Abstract

Electrospun hollow polymeric microfibers (microtubes) were evaluated as an encapsulation method for the atrazine degrading bacterium Pseudomonas sp. ADP. Pseudomonas sp. ADP cells were successfully incorporated in a formulation containing a core solution of polyethylene oxide dissolved in water and spun with an outer shell solution made of polycaprolactone and polyethylene glycol dissolved in a chloroform and dimethylformamide. The resulting microtubes, collected as mats, were partially collapsed with a ribbon-like structure. Following encapsulation, the atrazine degradation rate was low (0.03 ± 0.01 mg atrazine/h/g fiber) indicating that the electrospinning process negatively affected cell activity. Atrazine degradation was restored to 0.5 ± 0.1 mg atrazine/h/g fiber by subjecting the microtubes to a period of growth. After 3 and 7 days growth periods, encapsulated cells were able to remove 20.6 ± 3 and 47.6 ± 5.9 mg atrazine/g mat, respectively, in successive batches under non-growth conditions (with no additional electron donor) until atrazine was detected in the medium. The loss of atrazine degrading capacity was regained following an additional cell-growth period.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Atrazine (2-chloro-4-ethylamino-6-isopropylamino-1,3,5-triazine) is a herbicide of the s-triazine family used for broad leaf and grassy weed control, primarily on corn, sorghum, and sugarcane. Its widespread presence in the environment eventually led to a ban in 2004 from use in all EU member states. In the United States, however, atrazine is still one of the most widely used herbicides, primarily in corn production for either food or fuel. As a consequence, persistent concentrations in drinking water have been frequently detected [1].

Biodegradation is an effective remediation method that can achieve atrazine removal. Complete mineralization of atrazine, involving dechlorination and ring cleavage, has been extensively examined with mixed and pure bacteria cultures in either soil or water [2–4]. Pseudomonas sp. ADP, one of the best characterized atrazine degrading bacterium, was isolated from an herbicide spill site and has been found to rapidly mineralize atrazine under aerobic and denitrifying conditions as well as under non-growth conditions [5–7]. Enriched cultures of Pseudomonas sp. ADP were successfully used in a biofilm reactor for atrazine removal from groundwater under aerobic conditions using citrate as the carbon source [8]. High removal efficiencies were limited to aerobic conditions with atrazine as the sole nitrogen source. However, in situ bioaugmentation using Pseudomonas sp. ADP has been less promising [9]. Lately, bioreactors using a consortium of bacteria with the ability to use atrazine as a carbon and nitrogen source have been investigated [10]. While successfully removing atrazine, they do not overcome the major drawbacks of bioreactor systems in general, namely problems associated with reactor biomass growth (sludge disposal), bacterial contamination, and effluent post treatment.

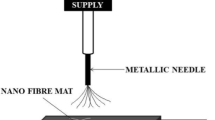

Under non-growth conditions, whole-cell encapsulation of Pseudomonas sp. ADP has the potential to overcome the drawbacks associated with in situ bioaugmentation and bioreactor systems by providing protection and preventing biomass loss while minimizing effluent post-treatment. Encapsulation of several atrazine degrading bacteria in various techniques have been reported including alginate encapsulation, cells entrapment in sol–gel and synthetic organic polymers [11–13]. The reported results, which vary in atrazine removal capabilities, demonstrate the complexity of developing an encapsulation method that preserves high cell viability upon encapsulation and throughout its use, while providing a long-term durable matrix. In the current work, we report a novel method for Pseudomonas sp. ADP immobilization that encapsulates the cells within electrospun core–shell microtubes. Electrospinning is a commonly used process for generating ultrafine polymer-based fibers with diameters ranging from tens to hundreds of nanometers. This technique has the beneficial characteristics of a large surface-to-volume ratio and variable permeability according to the microtube formulation used. Electrospun fibers can be produced from a variety of synthetic and natural polymers and are currently being used extensively in biomedical applications such as scaffolds and carriers for biologically active molecules such as proteins and enzymes [14]. In water-purification systems, the microtubes can potentially cover standard biofilm carrier surfaces, such as sand, plastic, and rocks. In previous research, the electrospinning solution setup was modified to achieve live microbial cell encapsulation and examined the ability of the microtube structure to support cell attachment and maintain the enzymatic activity of the encapsulated microbial cells [15]. In the specific application of atrazine degradation, the encapsulation and preservation of Pseudomonas sp. ADP cells in microtubes may provide a suitable platform for a bioremediation process without the addition of external electron donor.

