Abstract

Shake flasks are widely used to culture microorganisms, but they do not allow for pH control without additional infrastructure. In the presence of a carbon source like glucose, culture pH typically decreases due to overflow metabolism and can limit the growth of microorganisms in shake flasks. In this study, we demonstrate the use of magnesium hydroxide-loaded pH managing hydrogels (m-pHmH) for in situ base release to counter the decrease in culture pH in shake flasks using Escherichia coli as a model organism, in both complex and mineral salts medium. Base release from m-pHmH is shown to increase with decreasing pH (22-fold increase in release rate from pH 8 to 5), thus providing feedback from culture pH. The addition of m-pHmH resulted in better pH maintenance and higher biomass yields of E. coli K12 in media containing glucose as a carbon source. The use of m-pHmH with additional buffer resulted in pH being maintained above 6.9 while pH decreases below 5 without m-pHmH. We demonstrate one application of such in situ pH management to increase the volumetric plasmid yield from E. coli in shake flask culture. In situ glucose release through a hydrogel to mimic fed-batch culture along with the addition of m-pHmH resulted in a 395 % increase in volumetric plasmid yield to 38 μg/ml in shake flask culture.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microbial cell growth is affected by pH, which can decrease significantly during culture in the presence of carbon sources like glucose due to overflow metabolism [19]. A change in pH beyond the permissive range of the organism affects cell growth. For example, the growth of Escherichia coli M23 was shown to cease below a pH of 3.9 [11]. It is estimated that more than 90 % of all cultures in biotechnology are carried out in shake flasks [1], which traditionally have no control over pH. A decrease in pH of the culture can thus contribute to limited cell densities achieved in shake flasks and can also lead to results from shake flask experiments not being predictive of pH controlled bioreactor operation [17].

Weuster-Botz and colleagues [18] have reported the use of a precise syringe pump connected via a substrate distribution system for parallel nutrient feeding and pH control in shake flasks equipped with pH probes for pH monitoring. To avoid the use of any additional infrastructure and probes and to prevent excessive pH change, culture medium can be supplemented with high buffer concentrations. However, high buffer concentrations result in increased osmolarity and may be inhibitory to growth. Moreover, when acid produced exceeds the buffer capacity, the buffer will no longer be able to prevent changes in pH. The aim of this study was to investigate the application of hydrogels for in situ use without pH probes to counter the decrease in pH of microbial cultures in shake flasks due to acid formation and hence allow increased growth of the microbe. Hydrogels are hydrophilic polymers that absorb water and are insoluble in water under physiologic conditions due to the existence of a three-dimensional network [5]. Scheidle et al. [12] have previously demonstrated the use of sodium carbonate-loaded silicone polymer to maintain pH in E. coli culture. The authors report that with the commonly used carbon source, glucose, additional buffering was required with the use of the sodium carbonate-loaded silicone polymer for pH regulation. The authors also noted that systems showing enhanced base release in response to reducing pH need to be developed for balanced pH regulation in small-scale cultures. We have previously shown that a magnesium hydroxide-loaded hydrogel (pHmH) was able to maintain pH for animal cell culture [10]. This hydrogel showed an increase in the release rate of the base with decreasing pH. We further hypothesize that such hydrogels with a pH responsive release rate may be better able to prevent large pH decrease often seen in microbial cultures while minimizing pH overshoot, thus allowing higher microbial growth even in the absence of additional buffer. These hydrogels will need to be suitably modified with reduced cross-linking and increased surface area for application to faster growing microbial cultures.

In this study, we describe the use of such magnesium hydroxide-loaded pH-managing hydrogels (m-pHmH) for pH management for optimal growth of E. coli cultures in shake flasks. We demonstrate the use of m-pHmH to increase biomass yield for E. coli K12 in complex media supplemented with glucose and in defined medium containing glucose as the carbon source. We also illustrate its application in increasing volumetric plasmid yield in E. coli in shake flask cultures when used along with a slow glucose-releasing hydrogel for in situ feeding. Slow release of glucose for fed-batch cultivation in shake flasks has been previously reported [3, 4, 8]. The hydrogel system used for slow release of glucose in this study is similar to the one previously reported for slow glucose release [3].

