Abstract

The plant growth-promoting bacteria (PGPR) Raoultella planticola Rs-2 was encapsulated with the various blends of alginate, starch, and bentonite for development of controlled-release formulations. The stability and release characteristics of these different capsule formulations were evaluated. The entrapment efficiency of Rs-2 in the beads (capsules) was more than 99%. The diameter of dry beads ranged from 0.98 to 1.41 mm. The bacteria release efficiency, swelling ratio, and biodegradability of the different bead formulations were enhanced by increasing the starch or alginate contents, but were impeded by higher bentonite content. The release kinetics of viable cells from capsules and the swelling ratio of capsules were studied in simulated soil media of varying temperature, moisture, pH, and salt content. The release of loaded Rs-2 cells and swelling of capsules are greatly affected by moisture, temperature, pH and salt content of the release medium. The release of viable Rs-2 cells from capsules was positively associated with the swelling properties of the capsules. The release of Rs-2 cells occurred through a Case II diffusion mechanism. In summary, this work indicates that alginate-starch-bentonite blends are a viable option for the development of efficient controlled-release formulations of Rs-2 biofertilizer, and which could have a promising application in natural field conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Xinjiang Province is a hot and semi-arid region in northwestern China that is China’s largest cotton-producing area and high-quality commodity cotton base. Soil salinization, due to the long-term drip irrigation system under the mulch film model used for cotton cultivation, however, has started to negatively impact cotton growth and productivity [10, 31].

In recent years, a new eco-friendly management strategy has been developed to alleviate salt stress in plants by treating crop seeds and seedlings with plant growth-promoting rhizobacteria (PGPR). PGPR possess many advantageous properties, including nitrogen fixation, mineral dissolution, and synthesis of auxin, ethylene, cytokinin, vitamins, and other important plant hormones necessary for the rapid growth of crops and protection against salt stress. In fact, many recent reports have directly demonstrated that PGPRs promote plant growth and alleviate salt stress [1, 6, 13, 18, 28, 29, 31, 32].

In our previous screening studies, an indigenous Raoultella planticola Rs-2 with 1-aminocyclopropane-1-carboxylate acid (ACC) deaminase activity was obtained from salinized soil of cotton field in Xinjiang Province (unpublished results). This strain has been shown to increase the germination rate of cotton seeds and promote cotton seedling growth under salt stress conditions. The Rs-2 strain also has the ability to secrete phytohormones such as indole acetic acid, which is able to solubilize insoluble phosphate compounds and can fix nitrogen. However, direct inoculation of free PGPR cells into soil might encounter difficulty in colonizing and surviving around cotton roots because it is susceptible to a variety of environmental factors, such as the competition from indigenous microflora, unfavorable physicochemical conditions, and fluctuation of pH and temperature, as well as various kinds of stresses [1, 12, 22]. Encapsulation of the bacteria may be an effective alternative to free cell dispersal. Encapsulation could provide temporary protection against biotic and abiotic stresses, and offer more convenient formulation for transport, handling, and storage than free bacteria [4, 22]. In addition, encapsulated cells could be released into the targeted soil in a slow and controllable manner that confers greater long-term effectiveness [2, 3, 23, 25, 30].

One possible method for enhanced survival and for controlled release is through encapsulation of bacterial inoculants into biodegradable microcapsules. Alginate can be ionically crosslinked by the addition of divalent cations in an aqueous solution. Several properties of alginate, like its biodegradability and non-toxicity, make it a potential carrier for controlled delivery of biologically active agents [3]. However, the high cost of alginate greatly limits commercial applications and reduces its use. In addition, alginate matrix does not have a high mechanical strength and is easily destroyed in the presence of monovalent cations. For the purpose of controlled-release capsules, the matrices should have the feature of controllable destruction. Starch is an inexpensive and promising candidate biodegraded material controlled release of bacteria. Starch may be too degradable, however, resulting in overly rapid bacterial release, so an additional material that regulates capsule composite mechanical performance and degradation rate is also required [26]. Bentonite has received considerable attention as a carrier of pesticides, drugs, and biofertilizers in the field of agriculture due to its high adsorption and harmlessness towards the environment and animals [11]. Heijnen et al. [8] found that the use of bentonite clay as a protective agent could be increase survival of bacteria introduced into soil. Therefore, we surmised that the best possible combination of low cost and the controlled-release properties may be achieved using a blend of alginate, starch, and bentonite for the bacterial Rs-2 formulations. Furthermore, it is quite interesting and informative to investigate the release property of Rs-2 in beads prepared from the proper ingredients under simulation soil conditions.

