction [15], liquid–liquid extraction [16, 18], and solid phase extraction (SPE) [23, 27, 28, 30]. Solid phase microextraction (SPME), as a fast and solvent-free technique, has been applied to extract trace acrylamide derivatives from an aqueous matrix [1, 31]; however, its repeatability is not good. SPE is recognized as a very common sample pre-treatment technique for its simple, stable, and easy automation, and has been extensively used to enhance the concentration of acrylamide in sample analysis. SPE coupled with HPLC (SPE–HPLC) is an interesting method for the determination of trace organic compound, which possesses the advantages of both SPE and HPLC [29, 30, 32]. For SPE, the most important effect on the enrichment is by the sorbent. Thus, selection of a SPE sorbent having good performance toward acrylamide is crucial and necessary. Activated silica gel [33], multi-walled carbon nanotubes [34], magnetic chitosan [35], and modified chitosan [36, 37] used as new sorbents have been reported. As far as we know, the adsorption abilities of these materials for extraction of acrylamide have not yet been reported.

The objective of this work is to investigate the potential applications of activated silica gel, carbon nanotubes, magnetic chitosan, modified chitosan and reversed phase C18 bonded silica gel in solid phase extraction of acrylamide. The extraction conditions will be optimized in detail. Thus, a new solid phase extraction coupled to high performance liquid chromatography method for the determination of trace acrylamide can be established. The applicability of the presented method will be evaluated.

Materials and Methods

Chemicals and Materials

Acrylamide (99%) was obtained from Institute for the Control of Agrochemicals of Ministry of Agriculture (Beijing, China). The HPLC grade methanol was purchased from Tianjin YongDa Chemical (Tianjin, China). Acetonitrile was supplied from Tianjin Chemical Factory (Tianjin, China). Doubly deionized water (DDW) obtained from a Water Pro. Water System (Labconco, Kansas City, MO, USA) was used throughout the experiments. All other reagents were of the highest available purity and at least of analytical grade.

Multi-walled carbon nanotubes with an average diameter of 60–100 nm, length of 5–15 μm and surface area 40–300 m2 g−1 was obtained from Shenzhen Nanotechprot (Shenzhen, China). Silica gel (80–100 mesh) was obtained from Qingdao Ocean Chemical (Qingdao, China). Chitosan was purchased from the Hai Boao Biotechnology (Shanghai, China). The Cleanert ODS C18 SPE column (200 mg/3 mL) was obtained from Agela Technologies (Tianjin, China).

Instrumentation and HPLC Analysis

The HPLC system consisted of two LC-10ATVP pumps and a Shimadzu SPD-10AVP ultraviolet detector (Shimadzu, Kyoto, Japan). All separations were achieved on an analytical reversed phase Thermo C18 column (4.6 mm × 250 mm; Agela Technology, Tianjin, China) at a mobile phase flow rate of 0.8 mL min−1. The mobile phase was methanol/water (15:85, v/v). The sample volume injected was 15 μL, and the detection was operated at 210 nm. Class-vp software was used to acquire and process spectral and chromatographic data. A 721 ultraviolet spectrometer (Shimadzu, Kyoto, Japan) was used in this study.

Preparations of the Activated Silica Gel, Magnetic Chitosan and Modified Chitosan

The silica gel was activated according to the method of Han et al. [38]. A typical procedure that followed the method of Denkbas [39] was used for the preparation of magnetic chitosan microspheres.

The modified chitosan microsphere was prepared as follows: 30 mL 3% chitosan sodium, appropriate amount of ethyl acetate and epichlorohydrin (chitosan/ethyl acetate/epichlorohydrin = 60:3:2, V/V/V) were added to the flask. The mixture was stirred for 20 min in a water bath at 40 °C, and then ultrosonicated for 10 min. After that, 3% sodium tripolyphosphate solution was dropped into the mixture solution with a syringe. The modified chitosan microsphere was filtrated with ethanol for three times at pH 10, and then dried under vacuum at 40 °C for 10 h.