The objectives of the present study were (1) to evaluate two formulations of electrospun microtubes to encapsulate live Pseudomonas sp. ADP cells (2) to examine the electrospinning impact on atrazine removal capacity of the encapsulated cells, and (3) to assess the sustained atrazine removal potential of the encapsulated cells in repeated batches under non-growth experimental conditions with no additional carbon source.

Materials and methods

Chemicals

Atrazine (2-choro-4-ethylamino-6-isopropylamino- s-triazine, 94 % technical grade) was kindly supplied by Agan Chemicals, Ashdod, Israel. A 1,000 mg atrazine/l stock solution dissolved in methanol (HPLC grade, Merck, Germany) was prepared as a standard. Hydroxy-atrazine (97 % purity) was purchased from Riedel–deHaen (Germany) and was prepared in the same manner as atrazine stock solution for HPLC use. All other chemicals were of reagent-grade quality or higher.

Bacteria and growth conditions

Pseudomonas sp. ADP (PubMed ID 47660) isolated from an herbicide spill site was used for the experiments [6]. The bacterium was routinely grown on atrazine agar medium at 30 °C for 3–4 days and in atrazine liquid growth medium (ATZ medium) at 30 °C on an orbital shaker at 180 rev/min. Both growth media were prepared according to previous work [6, 16] and contained 0.2 % (wt/vol) sodium citrate as the carbon source and atrazine as the only nitrogen source at concentration of either 20 mg/l (ATZ medium) or 150 mg/l (atrazine agar medium).

For encapsulation and free cell solution experiments, fresh ATZ medium with 10 % (v/v) Luria broth (LB) medium was inoculated with cultures that were grown in ATZ medium for two consecutive days. Cells were harvested by centrifugation and the resulting pellets were washed twice with double-distilled water. Cells were resuspended with 5 % glycerol to a total volume of 100 μl and then mixed with either 900 μl of core solution for further electrospinning or 0.85 % saline solution for free cell solution experiments. The average bacterial concentration used for electrospinning and free cell suspension assays was 2.54 ± 0.14 × 1010 CFU/ml.

Electrospinning

The compositions of the shell and core solutions are given in Table 1. All polymers were purchased from Sigma-Aldrich (USA) and were used as is. Core–shell fibers were fabricated by a co-electrospinning process using the set up described in previous work [1]. All experiments were conducted at room temperature (~23 °C) and a relative humidity of about 40 %. The spinning parameters were as follows: the electrostatic field used was approximately 0.7 kV/cm and the distance between the spinneret and collector plate was 14 cm. The flow rates of both the core and shell solutions were controlled by two syringe pumps and were 3.5 ml/h for the shell and 0.5 ml/h or 0.3 ml/h for the core for type 1 and type 2 microtubes, respectively. The fibers were collected as a strip on the edge of a vertical rotating wheel [17] having a velocity of 1.2 m/s.

Atrazine removal assays

24-h atrazine removal assays

Whole mats were weighed directly after electrospinning and cut into 100-mg pieces. Each piece was further divided into four small pieces. For growth assays, the mat pieces were washed several times with 20 mM phosphate buffer (pH 7.2), and placed in sterile 250-ml Erlenmeyer flasks containing 20 ml ATZ medium for 24 h at 30 °C on an orbital shaker at 180 rev/min. For non-growth assays, mats were prepared in the same way except that the mats were placed in sterile 250-mL Erlenmeyer flasks containing 20 ml 20 mM phosphate buffer (pH 7.2) with 20 mg atrazine/l (BPA medium).

Atrazine degradation rate assays under non-growth conditions for free and encapsulated cells

Free cell suspensions were prepared as above. Mat pieces were prepared by either subjecting them to a 3-day growth period in ATZ medium immediately after electrospinning (i.e., initial growth period) or placed directly under non-growth conditions. The medium during the 3-day growth period was changed daily. The same amount of cells was used in the encapsulated cells assays and in the free cell suspension assay. Duplicate aliquots were taken from the degradation assays at predetermined intervals were immediately mixed with an equal volume of methanol for atrazine analysis. Aliquots taken from the free cells experiment were filtered through a Millex-HV 0.45-μm filter unit (Millipore, Germany) prior to mixing with methanol.