In the present study, characterization of different bead formulations prepared with alginate, starch, and bentonite contents were studied. Release dynamics and survival of Rs-2 cells in beads as well as swelling behavior of beads were evaluated under multiple simulated soil conditions. The main objectives of this work were to assess the feasibility of using a alginate-starch-bentonite composites for the development of efficient controlled-release formulations of Rs-2, and to provide theoretical guidance for the encapsulation of other PGPRs for potential applications in agriculture and related fields.

Materials and methods

Microorganism and culture medium

Raoultella planticola Rs-2 (GenBank accession number EF551363) with ACC deaminase activity previously isolated from saline soil of a cotton farmland located in Xinjiang Province of China. The strain was cultivated at 30°C and 200 rpm in nutrient agar (NA) broth (beef extract) consisting 10 g/l of tryptone, 5 g/l of beef extract, and 5 g/l of NaCl. The culture at the early stationary phase was collected for cell encapsulation. The cells concentration in the broth was determined as 9.11 × 1012 cfu/ml by counting the colony-forming units (cfu) present on NA agar plates after serial dilution for overnight incubation at 30°C.

Cell encapsulation

Encapsulation of bacteria within beads was carried out under sterile conditions. Encapsulated cell formulations were obtained by the extrusion technique using a method similar to that described by Wu et al. [27]. The blend solutions from different compositions were prepared by varying starch, sodium alginate, and bentonite (with cation-exchange capacity of 98.4 mmol/100 g, Xinjiang Xiazijie Bentonite Co., China) contents (Table 1), and measured amounts of starch, alginate, and bentonite were immersed in 50 ml of hot distilled water for 5 h and stirred for 15 min to form a homogenous solution. Collected Rs-2 cell was aseptically dispersed the blend solutions after sterilization at 121°C for 15 min. The solutions were then gently stirred until they became homogenous at room temperature. A sample of this mixture solution was extruded from a 10-ml sterile syringe into a sterilized 2.0% CaCl2 solution under gentle stirring for 30–60 min to form beads. The solidified capsules were removed from the CaCl2 solution and washed 2–3 times in sterile distilled water prior to testing.

Drying of the beads and determination of Rs-2 content in dry beads

A few samples of the wet beads were collected and dried in an oven maintained at 40°C for 48 h. The dried beads were removed and dissolved in 0.2 M, phosphate buffer (pH 7.0) at 30°C for 1–2 h in a rotary shaker at 100 rpm. These beads were then ground into the solution, resulting in release of the bacteria entrapped in or covering the beads. The released bacteria were counted using the conventional plate count method on nutrient agar (NA). The number of viable cells in dried beads was calculated to be 2.7 × 1014 cfu/g.

Characterization

Bead size measurement

The size of wet beads from each formulation was measured with 12-cm Vernier calipers, and the particle size of each completely dried capsule was measured by laser particle size analyzer (S3500, Microtrac, USA).

Scanning electron microscope (SEM) analysis

The capsules were treated with glutaraldehyde followed by immersing in 50–100% acetone. Then the samples were dried at 40°C for 48 h before coating with gold for SEM analysis. The morphology of the capsules was analyzed by using a scanning electron microscope (JSM-6700F, Jeol, Tokyo, Japan).

Entrapment efficiency (%)

The number of the unembedded bacteria left in the CaCl2 solution after formation of beads denoted as N u, it could be determined by plate count method on nutrient agar (NA). The entrapment efficiency of bacteria could then be calculated by Eq. (1).

where N 0 represents the initial number of Rs-2 cells in the mixture of the Rs-2 culture and alginate-starch-bentonite solution.

Release properties of immobilized Rs-2 cells from different bead formulations

We measured the cumulative release of viable Rs-2 cells from beads of different formulations (proportions of alginate, starch, and bentonite). The amount of Rs-2 released from the 100-mg capsules was determined at various intervals by immersing the beads in 10 ml of sterile saline solution (0.9% NaCl) for 8 days at room temperature. Samples (0.1 ml) were removed at various intervals and the cell concentration in the solution was determined by the plate count method on nutrient agar (NA). All the experiments were carried out in triplicate.