Characterization of the Sorbents

In order to obtain the optimal SPE sorbent, the adsorption capacities of magnetic chitosan, carbon nanotubes, activated silica gel, modified chitosan, and C18 toward acrylamide at 80 mg L−1 were investigated. For this purpose, 20.0 mg of magnetic chitosan, carbon nanotubes, activated silica gel, modified chitosan, and C18 were separately equilibrated with 10 mL acrylamide standard solution in a 50-mL volumetric flask. The mixtures were mechanically shaken (180 rpm) for 240 min at room temperature, and then centrifuged at 4,000 rpm for 15 min. The supernatants were determined by a UV spectrometry at 210 nm, and their respective binding capacities were calculated.

The adsorption ability of C18 sorbent was investigated. 20 mg C18 was added to 10 mL methanol solution containing acrylamide at various concentrations (20–100 mg L−1). The mixture was shaken (200 times/min) at room temperature for 4 h and then centrifuged (4,000 rpm) for 15 min. The concentration of unextracted acrylamide in the supernatant was determined, and the adsorption capacity (Q) was calculated.

The uptake kinetics of C18 and magnetic chitosan toward acrylamide at 80 mg L−1 concentration were tested. After shaking (200 times/min) for 5, 30, 60, 90, 120, 180, and 240 min at room temperature, the respective unextracted acrylamide was determined.

Procedure of SPE Combined with HPLC

The SPE cartridge was firstly rinsed with 5 mL methanol and DDW, followed by loading 100 mL standard acrylamide solution at a flow rate of 2.0 mL min−1. When the sample loading was finished, the cartridge was conditioned thoroughly with 0.5 mL methanol/DDW (40:60, v/v) at 6.0 mL min−1 to remove the impurities, and then eluted by 0.5 mL portions of acetonitrile/acetic acid (99:1, v/v) at 6.0 mL min−1 to completely desorb the analytes adsorbed on the SPE microcolumn. The elution fraction volume was accurately measured. The effluent was filtered with a 0.45-μm filter membrane, and 15 μL of the filtrate was injected into HPLC for analysis. Finally, the SPE cartridge was extracted with 5 mL methanol/acetic acid (3:1, v/v), then flushed sequentially with 5 mL methanol and DDW for the next sample preconcentration.

Sample Preparation

The samples (potato, potato chip, and bread) were purchased from the supermarket of Taian in June, 2011 (Shandong, China). To check the accuracy of the developed SPE–HPLC method, 2.0 g potato samples, which were determined by HPLC to be free of acrylamide, were spiked with 1.0 mL acrylamide standard solution (0.25, 0.5, and 0.75 mg L−1) in a 100-mL conical flask, respectively. After being incubated for 1 h, the spiked samples were ultrasonicated with 10 mL methanol for 30 min, and this step was repeated for two more times with 10 + 10 mL of methanol. The resulting extractions were collected and centrifuged at 4,000 rpm for 30 min, and the supernatants were used for the SPE–HPLC procedure. The actual samples of potato chips and bread crusts (2.0 g) were extracted and analyzed according to the same procedure.

Results and Discussion

Adsorption Ability Characterization

The adsorption capacity (Q) of C18 or other material was calculated using the following equation:

where C 0, C 1 are the concentrations of the target molecule in solution before and after absorption, V is the volume of the solution, and M is the mass of the material.

The adsorption capacities of the modified chitosan (a), carbon nanotubes (b), activated silica gel (c), magnetic chitosan (d), and C18 (e) toward acrylamide at 80 mg L−1 were investigated, which are shown in Fig. 2. The results showed that the C18 material exhibited a bigger adsorption capacity toward acrylamide in methanol than those of the magnetic chitosan, activated silica gel, carbon nanotubes or modified chitosan at the same concentration.

