Abstract

Lignocellulolytic enzymes are among the most costly part in production of bioethanol. Therefore, recycling of enzymes is interesting as a concept for reduction of process costs. However, stability of the enzymes during the process is critical. In this work, focus has been on investigating the influence of temperature and ethanol on enzyme activity and stability in the distillation step, where most enzymes are inactivated due to high temperatures. Two enzyme mixtures, a mesophilic and a thermostable mixture, were exposed to typical process conditions [temperatures from 55 to 65 °C and up to 5 % ethanol (w/v)] followed by specific enzyme activity analyses and SDS-PAGE. The thermostable and mesophilic mixture remained active at up to 65 and 55 °C, respectively. When the enzyme mixtures reached their maximum temperature limit, ethanol had a remarkable influence on enzyme activity, e.g., the more ethanol, the faster the inactivation. The reason could be the hydrophobic interaction of ethanol on the tertiary structure of the enzyme protein. The thermostable mixture was more tolerant to temperature and ethanol and could therefore be a potential candidate for recycling after distillation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bioethanol produced from lignocellulosic residues and other renewable sources has lesser CO2 impact on environment than gasoline. It is therefore predicted to be one of the major substitutes for fossil fuels in the future energy system. To accomplish this fuel replacement, bioethanol has to be cost competitive with oil. So far, the bioethanol process from lignocellulosic materials is costly and non-competitive with gasoline, and therefore cost-reducing initiatives are needed [23]. Due to price and amounts of lignocellulolytic enzymes required, one of the major process costs is the enzymatic hydrolysis [14]. Despite efforts to reduce the costs of enzymes, they still represent up to 22 % of the total ethanol production costs and up to 50 % of the running costs of simultaneous saccharification and fermentation [8, 19].

Several strategies are used to reduce the price of enzymes or the application costs. This includes reducing enzyme production costs, improving enzyme cocktails, increasing specific enzyme activities, improving enzyme stability, and recycling enzymes within the process [24, 28]. Much effort has been put into production and optimization of enzymes, a process which has been accelerated by a growing interest and investment in research by the large enzyme-producing companies [41]. In the beginning of 2012, the two leading producers of lignocellulolytic enzyme mixtures, Novozymes (Denmark) and Genencor (CA, USA), launched their latest generation of products, Cellic CTec 3 and Accellerase Trio, respectively. Both enzyme mixtures are claimed to reduce enzyme loading up to twofold and thereby reduce enzyme costs and overall process expenses [9, 25]. Moreover, today’s commercial enzyme mixtures have better stability and activity, which enhance the possibilities of recycling for numerous rounds of hydrolysis [34]. Another approach to improve the financial feasibility is to operate the process at high dry matter content (above 15–20 %) in order to get at least 4 % (w/w) ethanol in the final fermentation broth, which is required for economical distillation of ethanol [16, 19].

From an operational point of view, enzyme recycling is one of several strategies for reducing the overall enzyme costs. The efficiency of enzyme recycling is highly dependent on the design of the bioethanol process. Enzyme recycling can be divided into two steps; recovery and recycling. The major bottleneck in enzyme recovery is the 20–30 % lignin found in lignocellulosic biomass, which has a strong binding affinity to many of the enzymes [24, 36, 37]. Besides lignin, high temperatures and inhibitors can also affect the stability and recovery of enzymes. Much applied research within recovery and recycling of enzymes is performed at low dry matter loadings (<10 %) during hydrolysis because unit operations become more complicated at high dry matter loadings [21, 29, 31]. The major part of bioethanol demonstration and pilot plants in Europe uses simultaneous saccharification and fermentation (SSF) meaning that enzyme recovery should happen after fermentation [12, 19]. However, separation of enzymes from the slurry before distillation is critical due to the potential loss of ethanol. After distillation, the enzymes can be recovered and recycled back in the process. However, the ethanol stripping involves heating, which can be harmful to the enzymes. Consequently, temperature and retention time in the distillation unit are critical parameters due to the heat sensitivity of most cellulolytic enzymes.

Two challenges should be solved before considering recycling after distillation; ethanol concentrations and temperature. During hydrolysis, it has been found that ethanol is a non-competitive inhibitor binding to the allosteric site of the enzyme, e.g., cellulase, which results in reversible denaturation because of the solvent properties of ethanol [15]. At elevated temperatures, the destabilizing effect of ethanol can accelerate denaturation of the enzyme even when the temperature itself does not cause protein denaturation [45]. Ethanol destroys the tertiary hydrophobic interactions in the enzyme, breaking or loosening the compact structure of the enzyme [30, 46]. Ethanol concentrations above 4 % (w/w) are favorable, as the energy consumption for distillation is markedly reduced and hence the process costs are decreased [19]. However, ethanol concentrations as low as 2 % (w/v) are enough to reduce the overall activity of cellulases from Trichoderma reesei [11, 32]. Podkaminer et al. illustrated the influence of ethanol on T. reesei enzymes when increasing temperature. Ethanol had a large effect on enzyme activity at 50 °C compared to no effect at 37 °C, which indicated that ethanol combined with high temperature had a negative effect on enzyme activity during hydrolysis [27]. Furthermore, raising the temperature will shorten the half-life for most mesophilic lignocellulolytic enzymes dramatically [22]. The challenge of maintaining enzyme activity and stability at high temperatures and increased ethanol concentration could possibly be overcome by using thermostable lignocellulolytic enzymes in the bioethanol process.