Materials and methods

2 Hydroxy ethyl methacrylate (HEMA) (97 %-pure), ethylene glycol dimethacrylate (EGDMA) and dichlorodimethylsilane were purchased from Sigma-Aldrich (St. Louis, MO, USA). Azoisobutyronitrile was purchased from Spectrochem (Mumbai, India). Heptane and glucose were purchased from Merck (Mumbai, India). E. coli K12 and a clone of TOP10 E. coli (Invitrogen Corporation, Carlsbad, CA, USA) transformed with a 5-kb pcDNA3.1-based plasmid with an ampicillin resistance gene were used. GOD/POD glucose assay kit was purchased from Beacon Diagnostics, Navsari, India. QIAprep Spin Miniprep Kit from QIAGEN (Hilden, Germany) was used for plasmid DNA purification.

Media composition and culture conditions

LB broth consists of 10 g/l tryptone, 5 g/l yeast extract, and 10 g/l NaCl. Where LB is stated to be supplemented with glucose as a bolus, 20 g/l glucose was added to LB broth after autoclaving. For the culture of TOP10 E. coli cells, culture medium was supplemented with 100 μg/ml ampicillin.

The modified Wilms and Reuss medium was prepared as described by Scheidle et al. [12] and consists of 20 g/l glucose; 5 g/l (NH4)2SO4; 0.5 g/l NH4Cl; 3 g/l K2HPO4; 2 g/l Na2SO4; 0.5 g/l MgSO4·7H2O; 0.01 g/l thiamine hydrochloride; 1 ml/l trace element solution (0.54 g/l ZnSO4·7H2O; 0.48 g/l CuSO4·5H2O; 0.3 g/l MnSO4·H2O; 0.54 g/l CoCl2·6H2O; 41.76 g/l FeCl3·6H2O; 1.98 g/l CaCl2·2H2O; 33.39 g/l Na2EDTA). 3-(N-morpholino) propanesulfonic acid (MOPS) was added at indicated concentrations in some experiments.

Analytical methods

Growth was monitored by measuring the optical density (550 nm) at regular intervals after appropriate dilution. pH of the culture supernatant was measured using a pH electrode (Sentek, Essex, UK). Samples were stored at −20 °C and glucose concentration was measured using GOD/POD glucose assay kit (Beacon Diagnostics, Navsari, India). Unless otherwise noted, all experiments were performed in triplicates.

Preparation of poly-HEMA hydrogels loaded with Mg(OH)2

Azobisisobutyronitrile (AIBN; 0.5 % w/v) was dissolved in 97 %-pure 2-hydroxyethyl methacrylate at room temperature. After dissolution, 1.5 ml of the mixture was poured onto a glass surface. 150 mg of Mg(OH)2 was subsequently added to the solution and mixed prior to polymerization. Hydrogels used with E. coli cultures for plasmid production were loaded with 100 mg Mg(OH)2. The gel mixture was allowed to polymerize at 75 °C for 3 h in an oven. The hydrogels thus prepared had a surface area of 23 cm2. The surface area was calculated from the measured diameter of the circular hydrogel assuming it to be a perfect circle. The hydrogels were washed in water for 1 day to remove any unreacted monomer before using them in microbial cultures. These hydrogels are henceforth referred to as m-pHmH. m-pHmH used in the study were autoclaved at 15 psi and 121 °C for 20 min before their addition to E. coli cultures.

Swelling kinetics

To study the swelling kinetics, empty m-pHmH were dried in an oven at 50 °C for a day to complete dryness. The dry weight of m-pHmH was measured. It was then immersed in water to allow it to swell. The weight of the swollen hydrogel was measured at several time points for a period of 8 h subsequent to its immersion in water. The swollen weight was measured after removing the surface water with blotting paper. Swelling percentage was calculated using the formula:

P t = 100 × (W s,t − W d)/W d, where P t is the percent swelling at time t, W d is the weight of the dry m-pHmH and W s,t is the weight of the swollen m-pHmH at time t.