The isothermal adsorption of C18 material toward acrylamide was evaluated. The data (Fig. 3) showed that the binding capacity of C18 increased with the increase of the initial concentration of acrylamide, and an adsorption capacity of 7.64 mg g−1 was obtained at 100 mg L−1 concentration. They indicated that the C18 was more suitable as a SPE sorbent than the other four materials in the acrylamide pretreatment procedure.

The kinetic uptake plots of the C18 and magnetic chitosan materials toward acrylamide are plotted in Fig. 4. For the C18 sorbent, an adsorption capacity of 1.27 mg g−1 was obtained after shaking for 30 min, which was 18.7% of the maximum adsorption capacity, and that adsorption equilibrium was almost reached within 180 min. When magnetic chitosan used as sorbent, the adsorption capacity of 0.66 mg g−1 was obtained after shaking for 30 min, which was 31.1% of the maximum adsorption capacity, and the adsorption equilibrium was almost reached within 180 min. These experimental results indicated that the C18 had slower uptake kinetic than that of the magnetic chitosan, which is the drawback of C18 for application as sorbent in SPE.

Magnetic chitosan exhibited fast adsorption dynamics, and had higher adsorption ability toward acrylamide than that of activated silica gel, carbon nanotubes, or modified chitosan. Therefore, it will be a good potential sorbent in the acrylamide pretreatment after modification.

Optimization of the SPE Conditions

Using C18 as sorbent, a SPE–HPLC for the determination of trace acrylamide was developed. To achieve good sensitivity and precision, the SPE conditions, including the composite and volumes of elution solution, sample acidity, sample loading flow rate and time, were optimized.

The DDW, methanol and acetonitrile using as elution solutions were investigated in this study. The results showed that the adsorbed acrylamide was more easily eluted by methanol than DDW, and the maximum peak area of acrylamide was obtained when acetonitrile was used as the elution solution. It is known that acetic acid can increase the eluting strength. As such, the volume of acetic acid (17.5 mol L−1) added to the solution was studied by varying it from 0.5 to 2.0%. Results indicated that as the concentration of acetic acid gradually increased from 0.5 to 1.0%, the chromatographic peak area increased, and then eventually stabilized in the range of 1.0–2.0%. Thus, a mixture of acetonitrile/acetic acid (99:1, v/v) was selected as the eluting solvent for the subsequent experiment.

The volume of elution solution is a key parameter for SPE. It was noted that too much elution solution would decrease the concentration of acrylamide in elution solution, and too small volume would not have the absorbed acrylamide be eluted completely. For selection of the optimum eluting solvent volume, 0.1–2.0 mL acetonitrile/acetic acid (99:1, v/v) was tested. It was found that with the eluting solvent volume increasing from 0.1 to 0.5 mL, the chromatographic peak of acrylamide increased, and then decreased in the range of 0.5–2.0 mL. Therefore, 0.5 mL acetonitrile/acetic acid (99:1, v/v) was used as the eluting solution in further study.

The effect of sample loading flow rate on the extraction of 5 μg L−1 acrylamide standard water solution was studied by varying from 0.83 to 3.33 mL min−1. The results showed that the chromatographic peak area decreased slowly when the sample loading flow rate increased from 0.83 to 2.0 mL min−1, and then decreased quickly in the range of 2.0–3.33 mL min−1. The influence of sample loading time on the adsorption of acrylamide was investigated at a sample flow rate of 2.0 mL min−1. The chromatographic peak areas increased almost linearly as the sample loading time increased up to at least 50 min. Based on the above results, a 2.0 mL min−1 of flow rate and 50 min of sample loading time were chosen as the experimental conditions.

The effect of standard acrylamide solution acidity was examined in the pH range of 4.0–12.0 at a sample flow rate of 2.0 mL min−1 for loading for 50 min. The results showed that the maximum chromatographic peak area of acrylamide was obtained in the range of 6.7–7.5. Outside this range, the chromatographic peak area decreased. Thus, a pH value of 7.0 was used in this study.