Normally, ethanol is distilled at 78.4 °C (boiling point), which is well above the optimum for most enzymes present. However, systems exist to strip off ethanol at lower temperature, e.g., vacuum distillation. This work is part of the EU FP7 funded project HYPE, which has also involved work on novel systems that allow ethanol stripping at lower temperatures by employing a diabatic Jensen distillation system. Based on this work, realistic process conditions are temperatures down to 60 °C and a residence time of <15 min (pers. comm., Børge Holm Christensen, Biosystemer Aps., Ålsgårde, Denmark).

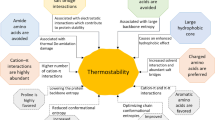

Another part of the HYPE project has been the development of thermostable enzyme preparations. Thermostability of an enzyme is usually defined as the retention of activity after heating the enzymes at a certain temperature for a prolonged period [38]. Thermostable enzymes are known for their higher specific activity, greater stability, and reduced hydrolysis time; advantages that can lower the process costs by reducing enzyme dosage [38, 39]. In addition, due to their increased stability at temperatures close to distillation temperatures, they are potentially interesting with respect to recycling. Improvement of thermostable enzymes is ongoing regarding development at molecular scale and usage at large scale. Genetic engineering used for improvement of thermostable cellulases with higher optimum temperature or better activity are addition of extra disulphide bonds in the protein [39], covalent linking of chitosan to cellulase [6] and structure-guided recombination with addition of stabilizing blocks in the protein [13]. Besides demonstrating the effects of genetic engineering, the advantage of using thermostable enzymes in a bioethanol process has also been demonstrated. For example, liquefaction of pre-treated biomass at increased temperatures using thermostable cellulases was shown to decrease viscosity efficiently [33], while thermostable xylanases were shown to promote the hydrolysis efficiency at raised temperatures [47]. In addition, thermostable cellulases have been shown to be pH-tolerant at increased temperatures, which eases the possibilities of process design [3, 7]. Overall, thermostable cellulases and xylanases are shown to be likely candidates for enzyme recycling.

In this study, it was investigated whether a thermostable lignocellulolytic enzyme mixture would have superior performance compared to a mesophilic mixture with regard to the combined effect of temperature and ethanol. The experimental design was chosen to mimic the conditions to which enzymes will be exposed during distillation in vacuum distillation or in a Jensen distillation system at an industrial scale. Enzyme activity and protein stability were measured to understand how the enzymes are influenced by thermal and chemical changes. In addition, the possible additive effect of high temperature and high ethanol concentration was considered during the measurements.

Materials and methods

Enzymes

Two enzyme mixtures were tested; a commercial and a thermostable mixture. The commercial enzyme mixture (CN mix) consisted of Celluclast, which contains enzymes from T. reesei, and Novozym188 (NZ188), which contains β-glucosidase from Aspergillus niger. They were both gifts from Novozymes (Bagsværd, Denmark). Celluclast and NZ188 were mixed at a ratio of 5:1 (w/w). The thermostable enzyme mixture (Thermomix) contained 51 % cellobiohydrolase I (CBHI) protein from Acremonium thermophilum, 17 % CBHII from Chaetomium thermophilum, and 13 % endoglucanase II (EGII), 14 % endo-xylanase (XYL), and 5 % β-glucosidase (BG) from Thermoascus aurantiacus. Thermomix was a kind gift from Roal Oy (Rajamäki, Finland).

Protein content

The protein content of the enzyme mixtures was measured by ninhydrin assay described by Tu [35]. In safe-lock Eppendorf tubes, a 40 μl sample was mixed with 60 μl 13.5 M NaOH and autoclaved 121 °C, 20 min. NaOH was neutralized by the addition of 100 μl glacial acetic acid followed by addition of 200 μl 2 % ninhydrin reagent (N7285, Sigma). Tubes were heated 20 min, 100 °C followed by addition of 1,000 μl 50 % ethanol (v/v). Absorbance of the solutions was measured at 570 nm. Tubes were vortexed between each step and samples were measured in triplicate. Bovine serum albumin was used as standard (A2153, Sigma).

