Abstract

The present study reports the feasibility of using Rhodotorula glutinis biomass as an alternative low-cost biosorbent to remove Ni(II) ions from aqueous solutions. Acetone-pretreated R. glutinis cells showed higher Ni(II) biosorption capacity than untreated cells at pH values ranging from 3 to 7.5, with an optimum pH of 7.5. The effects of other relevant environmental parameters, such as initial Ni(II) concentration, shaking contact time and temperature, on Ni(II) biosorption onto acetone-pretreated R. glutinis were evaluated. Significant enhancement of Ni(II) biosorption capacity was observed by increasing initial metal concentration and temperature. Kinetic studies showed that the kinetic data were best described by a pseudo-second-order kinetic model. Among the two-, three-, and four-parameter isotherm models tested, the Fritz-Schluender model exhibited the best fit to experimental data. Thermodynamic parameters (activation energy, and changes in activation enthalpy, activation entropy, and free energy of activation) revealed that the biosorption of Ni(II) ions onto acetone-pretreated R. glutinis biomass is an endothermic and non-spontaneous process, involving chemical sorption with weak interactions between the biosorbent and Ni(II) ions. The high sorption capacity (44.45 mg g−1 at 25°C, and 63.53 mg g−1 at 70°C) exhibited by acetone-pretreated R. glutinis biomass places this biosorbent among the best adsorbents currently available for removal of Ni(II) ions from aqueous effluents.

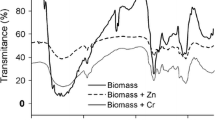

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Divalent nickel [Ni(II)] is a toxic heavy metal present in raw wastewater streams from industries such as electroplating, non-ferrous metal, mineral processing, paint formulation, porcelain enameling, copper sulfate and battery manufacture, as well as from steam-electric power plants [1]. The effluent emanating from these industries often contains high concentrations of Ni(II) ions, which are toxic to both higher and lower organisms [1, 2]. In humans, Ni(II) can cause various types of acute and chronic health disorders, such as severe damage of lungs and kidney, skin dermatitis, nausea, vomiting, diarrhea, pulmonary fibrosis, renal edema, chest pain, rapid respiration, cyanosis and extreme weakness [3, 4]. Besides, it is well known that nickel is carcinogenic and this effect is probably related to its lipid-peroxidation properties, which induce DNA-strand gaps and breaks, and DNA–protein crosslinks [5]. Moreover, nickel has been implicated as a nephrotoxin [5], teratogen and embryotoxin [3].

The United States Environmental Protection Agency (EPA) and the World Health Organization (WHO) have established drinking water guidelines for nickel of 0.1 mg l−1 [6] and 0.07 mg l−1 [7], respectively. In order to meet the water quality standards for most countries, it is essential to reduce the concentration of Ni(II) ions and of other heavy metals in industrial wastewaters to their permissible limits before discharge to the environment.

A number of conventional technologies, such as adsorption on activated carbon, ion exchange, chemical precipitation and crystallization in the form of nickel carbonate, have been used to remove Ni(II) ions from industrial wastewaters, surface water and ground waters [6, 7]. However, these technologies are either ineffective or expensive when heavy metals are present in the waters at low concentrations, usually in the range of 1–100 mg l−1, or when low concentrations of heavy metals in treated waters are required [8]. Therefore, it is crucial to develop economic, efficient and secure technologies to remove heavy metals in order to protect the environment, and public health and safety in a cost effective and environmentally friendly manner.

Biosorption has emerged as an alternative sustainable strategy for cleaning up water that has been contaminated with toxic metals by anthropogenic activities and/or by natural processes [9]. It utilizes the properties of certain kinds of inactive or dead biomass to bind and accumulate these pollutants by different mechanisms, such as physical adsorption, chemisorption, complexation, ion exchange and surface-microprecipitation [10]. A vast array of biological materials, especially bacteria, algae, yeasts and filamentous fungi have received increasing attention due to their good performance regarding heavy metal removal and water recovery, as well as their low cost and large available quantities [11].

