Abstract

A bacterial strain capable of hydrolyzing sulfate ester bonds of p-nitrophenyl sulfate (pNPS) and agar was isolated from the coast area of Qingdao, China. It was identified as Marinomonas based on its 16S rRNA gene sequence and named as Marinomonas sp. FW-1. An arylsulfatase with a recovery of 13 % and a fold of 12 was purified to a homogeneity using ion exchange and gel filtration chromatographies. The enzyme was composed of a single polypeptide chain with the molecular mass of 33 kDa estimated using SDS-PAGE. The optimal pH and temperature of arylsulfatase were pH 9.0 and 45, respectively. Arylsulfatase was stable over pH 8–11 and at temperature below 55 °C. The K m and V max of this enzyme for the hydrolysis of pNPS were determined to be 13.73 and 270.27 μM/min, respectively. The desulfation ratio against agar from red seaweed Gelidium amansii and Gracilaria lemaneiformis were 86.11 and 89.61 %, respectively. There was no difference between the DNA electrophoresis spectrum on the gel of the arylsulfatase-treated G. amansii agar and that of the commercial agarose. Therefore, this novel alkaline arylsulfatase might have a great potential for application in enzymatic conversion of agar to agarose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agar is a kind of linear polysaccharide that exists in the cell walls of red algae, especially the genus of Gracilaria and Gelidium. Agar is generally composed of agarose and agaropectin [3]. Agarose is composed of a repeating unit of alternating 1,4-linked 3,6-anhydro-α-l-galactosyl residues and 1,3-linked α-d-galactosyl residues, while the structure of agaropectin additionally contains sulfate groups in C6 position of galactosyl residues and forms l-galactose-6-sulfate [1]. Incorporation of sulfate groups in agar usually weakens gel strength due to the avoidance of a cross-linked structure during gelation [2].

Arylsulfatases existed in microorganisms, animal tissues, and even some plant seeds [29] catalyze the hydrolysis of arylsulfate esters to aryl compounds and inorganic sulfate. Most studies on microbial arylsulfatases have focused on pathogenic bacteria such as Klebsiella pneumoniase [23], Salmonella typhimurium [13], Pseudomonas aeruginosa [4], and Escherichia coli [14]. An arylsulfatase-producing marine bacterium was isolated and identified as Sphingomonas [7] and the gene encoding arylsulfatase was cloned [20] for cleaving the sulfate ester bonds in agar. Only arylsulfatase from Sphingomonas sp. AS 6330 had been purified and estimated for improving the agar quality [16].

Agarose can be used as the medium for electrophoresis and chromatographic resin, which were widely utilized in biotechnology and pharmaceutical industries. With increasing demand of agarose, more researches deal with the elimination the sulfate groups for improving the gel strength of agar [12]. There is evidence that the agar quality in terms of gel strength depends on the content of 3,6-anhydrogalactopyranosyl (3,6-AG). The alkali treatment is the traditional method widely used in the agar industry to remove the primary sulfate groups of the galactopyranosyl unit and convert the galatopyranhosyl to 3,6-AG [11]. However, the alkali treatment has many drawbacks, such as the reduction of polysaccharide yield, the formation of brown color in agar product, and the pollution of environment [22]. Therefore, the replacement of chemical processing by enzymatic process can resolve those problems.

In this study, an arylsulfatase-producing marine bacterium was isolated and identified. The enzyme activity was confirmed by the hydrolysis of p-nitrophenyl sulfate and sulfate ester bond in agar. A purification procedure for arylsulfatase produced by this strain was established and the enzymatic properties were characterized. This is the first report on the purification of arylsulfatase from bacteria of genus of Marinomonas. What is more, the pH stability facilitated the industrial utilization of enzymatic producing of agarose at alkaline pH condition.

Materials and methods

Materials

DEAE-Sepharose FF and Sephacryl S-100HR were purchased from Amersham Pharmacia Biotech (Uppsala, Sweden). p-nitrophenyl sulfate (pNPS), p-nitrophenl (pNP), and commercial agarose were obtained from Sigma Co. (St Louis, MO, USA). Molecular mass marker for sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) was from Bio-Rad (Hercules, CA, USA). Chemicals that were used in this study were of analytical grade.