Ethanol and temperature tolerance in buffer

The influence of temperature and ethanol content on enzyme activity were tested in 1.5-ml Eppendorf tubes. The tubes were filled with 50 mM sodium citrate buffer, pH 4.8, containing 0–5 % ethanol (w/v), and pre-heated to 55–65 °C in a heating block. The total concentration of CN mix or Thermomix was 2 mg enzyme protein/ml. Enzyme was added to the heated tubes, vortexed, and directly returned to the heating block. Samples were taken by moving tubes from the heating block to ice without opening them. Afterwards, the tubes were stored at −18 °C until further analysis. The ethanol content of the buffers was measured by HPLC as described by Kristensen et al. [18].

Filter paper activity

Total cellulase activity was measured by filter paper activity on a small scale following the procedure described by Xiao et al. [44]. The only change was that the 50 °C hydrolysis was run for 2 h instead of 1 h in order to minimize the background noise. Samples were measured in triplicate.

β-glucosidase activity

Activity of β-glucosidase was measured at microtiter scale. Substrate [5 mM p-nitrophenyl-β-d-glucopyranoside (N-7006, Sigma)] and standard [5 mM p-nitrophenol (6798, Merck)] were diluted in 50 mM sodium citrate buffer, pH 4.8. In 96-well flat-bottom microtiter plates, 20 μl of diluted sample was mixed with 100 μl of substrate and incubated for 15 min at 50 °C. The reaction was terminated by the addition of 120 μl 0.4 M glycine buffer, pH 10.8, followed by absorbance measurement at 405 nm [42]. Samples were measured in triplicate.

Endoglucanase and endoxylanase activity using azo dyes

Endoglucanase activity for the samples was measured using azo-CM-cellulose (Megazyme, Ireland) as a substrate. The substrate solution contained 1 g azo-CM-cellulose mixed with 100 ml 50 mM sodium acetate buffer, pH 4.8. Precipitation solution contained 40 g sodium acetate trihydrate and 4 g zinc acetate diluted in 200 ml of deionized water, which was mixed with 800 ml 96 % ethanol (v/v) as described by Megazyme. The standard was the respective enzyme mixture. A total of 100 μl of diluted sample or standard was added to a 1.5-ml Eppendorf tube and pre-equilibrated to 50 °C. Quickly, 100 μl of substrate solution was added to the tubes and mixed well. After 10-min incubation, reaction was terminated by the addition of 500 μl precipitation solution. Samples were cooled for 5 min before centrifugation for 10 min, 3,300 rpm, 1,000 × g. Absorbance was measured at 595 nm.

Endoglucanase activity for CN mix and Thermomix was measured following the procedure described by Ghose et al. [10].

Endoxylanase activity for the samples was measured using azo-xylan (birchwood) (Megazyme, Ireland) as a substrate. The endoxylanase assay followed the same procedure as for endoglucanase, except that the substrate solution was 100 ml 50 mM sodium acetate buffer, pH 4.8, mixed with 0.5 g azo-xylan and precipitation solution was 96 % ethanol (v/v). Xylanase activity for CN mix and Thermomix was measured following the procedure described by Bailey et al. [1].

Cellobiohydrolase activity

Measurement of the activity of cellobiohydrolase I was performed as described in [2, 5]. A 1 mM 4-methylumbelliferyl-β-d-lactopyranoside solution diluted in 0.1 M sodium acetate buffer, pH 4.8 was used as substrate, and 1 M sodium carbonate was used to terminate the reaction. The standard was mixed from a 1 mM 4-methylumbelliferone sodium salt. Samples were diluted and 10 μl was pipetted to a black-bottom 96-well UV fluorescence microplate. One sample was mixed with 10 μl 1.0 M glucose and another sample was mixed with 10 μl 1.0 M glucose and 50 mM cellobiose in sodium acetate buffer to inhibit β-glucosidase and cellobiohydrolase activity. Another well only contained cellobiose and glucose (blank). Samples were mixed with 80 μl substrate solution and incubated 15 min at 50 °C. Reaction was terminated by the addition of 100 μl 1 M sodium carbonate. To wells containing only glucose and cellobiose, a 10-μl sample was added and used as a blank. Sample fluorescence was measured with excitation 360 nm and emission 460 nm.

SDS-PAGE

For protein detection, enzyme mixtures and buffer samples were diluted in deionized water to obtain a protein concentration of 0.5–1.0 mg/g. Diluted samples and Laemmli Sample Buffer, containing 5 % 2-mercapthoethanol (v/v) were mixed 1:1 in Eppendorf tubes. Samples were heated 5 min, 95 °C, cooled, and 25 μl loaded on a Criterion TGX Stain-Free Precast Gel, 4–20 %. Precision Protein Plus Unstained Standard was used as standard. The gel was run for 45 min with Tris/Glycine/SDS buffer. The power conditions were 200 V (constant), and a starting and final current of 55–80 and 33–43 mA, respectively. Gel imaging was done by transferring the gel to a stain-free tray and using Gel Doc EZ System. Gel images were analyzed using the Image Lab Software. Buffers, gels, and gel imaging hardware and software were all from Bio-Rad (Hercules, CA, USA).