Magnesium release kinetics

m-pHmH gels were allowed to swell overnight in water. Each m-pHmH gel was then added to 500 ml of 200 mM phosphate buffer at pH 5, 6, 7, and 8 kept shaking at 200 rpm at 37 °C. Release was evaluated using three replicates for every pH. Samples were withdrawn to measure Mg+2 concentration using a SPECTRO ARCOS SOP inductively coupled plasma spectrometer (SPECTRO Analytical Instruments, Kleve, Germany).

Effect of addition of m-pHmH to E. coli K12 culture

E. coli K12 cells were cultured in 100 ml shake flasks with a filling volume of 20 ml and maintained at 37 °C with a shaking speed of 250 rpm. Inoculum was taken from an overnight culture in respective media. For inoculating the cultures, the required inoculum volume was centrifuged at 2,000 rcf for 10 min and resuspended in fresh culture medium to achieve an initial optical density of 0.5.

Sterile m-pHmH was added to the culture medium at indicated times. The m-pHmH were tested in Luria–Bertani (LB) broth and modified Wilms and Reuss medium, both containing glucose as the carbon source. m-pHmH was not added to control cultures. All the culture flasks were sampled at regular intervals for the measurement of optical density, pH, and glucose concentration.

Preparation of poly-HEMA hydrogels loaded with glucose

Monomer solution consisted of 0.5 % (w/v) AIBN as initiator dissolved in 2-hydroxyethylmethacrylate (HEMA) with 5 % ethylene glycol dimethacrylate (EGDMA as cross linker). Inner surfaces of glass tubes (with flat bottom) of 1.4-mm inner diameter were coated with silanization solution (5 % dichlorodimethylsilane (v/v) in heptane), to make the surface hydrophobic. These were then dried in an oven at 50 °C and then filled with 625 mg glucose and 50 mg Mg(OH)2. Monomer solution (600 μl) was then added. The gels were polymerized in a water bath for 1 h at 75 °C. The gels formed were then removed off the tube by breaking the tube and then washed for half an hour in water to reduce initial glucose burst when added in media. The amount of glucose lost during the wash was measured to be 33 ± 2.7 mg. Before addition to media, they were surface sterilized with 70 % ethanol. These hydrogels can also be gamma irradiated for assured sterility if necessary. Alternatively, the monomer solution can be filter sterilized through a 0.22-μm filter and glucose powder can be sterilized by incubating it in ethanol followed by drying. The hydrogels can then be prepared under sterile conditions with the pre-sterilized components.

Testing the effect of addition of m-pHmH in E. coli TOP10 cultures on plasmid DNA yield

Twenty-milliliter cultures of E. coli TOP10 transformed with a plasmid were cultured in LB supplemented with 20 g/l glucose and 100 μg/ml ampicillin. m-pHmH was added to the culture at indicated times. No hydrogels were added to the control flask. Eight hours after inoculation, 1 ml of sample was taken from control flasks and from the flasks containing m-pHmHs. Cells were harvested by centrifugation at 9,800 rcf for 5 min and the cell pellet was stored at −20 °C. Plasmid DNA was purified using QIAprep Spin Miniprep Kit (Qiagen, Hilden, Germany) according to the manufacturer’s instructions. The purified plasmid DNA was quantified by measuring absorbance at 260 nm using a NanoDrop 2000 Spectrophotometer (Thermo Scientific, Waltham, MA, USA). Purity of the samples was verified by measurement of the ratio of absorbance at 260 and 280 nm, which was >1.8 for all cultures. The experiment was performed in duplicate.

Testing the effect of addition of m-pHmH with continuous glucose release in E. coli TOP10 cultures on plasmid DNA yield

A continuous feed of glucose is expected to give better results than a single large glucose bolus. To achieve a continuous feed in the shake flask, glucose-loaded hydrogels were used. Fifty-milliliter cultures of E. coli TOP10 were cultured in LB supplemented with 100 μg/ml ampicillin in 250-ml shake flasks. Cultures were inoculated at an OD of 0.1 and were incubated at 250 rpm at 37 °C. When the culture OD reached approximately 2, the glucose-loaded hydrogels were added with or without m-pHmH. Cultures were incubated for a further 15 h. Both conditions were evaluated at least in triplicate. Control cultures were inoculated from an overnight culture in LB + ampicillin by a 500-fold dilution and cultured further for 14 h. One milliliter of sample was taken at harvest. Cells were harvested by centrifugation at 9,800 rcf for 5 min and the cell pellet was stored at −20 °C. Plasmid DNA was purified using QIAprep Spin Miniprep Kit (Qiagen, Hilden, Germany) according to the manufacturer’s instructions.