Screening and identification of bacteria producing arylsulfatase

Seawater, seaweed and sea sediment were collected from the coastal area of Qingdao, China. After enrichment culture, the supernatant was diluted by 100, 1000, 10000 times with sterile water and then plated onto screening culture medium plate (5 g peptone, 2 g yeast extract, 20 g agar, 1 L artificial seawater, pH of 7.5) including 0.1 mL 5 M pNPS. There was a yellow circle around the bacteria producing arylsulfatase incubated for 2 days at 28 °C. Isolated bacteria in glycerol were stored at −80 °C for further use.

Three arylsulfatase-producing strains were isolated. Only strain K2 was used for the identification because of its best performance. Series of taxonomic characteristics such as gram staining, motile, oxidase, catalase, lipases were performed to identify and characterize the isolated microorganism. Chromosomal DNA of strain K2 was isolated using the method of Chelex [26]. The 16S ribosomal RNA (rRNA) gene fragment was amplified using polymerase chain reaction (PCR) with the universal primers 27F and 1492R. The amplification was performed using a GeneAmp PCR System 9700 (Applied Biosystems, Foster City, CA, USA). The PCR fragment was purified using a Solgent PCR purification kit (Solgent, Daejeon, Korea). Sequencing was performed on an ABI Prism 3730 DNA analyzer using an ABI BigDye cycle sequencing kit with Solgent EF-Taq DNA polymerase (Solgent). The 16S rRNA gene sequence was compared with sequences in nucleotide database using the BLAST algorithm at the NCBI site.

Medium composition and culture condition

For arylsulfatase production, the microorganism was cultured in a fermentation medium at 35 °C with shaking at 130 rmp for 72 h. The fermentation medium was prepared by artificial seawater (3 % NaCl, 0.412 % MgCl2·6H2O, 0.1 % KCl, 0.02 % CaCl2, 0.013 % K2HPO4·3H20, and 0.002 % FeCl2·4H2O) supplemented with 0.09 % MnCl2·4H2O, 0.043 % Na4P2O7·10H2O, 0.25 % agar, 0.2 % yeast, and 0.5 % peptone. The initial pH was adjusted to 7.5 by 1 M NaOH.

Enzyme assay and protein determination

In this study, the arylsulfatase produced by strain K2 was an intracellular enzyme. The enzyme solution was collected by centrifugation of the cell lysate and diluted. After dilution, 1 mL of diluted enzyme solution was incubated with 0.5 mL of 5 mM pNPS (pH 9.0) at 45 °C for 1 h. The reaction was ended by adding 1 mL of 0.5 M NaOH solution. Arylsulfatase activity was determined by measuring the amount of formed pNP at 410 nm. Enzyme activity (U) was defined as the absorbance equivalent of 1 μmol pNP produced per minute per milliliter of enzyme solution under the experimental condition. The relative protein concentration was estimated by the method of Bradford using bovine serum albumin as the strand protein [6].

Enzyme purification

All the purification procedures were performed at 4 °C. 1 L of culture fluid was centrifuged at 12,000×g for 10 min. The cell pellet was suspended in 100 mL buffer A (20 mM Tris–HCl buffer, pH 7.2) and sonicated for 40 min in ice water. The sonicated cell suspension was centrifuged at 12,000×g for 15 min, and the supernatant was concentrated by ultrafiltration (10-kDa cutoff membrane, Millipore, Bedford, MA, USA) to 50 mL. After dialysis against buffer A overnight, the solution was applied to a DEAE-Sepharose column (2.6 × 30 cm) equilibrated with buffer A. Bound proteins were eluted with 800 mL linear gradient of 0–0.75 M NaCl in equilibration buffer at a flow rate of 2 mL/min (6 mL/tube). Main active fraction was pooled, concentrated to 2 mL, and dialyzed against buffer A containing 0.14 M NaCl. The enzyme solution was applied to a Sephacryl S-100 HR column (1.6 × 36 cm), equilibrated with buffer A containing 0.14 M NaCl. Bound proteins were eluted with the same buffer at a flow rate of 0.5 mL/min (2 mL/tube). Active fractions were pooled and used for further study.