Swelling studies

Studies of bead swelling were performed in 0.9% NaCl solution at room temperature by the gravimetric methods as reported previously [17, 20, 27]. Dried beads (100 mg) were immersed in a 10-ml 0.9% NaCl solution for 8 days. The swollen beads were taken out and the excess solution gently removed by pressing the beads in between two pieces of filter paper. The swollen beads were then weighed using an electronic balance. The swelling ratio of the capsules was calculated by Eq. (2).

where W s and W d are weights of swollen beads in time t and weights of the initial dry beads, respectively. All the experiments were carried out in triplicate.

Biodegradability studies

The biodegradability of the encapsulated beads was studied by evaluating the weight loss of samples at designated time in a soil environment. Ten types of beads were placed in very fine mesh (10–20 μm) nylon bags, with a certain amount of dried beads per bag, and were buried 5 cm below the soil surface in the natural soil described below for plant cultivation. The soil was maintained at room temperature for 30 days and kept slightly below water saturation by adding distilled water as necessary. In order to monitor the progress of degradation, the initial weight of the dried beads was defined as W i, while the buried samples were dug out after various time periods, washed in distilled water, then weighed as Wt after drying them for 48 h to get constant weights. The % biodegradation was calculated by Eq. (3).

Release of loaded Rs-2 cells and swelling of beads under simulated soil conditions

Effects of soil moisture

The release kinetics of Rs-2 cells from alginate-starch-bentonite beads were examined under conditions of varying soil moisture. Soil samples were collected from cotton fields in the northern part of Xinjiang in China. The water content and saturation moisture capacity of the soils were measured as 28 and 40%, respectively. The chemical composition of the soil samples are included (g/kg), the total organic 24.1, total nitrogen 1.28, total phosphorous 1.1, Ca 0.12, Mg 0.04, Na 0.14, K 0.15, and the total salt 1.32, respectively. In vitro release of Rs-2 cells was measured by mixing dried capsules (100 mg) with 1 g sterile soil containing 10, 20, 30, or 40% moisture for 60 days at 20°C. The different soil samples were prepared by adding different volumes of sterile 0.9% salt solution (pH 7.0). At specific times during incubation, beads were recovered from the soil, washed, and the swelling ratio then determined. Then, the soil sample-removed beads were transferred into 10 ml of sterile saline solution (0.9% NaCl) and gently shaken at 30°C for 1 h. The number of released bacteria in the solution was determined by the plate count method on nutrient agar (NA). All the experiments were carried out in triplicate under sterile conditions.

Effect of soil pH

The release profile of Rs-2 from beads in soils of different pH was determined as above. Briefly, 100 mg of dried capsules loaded with Rs-2 cells were mixed in 1 g sterile soil under conditions of variable soil pH and constant (40%) moisture at 20°C. Soil samples of different pH were obtained by adding 0.73 ml sterile 0.9% salt solution balanced to pH 3, 5, 7, 9, or 11. The swelling ratio of beads and the number of bacteria released into the soil samples were determined at predetermined time intervals as described above.

Effect of soil salinity

Dried beads (100 mg) loaded with Rs-2 cells were mixed in 1-g samples of sterile soil with different salt contents but constant moisture (40%) and temperature (20°C). The different salt contents were obtained by adding 0.73 ml sterile saline with 0.3, 0.6, 0.9, and 1.2% salt. The tests were performed as above.

Effect of temperature

Dried capsules (100 mg) loaded with Rs-2 cells were mixed in 1 g sterile soil (pH 7.0, 40% moisture, 0.9% salt content) and examined as above at 4, 10, 20, and 30°C. All the experiments were carried out in triplicate.

Mathematical modeling of Rs-2 release

For a deeper understanding of the release profile of the cumulative viable bacteria from the swellable capsule system, mathematical modeling of the active ingredient release from swellable polymeric systems was applied [5, 9, 19]. Although there are a number of reports dealing with mathematical modeling of drug release from swellable polymeric systems, no single model successfully predicts all the experimental observations. The release kinetics was analyzed by applying the empirical Eq. (4) as proposed by Ritger and Peppas [5, 16]:

where M t/M 0 is the fractional release of bacteria at time t, while ‘k’ is a constant related with the features of the bacterial-capsule system, and ‘n’ is the diffusion exponent of the release mechanism.

Data analysis

Data were subjected to analysis of variance using SPASS software version 4.0.4 (SAS Institute, Inc., Cary, NC). When a significant F test was obtained for treatments (p > 0.05), separation of means was accomplished using Fisher’s protected least significant difference (LSD).