Results

Swelling kinetics

A m-pHmH without Mg(OH)2 was added to water, and the increase in weight of the m-pHmH was measured as a function of time to estimate swelling kinetics. Equilibrium swelling was achieved in approximately 4 h (Fig. 1). The m-pHmH gels have an equilibrium swelling percentage of 67 %.

Release kinetics from m-pHmH as a function of pH

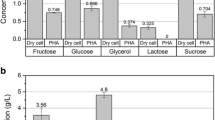

Since the solubility of Mg(OH)2 increases with decreasing pH, it was expected that the release rate will vary with pH, as also reported earlier for a different hydrogel formulation [10]. Figure 2 shows the release rate of Mg+2 from m-pHmH at pH 5, 6, 7, and 8. Based on stoichiometry, the release rate of OH− will be twice the release rate for Mg+2. A straight line was fit to a plot of magnesium released vs. time0.45 for all pH values. The exponent 0.45 was empirically reported to predict release rates for diffusion controlled systems up to 60 % of release of payload [9, 15]. The slopes of these lines, denoted k, are an estimate of the release rate at the respective pH and are shown in Fig. 2b as a function of pH. The release rate varies inversely with pH; release rate increases 22-fold when pH decreases from 8 to 5. This pH dependence of the base release rate will thus incorporate feedback from culture pH and allow for better pH maintenance compared to any slow release technique that is not pH responsive.

a Release kinetics of Mg+2 from m-pHmH at pH 5 (circle), pH 6 (triangle), pH 7 (square), and pH 8 (diamond). Error bars show ±1 standard deviation, n = 3. b A straight line was fit to a plot of magnesium released vs. time0.45, resulting in r 2 above 0.94 for all pH values, except pH 8, which resulted in a r 2 value of 0.87. The slopes of these lines, denoted k, are an estimate of the release rate and are shown as a function of pH

E. coli K12 cultured in Luria–Bertani broth supplemented with glucose

Luria–Bertani (LB) broth is the most widely used media for cultivating E. coli strains for routine applications. Growth in LB has been shown to be limited by carbon source [14]. When supplemented with glucose, the pH of the medium decreases due to formation of overflow metabolites like acetate [19]. m-pHmH were evaluated for their ability to maintain pH of E. coli K12 cultured in LB medium supplemented with glucose as the carbon source.

In control cultures containing no m-pHmH, pH decreased below 5.5, resulting in a maximum optical density of 2.7 as shown in Fig. 3. This was accompanied by incomplete consumption of glucose. The addition of a single m-pHmH at the time of inoculation resulted in pH being maintained above 5.8 up to 14 h without addition of buffer in the culture medium. This resulted in a higher optical density of 8.7.

E. coli K12 was cultured in LB-glucose with and without m-pHmH (a) growth (b), and glucose consumption (c) pH profiles. Control, without m-pHmH (triangle), with single m-pHmH added at the time of inoculation (square), and with staggered addition of two m-pHmH, one added at the time of inoculation and the other 2 h post-inoculation (circle)

Two m-pHmH can be added to the culture to further minimize the decrease in culture pH. However, the hydrogel-based system in this study is not a completely self-regulatory system like the traditional pH control method of pH measurement followed by the addition of base to maintain pH at a set point. In the beginning of the culture, the cell density is low and hence the rate of proton production is expected to be correspondingly low. The simultaneous addition of two m-pHmHs at the beginning of culture to reduce the pH decrease can cause a large initial overshoot in pH beyond 7. To avoid the initial overshoot in pH with two m-pHmHs, they were added to the culture in a staggered manner.