Despite the well-known potential of yeasts to remove heavy metal cations from aqueous solutions, only scarce information is available on the sorption ability of heavy metals by Rhodotorula glutinis [12, 13]. This yeast is distributed widely in nature and is potentially useful to industry since it is able to produce carotenoids when grown on various cheap raw materials of agro-industrial origin [14, 15]. The biomass left after carotenoid extraction from R. glutinis is a waste material from biotechnological processes that may be used as a potential biosorbent for the removal of heavy metals from aqueous solutions.

To the best of our knowledge, R. glutinis has not been used previously as a biosorbent for Ni(II) biosorption from aqueous solutions containing this heavy metal. In Saccharomyces cerevisae, a yeast amply studied for biosorption purposes, the highest Ni(II) biosorption level was at pH 5 [16]. In the case of protonated baker’s yeast and of three different species of Candida, the highest Ni(II) biosorption levels were obtained at pH values of 6.75 [2] and 6.5 [17], respectively.

The main aim of the present work was to study the effect of different environmental parameters such as pH, initial Ni(II) concentration, contact time, and temperature on the ability of untreated and acetone-pretreated R. glutinis biomass to biosorb Ni(II) ions from aqueous solutions. Furthermore, the kinetics, isotherm and thermodynamics of Ni(II) biosorption by R. glutinis are described.

Materials and methods

Microorganism

The Rhodotorula glutinis strain used throughout this work was obtained from the Biotechnology and Bioengineering Department Culture Collection at the Centro de Investigación y de Estudios Avanzados (CINVESTAV), Instituto Politécnico Nacional, Mexico. The yeast was maintained on YPD agar slants (2% dextrose, 1% yeast extract, 1% casein peptone, and 2% agar) at 4°C.

Preparation of R. glutinis biomass for biosorption experiments

Rhodotorula glutinis yeast cells were grown in 500 ml Erlenmeyer flasks containing 100 ml liquid YPD medium (20 g l−1 dextrose, 10 g l−1 yeast extract, and 10 g l−1 casein peptone). Yeast cultures were incubated in a shaker (model K12504-70, Cole Parmer, Vernon Hills, IL) at 120 rpm for 24 h at 25°C. The yeast cells obtained were separated by centrifuging at 3,500 rpm for 15 min, and washed three times with distilled deionized water. The resulting cell pellet was then divided into two equal portions. One portion was dried at 60°C for 24 h and used further for Ni(II) biosorption experiments. The other portion was treated three times with analytical grade acetone (Baker, Phillipsburg, NJ), following the procedures described by Aksu and Eren [14], in order to extract total carotenoids. The acetone-pretreated yeast biomass was then washed thoroughly with distilled deionized water, dried at 60°C for 24 h, and subsequently used for Ni(II) biosorption experiments.

Nickel(II) solutions for biosorption experiments

Ni(II) solutions were obtained by diluting 2 g l−1 stock Ni(II) solution, which was prepared by dissolving a weighed quantity of analytical grade nickel sulfate hexahydrate (NiSO4·6H2O; Baker, purity >99.1%) in distilled deionized water. In this work, the initial Ni(II) concentration varied from 10 to 400 mg l−1 and the pH of each Ni(II) solution was adjusted to desired pH value in the range of 3–7.5 ± 0.1 with 0.1 N HCl and NaOH solutions.

Batch biosorption studies and analytical method

Batch biosorption dynamics were analyzed to determine the effect of solution pH, initial Ni(II) concentration, shaking contact time and temperature on Ni(II) biosorption by R. glutinis biomass. All experiments were conducted in 500 ml Erlenmeyer flasks containing 100 ml Ni(II) solution of known concentration and 1 g (dry weight) l−1 yeast biomass. The pH of each Ni(II) solution was maintained constant (±0.1 pH unit) throughout the course of the experiments by periodic checking and adjustment with 0.1 N HCl and/or NaOH aqueous solutions. Flasks were agitated in a shaker (model K12504-70, Cole Parmer) at 140 rpm constant shaking speed.

Untreated biomass and acetone-pretreated biomass of R. glutinis were used as biosorbents to study the influence of pH level on Ni(II) sorption. These experiments were performed at different pH values ranging from 3 to 7.5 ± 0.1, with a Ni(II) solution at an initial metal concentration of 60 mg l−1 [approximately 1 mM Ni(II)], at 25°C. In these experiments, the acetone-pretreated biomass of R. glutinis exhibited higher Ni(II) ion biosorption capacity than the untreated biomass, so that the acetone-pretreated biomass was chosen for subsequent studies. In addition, the optimum pH value for Ni(II) biosorption by acetone-pretreated biomass was determined to be 7.5 and used thereafter.

