Abstract

Pseudomonas putida was metabolically engineered to produce medium chain length polyhydroxyalkanoate (mcl-PHA) from acetate, a promising carbon source to achieve cost-effective microbial processes. As acetate is known to be harmful to cell growth, P. putida KT2440 was screened from three Pseudomonas strains (P. putida KT2440, P. putida NBRC14164, and P. aeruginosa PH1) as the host with the highest tolerance to 10 g/L of acetate in the medium. Subsequently, P. putida KT2440 was engineered by amplifying the acetate assimilation pathway, including overexpression of the acs (encoding acetyl-CoA synthetase) route and construction of the ackA-pta (encoding acetate kinase-phosphotransacetylase) pathway. The acs overexpressing P. putida KT2440 showed a remarkable increase of mcl-PHA titer (+ 92%), mcl-PHA yield (+ 50%), and cellular mcl-PHA content (+ 43%) compared with the wild-type P. putida KT2440, which indicated that acetate could be a potential substrate for biochemical production of mcl-PHA by engineered P. putida.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Medium chain length polyhydroxyalkanoate (mcl-PHA) are polyesters of hydroxyalkanoates produced mainly by fluorescent pseudomonads under unbalanced growth conditions [22, 38, 40]. They have been proposed as alternative materials to synthetic plastics as they are biodegradable and can be produced from renewable resources [6]. Additionally, they have low crystallinity, low tensile strength, low glass transition temperature, and high elongation at break, which broadens the range of applications for mcl-PHA [26, 33, 37]. However, high production costs make mcl-PHA less competitive compared with low-cost petroleum-based plastics. Major factors leading to the relatively high cost of mcl-PHA production include high cost of the substrate, low polymer concentration, yield, and productivity of the production processes [20, 42]. The cost of the substrate is known to account for approximately 50% of the total production cost. Therefore, the production of mcl-PHA from inexpensive and renewable carbon sources is an effective strategy to reduce the production cost [1, 32].

Acetate is a quite promising substrate as it is inexpensive ($340 per metric ton) [25] and sustainable; it widely exists in waste streams [30, 43] and hydrolysates of biomass. Moreover, recent studies confirmed that acetate could be produced from low-cost substrates via biochemical processes. For example, acetate is a primary fermentation product during anaerobic digestion of organic wastes and syngas [9, 17]. In recent years, acetate has been used as a promising cost-effective substrate for PHA production. Chen et al. [8] reported production of poly-3-hydroxybutyrate (P3HB) and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by recombinant Escherichia coli strains using acetate as the main carbon source. Acetate and propionate were utilized as carbon sources for the production of P3HB and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) from excess activated sludge [23]. Pseudomonas putida mt-2 was examined for its ability to produce mcl-PHA from different carbon sources, including acetate, under rich and depleted nitrogen conditions [36]. However, no effort has been made for the elevated production of mcl-PHA using acetate as the sole substrate.

To develop a highly efficient process for producing mcl-PHA from acetate, a rapid assimilation of acetate is required to accomplish high productivity. However, the growth of most bacteria is inhibited by the presence of acetate in the culture medium [10, 14, 18]. Slow acetate assimilation compared to other carbon sources due to insufficient metabolic activity also limits the development of an efficient microbial cell factory [34]. Besides, the activity of the acetate assimilation pathway is highly essential for mcl-PHA production because it can convert acetate to acetyl-CoA for the fatty acid de novo biosynthesis pathway, which synthesizes the 3-hydroxyacyl-ACP used for PHA biosynthesis [1, 5, 26]. In this case, the cell factory should obtain enhanced acetate assimilation and tolerance to acetate.

The current work was aimed at producing mcl-PHA from acetate in Pseudomonas strains known to produce large amounts of mcl-PHA [38]. For rapid acetate assimilation, several Pseudomonas strains (P. putida KT2440, P. putida NBRC14164, and P. aeruginosa PH1) were characterized for their acetate tolerance and absorption (10 g/L of initial acetate). P. putida KT2440 was selected as the host strain. The effects of the overexpression of the acs route and the construction of the ackA-pta pathway were also assessed for mcl-PHA production in P. putida KT2440. This study is the first to demonstrate the increased production of mcl-PHA from acetate.