In staggered addition of two m-pHmHs, one m-pHmH was added at the time of inoculation and another was added 2 h after inoculation (Fig. 3). The staggered addition of m-pHmHs allowed pH to be maintained above 6, resulting in a final optical density of 14. Figure 3 shows complete utilization of glucose in cultures containing two m-pHmHs.

Thus, even in the absence of additional buffer, the staggered addition of two m-pHmH was able to maintain pH above 6, resulting in a fivefold increase in biomass in complex medium supplemented with glucose.

E. coli K12 cultured in modified Wilms and Reuss medium containing glucose as a carbon source

In order to evaluate the ability of m-pHmH to maintain pH in defined minimal medium, these hydrogels were also tested with E. coli K12 cultivated in modified Wilms and Reuss medium.

E. coli K12 cultured in modified Wilms and Reuss medium containing no buffer

Initially, cultures were tested without any additional buffer. The addition of a single m-pHmH at the time of inoculation resulted in pH decreasing to 5.4 while the pH of the control cultures containing no m-pHmH decreased up to 4 as shown in Fig. 4. Despite the eventual decrease in pH, a fourfold increase in the final biomass yield was seen in the cultures containing m-pHmH. As seen with LB medium containing glucose, partial consumption of glucose was seen in both the cultures, containing no m-pHmH and a single m-pHmH indicating cellular metabolism is impaired due to the low culture pH.

E. coli K12 was cultured in modified Wilms and Reuss medium with and without m-pHmH. a Growth, b glucose consumption, and c pH profiles. Control, without m-pHmH (triangle), with single m-pHmH added at the time of inoculation (square) and with staggered addition of two m-pHmH, one added at the time of inoculation and the other 4-h post-inoculation (circle)

Staggered addition of two m-pHmHs, one at the time of inoculation and another 4 h after inoculation, maintained pH in the range 7.6–5.8 (Fig. 4) while glucose is available in the culture. Complete utilization of glucose was observed in these cultures after which culture pH increased, possibly due to the consumption of the predominant waste metabolite acetate [6, 13]. pH reaches a value similar to the culture pH in LB medium (compare to control culture pH in Table 1). The final optical density was 17. The staggered addition of two m-pHmHs could thus allow better cell growth without addition of additional buffer to the medium.

For some experimental designs, for example to mimic culture conditions upon scale-up, the actual maintenance of pH around 7 could be important instead of a simple increase in biomass. To assess if additional buffering of media could result in better maintenance of pH with m-pHmH, MOPS buffer at varying concentration was supplemented into the modified Wilms and Reuss media.

E. coli K12 cultured in modified Wilms and Reuss medium containing MOPS buffer

Initially, cultures were tested with medium containing 50 mM MOPS with staggered addition of two m-pHmH discs (Fig. 5). One m-pHmH was added at the time of inoculation and another after 4 h from the time of inoculation, while no m-pHmHs were added to the control culture. As expected, the presence of buffer resulted in higher cell density for the control culture, compared to growth in the absence of buffer (compare to control in Fig. 4), though the pH eventually decreased to 4.2. With the staggered addition of m-pHmHs, pH was maintained between 6.4 and 7.7 while glucose was available in the culture and the optical density reached 14. pH increases after glucose is completely consumed. Not surprisingly, complete utilization of glucose was seen in cultures with staggered addition of two m-pHmHs. Thus, staggered addition of m-pHmHs along with 50 mM MOPS buffer allowed better maintenance of pH.

E. coli K12 was cultured in modified Wilms and Reuss medium with 50 mM MOPS, with and without m-pHmH. a Growth, b glucose consumption, and c pH profiles. Legend same as in Fig. 4

To evaluate whether the addition of higher concentration of buffer could result in better pH management, we also evaluated the effect of using m-pHmHs with medium containing 200 mM MOPS. Control cultures grown in modified Wilms and Reuss medium containing 200 mM MOPS with no m-pHmH reached an optical density of 5.2. pH of the control cultures with 200 mM MOPS decreased to a minimum of 4.9 (Fig. 6) while staggered addition of two m-pHmHs as described above allowed pH to be maintained between 6.9 and 7.5 while glucose was available in the culture. A threefold increase in final biomass yield was observed with m-pHmH addition as compared to control cultures containing 200 mM MOPS. Complete utilization of glucose is seen in cultures with added m-pHmH, but not in the control. The addition of m-pHmHs along with 200 mM MOPS thus allowed better pH maintenance compared to other lower buffer concentrations, but the increase in buffer concentration increases the osmolarity of the medium, and may not be suitable for all applications.