Repeated batch assays under non-growth conditions

Whole mats were prepared in the same manner as the 24-h assays. Pieces of washed mats were either directly placed under non-growth conditions or subjected to a growth period in ATZ medium before being placed under non-growth conditions (BPA medium). Growth periods of 3 and 7 days were tested. The medium during the growth period was changed daily. At the end of the growth period, the pieces were washed twice with 20 mM phosphate buffer (pH 7.2) with 20 mg atrazine/l (BPA medium) using a vortex in order to wash away any cells that might be on the exterior of the microtubes.

Mat pieces directly from electrospinning or growth period were transferred to sterile 250-ml Erlenmeyer flasks with 20 ml BPA medium for repeated 24-h batch assays. At the end of a 24-h period, the batch was sampled and the solution replaced and the batch repeated. When a significant amount of atrazine remained in solution, the experiment was stopped. Data presented are means from at least three independent experiments with error bars indicating standard error of mean.

Analysis of atrazine and hydroxy-atrazine

The analysis of atrazine and hydroxy-atrazine was modified from previous work [15]. Duplicate aliquots taken from the experiment assays were mixed with an equal volume of methanol. The samples mix was then stored at –20 °C until HPLC analysis was performed using a Hewlett Packard HP1100 (USA). The separation was carried out in a LiChrospher 100 RP-18 (5 μm) column (LiChroCART HPLC Cartridge system, 250-4, Merck). The mobile phase was 200 mM NH4CH3COO in 70:30 % (v/v) methanol/water at a flow rate of 0.6 ml/min. Concentrations of atrazine and hydroxy-atrazine were quantified relative to a standard by integrating peak area at 220 nm. Samples were centrifuged at 10,000 × g for 10 min to remove salts and other insoluble materials prior to analysis.

Imaging

Images of the fibers were obtained using a Leo Gemini (Germany) high-resolution scanning electron microscope (HRSEM) at an acceleration voltage of 3 kV and a sample-to-detector distance of 3–5 mm. The specimens were coated with a thin gold film to increase their conductivity.

Results and discussion

Microtube fabrication and selection of microtube type for cell encapsulation

Two types of microtubes with different formulations were tested for Pseudomonas sp. ADP cell encapsulation and atrazine removal. The polymer solutions used for the fabrication of both microtubes are listed in Table 1. The resultant microtubes varied greatly in their morphology as well as in their atrazine removal ability. Cross sections of the microtubes and their surface morphology are shown in Fig. 1. Type 1 microtubes (as shown in Fig. 1a and 1b) are partially collapsed with a ribbon-like structure. The microtube wall thicknesses averaged 0.5 μm and are porous due to the presence of PEG (polyethylene glycol) in the shell solution [14]. The radial collapse of microtubes for this combination of core–shell solutions has been previously shown [18, 19]. The tubular space available for the encapsulated bacteria appears rather restricted due to the collapsing effect, averaging 3.5 μm in diameter.

In contrast, type 2 microtubes preserved a cylindrical shape and their walls, which were formed without PEG in the shell solution, exhibited a pore-like surface morphology as shown in Fig. 1c, d. The microtube wall thickness was also thicker than the type 1 microtubes, averaging 1 μm. The tubular space available for the encapsulated bacteria in the type 2 microtubes is completely hollow and unrestricted, averaging a similar diameter as the type 1 microtubes.

In order to determine the compatibility of the different microtubes to Pseudomonas sp. ADP cell encapsulation, preliminary atrazine degradation tests were conducted. The encapsulated cells ability to degrade atrazine was evaluated in three separately fabricated electrospun mats of both types subjected to a 24-h incubation under growing (ATZ medium) and resting conditions (BPA medium; Table 2) immediately following microtube fabrication. The resting cell assay, or more accurately, the non-growth cell assay, enables the evaluation of atrazine enzymatic activity of the encapsulated cells, without the interference of cell growth (change in cell concentration). The growth conditions assay, as compared to resting conditions, can show the encapsulated cells ability to retain enzymatic activity presumably by cell proliferation inside the microtubes. Also, atrazine adsorption by mats without cells was also tested as control.