Materials and methods

Bacterial strains, plasmids, and reagents

The parent strain P. putida KT2440 (ATCC 47054) was obtained from the American type culture collection (ATCC, Manassas, VA, USA). The plasmid pBBR1MCS-2 was donated by Dr. Yingjin Yuan of Tianjin University, China. P. putida NBRC 14164 was acquired from the China Center of Industrial Culture Collection (No. 10298). P. aeruginosa PH1 was an in-house isolate, which was saved in the General Microbiology Center of the China Microbial Culture Collection Management Committee (CGMCC No.12142). The E. coli MG1655 was donated by Dr. Tao Chen of Tianjin University. Acetate (HPLC grade) was purchased from Concord Tech (China). DNA manipulating agents, including restriction endonucleases and T4 DNA ligase, were obtained from Thermo Scientific (Beijing, China). DNA polymerase of Phanta Super Fidelity and Taq for polymerase chain reaction (PCR) were obtained from Vazyme (Nanjing, China). PCR primers were synthesized by GENEWIZ (Suzhou, China) and are listed in Table 1.

Plasmid and strain construction

Plasmids and strains were constructed according to the standard protocols [35]. P. putida KT2440 was employed in the mcl-PHA production studies. The 1689 bp acs (Gene ID 1045574), 1203 bp ackA (Gene ID 946775), and 2145 bp pta (Gene ID 946778) genes were PCR amplified using primer pairs acs-F/acs-R, ackA-F/ackA-R, and pta-F/pta-R (Table 1). Amplified genes were cloned into pBBR1MCS-2 [19], resulting in pBBR1-acs, pBBR1-ackA, and pBBR1-ackA-pta, respectively. Expression vectors were confirmed by enzymatic digestion and DNA sequencing and then transformed into P. putida KT2440, generating engineered strains. Transformation of the P. putida strains was accomplished via electroporation applying a voltage of 2.5 V, 200 Ω, and 25 μF.

Culture media and conditions

Cells were cultivated in a defined M9 medium consisting of 12.8 g/L Na2HPO4 7H2O, 3 g/L KH2PO4, 1 g/L NH4Cl, and 0.5 g/L NaCl. This basic solution was autoclaved and supplemented with 0.24 g/L MgSO4 and a trace element solution made of 6.0 mg/L FeSO4 7H2O, 2.7 mg/L CaCO3, 2.0 mg/L ZnSO4 H2O, 1.16 mg/L MnSO4 H2O, 0.37 mg/L CoSO4 7H2O, 0.33 mg/L CuSO4 5H2O, and 0.08 mg/L H3BO3 (all filter-sterilized). The neutralized-acetate solution was added to the medium as the carbon source. Appropriate amounts of antibiotics (50 μg/ml Kanamycin) were supplemented to the medium when needed.

To produce mcl-PHA, single colonies of each strain were inoculated into 5 ml of LB medium in a 35-ml test tube and incubated overnight under aerobic conditions at 30 °C and 220 rpm. Cells cultured overnight were then inoculated into 500-mL baffled shake flasks containing 50 mL of defined M9 medium to an initial OD600 of 0.05 and placed in a rotary shaker (220 rpm) under aerobic conditions at 30 °C. The initial concentration of acetate was 10 g/L, and 10 g/L neutralized-acetate solution was added after 24 h. Each culture was carried out in triplicate.

For a reactor study, the cells were cultured at 30 °C in a 5 L bioreactor with a working volume of 2 L. Sterile air was provided at a flow rate of 2 vvm, and the dissolved oxygen level was kept above 25% of air saturation by control of the agitation speed. The pH was maintained at 7.0 by automatic addition of 0.5 M H2SO4 and 1 M KOH. The concentration of acetate was periodically measured and maintained to about 10 g/L with the addition of 200 g/L neutralized-acetate solution.

Analysis methods

The growth of bacterial cells was followed by measuring the optical density at 600 nm (OD600) using a UV-1200 spectrophotometer (Mapada, China).

Acetate was quantified in the culture supernatant using an Ultimate 3000 HPLC (Dionex, Sunnyvale, CA, USA) equipped with an Aminex HPX-87H ion-exchange column (Bio-Rad, USA) operating at 65 °C with a flow rate of 0.6 ml min−1 of 5 mM H2SO4 using a differential refraction detector. The extraction and detection of PHA were performed as described previously [32]. Bacterial cells were harvested by centrifugation at 10,000g for 10 min, then washed with distilled water, frozen at − 80 °C, and lyophilized in a freeze-dryer. The obtained lyophilizate was subjected to methanolysis at 100 °C for 4 h in the presence of 15% (v/v) H2SO4. Benzoic acid was used as an internal standard. Gas chromatography (Agilent, USA) was used for this study. The resulting 1 μL of the PHA methyl esters was injected into the gas chromatography. The column temperature was started at 80 °C for 1 min, then increased to 250 °C at the rate of 20 °C/min, and finally maintained for 1.5 min.

