Abstract

This work aimed at the production of stabilized derivatives of Thermomyces lanuginosus lipase (TLL) by multipoint covalent immobilization of the enzyme on chitosan-based matrices. The resulting biocatalysts were tested for synthesis of biodiesel by ethanolysis of palm oil. Different hydrogels were prepared: chitosan alone and in polyelectrolyte complexes (PEC) with κ-carrageenan, gelatin, alginate, and polyvinyl alcohol (PVA). The obtained supports were chemically modified with 2,4,6-trinitrobenzene sulfonic acid (TNBS) to increase support hydrophobicity, followed by activation with different agents such as glycidol (GLY), epichlorohydrin (EPI), and glutaraldehyde (GLU). The chitosan-alginate hydrogel, chemically modified with TNBS, provided derivatives with higher apparent hydrolytic activity (HAapp) and thermal stability, being up to 45-fold more stable than soluble lipase. The maximum load of immobilized enzyme was 17.5 mg g−1 of gel for GLU, 7.76 mg g−1 of gel for GLY, and 7.65 mg g−1 of gel for EPI derivatives, the latter presenting the maximum apparent hydrolytic activity (364.8 IU g−1 of gel). The three derivatives catalyzed conversion of palm oil to biodiesel, but chitosan-alginate-TNBS activated via GLY and EPI led to higher recovered activities of the enzyme. Thus, this is a more attractive option for both hydrolysis and transesterification of vegetable oils using immobilized TLL, although industrial application of this biocatalyst still demands further improvements in its half-life to make the enzymatic process economically attractive.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipases (triacylglycerol acylhydrolases, E.C. 3.1.1.3) are enzymes that catalyze hydrolysis of ester bonds of triglycerides. In organic medium, lipases also catalyze the reverse reaction, namely ester synthesis and transesterification [7, 32]. They can also catalyze stereoselective and regioselective reactions, being one of the most widely used enzymes in industrial processes.

A peculiarity of the mechanism of action of lipases is interfacial activation. Most lipases have an oligopeptide chain “lid” that covers their active site and makes them inaccessible to substrates. In the absence of a hydrophobic interface, the active site is secluded from the reaction medium and the enzyme is in the so-called “closed conformation.” However, in the presence of a hydrophobic interface (e.g., a drop of oil or gas bubbles), important conformational rearrangements take place, yielding the “open conformation” [24–26, 31, 39]. In addition, lipases show high affinity for hydrophobic interfaces, including supports chemically modified with hydrophobic agents [4].

Lipases can be produced by several microorganisms, exhibiting different physical properties and specificities. Lipolase® is a commercial lipase preparation from the fungus Thermomyces lanuginosus, which is produced on industrial scale using Aspergillus oryzae as a host organism [12]. Its main application is in fabric laundry detergents to improve fatty-soil removal. Lipolase® is classified as 1,3-specific and has high affinity for long-chain fatty acids. Its high thermal stability as well as availability and specificity make this enzyme very convenient to catalyze transesterification of triglycerides, particularly in synthesis of biodiesel [34].

The feasibility of the use of enzymes in industrial processes is mostly determined by the cost of the biocatalyst. Hence, easy recovery of the enzyme and improvement of its stability are crucial points. Immobilization of the protein on insoluble supports, besides facilitating their recovery, may also help to stabilize the enzyme structure, thus reducing biocatalyst inactivation, either thermal or due to interactions with solvents [17]. The selection of the most suitable method of immobilization must be based on different performance criteria, such as the maximum immobilized enzyme activity, operational stability, immobilization costs, toxicity of immobilization reactants, etc. [18]. Among the different available immobilization procedures, multipoint covalent immobilization seems to be one of the most promising to improve enzyme stability [1, 8, 9, 17, 19, 20, 26–28, 36, 37].

Biodiesel is a commodity, and its synthesis is a large-scale process. Therefore, the biocatalyst must be robust and inexpensive. Besides that, the support must have numerous reactive groups, available to be linked to the enzyme, and good geometrical congruency with the protein, to allow interaction between several reactive groups of the support with the same enzyme molecule [8].

In this work, chitosan was selected as the immobilization support. It has natural reactive amine groups, is biocompatible, is available in various forms (hydrogel, membrane, fiber, and film), is nontoxic, and is readily susceptible to chemical modification [3, 14]. The interest in modifying chitosan using different activation agents, and the use of polyelectrolyte complexes, have arisen recently mostly for applications in the field of enzyme immobilization [1, 19, 28]. Several biopolymers have been used to prepare chitosan hybrid hydrogels, such as gelatin, collagen, carrageenan, alginate, polyvinyl alcohol (PVA), and carboxymethylcellulose (CMC) [3]. Formation of hybrid hydrogels by mixing chitosan with other biopolymers may increase gel density and mechanical resistance, thereby extending the range of applications. The polyelectrolyte complexes are formed by ionic interactions between the positively charged amine groups of chitosan and negative charges of other biopolymers, such as sulfonic and carboxylic groups. However, the resulting mechanical stability of these hybrid gels is still not good, since they may swell when submitted to changes in pH [3].

Covalent cross-linking of the hybrid chains may be used to increase matrix density and mechanical strength. These cross-linked hydrogels exhibit good mechanical properties and do not dissolve even at extreme pH conditions. Different compounds have been used for covalent cross-linking of chitosan hybrid hydrogels, such as glutaraldehyde [6, 22], glyoxal [16], and genipin [21]. On the other hand, lipases have strong affinity for hydrophobic surfaces. Chitosan gel, pure or mixed with other biopolymers, is a very hydrophilic material, mainly because of the charged amine groups, and their blockage may favor immobilization of the enzyme. To the best of our knowledge, the strategy of using 2,4,6-trinitrobenzene sulfonic acid (TNBS) to modify the internal surface of chitosan beads has not been reported in the literature yet.