The effect of contact time on Ni(II) biosorption of between 0 and 120 h was studied, with Ni(II) solutions at initial metal concentrations ranging from 10 to 400 mg l−1, at 25°C.

To investigate the effect of initial Ni(II) concentration on kinetic performance, experiments were carried out with Ni(II) solutions at initial metal concentrations ranging from 10 to 400 mg l−1, at 25°C.

For the isotherm studies, the biosorbent (1 g l−1) was brought into contact with solutions of different initial Ni(II) concentration (10–400 mg l−1) at 25°C, with constant agitation (140 rpm) for 120 h to ensure sorption equilibrium was reached.

The effect of temperature on Ni(II) biosorption was studied by varying temperatures from 25 to 70°C and two different initial Ni(II) concentrations (60 and 150 mg l−1) were used.

Blanks and biosorbent-free controls were run concurrently and under exactly the same conditions as those used for the Ni(II) biosorption experiments in order to check for glassware sorption of the heavy metal and other side potential effects (metal precipitation, etc.). Biosorbent-free controls included Ni(II) solutions but not biosorbent, and blanks consisted on biosorbent and distilled deionized water. No measurable change in Ni(II) concentration was detected in the blanks and biosorbent-free controls throughout the various sorption experiments conducted in our work, which suggests that the observed removal of Ni(II) in the experiments with R. glutinis biomass was due only to the biosorbent.

Samples were collected at different experimental times and filtered through 1.6 μm filters (Whatman GF/A). The filtrates obtained were then analyzed for Ni(II) concentrations by using the dimethylglyoxime method [18]. The absorbance of the wine red-to-brown colored complex of Ni(II) ion with dimethylglyoxime was read at a wavelength of 465 nm in a Genesys™ 10 UV–Visible spectrophotometer (Thermo Scientific, Rockford, IL).

The amount of Ni(II) sorbed at time t by the biosorbent (q t ), which represents the Ni(II) biosorption capacity (mg g−1), was calculated according to the following mass balance relationship:

where C o is initial Ni(II) concentration (mg l−1) at time t o = 0 h, C res is residual Ni(II) concentration (mg l−1) at time t = t, and X is biosorbent concentration (g l−1). At the sorption equilibrium, C res equals the equilibrium concentration of Ni(II) ions in the solution (C e, mg l−1) and q t equals Ni(II) sorption uptake or equilibrium biosorption capacity of Ni(II) (q e, mg g−1).

Batch experiments were conducted in triplicate and the mean values are reported herein. The maximum coefficient of variation of the three replicas was 5%.

Ni(II) biosorption data were analyzed statistically by analysis of variance (Holm-Sidak method; overall confidence level = 0.05) using SigmaStat 3.5 software. Statistical analysis revealed that the longest contact time required to reach the sorption equilibrium was 2 h and this was found when high initial Ni(II) concentrations were tested; therefore, the results obtained during the first 4 h of contact only are shown in the present work.

Biosorption kinetics modeling

In order to evaluate the kinetic mechanism that controls the Ni(II) biosorption process, pseudo-first-order and pseudo-second-order kinetic models were tested to interpret the experimental data [6, 19]. The pseudo-first-order model and pseudo-second-order model parameters were evaluated by non-linear regression analysis using MATLAB® software (version 7.9; http://www.mathworks.com/products/matlab).

Equilibrium modeling

The equilibrium distribution of Ni(II) ions between the liquid phase and R. glutinis biomass was expressed in terms of a Ni(II) biosorption isotherm. Several two-parameter (Langmuir, Freundlich, Temkin and Dubinin-Radushkevich) [6, 16, 20], three-parameter (Sips, Toth, Redlich-Peterson and Radke-Prausnitz) [20–22], and four-parameter (Fritz-Schluender) [23] sorption isotherm models were used to fit the experimental equilibrium data obtained at different initial Ni(II) concentrations.