The amount of acs transcripts was measured by Biolino, Inc. (Beijing, China). RNA samples were prepared from the cells cultured for 48 h using TRNzol total RNA extraction reagent (TIANGEN, Beijing, China). Complementary DNA was synthesized using PrimeScript™ RT Reagent Kit with gDNA Eraser (TaKaRa, Beijing, China), and it was measured by real-time fluorescent quantitative PCR (ABI7500, Applied Biosystems). For this assay, SYBR® Premix Ex Taq™ II (Tli RNaseH Plus) (TaKaRa, Beijing, China) was used as a reagent. The primers RT-acs_F and RT-acs_R (Table 1) were used for the amplification of acs transcripts. Then, the amounts of acs transcript were quantified using the comparative CT method [24] with the amplified 16sRNA transcript as a standard; the 16sRNA transcript was amplified with the same method using RT-16S_F and RT-16S_R (Table 1). The experiments were conducted in technical triplicates.

Results and discussion

Selection of a suitable Pseudomonas host strain for acetate assimilation

It has been demonstrated that the presence of acetate in the medium (more than 5.0 g/L) can inhibit cell growth [10, 21], and the extent of inhibition is known to vary depending on the bacteria [34]; thus, several laboratory Pseudomonas strains were evaluated to identify a superior host strain with rapid acetate assimilation for mcl-PHA acid production.

This study evaluated three different Pseudomonas strains (P. putida KT2440, P. putida NBRC14164, and P. aeruginosa PH1) for their ability to utilize acetate in a medium containing the different concentration of acetate (i.e., 2, 4, 6, 8, and 10 g/L). After cultivation, significant differences were found among the strains. Only P. putida KT2440 and P. aeruginosa PH1 could grow in the medium containing 10 g/L acetate (Fig. 1a). The P. putida KT2440 demonstrated the highest growth rate (0.21 h−1), as well as acetate consumption rate (0.20 g/g CDW/h) (Fig. 1b). The lower growth rate and acetate assimilation of P. aeruginosa PH1 indicate that it can be inhibited more seriously; thus, the P. aeruginosa PH1 and P. putida NBRC14164 are not suitable for acetate assimilation. The high performance of the P. putida KT2440 may be attributed to its acid tolerance; however, the detailed mechanism remains unclear. Furthermore, for more than 10 years, P. putida KT2440 has been investigated as a model strain for PHA production [11, 13, 28]. As these results indicated the potential of the P. putida KT2440 for efficient acetate utilization, this strain was chosen as the host to produce mcl-PHA from acetate.

Increased mcl-PHA production in P. putida KT2440 by overexpression of the acetate assimilation pathway

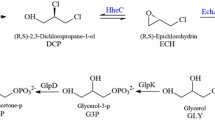

In this work, activating the acetate assimilation pathway was conducted to achieve a higher mcl-PHA production. The most common metabolic pathway, found in a wide range of bacteria producing mcl-PHA, is related to a common precursor: acetyl-CoA [27]. Figure 2 depicts the proposed metabolic pathways for PHA biosynthesis. Precursors for mcl-PHA synthesis are thought to be derived from fatty acid biosynthesis when growing on acetate [1, 41]. In this regard, enhancement of the carbon flux from acetate to acetyl-CoA might promote the production of mcl-PHA. Borrero-de Acuña et al. [5] demonstrated that the overproduction of pyruvate dehydrogenase subunit AcoA in P. putida KT2440 led to an increase of mcl-PHA production. Acetate can primarily be assimilated via two different routes (catalyzed by acetate kinase-phosphotransacetylase and acetyl-CoA synthetase, respectively, in E. coli) [3, 39]. The acetate kinase-phosphotransacetylase (encoded by ackA and pta) route is a reversible two-step reaction to obtain acetyl-CoA with acetyl-phosphate as an intermediate; in contrast, acetyl-CoA synthetase (encoded by acs) can irreversibly convert acetate to acetyl-CoA. However, there are few reports about acetate assimilation in P. putida; this study only obtained information about the acs and pta genes in P. putida KT2440 [2, 29]. For the purpose of activating the acetate assimilation pathway in P. putida KT2440, this study attempted to amplify the acs route and construct the ackA-pta pathway. Three genes in P. putida KT2440 are predicted to encode for acetyl-CoA synthetase, but only the one with gene ID 1045574 has been experimentally verified. One of the aims of the study is to overexpress the acs gene, thus this one with validated function was chosen. To expand the acs route, the acs gene from P. putida KT2440 was cloned into the broad host range vector pBRR1MCS-2 and then transformed into the P. putida KT2440. To construct the ackA-pta pathway, the ackA and pta (from E. coli MG1655) genes were co-inserted into pBRR1MCS-2 and then transformed into the P. putida KT2440. Moreover, the ackA gene also was individually introduced (from E. coli MG1655) to P. putida KT2440. A list of all used strains, vectors, and primers is presented in Table 1. Wild-type P. putida KT2440 carrying the vector without insert served as the experimental controls.