Analytical Parameters of the SPE-HPLC Method

The analytical parameters of the presented method for the determination of acrylamide were evaluated under optimal experimental conditions, which are shown in Table 1. Results indicated that at the loading flow rate of 2.0 mL min−1 for loading 100 mL, an enrichment factor obtained by the slope of the linear portion in comparison with the direct injection of 15 μL standard sample solution was 182. The detection limit based on three times the signal-to-noise ratio of the baseline near the analyte peak was 66.0 ng L−1, and the linear range of the calibration graph was 0.3–300 μg L−1. The RSD for five replicate extractions of 50 μg L−1 acrylamide was 4.1%.

Accuracy and Applicability of SPE-HPLC

The applicability and accuracy of developed SPE–HPLC method for the preconcentration and determination of acrylamide in the potato sample was investigated. The blank potato samples spiked with acrylamide at 0.125, 0.250, and 0.375 μg g−1 levels were analyzed. For each sample and concentration, three measurements were performed. The data are shown in Table 2. Good recoveries ranging from 88.9 to 89.5% were achieved.

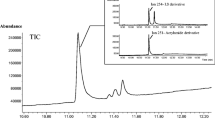

Potato chip and bread are starch-based foods, and the acrylamide can be produced during processing. The performance of the developed method was evaluated by extraction and determination of acrylamide in bread crust and potato chip, and the chromatograms are depicted in Fig. 5. The acrylamide was quantitatively detected with different levels of 0.198 (0.006) μg g−1 in bread crust and 0.371 (0.012) μg g−1 in potato chip samples, respectively. Therefore, a large number of acrylamides were formed in bread and potato chip during the deep-heating process, which was consistent with the reported results [5–7].

As the data show, the amount of acrylamide in the potato chip product is higher than that in bread (crust), which is considered to result from their differences in materials and production methods. It is known that potato has a considerable potential to form acrylamide, and that fried potato is a food category which has probably chalked up the highest concentrations of acrylamide recorded so far [2]. Therefore, it is necessary to control and reduce the level of acrylamide in these products, and especially in potato chips as they are very much loved by children.

Merits of the Developed Method

Some methods including chromatography [16–18], LC or GC coupled with MS [1, 17], CE [20], and ELISA [19] have been reported to be suitable for acrylamide detection, and are summarized in Table 3. Each method has its advantages and limitations in terms of specificity, sensitivity and interference of matrix compound. Generally, the LOD values of these methods are μg kg−1 (μg L−1 or ng mL−1). ELISA has lower sensitivity than other methods.

Compared to these reported methods, the developed method is more sensitive and simple for the screening of trace acrylamide in foods. Generally, the SPE column is useful for one analysis only. The application lifetime of this SPE column was investigated, and it could be reused for more than 10 times without loss of sensitivity after extracting with 5 mL methanol/acetic acid (3:1, v/v), thus the cost per analysis of this method was drastically reduced. Based on these results, the reversed phase C18 SPE is appropriate for enrichment of the trace acrylamide in food samples.

Conclusions

In this study, the SPE conditions were optimized, and a sensitive method of SPE–HPLC was reported. This developed method was applied to the extraction and determination of acrylamide in deep-heated food samples with a good accuracy. From this point of view, this study will provide a new method for the monitoring of acrylamide, which will be very helpful to control the production of acrylamide in foods.

References

Lee MR, Chang LY, Dou JP (2007) Anal Chim Acta 582:19–23

Friedman M (2003) J Agric Food Chem 51:4504–4526

Carere A (2006) Ann Ist Super Sanita 42:144–155

Swedish National Food Administration. Information about acrylamide in food (http://www.slv.se). Posted April 24, 2002

Becalski A, Lau BP, Lewis D, Seaman SW (2003) J Agric Food Chem 51:802–808

Mottram DS, Wedzicha BL, Dodson AT (2002) Nature 419:448–449

Tareke E, Ryberg P, Karsson P, Ericsson S, Törnqvist M (2002) J Agric Food Chem 50:4998–5006