Results and discussion

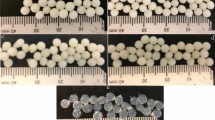

Effect of varying bead composition on size and yield

The beads were prepared using various blend solutions of alginate, starch, bentonite, and Rs-2 cell. The different compositions yielded beads with diameters of 2.26 ± 0.06 mm to 3.86 ± 0.08 mm when wet and from 0.98 ± 0.02 mm to 1.41 ± 0.07 mm after drying. The percentage yield varied from 72.38 to 88.89% depending on total blend concentration. The higher the total blend concentration, the higher the weight of beads obtained (Table 1). In addition, the wall material increase in starch content, capsule moisture gradually increased, and wet and dry capsule diameters increased. However, the capsule yield also gradually decreased, possibly due to the increased leaching of starch from the blends during the synthesis of beads. The yield and diameter of dry beads significantly increased as the bentonite increased. This may be due to an increase in the mixture viscosity, which results in larger droplets extruded from the syringe to form larger beads, while the loss of wall material was relatively small in CaCl2 solution during the formation of beads. Finally, with increasing alginate content, more alginate is available for crosslinking to calcium, which may also have increased the percent yield.

Effect of varying composition on entrapment efficiency

The cell entrapment efficiency for beads of different compositions is shown in Table 1. Entrapment efficiency was more than 99% for all formulations. The increase in alginate, starch, and bentonite contents in the preparations did not alter entrapment efficiency. This may be due to the relatively high concentration of Rs-2 cells during the entrapment process. Moreover, the combination of alginate, starch, and bentonite was a highly effective blend for encapsulation of Rs-2 cells and for protecting against environmental stress. A similar result has been reported by Sultana et al. [21] that improvements in the encapsulation efficiency of Lb. casei using alginate beads as the biopolymer by increasing the Hi-maize-resistant starch content (from 0 to 2%), suggesting that inclusion of starch can greatly enhance encapsulation efficiency with little additional cost. Additionally, as Reid et al. [14] linked encapsulation efficiency to two factors: (1) cell loss in CaCl2 solution and (2) viability losses in the beads themselves. Entrapment efficiency of Rs-2 cells was significantly higher than in previous studies, indicating that Rs-2 cell loss in CaCl2 solution was minimal, while high cell viability was maintained within beads due to good biocompatibility of the wall materials. In particular, the bentonite clay may have improved the long-term survival of Rs-2 cells [8].

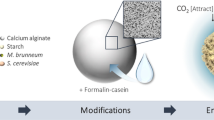

Morphology of the starch-alginate-bentonite capsules

The typical starch–alginate-bentonite bead was usually spherical, but ovoid beads were observed in formulations with high bentonite content (Fig. 1). This might be due to the increased viscosity of higher bentonite mixtures. A similar observation was made by Singh et al. [20]. After drying, some beads exhibited depressions and small cracks that may facilitate bacterial release upon water absorption and bead swelling [27].

External morphology of microcapsules under scanning electron microscope (SEM). The microcapsules were prepared with the blends of alginate-starch-bentonite (alginate content: 1.0% m/v, starch content: 3% m/v and bentonite content: 2% m/v). Magnification: a 5.0 kv 10.5 mm × 110; b 5.0 kv 10.0 mm × 1.8 k

Effect of bead composition on the swelling ratio of dry beads

The swelling ratio of all formulations ranged from 154.9 to 206.9% (Fig. 2). The equilibrium swelling of beads was attained after 1 day and the swelling remained almost constant up to 8 days in solution. A similar observation has been reported by Singh et al. [20]. The bead size also enlarged as the beads filled with water. The increase in starch contents from 1 to 7% w/v in the wall materials increased the swelling ratio from 165.8 to 206.9% (Fig. 2a), possibly due to the hydrophilic nature of starch. Higher starch content will enhance the interaction of water with the starch –OH groups, resulting in greater swelling. In contrast, swelling decreased from 179.2 to 149.5% as the amount of bentonite was increased (Fig. 2b). In addition, the swelling ratio of these beads varied from 160.7 to 193.6% as the alginate content increased (Fig. 2c), most likely due to the increased number of coordination sites provided by alginate COO− groups [19].