Proposed metabolic pathways for mcl-PHA biosynthesis. acs acetyl-CoA synthetase, ackA encoding acetate kinase, pta phosphate acetyltransferase, FabD malonyl-CoA-ACP transacylase, FabG 3-ketoacyl-ACP reductase, PhaC PHA synthase, PhaG 3-hydroxyacyl-ACP thioesterase. The acetyl-CoA synthetase was overproduced by amplifying the acs route and constructing the ackA-pta pathway (green thick arrow) (color figure online)

To evaluate the effects of acs route overexpression and ackA-pta pathway construction on mcl-PHA production, GC analyses of the extracted PHA were performed (Fig. 3). Triplicate aerobic cultures of P. putida strains KT2440, KT2440-pBBR1, KT2440-acs, KT2440-ackA, and KT2440-ackA-pta were tested. For this purpose, cells were grown in the defined M9 medium for 60 h until acetate as the sole carbon source was completely consumed (in all of the tested strains, no acetate was detected via HPLC at 60 h). In comparison with the parental strain, the KT2440-acs mutant strain showed an increased PHA content, amassing 26 wt% mcl-PHA (Fig. 3b). The biomass production of the KT2440-acs strain was found to be 1.26 times the production determined for the wild-type P. putida KT2440 strain (Fig. 3a). This was not the case for the KT2440-ackA (19 wt%; 1.6 g CDW/L) and KT2440-ackA-pta (17 wt%; 1.5 g CDW/L) strains. Additionally, the amounts of acs transcripts were measured to confirm the potential change in the acs expression; the relative expression of genes of the acs overexpressing strain was 12.05 times compared to the wild-type KT2440 strain.

Cell dry weight (a) and mcl-PHA (b) content of the wild-type P. putida KT2440 and the different metabolically engineered P. putida strains. KT2440: wild-type P. putida KT2440; KT2440-pBBR1: KT2440 harboring empty vector pBBR1MCS-2; KT2440-acs: acetyl-CoA synthetase gene overexpressing P. putida KT2440; KT2440-ackA: acetate kinase gene overexpressing P. putida KT2440; KT2440-ackA-pta: construction of acetate kinase-phosphotransacetylase pathway in KT2440

It was confirmed that heterologous expression of ackA-pta from E. coli in P. putida KT2440 cannot promote mcl-PHA production, which may be caused by the failed overexpression of acetyl-CoA from acetate. Noh et al. reported that the amplification of ackA-pta seems not to be suitable to increase the acetate assimilation rate in E. coli compared with the amplification of the acs pathway, although the negative effect requires further study. Hence, there may be multiple reasons for the failed overexpression, such as cofactor imbalance, toxic intermediates accumulation, or inefficient enzyme activities. The exact reason requires additional research.

In summary, the most efficient PHA producer was the KT2440-acs strain, where the PHA concentration was 1.65 times that of the P. putida KT2440 wild-type strain (Fig. 3b). The results indicated that enhancement of the carbon flux from acetate is effective in improving the mcl-PHA synthesis of P. putida KT2440.