Determination of molecular weight

The purified enzyme was applied to sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) on 12 % polyacrylamide gel containing 0.1 % SDS according to the method of Laemmli [19]. After electrophoresis, protein bands were detected by staining the gel with Coomassie Brilliant R-250. Molecular mass markers were obtained from GeneDirex (Taoyuan, Taiwan).

Effects of temperature and pH on enzyme activity and stability

The effect of temperature on arylsulfatase activity was determined using the enzyme activity assay at each temperature (25–85 °C) at pH 9.0. The effect of pH on arylsulfatase activity was assayed by replacing Tris–HCl buffer (pH 9.0) with 10 mM of each buffer: citrate-Na2HPO4 (pH 4.0–7.0), Tris–HCl (pH 7.0–9.0), and glycine-NaOH (pH 9.0–12.0) at 45 °C. The temperature stability of the arylsulfatase was determined by pre-incubating the enzyme solution at each temperature (25–85 °C) and pH 9.0 for 1 h, and then the residual enzyme activity was determined. The pH stability of the arylsulfatase was determined by pre-incubating the enzyme solution at each pH (4–12) and 45 °C for 1 h, and then the residual enzyme activity was determined by adjusting the pH with Tris–HCl (0.1 M, pH 9.0). The relative activity was defined as the percentage of activity determined with respect to the maximum arylsulfatase activity.

Effects of various reagents on enzyme activity

The effects of metal ions, denaturants, chelators, reducing reagents, and acid radicals on enzyme activity were assayed by mixing reagent into the reaction mixture. The relative activity was defined as the percentage of activity determined with respect to that measured under the standard condition described previously.

Estimation of kinetic parameter

Apparent K m and V max were calculated using linear regression analysis of Lineweaver–Burke [21], double-reciprocal, plots of initial velocity data. To obtain kinetic parameters, the reactions at 0.05‒0.5 mM pNPS were performed under the optimum condition.

Desulfation of agar

The purified arylsulfatase was applied to degrade the sulfate groups of agar. Each red seaweed Gelidium amansii and Gracilaria lemaneiformis agar (5 g) was suspended in 50 mL of 0.1 M Tris–HCl buffer (pH 9.0) and liquefied at 121 °C for 30 min. After cooling down to 45 °C, 200 U of purified arylsulfatase was added to the agar and incubated overnight at 45 °C. After reaction, the obtained carbohydrates were extracted and dried using a traditional freezing–melting and drying method. The amount of sulfate in the enzymatically produced carbohydrates was measured using the method of BaCl2-gelatin [9]. The FT-IR spectrum was used to compare the structure of G. amansii agar before and after the enzymatic treatment by purified arylsulfatase.

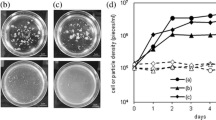

Application of enzymatic product in agarose gel electrophoresis

Agarose gel electrophoresis was performed using the enzymatically desulfated G. amansii agar, and the commercial agarose was used as the control. The experiment was performed with 0.8 % of gel and two DNA ladders of 250–15,000 and 100–2000 bp using a mini-sub cell GT 8 gel rigs (Bio-Rad) according to the method of Sambrook [25].

Results

Isolation and identification of arylsulfatase-producing strains

Three bacteria capable of degrading pNPS on the agar plate were isolated from seaweed samples, preliminary named as A, H, and K2. Strain K2 showed the most clear yellow circle around the colonies by releasing of pNP and the highest activity. Hence, the strain K2 was selected for further study.

The K2 strain was found to be a rod-shaped Gram-negative bacterium. K2 growed in 1 % NaCl and seawater, while it did not grow in distilled water. The other physiological and biochemical characteristics are listed in Table 1. 16S rRNA sequence of the strain K2 was determined and compared to the known 16S rRNA sequences in the NCBI GenBank (Accession No. lcl 69432). The 16S rRNA gene sequence of strain K2 showed highest similarity of 98 % to that of Marinomonas sp. bacterium. The phylogenetic analysis was done using the sequence data of 16 type strains of Marinomonas sp. bacteria. The result of the phylogenetic analysis showed that the strain K2 belonged to the Marinomonas sp. (Fig. 1) and named as Marinomonas sp. FW-1. The strain was deposited in the China Center for Type Culture Collection with the number of M 2013613.