Effect of varying composition on Rs-2 cells’ release from dry beads

Blending alginate, starch, and bentonite, followed by crosslinking with CaCl2 solution, resulted in the formation of beads with promising properties for the controlled release of Rs-2 cells. The number of bacteria released from dry capsules was significantly greater over 8 days than after 1 day. The amount of bacteria released in 1 day and 8 days ranged from 5.9 × 106 to 1.39 × 108 cfu/g and from 9.0 × 109 to 6.46 × 1011 cfu/g with different blends of alginate, starch, and bentonite. Adding starch significantly improved the release properties of the capsules. As the starch content increased from 1 to 7% (m/v), the amount of released Rs-2 also increased (Fig. 3), probably due to increased swelling. The influence of bentonite on the release of Rs-2 was investigated by varying the bentonite from 1 to 4% (m/v). Bacteria release decreased with higher bentonite, likely because bentonite increased the mechanical strength of beads [20]. Moreover, Rs-2 release was decreased as the alginate concentration increased, which is attributed to increase in the density of the polymer matrix and also increase in the diffusion path length, which the bacterial cells have to traverse. In addition, initial cell number in all beads made essentially is the same, so the release rates trends of bacterial from capsules and release amount trends of bacterial are also the same from different beads. Therefore, the release rate and amount of cells might be adjustable and controllable to meet the needs for plant growth by altering the composition of capsule materials.

Effect of varying composition on biodegradability of dry beads

Preliminary swelling studies indicated that after optimum swelling, bead-swollen weights began to decrease due to erosion concomitant with water–biopolymer interactions under sterile conditions. This biodegradation was further confirmed by the increasing weight loss of the beads matrix with longer incubation times in the nature and open conditions (Fig. 4). Indeed, bead exhibited a 12% weight loss in beads (ABS4) after incubation for 30 days. The rate of weight loss was increased with higher starch and alginate contents, which may be due to that the starch and sodium alginate in capsules are biodegradable. In contrast, based on the weight loss results shown (Fig. 4), the biodegradability of the beads decreased with increased bentonite. This may be attributed to the recalcitrant nature of clay, which contains SiO2 and other inorganic components that are quite difficult to degrade biologically [20, 26]. These results clearly indicate that the biodegradability of the beads, and the ensuing bacteria release, may be controlled by varying the alginate, starch, and bentonite composition of the capsule material.

Effect of temperature on release of loaded Rs-2 and swelling of capsules

The effect of temperature on the swelling ratio of beads was investigated by varying the temperature of the swelling medium from 4 to 30°C. The swelling ratio and rate were markedly increased with increase of temperature (Fig. 5a). At higher temperatures, possibly because increasing the temperature could enhance diffusion of water molecules into the beads and cause relaxation of network chains. It is worth mentioning that the swelling of beads became faster and swelling started earlier at 20–30°C, again suggesting that higher water diffusion acted to increase swelling. In addition, the swelling rate of the capsule is very high at different temperatures and the swelling equilibrium almost reach in 1 day, which may be due to the fact that the capsule can rapidly absorb water. The observed decrease in swelling ratio after 15 days could be attributed to continuous erosion of surface layers of the beads [17]. On the contrary, the initial swelling ratio and the rate of swelling were both decreased by lower temperatures.

Temperature is an important environmental factor and has a significant impact on the release of the capsule core [17]. In the temperature range studied, the amount and rate of Rs-2 cell release increased with higher temperatures (Fig. 5b) due to enhanced bead swelling with more rapid water diffusion. In addition, diffusion of Rs-2 cell with flagellum would also be enhanced due to both active movement. An increase in temperature also resulted in a greater rate of bead erosion, which also favors faster cell release. Therefore, the temperature has a prominent effect on the release of bacteria from the beads and is conducive to the release of bacteria. In addition, it is worth mentioning that the release course of Rs-2 from capsules was mainly divided into three phases within 0–60 days at different temperature. The first step of release is short and fast phase in 0–1 days may be due to the rapid release of the bacteria on the outer layer and surface of capsules with rapid swelling of capsules after absorbing water, the release rate of bacteria was considerably high while the release amount was relatively small, as compared to the release balance amount of bacterial. The second release step is a steady and rapid release process in 1–15 days, mainly due to the swelling of capsules was tends to balance in the soil medium. The release rate was decreased, while the cumulative release amount was still growing rapidly and the bacterial release appeared to dominate in the step. The third stage of the cells release is a steady and slow release phase in 15–60 days. The number of living Rs-2 cells released from capsules reached a release balance with the highest as 2.5 × 1012 cfu/g at 20–30°C after 15 days. Although erosion and degradation of swelling capsule matrix were increased, that live cell release unobviously increased after 15 days may reflect increased death of free Rs-2 cells. The number of viable cells released from capsules was still as high as 7.9 × 108 cfu/g at 60 days, however, even at 4°C. This long-term survival of encapsulated Rs-2 cells indicates that these beads may have sufficient protective capacity for applications in biofertilizers [7].