In a previous work, polyelectrolyte complexes of chitosan activated with different agents were used for immobilization of chymotrypsin to produce tailor-made protein hydrolysates with specific nutritional and pharmaceutical properties [1]. Different structures were obtained using chitosan with another biopolymer such as alginate, gelatin or κ-carrageenan. Changing the gel structure led to significant improvements in the multipoint covalent immobilization of chymotrypsin, and the thermostability was considerably improved with respect to pure chitosan hydrogels [1].

Since hybrid hydrogels are highly hydrophilic, their use as support for Thermomyces lanuginosus lipase (TLL) demands chemical modification of the matrix, using hydrophobic agents to improve the intragel microenvironment, favoring multipoint covalent immobilization of TLL.

Therefore, this work seeks modified chitosan gels to obtain highly active and thermostable lipase derivatives through multipoint covalent immobilization of TLL on polyelectrolyte complexes of chitosan. With this purpose, chemical modifications of the matrices, and their activation using different protocols, were investigated for biodiesel synthesis by enzymatic ethanolysis of palm oil.

κ-Carrageenan, gelatin, PVA, and sodium alginate were tested as co-biopolymers. Chemical modification of the hybrid hydrogels was done using TNBS, and distinct activation protocols were used, with glycidol, epichlorohydrin or glutaraldehyde as cross-linker/activating agent. Kinetic assays of ester hydrolysis and biodiesel synthesis were run for the best immobilized derivatives.

Materials and methods

Materials

Lipase from Thermomyces lanuginosus (TLL), named Lipolase®, was kindly donated by Novozymes (Araucária, Brazil), and had hydrolytic activity of 1,760 IU ml−1 and 9 mg protein ml−1 solution. Native chitosan (85% deacetylation degree) was purchased from Polymar S.A. (Ceará, Brazil). Glycidol (GLY), epichlorohydrin (EPI), κ-carrageenan, and 2,4,6-trinitrobenzene sulfonic acid (TNBS) were purchased from Sigma–Aldrich Co. (St. Louis, MO, USA). Glutaraldehyde (GLU), 25% (v.v−1) solution, and sodium alginate were obtained from Vetec (São Paulo, Brazil). Ethanol (minimum 99%) was supplied by Chromoline (SP, Brazil). Olive oil (low acidity) from Carbonell (Spain) and gelatin (Oetker, Brazil) were purchased in the local market. Palm oil was a kind gift from Agropalma (Pará, Brazil), having the following fatty-acid composition (% w/v): 0.1% lauric, 1.2% myristic, 46.8% palmitic, 3.8% stearic, 37.6% oleic, and 10.5% linoleic, with average molecular weight 849.0 g mol−1. All other reactants were of analytical grade.

Methods

Preparation of chitosan beads

Pure chitosan (4% wt.) and polyelectrolyte complexes (PEC) [chitosan (4% wt.)-gelatin (3% wt.), chitosan (2.5% wt.)-sodium alginate (2.5% wt.), chitosan (2.5% wt.)-PVA (2.5% wt.), and chitosan (2.5% wt.)-κ-carrageenan (2.5% wt.)] were added to 5% (v.v−1) acetic acid solution and mixed for 24 h at room temperature. The chitosan solution was then injected into a 0.1 M NaOH solution (1:10) to form hydrogel beads under slow stirring (50 rpm) for 24 h. The beads were filtered and rinsed thoroughly, with distilled and Milli-Q water, and then stored in refrigerator for further use.

Chemical modification with TNBS

Gel (10 g) was suspended in 37.5 ml 0.1 M bicarbonate buffer, pH 10.05, and 0.25 ml TNBS solution. The suspension was stirred in a shaker operated at 150 rpm and 25°C for 24 h. The beads were filtered and rinsed thoroughly with distilled and Milli-Q water. The following reaction is expected to occur (Scheme 1).

Bead activation

Chitosan beads were activated with different agents: glycidol, epichlorohydrin, and glutaraldehyde. For glycidol, 10 g chitosan beads was added to a solution composed of 3 ml distilled water and 5 ml 1.7 M NaOH solution containing 0.15 g sodium borohydride (NaBH4). Following this, a suitable amount of glycidol (3.6 ml) was slowly added, and the mixture was kept in an ice bath for 15 h [10]. For epichlorohydrin activation, 10 g gel was suspended in 100 ml 2 M NaOH solution containing 0.6 g NaBH4. Then, 10 ml epichlorohydrin was slowly added, and the suspension was kept in an ice bath for 15 h [2]. Glyceryl supports (activated with glycidol and epichlorohydrin) were further suspended in 60 ml Milli-Q water and 30 ml 0.1 M sodium periodate to produce glyoxyl groups [10]. The suspension was kept under slight stirring for 2 h at room temperature. For activation with glutaraldehyde, 10 g chitosan beads was suspended in 16.8 ml 25% (v/v) glutaraldehyde solution in 0.2 M buffer phosphate, pH 7.0 (11.2 ml) for 1 h at room temperature [28]. Following this, the activated hybrid hydrogels were filtered and washed thoroughly with distilled and Milli-Q water.

Immobilization procedure

The enzyme solution was added to 9 ml 0.1 M bicarbonate buffer (pH 10.05) and mixed with 1 g support under slow stirring for 12 and 24 h at room temperature. After this, the derivative was filtered (Whatman filter paper 41) and thoroughly rinsed with 0.2 M phosphate buffer, at pH 7.0, and finally washed thoroughly with distilled and Milli-Q water. Immobilization was followed by measuring the hydrolytic activities and protein concentration in the supernatant solution. The chemically modified chitosan-alginate support was further tested by offering different loadings of protein (5.0, 10.0, 30.0, and 50 mg g−1 of gel) to determine the support saturation enzymatic load.