Results and discussion

Individual enzyme activity and protein content

Filter paper activity and individual enzyme activities were measured together with the protein content of CN mix and Thermomix (Table 1). The enzyme loading used in the experiments was based on protein content, hence the specific enzyme activities are also shown. Thermomix differs from CN mix by its high β-glucosidase and very high endoxylanase activity. The specific filter paper activity, which only measure cellulase activity, was the same for both mixtures.

Enzyme activity at high temperatures

The thermostability of mesophilic CN mix (Celluclast and Novozym188 from Novozymes) and Thermomix (mixture from Roal Oy) was tested in 50 mM sodium citrate buffer, pH 4.8. Within the first 2 min of incubation at 55–65 °C, no significant change in filter paper activity was seen for any of the two mixtures (Fig. 1). For CN mix, a 50 % reduction in filter paper activity was seen at 60 and 65 °C after 15 and 5 min, respectively. For Thermomix, <50 % filter paper activity was not observed before 10 min incubation at 65 °C, while the activity was at least 90 % after 10 min at 55 and 60 °C (Fig. 1). Interestingly, the activity of Thermomix fell to 90 % within the first 3 min of incubation at 60 °C and hereafter remained stable. The reasons may be that one of the enzymes in Thermomix was more temperature sensitive than the others. However, the thermostable enzymes are expressed in a Trichoderma strain and a more likely reason is that the drop in activity reflects inactivation of some of the background activity of native cellulase present in Thermomix.

Overall, CN mix was sensitive to temperatures above 60 °C, whereas Thermomix remained stable at 65 °C based on filter paper activity.

Enzyme activity at high temperatures and high ethanol concentrations

The influence of high temperature and ethanol concentrations up to 5 % (w/v) on enzyme activity was measured for CN mix and Thermomix. The ethanol concentrations tested were chosen based on the concentrations that are likely reached in an average lignocellulosic bioethanol plant [19]. Samples were taken after 2, 5, and 10 min to explore both long- and short-term effects of temperature on enzyme activity in relation to distillation. When adding ethanol to the samples at 55 °C, no remarkable change was seen for either of the enzyme mixtures, indicating that they were still within their limits of functionality (Fig. 2). Increasing the temperature to 60 °C resulted in a drop in enzyme activity for CN mix, which was further accelerated by addition of ethanol, i.e., the more ethanol the less filter paper activity. This tendency was even more distinct at 65 °C for both CN mix and Thermomix. The filter paper activity after 5 min at 65 °C with 0 and 5 % ethanol was for CN mix 48 ± 0.2 and 6 ± 1.9 %, respectively, and for Thermomix 80 ± 0.9 and 43 ± 0.6 %, respectively. The combined negative effect of increased temperature and high ethanol concentration has also been observed during hydrolysis at up to 5 % dry matter [26, 27, 43]. For example, Podkaminer et al. tested the activity of a commercial T. reesei-mixture at 37 and 50 °C in a 100 h hydrolysis with up to 8 % ethanol (w/v) in the solution [27]. At 37 °C, the relative residual activity of the ethanol containing solutions were nearly equal after 100 h, while an increase of temperature to 50 °C resulted in a larger activity drop for solutions containing 6–8 % ethanol compared to 0 % ethanol. For example, the enzyme activity after 24-h incubation at 50 °C with 0 and 6 % ethanol was 87 and 62 % of max, respectively, while the activity in both cases was above 90 % when incubating 24 h at 37 °C [27]. In our study, samples were diluted at least tenfold before measuring the enzyme activity to avoid ethanol inhibition while running the activity assay. Therefore, we are confident that the effect of ethanol on loss of activity is not related to inhibition but rather destabilization of the enzymes. The results indicate that mixtures containing the well-studied T. reesei enzymes are not suitable for recovery and recycling after distillation due to inactivation. On the other hand, Thermomix has potential for recycling when tested in buffer. However, more studies are required since the experimental setup was in buffer and not slurry from a bioethanol plant. It is generally known that cellulases are more stabilized when in a mixture containing biomass compared to pure buffer. Hence, Thermomix could be imagined to perform even better when in a mixture containing substrate.

Influence of temperature and ethanol on specific enzyme activities

Measurement of filter paper activity describes the overall activity of cellulases, and not the activity of the individual cellulases or the hemicellulases. Individual classes of enzymes are presumably not equally stable. Therefore, the activity of β-glucosidase, endoglucanase, and cellobiohydrolase was measured to identify which enzymes could be the cause of reduced filter paper activity. In addition, endoxylanase was measured because it was the only hemicellulase present in Thermomix.