Purification of arylsulfatase

The arylsulfatase was purified using DEAE-Sepharose and Sephacryl chromatographies (Fig. 2). The purification procedure from cell lysate is summarized in Table 2. Through DEAE-Sepharose chromatography, the target protein was purified by sixfolds with a yield of 58 %. The major activity peak was coincident with the protein peak, which was eluted with NaCl gradient of 0.4–0.45 M (Fig. 2a). Through Sephacryl chromatography (Fig. 2b), the target protein was purified by 12 folds with a yield of 13 %.

Samples from each purification procedure were loaded onto SDS-PAGE (Fig. 3). The single band of SDS-PAGE (lane 4) revealed that enzyme was purified to homogeneity with the molecular mass of 33 kDa.

Effects of temperature and pH on enzyme activity and stability

The temperature profile of arylsulfatase is shown in Fig. 4a. The optimal temperature for arylsulfatase was 45 °C. This enzyme showed more than 80 % of the maximum activity at temperature ranges of 35–55 °C. The arylsulfatase possessed 85 % activity after incubation at 55 °C for 1 h and quickly inactivated as temperature increased. These results indicated that arylsulfatase was thermostable up to 55 °C.

The pH profile of arylsulfatase is shown in Fig. 4b. The enzyme activity increased until pH 9.0, at which the maximum activity was observed. At pH 10.0, the enzyme activity rapidly decreased. The enzyme was most stable at pH 9.0 and 90 % of activity was retained after incubation at wide pH ranges of 8.0–11.0 for 1 h.

Effects of various reagents on enzyme activity

The effects of various metal ions on the enzyme activity are shown in Table 3. Most metal ions (Ca2+, K+, Ba2+, Mg2+, Mn2+ and Sn2+) had no effects on enzyme activity. Addition of 1 mM Fe2+ and Fe3+ ions were found to increase the activity of the enzyme by more than 10 %. On the other hand, the activity was inhibited by Zn2+ or Cu2+ ions. No significant activation or inhibition of arylsulfatase was observed by acid radicals in Table 4. SH-inhibitor HgCl2 was strongly inhibitory, causing about 80 % inhibition, even at a concentration of 1 mM. Furthermore, the effects of several reagents such as reducing reagents, chelators and detergents on the enzyme action are shown in Table 5. SDS at 1 and 10 mM were found to depress the activity by 80 and 99 %, respectively, whereas urea at 10 mM inhibited less.

Kinetic parameters

The K m and V max values of arylsulfatase calculated from Lineweaver–Burke plot are shown in Fig. 5. The K m and V max values of arylsulfatase for the hydrolysis of pNPS were 13.73 and 270.27 μM/min, respectively.

Desulfation of agar

The purified arylsulfatase was applied to remove the sulfate groups of the agar from G. amansii and G. lemaneiformis under optimum enzyme reaction condition. As shown in Table 6, after enzymatic treatment, the sulfate content of G. amansii decreased remarkably from 1.08 to 0.15 % with the desulfation ratio of 86.11 %. In the same way, the sulfate content of G. lemaneiformis decreased remarkably from 1.08 to 0.15 % with the desulfation ratio of 89.61 %. The peak of 1250 cm−1 in FT-IR spectra was attributed to sulfate groups [27]. The FT-IR spectra (Fig. 6) indicated that the peak signal in 1250 cm−1 significantly decreased after enzymatic treatment using the purified arylsulfatase.

The enzymatic produced carbohydrate was applied to agarose gel electrophoresis (Fig. 7). Both the gel showed good separation resolution of large DNA fragments of 5–10 kb and small DNA fragments 5–10 kb. There was no difference between the spectra of the enzymatic product in this study and the commercial agarose.

Discussion

Among arylsulfatase-producing bacteria that have been reported [4, 7, 13, 14, 23], few species, such as Sphingomonas sp. AS6330 [16] and Pseudoalteromonas carrageenovora [17], can degrade sulfate bonds in agar and other species, such as S. typhimurium [13], P. aeruginosa PAO [4], Streptomyces sp. T109-3 [28], and Aspergillus oryzae [5], are applied in the pharmacy industry. Given the wide application of agarose and the disadvantages of traditional purification methods, this work aimed to study arylsulfatases applied in desulfation of red seaweed agar. 16S rRNA sequence analysis identified the isolated strain as Marinomonas. Database search (http://www.expasy.org/) and literature review revealed that this study was the first to report that bacteria in the genus Marinomonas could produce arylsulfatase.