As shown in Table 2, encapsulated Pseudomonas sp. ADP cells in type 1 microtubes under resting conditions exhibited lower atrazine degradation efficiency (ca. 35 %). Under growth conditions, type 1 encapsulated cells were able to regain their atrazine-removal abilities. These results are in agreement with previous work done with type 1 microtubes showing that an apparently low number of viable encapsulated cells retained their enzymatic activity when growth conditions were provided [15].

Contrary to the positive results using type 1 microtubes, when Pseudomonas sp. ADP cells encapsulated in type 2 microtubes were placed in either resting conditions or growth conditions, no significant biological atrazine removal was observed. These results clearly show the poor compatibility of type 2 microtubes to Pseudomonas sp. ADP cell encapsulation. Moreover, the lack of biological activity demonstrates the detrimental effects of the type 2 formulation not only on the viability of the encapsulated cells but also on enzyme functionality. The reasons for the difference in results between the two microtube types are unclear and illustrate the complexity of the electrospinning process.

Atrazine biodegradation and viability of encapsulated Pseudomonas sp. ADP cells in type 1 microtubes

Atrazine degradation by resting encapsulated Pseudomonas sp. ADP cells and their equivalent free resting cells suspension were studied in order to further evaluate both the impact of the electrospinning process on the cells ability to degrade atrazine and their viability. Due to the insoluble character of the microtube, a direct assessment of cell viability by plate-counting is not possible. The viability of the encapsulated cells was therefore examined by comparing (i) atrazine degradation rates of mats containing Pseudomonas sp. ADP cells immediately after electrospinning to equivalent free cell suspensions, and (ii) atrazine degradation rates of mats containing Pseudomonas sp. ADP cells immediately after electrospinning to mats containing Pseudomonas sp. ADP cells that were subjected to a 3-day growth period in ATZ medium following the electrospinning process. Results of atrazine degradation by free cell suspensions and the encapsulated cells are presented in Fig. 2a. Results of atrazine removal by encapsulated Pseudomonas sp. ADP cells refer to biological atrazine degradation only, and take into account atrazine adsorption by the microtubes (data not shown).

a Atrazine degradation by free Pseudomonas sp. ADP cell suspension and encapsulated cells under non-growth conditions (BPA medium), free Pseudomonas sp. ADP cell suspension (open square), encapsulated Pseudomonas sp. ADP cells after initial growth period (3 days, filled triangle) and encapsulated Pseudomonas sp. ADP cells without initial growth period (filled diamond). b Hydroxy-atrazine accumulation (diamond) following atrazine degradation (filled square) under non-growth conditions by encapsulated Pseudomonas sp. ADP cells without initial growth period

While atrazine degradation by free cell suspensions showed total removal of atrazine after ca. 4 h, the concentration of atrazine remained at ca. 15 mg/l even after 35 h (25.3 ± 4.3 % atrazine removal) for encapsulated cells taken immediately after the electrospinning process. Comparison of the degradation rates of the encapsulated cells to the free cell suspensions (similar initial cell concentrations) showed a reduction in more than a magnitude in rate (0.15 ± 0.05 mg atrazine/l/h vs. 6.95 ± 1.1 mg atrazine/l/h, respectively). In addition, about 80 % of the degraded atrazine was found to be in the form of hydroxy-atrazine immediately after the electrospinning process, the first intermediate of atrazine metabolism (Fig. 2b). This suggests that the stability of the enzymatic pathway for atrazine biodegradation was in general affected by the electrospinning process as shown previously in the preliminary atrazine degradation tests.

Unlike the kinetic behavior observed with encapsulated cells tested immediately after the electrospinning process, encapsulated cells subjected to an initial growth period of 3 days were able to fully degrade atrazine within 15 h with no hydroxy-atrazine detected in the medium (Fig. 2a). Comparison of the atrazine degradation rate of encapsulated cells subjected to a growth period and the rate of encapsulated cells taken immediately after electrospinning showed that the rate is more than a magnitude higher (0.5 ± 0.1 mg atrazine/h/g fiber vs. 0.03 ± 0.01 mg atrazine/h/g fiber, respectively). These results can only be attributed to a higher biomass concentration inside the microtubes subjected to a growth period and thus demonstrates the cells ability to proliferate inside microtubes when growth conditions are provided and to fully degrade the atrazine. Similar results were reported for both the loss of Pseudomonas sp. ADP atrazine degrading ability encapsulated in a combined Ca-alginate and sol-gel matrix and partial restoration following nutrient amendments [11].