Schiff’s bases reduction

After the enzyme immobilization step, 1.0 mg ml−1 sodium borohydride was added to the immobilization suspension, which was kept under agitation during 30 min at 25°C. After this, the derivative was filtered (Whatman filter paper 41) and thoroughly rinsed with 0.2 M phosphate buffer, pH 7.0, and finally washed thoroughly with Milli-Q water.

Thermal stability

Soluble and immobilized lipase were incubated in the presence of 1 ml phosphate buffer, pH 8.0 (0.1 M) at 70°C for different time intervals. The half-life times (t 1/2) were determined after fitting an exponential nonlinear decay model [30].

Determination of hydrolytic activity

Hydrolytic activities of soluble and immobilized lipase were assayed using olive oil emulsion as substrate, according to the methodology described by Soares et al. [33], with slight modifications. The substrate was prepared by mixing 50 g olive oil with 150 g Arabic gum solution (3% wt.). The reaction mixture containing 5 ml emulsion, 5 ml 0.1 M phosphate buffer (pH 8.0), and immobilized (0.1 g) or soluble (0.2 ml, 0.5 mg ml−1) lipase was incubated for 5 min at 37°C. The reaction was stopped by addition of 10 ml commercial ethanol. The fatty acids formed were titrated with 0.02 M sodium hydroxide solution in the presence of phenolphthalein as indicator. One international unit of activity was defined as the amount of enzyme that liberates 1 μmol free fatty acid per minute (1 IU) under the assay conditions.

Determination of protein

Protein was determined according to the methodology described by Bradford [5] using bovine serum albumin (BSA) as standard. All solutions were prepared using Milli-Q water.

Immobilization parameters

Immobilized protein (IP) was calculated after determining the amount of protein and enzyme units that disappeared in the supernatant, and comparing with the initial protein and enzyme concentration that were offered (U g−1 of gel). Recovered activity (RA) was calculated after determining the activity of the immobilized enzyme (apparent hydrolytic activity) and comparing with the number of enzyme units that disappeared from the supernatant (theoretically immobilized). Stabilization factor (SF) is the ratio between the half-life of the immobilized derivate and the half-life of the soluble enzyme.

Swelling degree in chitosan chemically modified with TNBS

The swelling degree (SD) of chitosan-alginate hydrogel chemically modified with TNBS was determined by keeping 100 mg hydrogel in 20 ml phosphate buffer at pH 7.0 (0.1 M), and weighing the gels during 24 h. SD was the relative gain of weight of the matrix at 24 h with respect to its initial weight [11]. Assays were carried out in triplicate. The control was chitosan-alginate without chemical modification. SD was calculated using equation 1.

where W t and W 0 are the weights of hydrogels at 24 h and at zero time of swelling, respectively.

Surface hydrophobicity of the hydrogels

The hydrophobicity of the chemically modified hybrid hydrogels was determined by measuring the adsorption of the hydrophobic Rose Bengal dye: hydrogel microspheres (0.15 g) were added to different flasks containing 10 ml Rose Bengal solution (20 μg ml−1) at pH 7.0, for 1 h. The amount of adsorbed dye was determined by recording the absorbance (at λ = 549 nm), in triplicate, according to the methodology described by Gupta and Jabrail [11]. An assay control was carried out with chitosan-alginate hydrogel without chemical modification. The adsorption quotient was given by the amount of Rose Bengal dye adsorbed per gram of solid.

Determination with TNBS of the degree of linkage of amine groups in the chitosan-alginate PEC treated with different activation agents

The ratio between linked and free amino groups in the chitosan chains of the supports, chitosan-alginate chemically modified with TNBS and activated with glycidol, epichlorohydrin, and glutaraldehyde, was determined according to the methodology described by Kathuria et al. [13]. In brief, 5 mg dried chitosan-alginate-TNBS and activated chitosan-alginate-TNBS were treated with a reaction mixture of 1 ml 4% (w/v) NaHCO3, pH 9, and 1 ml 0.5% (v/v) TNBS during 2 h at 40°C. TNBS reacts with free amine groups. Following that, 3 ml 6 M HCl solution was added, and the temperature was raised to 60°C for 90 min. Absorbance of the resulting solution was measured at 345 nm after dilution. The control was non-chemically modified chitosan-alginate, prepared with the same procedure except that 6 M HCl was added before addition of TNBS. The degree of linkage was calculated using equation 2.

where DL is the degree of linkage (%), Abssample is the absorbance of the chitosan-alginate-TNBS samples activated with different agents (GLY, EPI, and GLU), Abscontrol is the absorbance of the control (chitosan-alginate), and m sample and m control are the sample amounts (mg).

Biodiesel synthesis

The reactions were performed in closed 25-ml flasks containing 20 g substrate consisting of palm oil and anhydrous ethanol, without addition of solvents, at fixed molar ratio of oil to alcohol (1:18) [23]. The mixtures were incubated with immobilized lipase at proportions of 2 mg immobilized protein per gram of palm oil. The experiments were carried out at 45°C. Reactions were performed for a maximum period of 48 h under constant magnetic agitation at 180 rpm. For batch reactions, an aliquot of reaction medium was taken at different times and diluted in n-hexane for gas-chromatography (GC) analysis.

GC analysis

Fatty-acid ethyl esters (FAEE) were analyzed by injecting 1 μl hexane solution and internal standard hexanol into a FID gas chromatograph (Varian CP 3800), using a 6-ft 5% DEGS on Chromosorb WHP, 80/10 mesh column (Hewlett Packard, Palo Alto, CA, USA), following previous established conditions [38]. The yield was defined as the concentration ratio of transformed oil to initial oil × 100.