Marinomonas arylsulfatase was purified to homogeneity through ion exchange and gel filtration chromatography. The properties of three agar desulfation arylsulfatases are shown in Table 7. The calculated molecular mass of the purified enzyme through SDS-PAGE was 33 kDa. Two agar desulfation arylsulfatases, with molecular masses of 62 and 33 kDa, were also purified [16, 17], and other arylsulfatases exhibited molecular masses ranging from 33 to 62 kDa [4, 5, 24, 28]. The molecular mass of Marinomonas arylsulfatase belonged to the latter range.

Marinomonas arylsulfatase exhibited maximum activity at 45 °C, which was similar to the results of the two agar desulfation arylsulfatases [16, 17]. Nevertheless, the thermo-stabilities of agar desulfation arylsulfatases were not reported [16, 17]. Arylsulfatase was stored at 4 °C for 7–14 days without losing enzyme activity (data not shown), indicating the excellent stability of arylsulfatase. The enzyme also remained stable when incubated for 60 min at 55 °C. By contrast, arylsulfatase from the pathogenic bacteria P. aeruginosa PAO was inactivated when subjected under the same condition [4]. The enzyme activity of Marinomonas arylsulfatase ceased completely after incubation at 65 °C for 60 min, which could be due to thermal denaturation of the enzyme. When the enzyme was incubated for more than 10 h, it still possessed 98 % of the activity (data not shown). Agar must be heated and stirred to maintain its liquid state, which could be efficiently treated by arylsulfatase. Thus, temperature stability could facilitate the industrial application of arylsulfatase in the liquid form of agar at 45 °C.

Arylsulfatases can be divided into two groups according to their optimal pH values: the first group exhibited optimal activity at pH of 6.5–7.1 and the other group at 8.3–9.0 [4]. Arylsulfatases from Sphingomonas sp. AS6330 [16], P. carrageenovora [17], S. typhimurium [13], and Klebsiella aerogenes [24] showed optimal pH values of 6.7–7.5, and these enzymes belonged to the first group. Marinomonas arylsulfatase showed an optimal pH of 9.0 and was classified to the second group. Only arylsulfatase from Streptomyces sp. T109-3, which is used for cancer therapy, presented an optimal pH of 8.5 but was stable at narrow pH ranges of 8–9 [28]. Agar is stable under alkaline conditions, but can be degraded under acidic conditions. To avoid backbone degradation and maintain the gel strength, we performed enzymatic desulfation under alkaline condition. Therefore, the optimal pH under alkaline condition and the pH stability of Marinomonas arylsulfatase may benefit its industrial applications.

The K m and V max values of Marinomonas arylsulfatase differed from those of Sphingomonas [16], P. carrageenovora [17], and P. aeruginosa PAO [4]. The K m values for pNPS hydrolysis by arylsulfatase purified from P. carrageenovora and Sphingomonas sp. AS6330 were estimated to be 54.9 and 1150 μM, respectively [16, 17]. In comparison with P. carrageenovora and Sphingomonas sp. arylsulfatases, Marinomonas arylsulfatase presented a lower K m value, indicating its superior property.

Arylsulfatases exhibited different resistance levels to acid radicals. For example, a group of arylsulfatases exhibited resistance to acid radicals, such as phosphates, sulfates, and chlorides, and other groups were suppressed by acid radicals [28]. As shown in Table 4, Marinomonas arylsulfatase exhibited resistance to acid radicals, similar to P. aeruginosa PAO [4].

Two reviews suggested the classification of arylsulfatases [8, 15]. Kertesz [15] classified arylsulfatases into three groups based on the type of substrates: the first group was named as bacterial arylsulfatases, and enzymes in this group can cleave the O–S bond of the substrates; the second group was named as alkylsuldatases; long chains of these enzymes can break the C–O bond of the substrates, whereas short-chains can break the O–S bond; and the third group was named as carbohydrate sulfatases, and these enzymes can act on glycosaminoglycans as substrates. Cregut and Rondags [8] divided arylsulfatases into two groups based on different properties and application domains: the first group of arylsulfatases was considered sulfur metabolism-linked arylsulfatases, which were used at the cellular level for recovery of inorganic sulfate under sulfate starvation conditions; and the second was named as carbohydrate sulfatases, which were used to recover the organic skeleton of sulfated organic molecules. No glycine or serine residues were found in the catalytic site of the second sulfatase group; conversely, these residues were important in the catalytic site of the first sulfatase group [8, 17]. The category of this Marinomonas arylsulfatase will be determined after investigating the amino acid residues on the active site through gene cloning.