Generally, the measured individual activities remained stable at 55 °C, except for the endoxylanase in CN mix, which dropped after 10 min at 5 % ethanol (c, Fig. 3). At 65 °C, specific enzyme activities of Thermomix did not change remarkably except for cellobiohydrolase (Fig. 3, e–h), whereas several activities within the CN mix were quite affected by temperature (Fig. 3, a–d). The β-glucosidase activity in CN mix at 65 °C was unaffected the first 2 min of incubation, but after 10 min incubation with 0 and 5 % ethanol it was reduced to 75 ± 4.2 and 18 ± 2.1 % of max, respectively. Again, ethanol was shown to influence enzyme activity during incubation at high temperature. The same pattern was seen for endoglucanase, cellobiohydrolase, and endoxylanase activity in CN mix. The endoglucanase activity after 10-min incubation at 0 and 5 % ethanol was 59 ± 1.2 and 44 ± 0.6 % of max, respectively, cellobiohydrolase activity was 5.3 ± 1.1 and 0.6 ± 0.1 at 0 and 5 % ethanol, respectively, while the endoxylanase activity was 15 ± 3.0 and 4 ± 0.6 %, respectively. Ethanol has been shown to destabilize proteins at elevated temperatures, where the temperature itself would not cause denaturation of the protein [45]. Previous results have indicated that xylanases from T. reesei may be more sensitive to ethanol compared to the cellulases (β-glucosidase and endoglucanase) even at low temperatures [32]. By exposing CN mix to temperatures above 65 °C for a few minutes, most of the enzyme activity is lost. It is therefore not the optimal mixture if recycling after distillation is planned unless the distillation temperature is below 60 °C and the retention time is very short, i.e., minutes.

For Thermomix, a decrease in specific enzyme activity at 65 °C was expected according to the filter paper activity data (Fig. 2). Interestingly, the β-glucosidase and endoglucanase activities for Thermomix remained mostly above 90 % of initial activity, while cellobiohydrolase activity decreased markedly at 65 °C. Endoglucanase activity was reduced to 81 ± 4.1 % of the maximum after 10 min incubation in 5 % ethanol at 65 °C. The reduced activity is probably due to the presence of ethanol and not because of high temperature since this endoglucanase from T. aurantiacus has been shown to be stable at temperatures up to 75 °C [33]. Recently, hydrolysis performance and temperature stability were measured for the endoxylanase (also from T. aurantiacus) in Thermomix. The results indicated that even when incubating for 24 h at 65 °C the endoxylanase remained active, which is similar to our results [47]. Concerning the specific activities for Thermomix, most enzymes performed well at 65 °C except the cellobiohydrolases, which seemed to be the weak point. To improve the performance of Thermomix, the cellobiohydrolases should be replaced with a more thermostable version.

Enzyme protein stability at high temperatures

The major reason why the activity of an enzyme decreases at higher temperatures is due to a change in the tertiary structure of the protein causing denaturation and degradation. For an enzyme to function optimally, the conformation of the active site is obviously crucial, but in the case of cellulases, the surface conformation of the enzyme can also be critical in order to ensure recognition and correct binding/attachment to the solid substrate. In this respect, the cellulose-binding domain and the conformation around the active site plays an important role [4]. Changes in the tertiary structure, which can lead to denaturation and subsequent degradation, can be caused by thermal energy from heat (increased temperature) and extreme pH as well as strong chemicals that disrupt the weak non-covalent bonds in the conformation of the native enzyme protein [20].

Measurement of filter paper activity (Fig. 2) and specific enzyme activities (Fig. 3) indicated that CN mix and Thermomix was affected by thermal energy. To figure out whether the decreased enzyme activity was due to conformational changes or due to degradation of the enzyme, samples taken at 55 and 65 °C incubated in up to 5 % ethanol were analyzed by SDS-PAGE (Fig. 4).

SDS-PAGE of CN mix (a) and Thermomix (b). Lane 1 10 min, 55 °C, 0 % ethanol; Lane 2 10 min, 55 °C, 5 % eth.; Lane 3 65 °C, 0 % eth., 2 min; Lane 4 65 °C, 0 % eth., 10 min; Lane 5 65 °C, 5 % eth., 2 min; Lane 6 65 °C, 5 % eth., 10 min; Lane 7 control (enzyme mixture not exposed to heat or ethanol). BG β-glucosidase, CBH cellobiohydrolase, EG endoglucanase, XYL endoxylanase

The interpretation of bands from CN mix was based on the MW (kDa) given by [28], while the data for Thermomix was given by SDS-PAGEs run of the individual enzymes in the mixture (data not shown) and by [33, 40]. The intensity of the bands for CN mix and Thermomix was not equal because the ratio of lignocellulolytic enzymes differs in the two mixtures.