Viscosity determination

The absolute viscosity of biodiesel was determined with a LVDV-II cone-and-plate spindle Brookfield viscometer (Brookfield Viscometers Ltd., UK) using a CP 42 cone. A circulating water bath was used to maintain the temperature at 40°C during the assays. Biodiesel samples of 0.5 ml were used, and the measurements were replicated three times.

Results and discussion

Effects of polyelectrolyte complex type, chemical modification with TNBS, and activation agent on immobilization performance

Polyelectrolyte complexes (PEC) were used as matrices for immobilizing Lipolase® by different protocols. Immobilization performance was assessed through three parameters: immobilized protein, recovered activity, and thermal stability of the biocatalyst. Chitosan hydrogel without hybridization was used as a control for comparisons. The concentrations of chitosan and other biopolymers were previously established in our laboratory [1].

The effect of using TNBS to increase support hydrophobicity was also evaluated. This compound blocks the chitosan NH2 groups, increasing the hydrophobicity of the support and, consequently, reducing its degree of swelling. This action of TNBS is expected to improve the affinity of TLL with respect to the immobilization support, thus facilitating interaction between the enzyme and accessible active groups of the matrix and, consequently, increasing the number of covalent immobilization points and enhancing enzyme stability. On the other hand, TNBS will react with amine groups of the support and thus will reduce the number of reactive sites for glutaraldehyde, which negatively impacts on multipoint covalent immobilization and stabilization of the protein for this activation agent. Nevertheless, glutaraldehyde is reported to react also with hydroxyl groups of the support, although it is more reactive with amine groups. This fact was observed when sodium alginate was cross-linked with glutaraldehyde, for encapsulating a natural liquid pesticide [15].

Addition of alginate to chitosan improved the structure of the hybrid gel with respect to pure chitosan beads. Although similar loads of immobilized protein were attained, the apparent hydrolytic activity (HAapp) for chitosan-alginate was twofold higher than pure chitosan. Chitosan-PVA showed a less pronounced improvement in activity, and the other two hybrid hydrogels did not present a consistent tendency for increased activity with respect to pure chitosan.

Another aspect that can be pointed out from the results in Table 1 is that the action of TNBS generally resulted in higher half-lives and, consequently, higher SF. Chitosan-alginate-TNBS presented the greatest improvement in t 1/2 (460% for GLY, 270% for EPI, and 370% for GLU). Chitosan-alginate without chemical modification was 4–5-fold less stable than the hybrid hydrogels modified by TNBS. The second hybrid matrix with higher thermal stability was chitosan-PVA activated with glycidol and epichlorohydrin, which were 30.1- and 31.4-fold more stable than soluble lipase, respectively. With respect to thermal stability, the influence of the biopolymer was found to be in the following order: alginate > PVA > gelatin > pure chitosan > κ-carrageenan. Pure chitosan and chitosan-κ-carrageenan linked by TNBS showed similar thermal stability at 70°C.

Chemical modification of pure chitosan with TNBS did not improve the immobilization parameters for any of the activation agents. Probably, even if TNBS might have improved the microenvironment for lipase immobilization, the poor geometric congruency between pure chitosan and the enzyme did not allow the formation of new bonds between lipase and the active groups in the support. However, when using polyelectrolyte complexes to form hybrid matrices, the presence of TNBS did lead to an increase in the stability factor and hydrolytic activity.

Among the tested activating agents, glutaraldehyde (GLU) gave the highest percentage of immobilized protein, due to its higher reactivity at basic pH [1, 28]. However, the formation of a greater number of links between the support and active groups of the enzyme may cause distortions in its tertiary structure. This behavior may be the cause of the lower RA observed for all cases where GLU was used, as shown in Table 1. Besides, it has been reported that glutaraldehyde can also react with other groups of the enzyme [19]. In consequence, higher amounts of protein could be immobilized on supports activated with GLU (see IP values in Table 1), but the immobilized enzyme activity and the enzyme recovery were higher for derivatives obtained using glyoxyl groups (GLY and EPI).

Among the four tested biopolymers, the best immobilization parameters were obtained using alginate, with the hybrid matrix modified with TNBS. After offering 5 mg enzyme per gram of gel, the three activation agents led to similar immobilized enzyme activities, the one obtained with GLY (234 IU g−1 of gel) being the highest. Similar stability factors, around 45, were obtained with the three activation agents.

It should be noticed that GLU always demanded a higher amount of enzyme offered for immobilization (IP for GLU was 2–3 times higher than for GLY and EPI for all the matrices studied, see Table 1).

A general trend observed in these data is that TNBS always improved the recovered activity (RA), and the ratio HAapp/IP was always higher for the more hydrophobic matrix. This means that, in this case, the percentage of immobilized lipase molecules that were catalytically active was larger, an indication that the lipase may have been linked preferably in the open-lid conformation, thus providing an overall more active biocatalyst. Additionally, access of olive oil to the enzyme active site may have been facilitated by the higher hydrophobicity of the microenvironment.

Chitosan-alginate, chemically modified with TNBS, was the support that showed best performance, for all the activation agents. With GLY and EPI, its HAapp/IP ratio was significantly higher than for the other supports. For GLU, the effect of hydrophobization was less pronounced, and for chitosan-alginate this ratio even decreased after chemical modification with TNBS. This may be due to distortion of the enzyme structure, or to reduction of pore diameters after cross-linking of the matrix, both caused by the high reactivity of this activation agent.