As shown in Tables 3 and 5, metal ions, such as Fe2+ and Fe3+, enhanced the activity of arylsulfatases, whereas EDTA inhibited enzyme activity. This result indicated that metal ions played an important role during the catalytic process of this enzyme. The presence of SDS strongly inhibited enzyme activity even at low concentrations, which could be due to binding of the detergent alkyl chain to the hydrophobic protein [4].

Sulfate content is an important quality criterion of agar or agarose as it indicates the level of charge in agar [12]. Laas [18] concluded that low sulfate content resulted in low electroendomosis (EEO). Low EEO agarose may also result in high resolution in agarose electrophoresis. Therefore, desulfation must be performed to apply agar as an electrophoresis medium. Thus far, conventional methods for agarose production have focused mainly on reduction of sulfate content using selective adsorption through chromatography or fractionation with organic solvents [11]. Although both methods successfully decreased sulfate content, agarose yield was low ranging from 25 to 30 % [10]. Arylsulfatase is an ideal candidate used to simplify the process of agarose preparation under mild conditions and remove sulfate groups in agar with a high recovery rate. After incubating 200 U arylsulfatase at 45 °C overnight, the sulfate content decreased by more than 86 %, which demonstrated that Marinomonas arylsulfatase was an efficient catalyst for removing sulfate groups in agar. The FT-IR and electrophoresis spectra further revealed the excellent properties of the enzymatic product.

In conclusion, this novel alkaline arylsulfatase was purified from Marinomonas sp. FW-1. The thermal and pH stability of this enzyme distinguished it from other reported arylsulfatases. As Marinomonas arylsulfatase exhibited excellent properties, it could be potentially applied to produce agarose, which will be used as electrophoresis medium and chromatographic resin. To facilitate large-scale production of arylsulfatases, further studies must focus on cloning and expressing this enzyme.

References

Allan GG, Johnson PG, Lay Y, Sarkanen KV (1971) Marine polymers; part 1. A new procedure for the fractionation of agar. Carbohydr Res 17:234–236

Amott S (1974) The agarose double helix and its function in agarose gel structure. J Mol Biol 90:269–284. doi:10.1016/0022-2836(74)90372-6

Araki CH (1937) Acetylation of agar like substance of Gelidium amansii. J Chem Soc Jpn 58:1138–1150

Beil S, Kehrli H, Peter J, Staudenmann W, Cook AM, Leisinger T, Kertesz MA (1995) Purification and characterization of the arylsulfatase synthesized by Pseudomonas aeruginosa PAO during growth in sulfate-free medium and cloning of the arylsulfatase gene (atsA). Eur J Biochem 229:385–394. doi:10.1111/j.1432-1033.1995.tb20479.x

Benkovic SJ, Vergara EV, Hevey RC (1971) Purification and properties of an arylsulfatase from Aspergillus oryzae. J Biol Chem 246:4826–4933

Bradford MM (1976) A rapid and sensitive method for quantification of microgram quantities of protein utilizing the principle of protein–dye binding. Anal Biochem 72:248–254

Byun D-S, Kim D-S, Samuel Godber J (2004) Isolation and characterization of marine bacterium producing arylsulfatase. J Microbiol Biotechnol 14:1134–1141

Cregut M, Rondags E (2013) New insights in agar biorefinery with arylsulphatase activities. Process Biochem 48:1861–1871. doi:10.1016/j.procbio.2013.09.020

Dodgson KS, Price RG (1963) A note on the determination of the ester sulfate content of sulfated polysaccharides. Biochem J 84:350–356

Duckworth M, Yaphe W (1971) The structure of agar. Part 1 Fractionation of a complex mixture of polysaccharides. Carbohydr Res 16:189–197

Guiseley KB (1970) The relationship between methoxyl content and gelling temperature of agarose. Carbohydr Res 13:247–256