Evaluation of the engineered P. putida in bioreactors

Reactor-scale fermentation was conducted with the KT2440-acs and P. putida KT2440 strains (Fig. 4) for additional supplementation of acetate. The culture profile of the parent strain P. putida KT2440 on acetate as the sole carbon and energy source is presented in Fig. 4a. During the initial period of about 12–18 h, acetate was depleted. The mcl-HA level began to increase after 18 h, and continuously increased up to a final value of 0.350 g/L. At the final stage of the process, the cells consisted of about 22% of the polymer. The designer mutant, KT2440-acs, revealed a much higher synthesis of the mcl-PHA (Fig. 4b). The final PHA titer was 0.674 g/L, and thus 92% higher compared to the parent strain. At the same time, the cellular mcl-PHA content was also substantially increased to more than 43%, resulting in an almost 1.5 times polymer yield. The yields of mcl-PHA on acetate from wild-type P. putida KT2440 and KT2440-acs were 0.02 g/g and 0.03 g/g, respectively. Additionally, no apparent differences of the mcl-PHA monomer composition between the KT2440 and KT2440-acs strains were observed (Table 2). The principal monomer was 3-hydroxy-decanoate (C10), accounting for a fraction of more than 60%. Additionally, larger monomers up to C12 were also incorporated.

During the fed-batch fermentation, the acetate was consumed faster (average rate: 0.74 g/L/h) compared with the shake flask cultivation (average rate: 0.33 g/L/h). In fed-batch fermentation, the pH was maintained at 7.0 ± 0.1. On the contrary, in the shake flask experiments, the pH gradually increased from 7.0 to about 9.0, which may be repressive to acetic acid consumption. The rise in pH may mainly be caused by the hydrolysis of CH2COO−. The CH2COOH was more easily absorbed than the CH2COO−, which is effective to promote the hydrolysis of CH2COO−. Faster acetate consumption is conducive to improve mcl-PHA productivity. Several investigations have indicated that volumetric productivity is the critical parameter for the industrial production of PHA, and thus any factor influencing this parameter affects the economics and cost competitiveness of PHA synthesis via microbial fermentation [20, 31]. These results indicated that controlling the pH at a level which is efficient for acetate absorption is advantageous to improve mcl-PHA productivity when acetate is the sole carbon source.

In conclusion, the engineered strain KT2440-acs could produce more mcl-PHA in the minimal medium containing acetate as the sole carbon source, which provides new research ideas for reducing the production cost of mcl-PHA. The content and productivity of mcl-PHA were 31.5% and 0.02 g/L/h, which were competitive with the results of other studies (Table 3). Optimization of culture conditions could also be applied as another strategy to further improve mcl-PHA production. For example, Chen et al. [8] promoted the P3HB production from acetate by optimizing culture conditions. Such a method might allow for more production of mcl-PHA from acetate.

Conclusions

In this work, P. putida KT2440 was engineered to synthesize mcl-PHA using acetate as the sole carbon source. This is the first study reporting the increased production of mcl-PHA using acetate as the sole carbon source by engineered P. putida. In fed-batch cultures, the acetyl-CoA overexpressing P. putida KT2440 (KT2440-acs) produced 674 mg/L of mcl-PHA, which is 92% higher compared with the parent strain. Research on the optimization of culture conditions, which could be applied to further improve mcl-PHA production, is underway in our laboratory.

References

Agnew DE, Pfleger BF (2013) Synthetic biology strategies for synthesizing polyhydroxyalkanoates from unrelated carbon sources. Chem Eng Sci 103:58–67

Belda E, Van Heck RGA, José Lopez-Sanchez M et al (2016) The revisited genome of Pseudomonas putida KT2440 enlightens its value as a robust metabolic chassis. Environ Microbiol 18(10):3403–3424

Bernal V, Castaño-Cerezo S, Cánovas M (2016) Acetate metabolism regulation in Escherichia coli: carbon overflow, pathogenicity, and beyond. Appl Microbiol Biotechnol 100(21):8985–9001

Blattner FR, Plunkett G, Bloch CA et al (1997) The complete genome sequence of Escherichia coli K-12. Science 277(5331):1453–1462

Borrero-de Acuña JM, Bielecka A, Häussler S et al (2014) Production of medium chain length polyhydroxyalkanoate in metabolic flux optimized Pseudomonas putida. Microb Cell Fact 13:88

Brandl H, Gross RA, Lenz RW, Fuller RC (1988) Pseudomonas oleovorans as a source of poly(beta-Hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl Environ Microbiol 54(8):1977–1982

Cerrone F, Davis R, Kenny ST et al (2015) Use of a mannitol rich ensiled grass press juice (EGPJ) as a sole carbon source for polyhydroxyalkanoates (PHAs) production through high cell density cultivation. Bioresour Technol 191:45–52