For both CN mix and Thermomix, the 55 °C samples in lanes 2 and 3 were equal to the control in lane 7 (Fig. 4a, b), which confirmed the results illustrated in Fig. 2. For CN mix (Fig. 4a), β-glucosidase (~98 kDa) and CBH (~66–70 kDa) bands had less intensity after 10-min incubation (lanes 4 and 6) compared to the bands seen after 2 min (lanes 3 and 5). The band for EG II (~51 kDa) in CN mix remained unchanged at all conditions, which is contradictory to the measured endoglucanase activities (Fig. 3). However, T. reesei is reported to secrete at least five endoglucanases and it is not known which of the T. reesei endoglucanases that accounts for the reduced activity shown in Fig. 3. According to Karlsson et al., the optimal temperature after 30 min incubation for EG II (Cel5A) and EG III (Cel12A) was 70 and 50 °C respectively [17]. These results indicate that EGIII is more sensible than EGII when operating at high temperatures and hence confirm the strong EG II band observed on the SDS-PAGE gel even after 10 min incubation at 65 °C. Combining the SDS-PAGE data for the control (lane 7) with the kDa-weight given in [28], it was not possible to quantify the EG III to confirm the results of Karlsson et al., since the quantities of the remaining EGs in CN mix was low and some proteins cannot be separated by SDS-PAGE. The reduced endoglucanase activity at 65 °C in CN mix could therefore be due to the other endoglucanases present in the mixture. On the other hand, the EG II band shows that the protein size is intact, but does not describe how active the enzyme is. As a consequence, the low endoglucanase activity could also be due to a moderated active site in EG II (or the other endoglucanases).

The individual activities of β-glucosidase, endoglucanase, and endoxylanase remained stable at 65 °C when testing Thermomix. However, filter paper activity decreased at this temperature, which indicated that one or more cellulases were inactivated during heat treatment. In Fig. 4b, the CBH band (~68 kDa) was fainting after 10 min incubation at 65 °C (lanes 4 and 6), indicating that the enzyme was degrading. Furthermore, the bands around 10, 24, and 37 kDa became stronger, which could be due to fragments from the degraded enzyme proteins.

Overall, the SDS-PAGE analysis revealed that in certain conditions, the loss of activity could indeed be correlated directly to the degradation of enzymes. The CBHs represented in both enzyme mixtures turned out to be markedly degraded after 10 min treatment at 65 °C, which relates to the specific activity of CBHI as well as reduced filter paper activities. For the other enzymes, the conformation remained intact for both CN mix and Thermomix.

Conclusions

When increasing temperature, the activity of both CN mix and Thermomix decreased. The decrease was more pronounced when ethanol was added. High temperature and increased ethanol concentrations were thus shown to have a combined negative effect on enzyme activity. Where loss in activity was observed at 60 °C for CN mix an effect of temperature and ethanol was not seen for Thermomix until at 65 °C. According to SDS-PAGE results, the activity of cellobiohydrolase was caused by degradation of the enzyme protein, while the loss in activity of β-glucosidase, endoglucanase, and endoxylanase was primarily due to structural changes within the enzymes.

In this study it was shown that using thermostable enzyme in a bioethanol process would be an advantage if recovery and recycling after distillation is planned. However, increased temperature and high ethanol content should both be taken into consideration due to the combined negative effect on activity and stability.

References

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23(3):257–270

Bailey MJ, Tahtiharju J (2003) Efficient cellulase production by Trichoderma reesei in continuous cultivation on lactose medium with a computer-controlled feeding strategy. Appl Microbiol Biotechnol 62(2–3):156–162. doi:10.1007/s00253-003-1276-9

Boer H, Koivula A (2003) The relationship between thermal stability and pH optimum studied with wild-type and mutant Trichoderma reesei cellobiohydrolase Cel7A. Eur J Biochem 270(5):841–848. doi:10.1046/j.1432-1033.2003.03431.x

Boraston AB, Bolam DN, Gilbert HJ, Davies GJ (2004) Carbohydrate-binding modules: fine-tuning polysaccharide recognition. Biochem J 382(Pt 3):769–781. doi:10.1042/BJ20040892

Claeyssens M, Aerts G (1992) Characterization of cellulolytic activities in commercial Trichoderma reesei preparations—an approach using small, chromogenic substrates. Bioresour Technol 39(2):143–146. doi:10.1016/0960-8524(92)90133-I

Darias R, Villalonga R (2001) Functional stabilization of cellulase by covalent modification with chitosan. J Chem Technol Biotechnol 76(5):489–493