Atrazine removal by encapsulated Pseudomonas sp. ADP cells in repeated batches under non-growth conditions

As mentioned previously, Pseudomonas sp. ADP has been found to metabolize atrazine under non-growth conditions, i.e., without the supplement of a readily available carbon source [6, 7, 11]. However, single applications of Pseudomonas sp. ADP to soils contaminated with high concentrations of atrazine suggest that Pseudomonas sp. ADP does not survive and/or retain its metabolic competence for complete removal of atrazine [9]. Citrate amendments, as a readily available carbon source and electron donor, or re-inoculations of the bacteria were found to improve atrazine removal [20, 21].

The retentive and protective characteristics of microtube technology may provide a suitable platform for atrazine degradation by Pseudomonas sp. ADP without the need for the addition of an external carbon source. Assessment of encapsulated Pseudomonas sp. ADP cells stability and their ability for sustained atrazine degradation was, therefore, carried out in repeated batch experiments (each batch was 24 h) without the addition of external carbon.

As results in the previous section demonstrated the need of subjecting the encapsulated cells to a growth period following the electrospinning process in order to enhance their ability to degrade atrazine under non-growth conditions, two initial growth periods (i.e., pretreatments) were tested: (1) a 3-day growth period in ATZ medium, and (2) a 7-day growth period in ATZ medium. The results of atrazine degradation following the pretreatments were compared to a control where encapsulated Pseudomonas sp. ADP cells received no pretreatment. As shown in Fig. 3a, results with encapsulated cells taken immediately after the electrospinning process showed a relatively constant but low atrazine removal capability in the course of eight successive batches (averaging 36.6 ± 5 %). On the other hand, microtube mats that were subjected to either 3 or 7 days of initial growth period showed that the cells maintained 100 % atrazine removal for the first ca. 6 and 13 successive batches, respectively. The higher atrazine removal by mats subjected to 7-day growth period strongly suggests that the mats contain a higher biomass concentration than mats subjected to a 3-day growth period. The high removal ability in both cases was followed by a gradual decline in atrazine degradation ability. This decline is probably the result of a deterioration of the enzymes’ stability. A similar decline over time was also observed with pure chlorohydrolase, the first enzyme in the atrazine degradation pathway, entrapped in sol-gel glass matrix [22].

Atrazine removal by encapsulated Pseudomonas sp. ADP cells in repeated batches (each batch 24 h) under non-growth conditions. a Encapsulated cells with and without initial growth period: with a 3-day initial growth period (filled square), with a 7-day initial growth period (diamond) and without initial growth period (filled triangle). b Encapsulated cells (with 3-day initial growth period) that were subjected to an additional 7-day growth period (i.e., revitalization period) following a reduction in atrazine removal efficiency. Atrazine removal is presented as a percentage of the initial atrazine concentration in the BPA medium (20 mg/l)

Encapsulated cells (subjected to 3-day initial growth period) that had lost most of their atrazine degrading capability following ca. 15 sequential batches under non-growth conditions (average removal efficiency of 35 %) were tested for their ability to recover atrazine degradation. The mats were subjected to a 7-day growth period (i.e., revitalization period) in ATZ medium. At the end of this period, the mats were washed three times in BPA medium (with vortex) to remove any free cells from the mat surface and transferred to a fresh sterile 20 ml of BPA medium for additional batch experiments under non-growth conditions. Results showed that the encapsulated cells regained their atrazine removal capabilities (Fig. 3b). High atrazine removal ability for the first ca. 14 successive batches followed by a sharp decrease was observed for the mats, similar to mats that were subjected to 7-day initial growth period after electrospinning. The successful recovery of atrazine degradation capacity after the detrimental effects of electrospinning and after loss under non-growth conditions allows for the practical application of this technology for atrazine bioremediation.