Chen J, Li W, Zhang ZZ, Tang TW, Li ZJ (2018) Metabolic engineering of Escherichia coli for the synthesis of polyhydroxyalkanoates using acetate as a main carbon source. Microb Cell Fact 17(1):102

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064

Chong H, Yeow J, Wang I, Song H, Jiang R (2013) Improving acetate tolerance of Escherichia coli by rewiring its global regulator cAMP receptor protein (CRP). PLoS ONE 8(2):e77422

Davis R, Duane G, Kenny ST, Cerrone F, Guzik MW, Babu RP, Casey E, O’Connor KE (2015) High cell density cultivation of Pseudomonas putida KT2440 using glucose without the need for oxygen enriched air supply. Biotechnol Bioeng 112(4):725–733

Davis R, Kataria R, Cerrone F, Woods T, Kenny S, O’Donovan A, Guzik M, Shaikh H, Duane G, Gupta VK (2013) Conversion of grass biomass into fermentable sugars and its utilization for medium chain length polyhydroxyalkanoate (mcl-PHA) production by Pseudomonas strains. Bioresour Technol 150(4):202–209

Escapa IF, Del Cerro C, Garcia JL, Prieto MA (2013) The role of GlpR repressor in Pseudomonas putida KT2440 growth and PHA production from glycerol. Environ Microbiol 15(1):93–110

Fernández-Sandoval MT, Huerta-Beristain G, Trujillo-Martinez B, Bustos P, González V, Bolivar F, Gosset G, Martinez A (2012) Laboratory metabolic evolution improves acetate tolerance and growth on acetate of ethanologenic Escherichia coli under non-aerated conditions in glucose-mineral medium. Appl Microbiol Biotechnol 96(5):1291–1300

Gillis J, Ko K, Ramsay JA, Ramsay BA (2018) Potential for mcl-PHA production from nonanoic and azelaic acids. Can J Microbiol 64:11–19

Guzik MW, Kenny ST, Duane GF et al (2014) Conversion of post consumer polyethylene to the biodegradable polymer polyhydroxyalkanoate. Appl Microbiol Biotechnol 98(9):4223–4232

Hu P, Chakraborty S, Kumar A, Woolston B, Liu H, Emerson D, Stephanopoulos G (2016) Integrated bioprocess for conversion of gaseous substrates to liquids. Proc Natl Acad Sci USA 113(14):3773

Kirkpatrick C, Maurer LM, Oyelakin NE, Yoncheva YN, Maurer R, Slonczewski JL (2001) Acetate and formate stress: opposite responses in the proteome of Escherichia coli. J Bacteriol 183(21):6466

Kovach ME, Elzer PH, Hill DS, Robertson GT, Farris MA, Roop RM, Peterson KM (1995) Four new derivatives of the broad-host-range cloning vector pBBR1MCS, carrying different antibiotic-resistance cassettes. Gene 166:175–176

Lee GN, Na J (2013) Future of microbial polyesters. Microb Cell Fact 12(1):1–4

Lee HM, Jeon BY, Oh MK (2016) Microbial production of ethanol from acetate by engineered Ralstonia eutropha. Biotechnol Bioprocess Eng 21(3):402–407

Lee SY (2015) Bacterial polyhydroxyalkanoates. Biotechnol Bioeng 49(1):1–14

Lemos PC, Serafim LS, Reis M (2004) Polyhydroxyalkanoates production by activated sludge in a SBR using acetate and propionate as carbon sources. Water Sci Technol 50(10):189–194

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2[-Delta Delta C(T)] method. Methods 25(4):402–408

Li Y, Huang B, Wu H, Li Z, Ye Q, Zhang YP (2016) Production of succinate from acetate by metabolically engineered Escherichia coli. ACS Synth Biol 5(11):1299

Li ZB, Loh XJ (2015) Water soluble polyhydroxyalkanoates: future materials for therapeutic applications. Chem Soc Rev 44(10):2865–2879

Magdouli S, Brar SK, Blais JF, Tyagi RD (2015) How to direct the fatty acid biosynthesis towards polyhydroxyalkanoates production? Biomass Bioenergy 74:268–279

Mozejko-Ciesielska J, Dabrowska D, Szalewska-Palasz A, Ciesielski S (2017) Medium-chain-length polyhydroxyalkanoates synthesis by Pseudomonas putida KT2440 relA/spoT mutant: bioprocess characterization and transcriptome analysis. AMB Express 7(1):92