Thermodynamic studies

From the results obtained in the kinetic study carried out at different temperatures, the activation energy (E A) for Ni(II) biosorption was calculated by the Arrhenius equation:

Taking the natural log of both sides of Eq. 2, one obtains:

where k 2 is the rate constant of second-order biosorption (g mg−1 h−1), A 0 (g mg−1 h−1) is the frequency factor [24], and E A is the activation energy (kJ mol−1). By plotting ln k 2 versus T −1, a linear relationship is obtained and one can determine E A from the slope (−E A /R) and A o from the y-intercept.

In environmental engineering practice, both energy and entropy factors must be considered in order to determine whether a process will occur spontaneously or not. Therefore, in the present work, the changes in enthalpy (ΔH ‡), entropy (ΔS ‡) and Gibbs free energy (\( \Updelta G^{{\text{\ddag }}} \)) of activation for Ni(II) biosorption were calculated by the Eyring equation [25]:

where k b is the Boltzmann constant (1.3807 × 10−23 J K−1) and h is the Planck constant (6.6261 × 10−34 J s).

The Gibbs free energy change of activation (\( \Updelta G^{{\text{\ddag }}} \)) may be described in terms of entropy change and enthalpy change of activation, as follows [25]:

Non-linear regression analysis

All the model parameters were evaluated by non-linear regression using MATLAB® software (version 7.9). The optimization procedure requires an error function to be defined in order to be able to evaluate the fit of the mathematical model to the experimental data [26]. Therefore, the correlation coefficient (r 2), the residual or sum of squares error (SSE), the root mean squared error or standard error (RMSE) of the estimate and the 95% confidence intervals of the models parameters were used with the purpose of measuring the goodness-of-fit of the sorption models.

SSE can be defined as [26]:

RMSE can be defined as follows [26]:

where q i is the experimental sorption capacity from the batch experiment i, Q i is the sorption capacity estimated from the sorption model for corresponding q i, m is the number of observations in the batch experiment and p is the number of parameters in the regression model [26]. The closer r 2 to 1.0 and the smaller SSE, RMSE and confidence interval values indicate the better curve fitting.

Results and discussion

Effect of pH on Ni(II) ion biosorption

The present work analyzed the effect of solution pH on Ni(II) biosorption onto R. glutinis biomass, either untreated or pretreated with acetone to extract total carotenoids. Different pH levels were assayed within the range of 3 to 7.5 ± 0.1, which were kept constant along each experiment. It is known that at pH > 7.7, hydroxide ions (OH−) in solution may bind to Ni(II) ions to form hydroxylated nickel complexes, such as nickel hydroxide, which tend to precipitate in solution [27, 28]. Under these pH conditions a combined process of nickel biosorption and microprecipitation occurs in which the latter predominates.

In the present study, it was found that, at the different pH levels tested, the Ni(II) biosorption capacity of untreated and acetone-pretreated R. glutinis increased as contact time increased, until it reached a maximum constant value, which corresponded to biosorption equilibrium (Fig. 1). Furthermore, Ni(II) biosorption onto the untreated or acetone-pretreated R. glutinis biomass depended strongly on solution pH. Ni(II) biosorption capacity increased as pH levels rose and was highest at pH 7.5, both for untreated and for acetone-pretreated yeast (Fig. 1).

Effect of solution pH on Ni(II) biosorption by untreated (a) and acetone-pretreated (b) Rhodotorula glutinis biomass [solution pH: multisymbol 3.0, open square 4.0; filled triangle 5.0; filled circle 6.0; open diamond 7.0; plus symbol 7.5; solid line pseudo-second-order model prediction]. Conditions: initial Ni(II) concentration = 60 mg l−1; temperature = 25°C; biosorbent concentration = 1 g l−1. When not shown, error bars are smaller than symbol size

The low levels of Ni(II) biosorption capacity observed at low pH levels could be attributed to the high concentration of hydrogen (H+) and hydronium (H3O+) ions in solution, which compete with Ni(II) ions for the binding sites present in the biomass. At low pH levels, the concentration of H+ and H3O+ ions greatly exceeds the Ni(II) ion concentration and, therefore, the former bind to the ligands and leave Ni(II) ions unbound [29]. As the pH increases, the competing effect of the H+ and H3O+ ions diminishes and the positively charged Ni(II) ions are adsorbed to the free binding sites [2].