Farinas CS, Loyo MM, Baraldo A, Tardioli PW, Neto VB, Couri S (2010) Finding stable cellulase and xylanase evaluation of the synergistic effect of pH and temperature. New Biotechnol 27(6):810–815

Galbe M, Zacchi G (2002) A review of the production of ethanol from softwood. Appl Microbiol Biotechnol 59(6):618–628. doi:10.1007/s00253-002-1058-9

Genencor (2012) Datasheet for Accelerase Trio. Available via Genencor’s homepage http://www.genencor.com. Accessed 11 Dec 2012

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59(2):257–268

Ghosh P, Pamment NB, Martin WRB (1982) Simultaneous saccharification and fermentation of cellulose—effect of beta-d-glucosidase activity and ethanol inhibition of cellulases. Enzyme Microb Tech 4(6):425–430

Gnansounou E (2010) Production and use of lignocellulosic bioethanol in Europe: current situation and perspectives. Bioresour Technol 101(13):4842–4850. doi:10.1016/j.biortech.2010.02.002

Heinzelman P, Snow CD, Wu I, Nguyen C, Villalobos A, Govindarajan S, Minshull J, Arnold FH (2009) A family of thermostable fungal cellulases created by structure-guided recombination. Proc Natl Acad Sci USA 106(14):5610–5615. doi:10.1073/pnas.0901417106

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807. doi:10.1126/science.1137016

Holtzapple M, Cognata M, Shu Y, Hendrickson C (1990) Inhibition of Trichoderma Reesei cellulase by sugars and solvents. Biotechnol Bioeng 36(3):275–287

Jørgensen H, Vibe-Pedersen J, Larsen J, Felby C (2007) Liquefaction of lignocellulose at high-solids concentrations. Biotechnol Bioeng 96(5):862–870. doi:10.1002/Bit.21115

Karlsson J, Siika-aho M, Tenkanen M, Tjerneld F (2002) Enzymatic properties of the low molecular mass endoglucanases Cel12A (EG III) and Cel45A (EG V) of Trichoderma reesei. J Biotechnol 99(1):63–78

Kristensen JB, Felby C, Jørgensen H (2009) Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 2. doi:10.1186/1754-6834-2-11

Larsen J, Petersen MØ, Thirup L, Li HW, Iversen FK (2008) The IBUS process—lignocellulosic bioethanol close to a commercial reality. Chem Eng Technol 31(5):765–772. doi:10.1002/ceat.200800048

Lodish HBA, Matsudaira P, Kaiser CA, Krieger M, Scott MP, Zipursky SL, Darnell J (2004) Molecular cell biology, 5th edn. Freeman

Lu YP, Yang B, Gregg D, Saddler JN, Mansfield SD (2002) Cellulase adsorption and an evaluation of enzyme recycle during hydrolysis of steam-exploded softwood residues. Appl Biochem Biotech 98:641–654

Maheshwari R, Bharadwaj G, Bhat MK (2000) Thermophilic fungi: their physiology and enzymes. Microbiol Mol Biol R 64(3):461–488

Margeot A, Hahn-Hägerdal B, Edlund M, Slade R, Monot F (2009) New improvements for lignocellulosic ethanol. Curr Opin Biotech 20(3):372–380. doi:10.1016/j.copbio.2009.05.009

Merino ST, Cherry J (2007) Progress and challenges in enzyme development for biomass utilization. Biofuels 108:95–120. doi:10.1007/10_2007_066

Novozymes (2012) Datasheet for Cellic CTec 3. Available via Novozymes homepage http://bioenergy.novozymes.com. Accessed 12 Dec 2012

Ooshima H, Ishitani Y, Harano Y (1985) Simultaneous saccharification and fermentation of cellulose—effect of ethanol on enzymatic saccharification of cellulose. Biotechnol Bioeng 27(4):389–397

Podkaminer KK, Shao XJ, Hogsett DA, Lynd LR (2011) Enzyme inactivation by ethanol and development of a kinetic model for thermophilic simultaneous saccharification and fermentation at 50° C with Thermoanaerobacterium saccharolyticum ALK2. Biotechnol Bioeng 108(6):1268–1278. doi:10.1002/Bit.23050

Pribowo A, Arantes V, Saddler JN (2012) The adsorption and enzyme activity profiles of specific Trichoderma reesei cellulase/xylanase components when hydrolyzing steam pretreated corn stover. Enzyme Microb Tech 50(3):195–203. doi:10.1016/j.enzmictec.2011.12.004

Qi BK, Chen XR, Su Y, Wan YH (2011) Enzyme adsorption and recycling during hydrolysis of wheat straw lignocellulose. Bioresour Technol 102(3):2881–2889. doi:10.1016/j.biortech.2010.10.092