Chitosan-κ-carrageenan without TNBS was the polyelectrolyte complex with lowest hydrolytic activity, for all activation agents. This hydrogel, with its sulfonic groups, is the most hydrophilic hybrid support among the tested ones, which is corroborated by its high swelling behavior. Similar results were found by Tapia et al. [35], who reported that chitosan–alginate is also better than chitosan–carrageenan for use as a drug-release matrix system. In addition, the chitosan–alginate system showed higher mean dissolution time than the chitosan–carrageenan system, confirming the different internal structure of the compared gels.

Figure 1 shows the immobilization course of the enzyme on chitosan-alginate-TNBS activated with glycidol, epichlorohydrin, and glutaraldehyde. As expected, immobilization on the GLU-activated support was more rapid than on glyoxyl supports. At 12 h, 70% of the enzyme activity, corresponding to approximately 3.5 mg protein per gram of gel, was immobilized for GLU, while glyoxyl supports (GLY and EPI) had only 30% of the enzyme immobilized. Unsurprisingly, enzyme immobilization on glyoxyl-chitosan-alginate-TNBS was quite a slow process. According to Palomo et al. [26], this behavior may be credited to the low amount of Lys groups in the TLL structure (only seven lysine residues). Chitosan-alginate-TNBS-GLU was faster due to its high reactivity at alkaline pH.

Immobilization of TLL on chitosan-alginate-TNBS. Activity of the supernatant for the gel activated with glutaraldehyde (filled circles), glycidol (filled squares), and epichlorohydrin (open squares); the free enzyme control (open circles) shows that the soluble enzyme does not inactivate during the immobilization procedure

Figure 2 shows the stabilization effect for TLL-chitosan-alginate-TNBS derivatives. The half-lives (t 1/2) for the three derivatives were very close, from 3.89 to 3.99 h, with SF in the range 44.2–45.3.

Thermal stability of TLL soluble (open circles) and immobilized on hybrid hydrogel chitosan-alginate-TNBS activated with glutaraldehyde (closed circles), glycidol (closed squares), and epichlorohydrin (open squares). Inactivation tests were carried out at 70°C in 100 mM sodium phosphate buffer pH 8.0

The hydrophobicity of the matrices was evaluated by adsorption of the hydrophobic dye Rose Bengal. This methodology was used to estimate the increase of the hydrophobicity of the hydrogel chitosan-alginate chemically modified by TNBS. Chitosan-alginate without chemical modification was the control. The results are shown in Fig. 3, and they indicate that after 15 min chitosan-alginate-TNBS had adsorbed 3 times more Rose Bengal dye than the non-chemically modified hydrogel. After 60 min, the non-chemically modified hydrogel had adsorbed 771.0 ± 9.8 and the chemically modified one 973.3 ± 21 μg g−1 of gel.

Chitosan is hydrophilic due to the presence of the amino groups, but after chemical modification and cross-linking, an increase in its hydrophobicity, and therefore a reduction in its degree of swelling, is expected [11]. In view of this, the degree of swelling of nonmodified and modified chitosan-alginate was also evaluated, after incubation in water for 24 h at pH 7.0. The swelling degree of the nonmodified chitosan-alginate was 161.9 ± 14.4%, almost twice the value of TNBS-modified matrix, 68.8 ± 5.0%. At pH 3.0, total dissolution of the nonmodified chitosan-alginate hydrogel was verified while the modified matrix kept its integrity (data not shown).

The degree of linkage of amine groups in chitosan-alginate chemically modified and activated with GLY, EPI or GLU was determined by TNBS assays, as previously described. The results are shown in Fig. 4. The control, chitosan-alginate after chemical modification with TNBS but without activation, had 54% of its amine groups linked to TNBS after the hydrophobization procedure. GLY does not react with amine groups, within the accuracy of the experiments (Fig. 4). EPI has a significant interaction with these groups, since the ratio of free amine groups was reduced in 25% after activation with this agent (DL = 78%). As expected, the degree of linkage for GLU was very high (DL = 91%), considerably exceeding the DL of the control. During the activation with GLU, the amine groups of chitosan are activated to form Schiff bases, followed by covalent immobilization of the enzyme. GLY and EPI react preferentially with hydroxyl groups of the support. Consequently, the microenvironment of the support is more hydrophobic with GLU activation, since the number of amine groups available in the polymeric structure will be reduced [11].

The results obtained for dye adsorption, degree of swelling, and degree of linkage of amine groups of the chitosan-alginate hydrogel modified with TNBS confirmed the formation of a hydrophobic microenvironment, which may favor both the enzyme–support interaction during the immobilization procedure and the catalytic action of the enzyme on its substrate (vegetable oils).

A control assay also was carried out with chitosan-alginate-TNBS without activation. This hybrid matrix was submitted to oxidation with sodium periodate. The periodate ion (IO -4 ) attacks vicinal diols to cleave the carbon–carbon bond in complex carbohydrates such as chitosan and alginate, through an oxidation reaction, leading to the formation of a dialdehyde [40]. Cross-linking of amine and hydroxyl groups in chitosan and alginate reduces periodate oxidation and, consequently, the solubilization of biopolymers [40]. Nonactivated chitosan-alginate-TNBS was oxidized with sodium periodate (300 μmol g−1 of gel), and almost all support was solubilized in the immobilization conditions (pH 10.05). However, in activated chitosan-alginate-TNBS, solubilization of the support at pH 10.05 was not verified. Activation of chitosan-alginate-TNBS with these agents also cross-linked hydroxyl and amine groups of the support by intra- and intermolecular interactions of the biopolymers.

According to these results, activation with bifunctional agents was able to sustain support integrity at alkaline pH, with improvement in chemical and mechanical stability and physical durability, important characteristics to make enzyme immobilization on chitosan-alginate-TNBS hydrogel feasible.