E. coli K12 was cultured in modified Wilms and Reuss medium with 200 mM MOPS, with and without m-pHmH. a Growth, b glucose consumption, and c pH profiles. Legend same as in Fig. 4

It should be noted that the final optical density is similar with m-pHmH addition, whether in the presence or absence of additional buffer. Thus, if the goal is to maximize biomass, supplementation with additional buffer may not be necessary.

Application of m-pHmH to increase volumetric plasmid yield

We illustrate the application of m-pHmHs to increase volumetric plasmid yields in shake flasks.

Plasmid DNA yields from TOP10 E. coli strain transformed with a 5-kb pcDNA 3.1-based plasmid and cultured in LB supplemented with glucose in shake flasks were compared with and without m-pHmH. All cultures were supplemented with 100 μg/ml ampicillin. Staggered addition of two m-pHmHs, one at the time of inoculation and another after 2 h from the time of inoculation, resulted in a 3.5-fold increase in the biomass yield. Cultures were harvested 8 h post-inoculation. The average plasmid yield was 1.05 ± 0.01 μg/ml (95 % confidence interval) for the control and 4.8 ± 1.3 μg/ml (95 % confidence interval) for the culture with m-pHmH addition (the plasmid yields were similar for bolus glucose feeding between 0.5 and 2 %.). However, both these values were lower than the 8 μg/ml plasmid yield from overnight cultures in LB (without any addition of glucose) indicating that, in this case, even though addition of m-pHmH results in better results as compared to uncontrolled pH, bolus addition of glucose to LB at the beginning of the culture is detrimental to plasmid production.

Fed-batch cultures employing different feeding strategies have been used to increase plasmid yields in bioreactors [2, 7, 16]. To simulate a continuous glucose feeding strategy, in addition to pH management with m-pHmH, glucose was continuously released in the shake flask using a hydrogel instead of a bolus glucose supplementation at the initiation of the culture.

Addition of m-pHmH and glucose-loaded hydrogel increases plasmid yield significantly

Glucose was loaded in a HEMA:EGDMA hydrogel for in situ slow release. The hydrogel formulation used for the release of glucose reached equilibrium swelling in a day (Fig. 7a). Figure 7b shows the release rate of glucose through the glucose-loaded hydrogels. Glucose is released from the cylindrical hydrogel disc by diffusion. The release of payload by diffusion through a cylindrical disc can be described by the following empirical equation by Peppas et al. [9, 15].

where k is a constant for a particular system and n is the release exponent representing the release mechanism. The glucose-loaded hydrogels were not pre-swollen to prevent unnecessary loss of glucose. Since these hydrogels were not pre-swollen before addition to the culture, equilibrium swelling will not be achieved before addition to the culture indicating that the release mechanism may possibly be governed both by swelling and diffusion for the time duration under consideration. For a cylindrical geometry as in the case of the glucose-loaded hydrogels, in diffusion-controlled systems, n = 0.45 whereas for swelling controlled systems n = 0.89 [15]. A plot of the amount of glucose released vs. timen where n = 0.45 and 0.89 results in a r 2 value of 0.97 and 0.94, respectively, thus resulting in a better fit for the diffusion controlled mechanism.