The effect of pH on Ni(II) biosorption may also be explained by the ionization of cell surface ligands, which serve as metal binding sites. At high pH values, a net negative charge is present on the cell surface, and the ionic state of the ligands like carboxyl, phosphate, sulfhydril, hydroxyl, imidazole and amino groups is such that it favors the reaction with cationic metals. It is well known that at pH values from 4 to approximately 7.5, Ni(II) ions in aqueous solution are present as divalent positive ions that can interact with negatively charged groups in the biomass [16, 28]. However, as the pH falls, the overall charge of the cell surface becomes more positive, and positively charged cationic metals cannot therefore approach the surface [16, 29].

The highest values of Ni(II) biosorption capacity of untreated and acetone-pretreated R. glutinis cells were 18.1 and 21.1 mg g−1, respectively, and these values were obtained at a pH level of 7.5 (Fig. 1). At this optimum pH value, the Ni(II) biosorption capacity of acetone-pretreated R. glutinis was 16.6% higher than that of untreated biomass, and this difference was statistically significant (P < 0.05). Moreover, at pH 7.5, no statistically significant difference was observed in the biosorption capacities obtained at contact times higher than 1.5 h (P > 0.05), which indicates that biosorption equilibrium was reached at this contact time.

As these results show, acetone pretreatment of R. glutinis increased the Ni(II) biosorption capacity. This could be because acetone caused a change in cell permeability and removed some organic compounds from the cell wall, which caused an increment in binding site availability and in the access of Ni(II) ions to those sites [30]. These findings are of interest because the R. glutinis biomass that remains after total carotenoid extraction with acetone [14, 15] is a waste material with adequate Ni(II) biosorption characteristics, which could be used to detoxify waters contaminated with the metal.

On the other hand, in order to determine the mechanism of Ni(II) biosorption onto R. glutinis, pseudo-first-order and pseudo-second-order kinetic models were used to assay experimental data. Table 1 shows the rate constants (k 1 and k 2) and the Ni(II) biosorption capacity in equilibrium (q e) determined with the models, together with the corresponding correlation coefficients (r 2), SSE and RMSE. As shown, for untreated and acetone-pretreated biomass at all pH levels assayed, with the pseudo-second-order model the correlation coefficients were higher and the SSE and RMSE values lower than those obtained with the pseudo-first-order model. Besides, the values of biosorption capacity at equilibrium (q e) calculated from the pseudo-second-order model were closer to experimental values (exp q e) at all assayed pH levels. Furthermore, the pseudo-second-order model described well the variation of Ni(II) biosorption capacity at all contact times and assayed pH levels (continuous lines in Fig. 1). According to these results, the biosorption system of Ni(II) ions using untreated and acetone-pretreated R. glutinis biomass followed the pseudo-second-order kinetic model, which suggests that the rate-limiting step was a chemical sorption process involving valence forces through the sharing or exchange of electrons between R. glutinis biomass and Ni(II) ions, complexation, coordination and/or chelation [8, 20, 31].

The pseudo-second-order kinetic model has also been applied successfully to Ni(II) biosorption by protonated-baker’s yeast [2], Chlorella vulgaris [32] as well as by diverse agroindustrial by-products, such as wheat straw [33], hazelnut and almond shells [31], and protonated rice bran [8].

The present work revealed that the effect of pH on the rate constant (k 2) of the pseudo-second-order model was opposed to the effect of pH on experimental q e; i.e., the higher the pH level, the lower the k 2 (Table 1). This behavior could be explained because, at pH levels close to neutral, R. glutinis cells biosorb larger amounts of Ni(II) ions and therefore require longer periods of contact to reach equilibrium, as shown in Fig. 1. In contrast, at low pH levels, the amount of Ni(II) biosorbed by the yeast is very low, and therefore equilibrium is reached rapidly, which is manifested as a high k 2 value [34, 35].

Optimal characteristics of Ni(II) biosorption onto acetone-pretreated R. glutinis cells were found for aqueous solution at pH 7.5, and these conditions were therefore used in subsequent studies. In addition, the pseudo-second-order model was used henceforth to describe Ni(II) biosorption kinetics, since it clearly proved to represent them adequately.