Nelson KE, Weinel C, Paulsen IT, Dodson RJ, Hilbert H, Martins VDS, Fouts DE, Gill SR, Pop M, Holmes M (2002) Complete genome sequence and comparative analysis of the metabolically versatile Pseudomonas putida KT2440. Environ Microbiol 4(12):799–808

Ni C, Wu X, Jin D, Du D, Ni C, Wu X, Jin D, Du D (2014) Facile recovery of acetic acid from waste acids of electronic industry via a partial neutralization pretreatment (PNP)—distillation strategy. Sep Purif Technol 132:23–26

Oehmen A, Pinto FV, Silva V, Albuquerque MGE, Reis MAM (2014) The impact of pH control on the volumetric productivity of mixed culture PHA production from fermented molasses. Eng Life Sci 14(2):143–152

Poblete-Castro I, Binger D, Rodrigues A, Becker J, Dos Santos V, Wittmann C (2013) In-silico-driven metabolic engineering of Pseudomonas putida for enhanced production of poly-hydroxyalkanoates. Metab Eng 15(1):113–123

Rai R, Keshavarz T, Roether JA, Boccaccini AR, Roy I (2011) Medium chain length polyhydroxyalkanoates, promising new biomedical materials for the future. Mater Sci Eng R 72(3):29–47

Rajaraman E, Agarwal A, Crigler J, Seipeltthiemann R, Altman E, Eiteman MA (2017) Transcriptional analysis and adaptive evolution of Escherichia coli strains growing on acetate. Appl Microbiol Biotechnol 100(17):1–9

Sambrook J (2001) Molecular cloning: a laboratory manual. Anal Biochem 186(1):182–183

Shahid S, Mosrati R, Ledauphin J, Amiel C, Fontaine P, Gaillard JL, Corroler D (2013) Impact of carbon source and variable nitrogen conditions on bacterial biosynthesis of polyhydroxyalkanoates: evidence of an atypical metabolism in Bacillus megaterium DSM 509. J Biosci Bioeng 116(3):302–308

Sin MC, Tan IKP, Annuar MSM, Gan SN (2012) Thermal behavior and thermodegradation kinetics of poly(vinyl chloride) plasticized with polymeric and oligomeric medium-chain-length poly(3-hydroxyalkanoates). Polym Degrad Stab 97(11):2118–2127

Steinbüchel A, Füchtenbusch B (1998) Bacterial and other biological systems for polyester production. Trends Biotechnol 16(10):419

Switch TA (2005) The acetate switch. Mol Biol Rev 69(1):12–50

Valappil SP, Rai R, Bucke C, Roy I (2008) Polyhydroxyalkanoate biosynthesis in Bacillus cereus SPV under varied limiting conditions and an insight into the biosynthetic genes involved. J Appl Microbiol 104(6):1624–1635

Wang Q, Tappel RC, Nomura CT (2012) Development of a new strategy for production of medium-chain-length polyhydroxyalkanoates by recombinant Escherichia coli via inexpensive non-fatty acid feedstocks. Appl Environ Microbiol 78(2):519

Wang Y, Yin J, Chen GQ (2014) Polyhydroxyalkanoates, challenges and opportunities. Curr Opin Biotechnol 30(30):59–65

Xiao Y, Ruan Z, Liu Z, Wu SG, Varman AM, Liu Y, Tang YJ (2013) Engineering Escherichia coli to convert acetic acid to free fatty acids. Biochem Eng J 76(28):60–69

Acknowledgements

The authors are very grateful for the kind donation of E. coli MG1655 from Dr. Tao Chen and the plasmid pBBR1MCS-2 from Dr. Yingjin Yuan of Tianjin University (China). The authors wish to acknowledge the financial support provided by the National Basic Research Program of China (Grant No. 2014CB745100), the National Natural Science Foundation of China (Grant No. 21576197), Tianjin Research Program of Application Foundation and Advanced Technology (Grant No. 18JCYBJC23500), and Tianjin Key Research & Development Program (Grant No. 16YFXTSF00460). We thank LetPub (www.letpub.com) for its linguistic assistance during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, S., Li, S. & Jia, X. Production of medium chain length polyhydroxyalkanoate from acetate by engineered Pseudomonas putida KT2440. J Ind Microbiol Biotechnol 46, 793–800 (2019). https://doi.org/10.1007/s10295-019-02159-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-019-02159-5