Effect of soil moisture on release of loaded Rs-2 and swelling of capsules

Soil moisture is another important factor that could greatly impact the stability and release properties of the capsules. As shown in Fig. 6, the equilibrium swelling ratio and the number of loaded cells released from the capsules increased with higher soil moisture. Both total cell release and release rate were minimal in soil with no moisture, probably because bead swelling is water-dependent and because diffusion of Rs-2 cells from beads would be greatly impeded without a transmission fluid (water). This may come to a conclusion that the release of Rs-2 cells from dry beads involves the absorption of water into the matrix and simultaneous release of Rs-2 via diffusion. Therefore, the release kinetics of loaded Rs-2 beads was intimately related to swelling kinetics mediated by water absorption. That is, higher soil water will enhance swelling, leading to a greater release of entrapped Rs-2 cells. Based on these findings, soil moisture plays a particularly important role in the release of bacterial release from capsules.

Effect of soil pH on release of loaded Rs-2 and swelling of capsules

We next examined the effect of the medium pH (3.0–11.0) on the release of loaded Rs-2 and swelling of capsules (Fig. 7). The swelling ratio of beads increased from pH 3.0 to 9.0 and decreased as the pH rose further. This pH-dependence may reflect the extent of ionization of alginate carboxylic groups as pH rises. The greater number of carboxylate ions along the alginate molecules would repel each other and produce a rapid relaxation in network chains, facilitating inclusion of water molecules into the bead network. Enhanced water uptake into the beads would increase the rate of swelling and concomitant release of bacteria [17].

Nevertheless, the pattern of cell release was quite similar for all soil pH. For bead samples incubated under acidic conditions (pH 3.0), bacteria release was low (10.42 log cfu/g), while Rs-2 cell release reached 11.99 log cfu/g at pH 9.0. As reported by other groups, a possible reason for this pH effect is that the lower concentration of H+ ions produces relatively greater relaxation of alginate chains and so results in an enhanced release of Rs-2 as soil pH increases [17, 20]. However, at pH > 9, a greater number of hydroxyl ions in the release medium may restrict the expulsion of the Rs-2 cells from within the bead because of repulsion between the hydroxyl ions and OH− ions, resulting in a lower release of Rs-2 [17]. In addition, the profile curve of the bacterial release in soil at pH 7.0 was very close to that in soil at pH 9.0, and the difference in the number of viable cells released from the beads in the pH range 5.0–11.0 was not significant. Therefore, Rs-2 in these beads could be controlled release and good survival in a broad range of soil types (pH ranges), greatly expanding their utility.

Effect of soil salt contents on release of loaded Rs-2 and swelling of capsules

The influence of soil salt concentrations on release of loaded Rs-2 and the swelling of beads was studied and shown in Fig. 8. Higher concentrations of salt in the soil medium could inhibit the swelling of capsules due to a decrease in the osmotic pressure difference between the bead interior and the soil. However, the pattern of cell release was quite similar in all soils tested. The number of viable cells released reached 2.78 × 1011 cfu/g in soil with 0.6% salt and 1.55 × 1012 cfu/g in soil with 0.9% salt content at 15 days. Release was much slower thereafter, which was probably due to the death of released cells and slower release rate with time. The number of viable cells released from beads in 1.2% salt soils was lower than that in 0.3–0.9% salt soil at various time intervals, but release was still as high as 11.3 log cfu/g within 60 days. Thus, these Rs-2-loaded beads may be useful biofertilizers in highly salinized soils [15, 24, 27].