Given that atrazine was the only nitrogen source in the growth medium and the limiting factor, the total atrazine removed (mg/g fiber) during the growth periods can be used as an indication of new biomass accumulating in the mats. Results of the total atrazine removed during the initial growth periods and under non-growth conditions are presented in Table 3, as well as the total atrazine removed following the revitalization period. Comparison of the results for both initial growth periods showed a similar 1:2 ratio between the amount of atrazine removed during the growth period and the amount removed under non-growth conditions. The similar ratio suggests that the specific capacity of the encapsulated cells to remove atrazine under non-growth conditions is the same and total atrazine capacity is governed by the biomass concentration attained at the end of the growth period.

Microtube durability and stability

The atrazine removal capacities demonstrated by the encapsulated cells are an encouraging first step towards incorporation of the mats as coverings for standard biofilm carriers in bioreactors for atrazine bioremediation. However, due to the fact that PCL (polycaprolactone) polymers are prone to abiotic hydrolysis that can be followed by enzymatic degradation, microtube durability and stability may be short-termed [23, 24]. Therefore, these properties were followed during the experiments by HRSEM. HRSEM images of mats following six repeated batches under growth conditions showed intact mats (Fig. 4a). Also, no apparent differences were observed between the mats that were subjected to growth conditions and mats that were placed in BPA medium for the same time duration (Fig. 4b). Partial microtube deterioration was noticed, as shown in Fig. 4c, d, after a month of repeated batch experiments under growth conditions. Some microtubes seem to be torn open and broken. Results of total weight loss of mats, from four independent repeated batch experiments subjected to a month of non-growth conditions, showed 6.13 ± 1.5 % weight loss. Studies on a prototype bioreactor for atrazine bioremediation are currently being carried out on both the technical aspects of attaching the freshly spun microtubes onto standard plastic biofilm carriers as well as the degradation properties of the PCL-based microtubes under non-sterile conditions.

HRSEM micrographs of microtubes collected as mats and used for encapsulating Pseudomonas sp. ADP cells. a A mat after six repeated batches under growth conditions (ATZ medium), b a mat after six repeated batches under non-growth conditions (BPA medium), c a mat after a month of repeated batches under growth conditions, and d magnified area showing a rupture in one of the microtubes (indicated by the arrow) after a month of repeated batches under growth conditions

Conclusions

In the present study, atrazine degrading Pseudomonas sp. ADP cells were successfully encapsulated in electrospun microtubes. The encapsulation process was found to negatively affect the cells atrazine degradation activity, which was regained by immersing freshly spun microtubes in suitable growth medium in order to promote cells proliferation inside the microtubes. Encapsulated cells performed significant atrazine removal even under non-growth conditions bringing potential savings in process operation. Following extended operation under non-growth conditions, the atrazine degradation capacity deteriorated but could be recovered by periodically providing growth conditions to the encapsulated cells. The current results provide the basis for further development of microtubes as an artificial biofilm in a prototype bioreactor for atrazine bioremediation.

References

Benotti MJ, Trenholm RA, Vanderford BJ, Holady JC, Stanford BD, Snyder SA (2009) Pharmaceuticals and endocrine disrupting compounds in US drinking water. Environ Sci Technol 43:597–603

Park J, Feng Y, Ji P, Voice TC, Boyd SA (2003) Assessment of bioavailability of soil-sorbed atrazine. Appl Environ Microbiol 69:3288–3298

Smith D, Alvey S, Corwley DE (2005) Cooperative catabolic pathways within an atrazine-degrading enrichment culture isolated from soil. FEMS Microbiol Ecol 53:265–273

Topp E (2001) A comparison of three atrazine-degrading bacteria for soil bioremediation. Biol Fertil Soils 33:529–534

Katz I, Dosoretz CG, Mandelbaum RT, Green M (2001) Atrazine degradation under denitrifying conditions in continuous culture of Pseudomonas ADP. Water Res 35:3272–3275

Mandelbaum RT, Allan DL, Wackett LP (1995) Isolation and characterization of a Pseudomonas sp. that mineralizes the s-triazine herbicide atrazine. Appl Environ Microbiol 61:1451–1457