Influence of immobilization time and reduction with sodium borohydride

Increase of immobilization reaction time allows the formation of more bonds between enzyme and support. This is actually a trade-off between enzyme activity, which may decrease due to distortion of the macromolecule, and stability, since an increase of thermal stability is expected as the tertiary structure becomes more rigid [1, 20, 28]. The results in Table 2 were obtained running the enzyme immobilization for 12 and 24 h, using chitosan-alginate chemically modified with TNBS as support.

Although similar amounts of immobilized protein were obtained at 12 and 24 h, the immobilized apparent activities after 24 h were in the range from 24% (with GLU) to 40% (with GLY and EPI), lower than those obtained after 12 h. The increase in the immobilization time, however, did not improve the stability factors.

Multipoint covalent immobilization between enzyme and support occurs in two steps. First, single bonds are quickly formed. Since the support and the protein are not complementary structures, after the first linkages the enzyme loses flexibility and the formation of new bonds may require longer immobilization times, to allow correct alignment between the reactive groups of the enzyme and the support [8, 20, 27]. This effect can also distort the enzyme structure and reduce the hydrolytic activity of the biocatalyst, but an increase in thermal stability may occur [1]. However, our results indicated that, in the present case, an increase of the immobilization time did not enhance the thermal stability of the derivatives. Therefore, an immobilization time of 12 h was selected.

The influence of Schiff’s bases reduction with NaBH4 on the hydrolytic activity and thermal stability of the derivatives may also be assessed from the results in Table 2. Schiff’s bases (C=N double bond) are formed between the aldehyde group of the support and amine groups of the enzyme [1, 28]. The reduction of Schiff’s bases to transform them into stable covalent bonds, as well as to transform the reactive aldehyde groups into inert hydroxyl groups, is an important step in the immobilization process [1, 28]. The observed activities of the derivatives were 11–23% lower after the reduction step, for all the activation agents and immobilization times, with the losses being more significant for activation with GLU. According to the literature, loss of derivative activity after reduction with NaBH4 has been related to a possible reduction of disulfide bonds of the enzyme [28].

Maximum protein loading

To determine the maximum protein loading that could be used in immobilization of TLL on the chitosan-alginate-TNBS support activated using different protocols, the amount of protein offered to the support was varied from 5 to 50 mg g−1 of gel. Results are presented in Table 3.

For the maximum offered protein loading (50 mg g−1 of gel), hydrogel activated by GLU gave the highest value of immobilized protein (17.5 mg immobilized protein per gram of gel). With GLY and EPI, 7.76 and 7.65 mg protein were immobilized per gram of gel, respectively. However, the highest apparent activity was obtained with EPI (364.8 IU g−1 of gel). Again, the high reactivity of glutaraldehyde may be responsible for this result. It is possible that, under these conditions, there is formation of bonds between the enzyme and support that cause distortion in the three-dimensional structure of the enzyme, leading to an inactive conformation of many enzyme molecules, or to poor orientation of the immobilized protein, preventing substrate access to the catalytic site. Besides, diffusion effects may be responsible for part of the nonmeasured activity of the immobilized enzyme.

The recovered activity decreased with the increase of the protein loading for all derivatives, being more severe for GLU, as expected. The value of this parameter decreased from nearly 30% for the lower lipase offered loading (5 mg g−1 of gel) to less than 10% for the maximum loading (50 mg g−1 of gel). The intrinsic velocity, which would be measured in the absence of mass transfer effects, is proportional to the enzyme loading. However, when this loading increases, the rate-controlling step will shift from the intrinsic reaction to pore diffusion, and an intraparticle profile of substrate concentrations would cause a reduction of the effectiveness factor of the biocatalyst bead. Besides that, the effective diffusion coefficient within the gel may decrease even further in the presence of a high amount of immobilized molecules of enzyme, due to a reduction of the porous effective diameter caused by spatial hindrance [28].

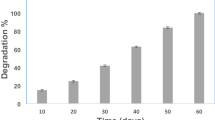

Biodiesel synthesis

In the biodiesel synthesis assays, the molar ratios were 1:18 (palm oil:ethanol), and 2 mg immobilized protein per gram of oil was used, in solvent-free medium. This means an enzyme loading, in terms of apparent hydrolytic activity, of 378.4, 391.0, and 120.7 IU per gram of oil for GLY, EPI, and GLU derivatives, respectively. Figure 5 shows the progress of the enzymatic reaction for each system. The maximum conversion (100%) was obtained at 48 h for GLY and EPI derivatives, time when the GLU derivative had converted only 85.5% of the substrate. The final viscosity of the biodiesel produced by derivatives activated via glyoxyl (GLY and EPI) was less than 5 cSt, in accordance with specifications of the Brazilian Petroleum Agency (ANP) for biofuel. Therefore, transesterification mediated by GLY and EPI derivatives provided a biodiesel complying with ANP specifications after 20 h of reaction, while the GLU derivative required more than 48 h to reach the same conversion.

The amount of immobilized protein was used as a basis for comparison of the performance of the derivatives in place of their apparent hydrolytic activity. This approach was taken because the three derivatives could well present different behaviors for palm oil transesterification and for olive oil hydrolysis. Still, the conversion profiles for biodiesel synthesis (Fig. 5) indicated that the recovered activity for each of the three derivatives was similar when assessed using palm oil transesterification or olive oil hydrolysis as the standard reaction for definition of biocatalyst activity. In other words, GLY and EPI derivatives showed recovered synthetic activities around threefold higher than GLU derivatives, the same proportion that was already observed for olive oil hydrolysis. Therefore, the enzyme loading in the reactor for the GLU derivative was approximately threefold lower than for the two other derivatives, and unsurprisingly a longer reaction time was required.

It should be stressed that TLL covalently immobilized on glyoxyl supports was already reported to present high stability in transesterification of soybean oil with ethanol, exhibiting similar activity after three sequential batches [29]. These results indicate that covalently immobilization of TLL is a promising approach for biodiesel synthesis by transesterification of vegetable oils with ethanol.