Release mechanics of loaded Rs-2 from capsules

To study the mechanisms of cell release from the alginate-starch-bentonite beads, the diffusion characteristic constant ‘k’ and diffusion exponent ‘n’ for the release of Rs-2 from the beads under different conditions was calculated from the slope and intercept of the plot of ln(M t/M 0) versus ln t. Based on all values obtained under different conditions, the correlation coefficients r > 0.892 (Table 2), the release data were fitted seemingly well. In the light of the fact that all the values for the diffusion exponent ‘n’ were > 1.0, the mechanistic aspects of the release process were well described by Fick’s equation, and consistent with a Case II diffusion mechanism [5, 9, 16, 17, 19, 20]. Furthermore, the interaction natures between water, polymer, and strain are the primary factors controlling the dynamics of a release process. Additionally, the release process is also affected by other factors such as moisture, temperature, pH, and salt content of the release medium. Hence, the studied release system offers a feasible method for controlled application of biofertilizers under a broad range of climate and soil conditions.

Conclusions

Bead composition was shown to exert a very strong effect on the swelling characteristics of the beads loaded Rs-2 and on the release pattern of the Rs-2 cells from these beads. The yield of the beads decreased with the increases in starch contents and increased with increases in alginate and bentonite. The prepared beads show significantly increased cellular release, swelling ratio, and biodegradability with higher alginate and starch contents, while increasing bentonite impeded swelling, release, and biodegradability. In addition, the swelling ratio of beads and the bacterial release efficiency from beads increased as the pH rose from 3.0 to 9.0, but both values decreased at pH > 9.0. An increase in swelling ratio and bacterial release was also observed at higher temperature and soil moisture. Higher salt content reduced the swelling ratio of beads and cellular release, but viable bacteria were still released over a broad range of soil salinities. Cell release was positively correlated with the swelling ratio of the capsules. The Rs-2 release kinetics was consistent with a Case II diffusion mechanism. Therefore, this study presents a feasible method for the encapsulation of R. planticola Rs-2 using alginate-starch-bentonite composites. These beads may be suitable for the efficient controlled release of bacterial fertilizers in real agricultural settings.

References

Bashan Y (1998) Inoculants of plant growth-promoting bacteria for use in agriculture. Biotechnol Adv 16:729–770

Bashan Y (1986) Alginate beads as synthetic inoculant carriers for slow release of bacteria that affect plant growth. Appl Environ Microb 51:1089–1098

Bashan Y, Hernandez JP, Levya LA, Bacilio M (2002) Alginate microbeads as inoculant carriers for plant growth-promoting bacteria. Biol Fertil Soils 35:359–368

Cassidy MB, Lee H, Trevors JT (1996) Environmental application of immobilized cells. J Ind Microbiol 16:79–101

Chen L, Xie ZG, Chen XS (2008) Controlled release of urea encapsulated by starch-g-poly (L-lactide). Carbohyd Polym 72:342–348

Glick BR (1995) The enhancement of plant growth by free-living bacteria. Can J Microbiol 41:109–117

Hegde SV, Brahmaprakash GP (1992) A dry granular inoculant of Rhizobium for soil application. Plant Soil 144:309–311

Heijnen CE, Hok-A-Hin CH, van Veen JA (1992) Improvement to the use of bentonite clay as a protective agent, increasing survival levels of bacteria introduced into soil. Soil Biol Biochem 24:533–538

Jay SM, Saltzman WM (2009) Controlled delivery of VEGF via modulation of alginate microparticle ionic crosslinking. J Control Rel 134:26–34

Li FH, Benhur M, Keren R (2003) Effect of marginal water irrigation on soil salinity, sodicity and crop yield. Trans Chin Soc Agric Eng 19:63–66

Li JF, Lu JH, Li YM (2009) Carboxylmethylcellulose/bentonite composite gels: water sorption behavior and controlled release of herbicide. J Appl Polym Sci 112:261–268

Liu CH, Wu JY, Chang JS (2008) Diffusion characteristics and controlled release of bacterial fertilizers from modified calcium alginate capsules. Bioresource Technol 99:1904–1910

Mayak S, Tirosh T, Glick BR (2004) Plant growth-promoting bacteria confer resistance in tomato plants to salt stress. Plant Physiol Bioch 42:565–572

Reid AA, Vuillemard JC, Britten M, Arcand Y, Farnworth E, Champagne CP (2005) Microentrapment of probiotic bacteria in a Ca2+-induced whey protein gel and effects on their viability in a dynamic gastrointestinal model. J Microencapsul 22:603–619

Rekha PD, Lai WA, Arun AB, Young CC (2007) Effect of free and encapsulated Pseudomonas putida CC-FR2–4 and Bacillus subtilis CC-pg104 on plant growth under gnotobiotic conditions. Bioresource Technol 98:447–451