Wyss A, Boucher J, Montero A, Marison I (2006) Micro-encapsulated organic phase for enhanced bioremediation of hydrophobic organic pollutants. Enzyme Microb Tech 40:25–31

Herzberg M, Dosoretz CG, Tarre S, Green M (2003) Patchy biofilm coverage can explain the potential advantage of BGAC reactors. Environ Sci Technol 37:4274–4280

Silva E, Fialho AM, Correia ISA, Burns RG, Shaw LJ (2004) Combined bioaugmentation and biostimulation to clean up soil contaminated with high concentrations of atrazine. Environ Sci Technol 38:632–637

Macias-Flores A, Tafoya-Garnica A, Ruiz-Ordaz N, Salmeron-Alcocer A, Juarez-Ramirez C, Ahuatzi-Chacon D, Mondragon-Parada ME, Galindez-Mayer J (2009) Atrazine biodegradation by a bacterial community immobilized in two types of packed-bed biofilm reactors. World J Microbiol Biotechnol 25:2195–2204

Reitti-Shati M, Ronen D, Mandelbaum RT (1996) Atrazine degradation by Pseudomonas sp. strain ADP entrapped in sol gel glass. J Sol-Gel Sci Technol 7:77–79

Siripattanakul S, Wirojanagud W, McEvoy J, Khan E (2008) Effect of cell-to-matrix ratio in polyvinyl alcohol immobilized pure and mixed cultures on atrazine degradation. Water Air Soil Pollut Focus 8:257–266

Vancov T, Jury K, Van Zwieten L (2005) Atrazine degradation by encapsulated Rhodococcus erythropolis NI86/21. J Appl Microbiol 99:767–775

Dror Y, Kuhn J, Avrahami R, Zussman E (2008) Encapsulation of enzymes in biodegradable tubular structures. Macromolecules 41:4187–4192

Klein S, Kuhn J, Avrahami R, Tarre S, Beliavski M, Green M, Zussman E (2009) Encapsulation of bacterial cells in electrospun microtubes. Biomacromolecules 10:1751–1756

Mandelbaum RT, Wackett LP, Allan DL (1993) Mineralization of the s-triazine ring of atrazine by stable bacterial mixed cultures. Appl Environ Microbiol 59:1695–1701

Theron A, Zussman E, Yarin AL (2001) Electrostatic field-assisted alignment of electrospun nanofibers. Nanotechnology 12:384–390

Arinstein A, Zussman E (2007) Post processes in tubular electrospun nanofibers. Phys Rev E 76:056303

Arinstein A, Avrahami R, Zussman E (2009) Buckling behavior of electrospun microtubes: a simple theoretical model and experimental observations. J Phys D Appl Phys 42:015507

Newcombe DA, Crowley DE (1999) Bioremediation of atrazine-contaminated soil by repeated applications of atrazine-degrading bacteria. Appl Microbiol Biotechnol 51:877–882

Zhao S, Arthur EL, Coats JR (2003) Influence of microbial inoculation (Pseudomonas sp. strain ADP), the enzyme atrazine chlorohydrolase, and vegetation on degradation of atrazine and metolachlor in soil. J Agric Food Chem 51:3043–3048

Kauffmann C, Mandelbaum RT (1998) Entrapment of atrazine chlorohydrolase in sol gel glass matrix. J Biotechnol 62:169–176

Lam CXF, Savalani MM, Teoh S, Hutmacher DW (2008) Dynamics of in vitro polymer degradation of polycaprolactone-based scaffolds: accelerated versus simulated physiological conditions. Biomed Mater 3:034108

Sinha VR, Bansal K, Kaushik R, Kumria R, Trehan A (2004) Poly-epsilon-caprolactone microspheres and nanospheres: an overview. Int J Pharm 278:1–23

Acknowledgments

We wish to thank the Russell Berrie Nanotechnology Institute, the Stephen and Nancy Grand Water Research Institute and the BMBF-MOST German-Israeli Water Technology Research Fund (grant no. GR2336/103WT 1) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klein, S., Avrahami, R., Zussman, E. et al. Encapsulation of Pseudomonas sp. ADP cells in electrospun microtubes for atrazine bioremediation. J Ind Microbiol Biotechnol 39, 1605–1613 (2012). https://doi.org/10.1007/s10295-012-1164-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1164-3