Higher recovered activity of the derivative implies lower demand for enzyme to produce the industrial biocatalyst, naturally leading to lower process costs. From this point of view, although the three derivatives were able to convert palm oil to biodiesel and presented similar apparent activities and thermal stabilization, TLL immobilized on chitosan-alginate-TNBS activated by glyoxyl (GLY and EPI) is a more attractive option for both hydrolysis and transesterification of vegetable oils.

Conclusions

Different biopolymers such as gelatin, κ-carrageenan, PVA, and sodium alginate were used to produce polyelectrolyte complexes (PEC) as supports for immobilization of a microbial lipase. Chitosan-alginate was the PEC that led to the highest thermal stability and apparent hydrolytic activity. Chemical modification of the hybrid hydrogels with TNBS increased the hydrophobicity of the enzyme microenvironment, which was confirmed by measuring hydrophobic dye adsorption, swelling degree, and degree of linkage of amine groups. The chemical modification led also to an increase in the thermal stability of all the produced hybrid hydrogels. Chitosan-alginate-TNBS derivatives presented higher hydrolytic activity and thermal stability, being 45-fold more stable than soluble lipase at 70°C. The maximum protein loading immobilized was 17.5 mg g−1 of gel for glutaraldehyde, 7.76 mg g−1 of gel for glycidol, and 7.65 mg g−1 of gel for epichlorohydrin derivatives, when 50 mg protein per gram of gel was offered for immobilization. The three derivatives presented similar apparent activities, both for hydrolysis of olive oil and for synthesis of biodiesel, but glycidol and epichlorohydrin showed higher recovered activities, being therefore more attractive for use either in aqueous or in organic media. Further studies are demanded, however, to increase the biocatalyst operational stability and to reduce the cost of immobilization, thus allowing application in a real industrial process.

References

Adriano WS, Mendonça DB, Rodrigues DS, Mammarella EJ, Giordano RLC (2008) Improving the properties of chitosan as support for the covalent multipoint immobilization of chymotrypsin. Biomacromolecules 9:2170–2179

Beppu MM, Arruda EJ, Vieira RS, Santos NN (2004) Adsorption of Cu(II) on porous chitosan membranes functionalized with histidine. J Membr Sci 240:227–235

Berger J, Reist M, Mayer JM, Felt O, Gurny R (2004) Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur J Pharm Biopharm 57:19–34

Blanco RM, Terreros P, Fernández-Pérez M, Otero C, Díaz-González G (2004) Functionalization of mesoporous silica for lipase immobilization characterization of the support and the catalysts. J Mol Catal B Enzym 30:83–93

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Chen L, Tian Z, Du Y (2004) Synthesis and pH sensitivity of carboxymethyl chitosan-based polyampholyte hydrogels for protein carrier matrices. Biomaterials 25:3725–3732

de Castro HF, Mendes AA, Santos JC, Aguiar CL (2004) Modificação de óleos e gorduras por biotransformação. Quim Nova 27:146–156

Fernandez-Lafuente R, Cowan DA, Wood ANP (1995) Hyperstabilization of a thermophilic esterase by multipoint covalent attachment. Enzyme Microb Technol 17:366–372

Fernandez-Lorente G, Godoy CA, Mendes AA, Lopez-Gallego F, Grazu V, de las Rivas B, Palomo JM, Hermoso J, Fernandez-Lafuente R, Guisan JM (2008) Solid-phase chemical amination of a lipase from Bacillus thermocatenulatus to improve its stabilization via covalent immobilization on highly activated glyoxyl-agarose. Biomacromolecules 9:2553–2561

Guisan JM (1988) Aldehyde gels as activated support for immobilization–stabilization of enzymes. Enzyme Microb Technol 10:375–382

Gupta KC, Jabrail FH (2006) Effects of degree of deacetylation and cross-linking on physical characteristics, swelling and release behavior of chitosan microspheres. Carbohydr Polym 66:43–54

Jaeger KE, Ransac S, Djikstra BW, Colson C, Van Heuvel M, Misset O (1994) Bacterial lipases. FEMS Microbiol Rev 15:29–63

Kathuria N, Tripathi A, Kar KK, Kumar A (2009) Synthesis and characterization of elastic and macroporous chitosan-gelatin cryogels for tissue engineering. Acta Biomater 5:406–418

Krajewska B (2004) Application of chitin-and chitosan-based materials for enzyme immobilizations: a review. Enzyme Microb Technol 35:126–139

Kulkarni AR, Soppimath KS, Aminabhavi TM, Dave AM, Mehta MH (2000) Glutaraldehyde crosslinked sodium alginate beads containing liquid pesticide for soil application. J Controlled Release 63:97–105

Li N, Bai R (2005) A novel amine-shielded surface cross-linking of chitosan hydrogel beads for enhanced metal adsorption performance. Ind Eng Chem Res 44:6692–6700

Lopez-Gallego F, Montes T, Fuentes M, Alonso N, Grazú V, Betancor L, Guisan JM, Fernandez-Lafuente R (2005) Improved stabilization of chemically aminated enzymes via multipoint covalent attachment on glyoxyl supports. J Biotechnol 116:1–10

Malcata FX, Reyes HR, Garcia HS, Hill CG Jr, Amundson CH (1990) Immobilized lipase reactors for modification of fats and oils. A review. J Am Oil Chem Soc 67:890–910

Manrich A, Galvão CMA, Jesus CDF, Giordano RC, Giordano RLC (2008) Immobilization of trypsin on chitosan gels: Use of different activation protocols and comparison with other supports. Int J Biol Macromol 43:54–61