Ritger PL, Peppas NA (1987) A simple equation for description of solute release II. Fickian and non-Fickian release from swellable devices. J Control Rel 5:37–42

Roy A, Bajpai J, Bajpai AK (2009) Dynamics of controlled release of chlorpyrifos from swelling and eroding biopolymeric microspheres of calcium alginate and starch. Carbohyd Polym 76:222–231

Saravanakumar D, Samiyappan R (2007) ACC deaminase from Pseudomonas fluorescens mediated saline resistance in groundnut (Arachis hypogea) plants. J Appl Microbiol 102:1283–1292

Singh B, Sharma DK, Gupta A (2009) A study towards release dynamics of Thiram fungicide from starch—alginate beads to control environmental and health hazards. J Hazard Mater 161:208–216

Singh B, Sharma DK, Kumar R, Gupta A (2009) Controlled release of the fungicide thiram from starch—alginate—clay based formulation. Appl Clay Sci 45:76–82

Sultana K, Godward G, Reynolds N, Arumugaswamy R, Peiris P, Kailasapathy K (2000) Encapsulation of probiotic bacteria with alginate–starch and evaluation of survival in simulated gastrointestinal conditions and in yoghurt. Int J Food Microbiol 62:47–55

Takei T, Yoshida M, Hatate Y, Shiomori K, Kiyoyama S (2008) Lactic acid bacteria-enclosing poly(ε-caprolactone) microcapsules as soil bioamendment. J Biosci Bioeng 106:268–272

Van Elsas JD, Trevors JT, Jain D, Wolters AC, Heijnen CE, Van Overbeek LS (1992) Survival of, and root colonization by, alginate-encapsulated Pseudomonas fluorescens cells following introduction into soil. Biol Fertil Soils 14:14–22

Vassilev N, Vassileva M, Azcon R, Medina A (2001) Application of free and Ca-alginate- entrapped Glomus deserticola and Yarowia lipolytica in a soil–plant system. J Biotechnol 91:237–242

Wu CS (2008) Controlled release evaluation of bacterial fertilizer using polymer composites as matrix. J Control Rel 132:42–48

Wu KJ, Wu CS, Chang JS (2007) Biodegradability and mechanical properties of polycaprolactone composites encapsulating phosphate-solubilizing bacterium Bacillus sp. PG01. Process Biochem 42:669–675

Wu ZS, Zhao YF, Kaleem I, Li C (2011) Preparation of calcium-alginate microcapsuled microbial fertilizer coating Klebsiella oxytoca Rs-5 and its performance under salinity stress. Eur J Soil Biol 47:152–159

Yang J, Kloepper JW, Ryu CM (2009) Rhizosphere bacteria help plants tolerate abiotic stress. Trends Plant Sci 14:1–4

Yao LX, Wu ZS, Zheng YY, Kaleem I, Li C (2010) Growth promotion and protection against salt stress by Pseudomonas putida Rs-198 on cotton. Eur J Soil Biol 46:49–54

Young CC, Rekha PD, Lai WA, Aru AB (2006) Encapsulation of plant growth-promoting bacteria in alginate beads enriched with humic acid. Biotechnol Bioeng 95:76–83

Yue HT, Mo WP, Li C, Zheng YY, Li H (2007) The salt stress relief and growth promotion effect of Rs-5 on cotton. Plant Soil 297:139–145

Zahir ZA, Ghani U, Naveed M, Nadeem SM, Asghar HN (2009) Comparative effectiveness of Pseudomonas and Serratia sp. containing ACC-deaminase for improving growth and yield of wheat (Triticum aestivum L.) under salt-stressed conditions. Arch Microbiol 191:415–424

Acknowledgments

This research work was supported by the National Natural Science Foundation of China (20904033), Xinjiang Bingtuan Key Science and Technology Industry Project (2008GG24), Xinjiang Uygur Autonomous Region High-tech Research and Development Project (20081108), and Graduate Innovation Fund Project of Shihezi University (YJCX2010-Y13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Z., Guo, L., Qin, S. et al. Encapsulation of R. planticola Rs-2 from alginate-starch-bentonite and its controlled release and swelling behavior under simulated soil conditions. J Ind Microbiol Biotechnol 39, 317–327 (2012). https://doi.org/10.1007/s10295-011-1028-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-1028-2