Guiseley KB, Kirpatrick FH, Provonchee RB, Dumais MM, Nochumson S (1993) A further fractionation of agarose. Hydrobiologia 260(261):505–511

Henderson MJ, Milazzo FH (1979) Arylsulfatase in Salmonella typhimurium: detection and influence of carbon source and tyramine on its synthesis. J Bacteriol 139:80–87

Jansen HJ, Hart CA, Rhodes JM, Saunders JR, Smalley JW (1999) A novel mucin-sulphatase activity found in Burkholderia cepacia and Pseudomonas aeruginosa. J Med Microbiol 48:551–557

Kertesz MA (1999) Riding the sulfur cycle–metabolism of sulfonates and sulfate esters in Gram-negative bacteria. FEMS Microbiol Rev 24:135–175

Kim JH, Byun DS, Godber JS, Choi JS (2004) Purification and characterization of arylsulfatase from Sphingomonas sp. AS6330. Appl Microbiol Biotechnol 63:553–559. doi:10.1007/s00253-003-1463-8

Kim D-E, Kim K-H, Bae Y-J, Lee J-H, Jang Y-H, Nam S-W (2005) Purification and characterization of the recombinant arylsulfatase cloned from Pseudoalteromonas carrageenovora. Protein Expr Purif 39:107–115. doi:10.1016/j.pep.2004.09.007

Laas T (1972) Agar derivation for chromatography, electrophoresis and gel-bound enzymes. J Chromatogr 66:347–355

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. doi:10.1038/227680a0

Lim J-M, Jang Y-H, Kim H-R, Kim YT, Choi TJ, Kim JK, Nam S-W (2004) Overexpression of arylsulfatase in E. coli and its application to desulfatation of agar. J Microbiol Biotechnol 14:777–782

Lineweaver H, Burke D (1934) The determination of enzyme dissociation constants. J Am Chem Soc 56:658–666

Lonnerdal B, Lass T (1976) Improved agarose for immunoelectrophoresis. Anal Biochem 72:527–532

Miech C, Dierks T, Selmer T, von Figura K, Schmidt B (1998) Arylsulfatase from Klebsiella pneumoniase carries a formylglycine generated from a serine. J Biol Chem 273:4835–4837. doi:10.1074/jbc.273.9.4835

Okamura H, Yamada T, Murooka Y, Harada T (1976) Purification and properties of arylsulfatase of Klebsiella aerogenes identity of the enzymes formed by non-repressed and de-repressed synthesis. Agric Biol Chem 40:2071–2076

Sambrook J, Russel DW (2001) Molecular cloning. In: Argentine J, Irwin N, Janssen KA, Curtis S, Zierler M, Dickerson M, Sialiano I, Mclnerny N, Brown D, Schaefer S, deBruin D, Atkeson E, Weiss D, Curtis MD (eds) A laboratory manual, 3rd edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New York

Singe SJ, Tanguay RL, Riggs AD (1989) Use of Chelex to improve the PCR signal from a small number of cells. Amplification 3:11–16

Skriptsova AV, Shevchenko NM, Zvyagintseva TN et al (2010) Monthly changes in the content and monosaccharide composition of fucoidan from Undaria pinnatifida (Laminariales, Phaeophyta). J Appl Phycol 22:79–86. doi:10.1007/s10811-009-9438-5

Ueki T, Sawada Y, Fukangawa Y, Oki T (1995) A new type of Streptomyces arylsulfatase with high affinity to the sulfuryl moiety of the substrate. Biosci Biotechnol Biochem 59:1069–1075

Yoy AB, Trudinger PA (1970) The biochemistry of inorganic compounds of sulfur. University Press, Cambridge

Acknowledgments

This work was supported by the Grant of the National Science Foundation of China (No. 31201298), the Grant of National Key Technology Research and Development Program of China (No. 2013BAB01B01), and the Grant of Public Science and Technology Research Funds Projects of Ocean (No. 201405040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Duan, D., Xu, J. et al. Characterization of a novel alkaline arylsulfatase from Marinomonas sp. FW-1 and its application in the desulfation of red seaweed agar. J Ind Microbiol Biotechnol 42, 1353–1362 (2015). https://doi.org/10.1007/s10295-015-1625-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-015-1625-6