Two sets of hydrogel-added cultures were evaluated to assess the requirement for pH management in the presence of slow glucose feeding through the glucose-loaded hydrogel. Cultures were set-up (a) with both glucose-loaded hydrogels and m-pHmH and (b) with only glucose-loaded hydrogels added to evaluate if pH management was necessary. In both cases, the hydrogel(s) were added when the OD of the culture reached around 2. Control cultures were cultured in LB with no hydrogels added and harvested after 14 h. Table 1 lists the final OD550, pH, and plasmid yields in the three conditions. The cultures with only the glucose-loaded hydrogels resulted in a 50 % increase in biomass; however, there was a 31 % decrease in plasmid yields as compared to the control cultures. This could be a result of reduced pH. The cultures with both the glucose-loaded hydrogels and m-pHmH showed a 348 % increase in OD and a 394 % increase in plasmid yields compared to the control cultures. The pH at the end of the culture was similar to the control. The plasmid yield per unit optical density for control culture is 3.1 ± 0.77 μg/OD600 ml, with only the glucose releasing hydrogel is 1.6 ± 0.26 and with glucose-releasing and pH-managing hydrogels is 3.4 ± 0.28. Thus, the plasmid yield per unit density is not statistically different for the control culture and the culture with glucose-releasing and pH-managing hydrogels. This indicates that the increase in plasmid yield is due to the increased biomass and not due to an increase in the plasmid yield per cell. We speculate that the lower plasmid yield per unit optical density with the use of only the glucose-releasing hydrogel is due to the decrease in culture pH.

Thus, continuous release of glucose along with m-pHmH in shake flasks resulted in better results than only the addition of glucose as a bolus or glucose loaded in a hydrogel. This illustrates the utility of such pH-managing hydrogels for microbial shake flask cultures in fed-batch mode.

Discussion

Control of culture pH is not easily possible in the widely used shake flask platform. Scheidle et al. [12] demonstrated the use of sodium carbonate-loaded silicone polymer to increase biomass in E. coli culture, albeit requiring additional buffering for use with the commonly used carbon source, glucose. The authors noted that systems showing enhanced base release in response to reducing pH need to be developed for small-scale cultures. We have previously described the use of hydrogels releasing Mg(OH)2 for pH management in animal cell cultures [10]. However, the rate of release of lactic acid in slow-growing animal cell cultures is slower than that of acetic acid in much faster growing E. coli culture. Correspondingly, the m-pHmH in this study have lower crosslinking and greater surface area compared to the pHmH described previously for cell culture. Similar to pHmH, though the m-pHmH hydrogel itself is not pH responsive, the release rate of base through m-pHmH is inversely proportional to pH, possibly due to the increase in solubility of base with decreasing pH. The m-pHmH hydrogels thus provide a means for in situ pH-responsive base release to counter the decrease in microbial culture pH due to acid formation owing to overflow metabolism. In addition to maintaining pH, the addition of m-pHmH also results in a collateral supply of Mg+2, which may be useful for some medium formulations (however, for the experiments described here, simple supplementation of medium with Mg+2 is insufficient to cause the ~350 % increase in biomass yields seen upon addition of m-pHmH, data not shown). The use of m-pHmH, without any additional buffering, allowed complete glucose utilization and increase in biomass yield of E. coli K12. Mg+2 is an essential cation whose concentration can be limiting in some medium formulations. The use of m-pHmH with additional buffer in the culture medium provided better pH maintenance, which could be useful to mimic culture behavior upon scale up in pH controlled bioreactors when used along with strategies to reduce oxygen limitation. The use of m-pHmH along with a glucose-releasing hydrogel in a shake flask resulted in a 394 % increase in volumetric plasmid yield demonstrating the utility of such hydrogel systems to mimic fed-batch cultures in shake flask cultures.

References

Büchs J (2001) Introduction of advantages and problems of shaken cultures. Biochem Eng J 7:91–98. doi:10.1016/S1369-703X(00)00106-6

Chen W, Graham C, Ciccarelli RB (1997) Automated fed-batch fermentation with feed-back controls based on dissolved oxygen (DO) and pH for production of DNA vaccines. J Ind Microbiol Biotechnol 18 (1):43–48. doi:10.1038/sj.jim.2900355

Hegde S, Pant T, Pradhan K, Badiger M, Gadgil M (2012) Controlled release of nutrients to mammalian cells cultured in shake flasks. Biotechnol Prog 28(1):188–195. doi:10.1002/btpr.729