Senyuya HZ, Gökmen V (2005) Food Addit Contam 22:204–209

Kjuus H, Hansteen IL, Ryberg D, Goffeng LO, Ovrebro S, Skaug V (2005) Scand J Work Environ Health 31:300–306

Rice JM (2005) Mutat Res 580:3–20

Bartow H, Bounds J, Macdonald N, Clewell H, Allen B, Van Landingham C (2006) Crit Rev Toxicol 36:481–608

International Agency for Research on Cancer (IARC) (1994) Lyon, France, pp 389–433

LoPachin RM (2004) Neurol Toxicol 25:617–630

Allen B, Zeiger E, Lawrence G, Friedman M, Shipp A (2005) Regul Toxicol Pharmcol 41:6–27

Pedersen JR, Olsson JO (2003) Analyst 128:332–334

Zhu YY, Li GR, Duan YP, Chen SQ, Zhang C, Li YF (2008) Food Chem 109:899–908

Zhang Y, Ren YP, Zhao HM, Zhang Y (2007) Anal Chim Acta 584:322–332

Casella IG, Pierri M, Contursi M (2006) J Chromatogr A 1107:198–203

Preston A, Fodey T, Elliott C (2008) Anal Chim Acta 608:178–185

Tezcan F, Erim FB (2008) Anal Chim Acta 617:196–199

Bermudo E, Moyano E, Puignou L, Galceran MT (2008) Talanta 76:389–394

Boroushaki MT, Nikkhah E, Kazemi A, Oskooei M, Raters M (2010) Food Chem Toxicol 48:2581–2584

Nielsen NJ, Granby K, Hedegaard RV, Skibsted LH (2006) Anal Chim Acta 557:211–220

Lagalante AF, Felter MA (2004) J Agric Food Chem 52:3744–3748

Ono H, Chuda Y, Ohnishi-Kameyama M, Yada H, Ishizaki M, Kobayashi H, Yoshida M (2003) Food Addit Contam 20:215–220

Wenzl T, Karasek L, Rosen J, Hellenaes KE, Crews C, Castle L, Anklam E (2006) J Chromatogr A 1132:211–218

Govaert Y, Arisseto A, Loco JV, Scheers E, Fraselle S, Weverbergh E, Degroodt JM, Goeyens L (2006) Anal Chim Acta 556:275–280

Rufian-Henares JA, Morales FJ (2006) Food Chem 97:555–562

Zhang Y, Zhang G, Zhang Y (2005) J Chromatogr A 1075:1–21

Gökmen V, Morales FJ, Ataç B, Sprpen A, Arribas-Lorenzo G (2009) J Food Compos Anal 22:142–147

Kataoka H, Lord HL, Pawliszyn J (2000) J Chromatogr A 880:35–62

Theodoridis G, Lasakova M, Skerikova V, Tegou A, Giantsiou N, Jandera P (2006) J Sep Sci 29:2310–2321

Xu ZX, Wang S, Fang GZ, Song JJ, Zhang Y (2010) Chromatographia 71:397–403

Fang GZ, He JX, Wang S (2006) J Chromatogr A 1127:12–17

Xu ZX, Zhang J, Cong L, Meng L, Song JM, Zhou J, Qiao XG (2011) J Sep Sci 34:46–52

Miretzkya P, Cirelli AF (2009) J Hazard Mater 167:10–23

Xu LH, Zhao DY, Song JM, Xu ZX, Zhou J (2011) Int J Polym Anal Ch 16:118–126

Han DM, Fang GZ, Yan XP (2005) J Chromatogr A 1100:131–136

Denkbas EB (2002) React Funct Polym 50:225–232

Acknowledgments

The authors are grateful for financial support from the National Natural Science Foundation of China (project no. 31071543).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Longhua, X., Limin, Z., Xuguang, Q. et al. Determination of Trace Acrylamide in Potato Chip and Bread Crust Based on SPE and HPLC. Chromatographia 75, 269–274 (2012). https://doi.org/10.1007/s10337-012-2195-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-012-2195-7