Shao Q, Fan Y, Yang L, Gao YQ (2012) From protein denaturant to protectant: comparative molecular dynamics study of alcohol/protein interactions. J Chem Phys 136(11):115101. doi:10.1063/1.3692801

Steele E, Raj S, Nghiem J, Stowers M (2005) Enzyme recovery and recycling following hydrolysis of ammonia fiber explosion-treated corn stover. Appl Biochem Biotech 121:901–910

Szczodrak J, Targonski Z (1989) Simultaneous saccharification and fermentation of cellulose—effect of ethanol and cellulases on particular stages. Acta Biotechnol 9(6):555–564

Szijarto N, Horan E, Zhang JH, Puranen T, Siika-aho M, Viikari L (2011) Thermostable endoglucanases in the liquefaction of hydrothermally pretreated wheat straw. Biotechnol Biofuels 4. doi:10.1186/1754-6834-4-2

Tu MB, Chandra RP, Saddler JN (2007) Evaluating the distribution of cellulases and the recycling of free cellulases during the hydrolysis of lignocellulosic substrates. Biotechnol Progr 23(2):398–406. doi:10.1021/Bp060354f

Tu MB, Chandra RP, Saddler JN (2007) Recycling cellulases during the hydrolysis of steam exploded and ethanol pretreated lodgepole pine. Biotechnol Progr 23(5):1130–1137. doi:10.1021/Bp070129d

Varnai A, Siika-Aho M, Viikari L (2010) Restriction of the enzymatic hydrolysis of steam-pretreated spruce by lignin and hemicellulose. Enzyme Microb Tech 46(3–4):185–193. doi:10.1016/j.enzmictec.2009.12.013

Varnai A, Viikari L, Marjamaa K, Siika-Aho M (2010) Adsorption of monocomponent enzymes in enzyme mixture analyzed quantitatively during hydrolysis of lignocellulose substrates. Bioresour Technol. doi:10.1016/j.biortech.2010.07.120

Viikari L, Alapuranen M, Puranen T, Vehmaanpera J, Siika-Aho M (2007) Thermostable enzymes in lignocellulose hydrolysis. Biofuels 108:121–145. doi:10.1007/10_2007_065

Voutilainen SP, Murray PG, Tuohy MG, Koivula A (2010) Expression of Talaromyces emersonii cellobiohydrolase Cel7A in Saccharomyces cerevisiae and rational mutagenesis to improve its thermostability and activity. Protein Eng Des Sel 23(2):69–79. doi:10.1093/protein/gzp072

Voutilainen SP, Puranen T, Siika-Aho M, Lappalainen A, Alapuranen M, Kallio J, Hooman S, Viikri L, Vehmaanpera J, Koivula A (2008) Cloning, expression, and characterization of novel thermostable family 7 cellobiohydrolases. Biotechnol Bioeng 101(3):515–528. doi:10.1002/Bit.21940

Wilson DB (2009) Cellulases and biofuels. Curr Opin Biotech 20(3):295–299. doi:10.1016/j.copbio.2009.05.007

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Method Enzymol 160:87–112

Wu Z, Lee YY (1997) Inhibition of the enzymatic hydrolysis of cellulose by ethanol. Biotechnol Lett 19(10):977–979. doi:10.1023/A:1018487015129

Xiao ZZ, Storms R, Tsang A (2004) Microplate-based filter paper assay to measure total cellulase activity. Biotechnol Bioeng 88(7):832–837. doi:10.1002/Bit.20286

Yoshikawa H, Hirano A, Arakawa T, Shiraki K (2012) Effects of alcohol on the solubility and structure of native and disulfide-modified bovine serum albumin. Int J Biol Macromol 50(5):1286–1291. doi:10.1016/j.ijbiomac.2012.03.014

Yoshikawa H, Hirano A, Arakawa T, Shiraki K (2012) Mechanistic insights into protein precipitation by alcohol. Int J Biol Macromol 50(3):865–871. doi:10.1016/j.ijbiomac.2011.11.005

Zhang JH, Tuomainen P, Siika-aho M, Viikari L (2011) Comparison of the synergistic action of two thermostable xylanases from GH families 10 and 11 with thermostable cellulases in lignocellulose hydrolysis. Bioresour Technol 102(19):9090–9095. doi:10.1016/j.biortech.2011.06.085

Acknowledgments

This research was financed by the EU project HYPE, grant agreement no. 213139. The authors thank Roal Oy and VTT (Finland) for providing thermostable enzymes and Novozymes (Denmark) for providing Celluclast and Novozym188.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Skovgaard, P.A., Jørgensen, H. Influence of high temperature and ethanol on thermostable lignocellulolytic enzymes. J Ind Microbiol Biotechnol 40, 447–456 (2013). https://doi.org/10.1007/s10295-013-1248-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-013-1248-8