Mateo C, Palomo JM, Fuentes M, Betancor L, Grazú V, Lopez-Gallego F, Pessela BCC, Hidalgo A, Fernandez-Lorente G, Fernandez-Lafuente R, Guisan JM (2006) Glyoxyl agarose: a fully inert and hydrophilic support for immobilization and high stabilization of proteins. Enzyme Microb Technol 39:274–280

Mi FL, Sung HW, Shyu SS (2002) Drug release from chitosan-alginate complex beads reinforced by a naturally occurring cross-linking agent. Carbohydr Polym 48:61–72

Mi FL, Tan YC, Liang HF, Sung HW (2002) In vivo biocompatibility and degradability of a novel injectable-chitosan-based implant. Biomaterials 23:181–191

Moreira ABR, Perez VH, Zanin GM, de Castro HF (2007) Biodiesel synthesis by enzymatic transesterification of palm oil with ethanol using lipases from several sources immobilized on Silica–PVA composite. Energy Fuels 21:3689–3694

Palomo JM, Fuentes M, Fernandez-Lorente G, Mateo C, Guisan JM, Fernandez-Lafuente R (2003) General trend of lipase to self-assemble giving bimolecular aggregates greatly modifies the enzyme functionality. Biomacromolecules 4:1–6

Palomo JM, Muñoz G, Fernandez-Lorente G, Mateo C, Fernandez-Lafuente R, Guisan JM (2002) Interfacial adsorption of lipases on very hydrophobic support (octadecyl–Sepabeads): immobilization, hyperactivation and stabilization of the open form of lipases. J Mol Catal B Enzym 19:279–286

Palomo JM, Ortiz C, Fernandez-Lorente G, Fuentes M, Guisan JM, Fernández-Lafuente R (2005) Lipase–lipase interactions as a new tool to immobilize and modulate the lipase properties. Enzyme Microb Technol 36:447–454

Pedroche J, Yust MM, Mateo C, Fernandez-Lafuente R, Girón-Calle J, Alaiz M, Vioque J, Guisan JM, Millán F (2007) Effect of the support and experimental conditions in the intensity of the multipoint covalent attachment of proteins on glyoxyl-agarose supports: correlation between enzyme–support linkages and thermal stability. Enzyme Microb Technol 40:1160–1166

Rodrigues DS, Mendes AA, Adriano WS, Gonçalves LRB, Giordano RLC (2008) Multipoint covalent immobilization of microbial lipase on chitosan and agarose activated by different methods. J Mol Catal B Enzym 51:100–109

Rodrigues RC, Pessela BCC, Volpato G, Fernandez-Lafuente R, Guisan JM, Ayub MAZ (2010) Two step ethanolysis: A simple and efficient way to improve the enzymatic biodiesel synthesis catalyzed by an immobilized–stabilized lipase from Thermomyces lanuginosus. Process Biochem 45:1268–1273

Sadana A, Henley AP (1987) Single-step unimolecular non-first-order enzyme deactivation kinetics. Biotechnol Bioeng 30:717–723

Sarda L, Desnuelle P (1958) Action de la lipase pancréatique sur les esters en émulsion. Biochim Biophys Acta 30:513–521

Sharma R, Chisti Y, Banerjee UC (2001) Production, purification, characterization and applications of lipases. Biotechnol Adv 19:627–662

Soares CMF, de Castro HF, Zanin GM, de Moraes FF (1999) Characterization and utilization of Candida rugosa lipase immobilized on controlled pore silica. Appl Biochem Biotechnol 77(79):745–757

Soumanou MM, Bornscheuer UT (2003) Lipase-catalyzed alcoholysis of vegetable oils. Eur J Lipid Sci Technol 105:656–660

Tapia C, Escobar Z, Costa E, Sapag-Hagar J, Valenzuela F, Basualto C, Gai MN, Yazdani-Pedram M (2004) Comparative studies on polyelectrolyte complexes and mixtures of chitosan–alginate and chitosan–carrageenan as prolonged diltiazem clorhydrate release systems. Eur J Pharm Biopharm 57:65–75

Tardioli PW, Fernandez-Lafuente R, Guisan JM, Giordano RLC (2003) Design of new immobilized–stabilized carboxypeptidase a derivative for production of aromatic free hydrolysates of proteins. Biotechnol Prog 19:565–574

Tardioli PW, Pedroche J, Giordano RLC, Fernandez-Lafuente R, Guisan JM (2003) Hydrolysis of proteins by immobilized-stabilized alcalase-glyoxyl agarose. Biotechnol Prog 19:352–360

Urioste D, Castro MBA, Biaggio FC, de Castro HF (2008) Síntese de padrões cromatográficos e estabelecimento de método para dosagem da composição de ésteres de ácidos graxos presentes no biodiesel a partir do óleo de babaçu. Quím Nova 31:407–412

Verger R (1997) Interfacial activation of lipases: facts and artifacts. Trends Biotechnol 15:32–38

Vold IMN, Christensen BE (2005) Periodate oxidation of chitosans with different chemical compositions. Carbohydr Res 340:679–684

Acknowledgments

The authors gratefully acknowledge FAPESP (Brazil) for financial support (Project 04/14593-4) and Novozymes S.A. (Araucária-PR, Brazil) for the donation of the TLL enzyme preparation used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation at the 32nd Symposium on Biotechnology for Fuels and Chemicals

Rights and permissions

About this article

Cite this article

Mendes, A.A., de Castro, H.F., de S. Rodrigues, D. et al. Multipoint covalent immobilization of lipase on chitosan hybrid hydrogels: influence of the polyelectrolyte complex type and chemical modification on the catalytic properties of the biocatalysts. J Ind Microbiol Biotechnol 38, 1055–1066 (2011). https://doi.org/10.1007/s10295-010-0880-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0880-9