Jeude M, Dittrich B, Niederschulte H, Anderlei T, Knocke C, Klee D, Buchs J (2006) Fed-batch mode in shake flasks by slow-release technique. Biotechnol Bioeng 95(3):433–445. doi:10.1002/bit.21012

Künzler JF (2002) Hydrogels. In: Encyclopedia of polymer science and technology. Wiley, doi:10.1002/0471440264.pst158

Luli GW, Strohl WR (1990) Comparison of growth, acetate production, and acetate inhibition of Escherichia coli strains in batch and fed-batch fermentations. Appl Environ Microbiol 56(4):1004–1011

O’Kennedy RD, Ward JM, Keshavarz-Moore E (2003) Effects of fermentation strategy on the characteristics of plasmid DNA production. Biotechnol Appl Biochem 37(Pt 1):83–90. doi:10.1042/BA20020099

Panula-Perälä J, Siurkus J, Vasala A, Wilmanowski R, Casteleijn MG, Neubauer P (2008) Enzyme controlled glucose auto-delivery for high cell density cultivations in microplates and shake flasks. Microb Cell Fact 7. doi:10.1186/1475-2859-7-31

Peppas NA, Bures P, Leobandung W, Ichikawa H (2000) Hydrogels in pharmaceutical formulations. Eur J Pharm Biopharm 50(1):27–46

Pradhan K, Pant T, Gadgil M (2012) In situ pH maintenance for mammalian cell cultures in shake flasks and tissue culture flasks. Biotechnol Prog 28(6):1605–1610. doi:10.1002/btpr.1614

Presser KA, Ross T, Ratkowsky DA (1998) Modelling the growth limits (growth/no growth interface) of Escherichia coli as a function of temperature, pH, lactic acid concentration, and water activity. Appl Environ Microbiol 64(5):1773–1779

Scheidle M, Dittrich B, Klinger J, Ikeda H, Klee D, Buchs J (2011) Controlling pH in shake flasks using polymer-based controlled-release discs with pre-determined release kinetics. BMC Biotechnol 11:25. doi:10.1186/1472-6750-11-25

Scheidle M, Klinger J, Buchs J (2007) Combination of on-line pH and oxygen transfer rate measurement in shake flasks by fiber optical technique and respiration activity monitoring system (RAMOS). Sensors 7(12):3472–3480. doi:10.3390/s7123472

Sezonov G, Dl Joseleau-Petit, D’Ari R (2007) Escherichia coli physiology in Luria-Bertani broth. J Bacteriol 189(23):8746–8749. doi:10.1128/jb.01368-07

Siepmann J, Peppas NA (2001) Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv Drug Del Rev 48 (2–3):139–157. doi:10.1016/S0169-409X(01)00112-0

Silva F, Queiroz JA, Domingues FC (2012) Plasmid DNA fermentation strategies: influence on plasmid stability and cell physiology. Appl Microbiol Biotechnol 93(6):2571–2580. doi:10.1007/s00253-011-3668-6

Weuster-Botz D (2005) Parallel reactor systems for bioprocess development. Adv Biochem Eng Biotechnol 92:125–143. doi:10.1007/b98916

Weuster-Botz D, Altenbach-Rehm J, Arnold M (2001) Parallel substrate feeding and pH-control in shaking-flasks. Biochem Eng J 7 (2):163–170. doi:10.1016/S1369-703X(00)00117-0

Wolfe AJ (2005) The acetate switch. Microbiol Mol Biol Rev 69(1):12–50. doi:10.1128/MMBR.69.1.12-50.2005

Acknowledgments

The authors gratefully acknowledge Dr. CV Satyanarayana for the analysis of Mg+2 concentrations. MG acknowledges financial support from CSIR.

Author information

Authors and Affiliations

Corresponding author

Additional information

R. Sanil and V. Maralingannavar contributed equally to this work.

Rights and permissions

About this article

Cite this article

Sanil, R., Maralingannavar, V. & Gadgil, M. In situ pH management for microbial culture in shake flasks and its application to increase plasmid yield. J Ind Microbiol Biotechnol 41, 647–655 (2014). https://doi.org/10.1007/s10295-014-1405-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-014-1405-8