Effect of initial Ni(II) concentration and contact time on metal biosorption

In the present work, the effect of initial Ni(II) concentration and contact time on Ni(II) biosorption onto acetone-pretreated R. glutinis was investigated at different initial Ni(II) concentrations, ranging from 10 to 400 mg l−1. Figure 2 shows variations in Ni(II) biosorption capacity as a function of biosorption time for the 12 different initial concentration values assayed. The biosorption curves were single, smooth and continuous leading to saturation of the biosorbent.

Effect of initial metal concentration on Ni(II) biosorption by acetone-pretreated R. glutinis biomass. Initial Ni(II) concentration: filled diamond 10 mg l−1; filled circle 20 mg l−1; Asterisk 30 mg l−1; open diamond 40 mg l−1; open circle 60 mg l−1; filled square 80 mg l−1; plus symbol 100 mg l−1; open triangle 130 mg l−1; multiplication symbol 150 mg l−1; zig zag line 200 mg l−1; filled triangle 300 mg l−1; open square 400 mg l−1; continuous line pseudo-second-order model prediction. Conditions: solution pH = 7.5; temperature = 25°C; biosorbent concentration = 1 g l−1. When not shown, error bars are smaller than symbol size

Biosorption capacity gradually increased as contact time increased, until it reached a maximum constant value. At this point, the Ni(II) amount adsorbed by the biosorbent and the Ni(II) amount desorbed from the biosorbent showed a dynamic equilibrium. Statistical analysis revealed that the contact time needed to reach equilibrium depended on initial Ni(II) concentration (Table 2). At concentrations lower than 100 mg l−1, equilibrium time (t e) increased in parallel to initial metal concentration; in contrast, at concentrations above 150 mg l−1, equilibrium time remained constant. Furthermore, equilibrium was reached in less than 30 min at low and in 2 h at very high initial Ni(II) concentrations (200–400 mg l−1).

Biosorption capacity at equilibrium (exp q e) increased from 6.98 to 44.45 mg g−1 as initial Ni(II) concentration rose from 10 to 400 mg l−1 (Table 2). This increase may be due to greater Ni(II) ion in solution available for biosorption. Besides, the increase in initial Ni(II) concentration could produce a stronger driving force [i.e., concentration gradient of Ni(II) ions] to overcome all mass transfer resistances of Ni(II) ions between the aqueous solution and the biosorbent, which results in a higher probability of collision between Ni(II) ions and the biosorbent. This, in turn, leads to a greater biosorption capacity of the metal ion [6]. These results also show that saturation of the biosorbent surface depends on initial Ni(II) concentration.

Table 2 also shows the parameters of the pseudo-second-order kinetic model (k 2 and q e) obtained at the different initial Ni(II) concentrations assayed. For all concentration values, correlation coefficients for pseudo-second-order kinetics were within 0.972–0.999, and SSE as well as RMSE values were acceptable. Likewise, experimental q e values (exp q e) come very close to the values predicted by the pseudo-second-order model (Table 2). Furthermore, the pseudo-second-order kinetic model satisfactorily described the variations in Ni(II) biosorption capacity as a function of time (continuous lines in Fig. 2).

The rate constant (k 2) of the pseudo-second-order model decreased rapidly as initial metal concentration increased from 10 to 100 mg l−1. At higher concentrations, k 2 remained virtually constant at a value of approximately 0.23 g mg−1 h−1 (Table 2). An explanation for this behavior is that, as initial metal concentration is increased, longer contact time is required to reach equilibrium (Fig. 2), as has been reported for different biosorption systems [2, 19, 36].

Studies in equilibrium: sorption isotherms

In the present study, the Ni(II) ion biosorption isotherm was generated by varying the initial concentration of the metal (10–400 mg l−1), while the amount of biosorbent (1 g l−1), the solution pH (7.5) and the temperature (25°C) were kept constant. The experimental biosorption isotherm is shown in Fig. 3. Several models of two (Langmuir, Freundlich, Dubinin-Radushkevich and Temkin), three (Sips, Radke-Prausnitz, Redlich-Peterson and Toth), and four (Fritz-Schluender) parameters were used to describe the experimental Ni(II) biosorption isotherm. The model parameters values along with 95% confidence intervals, as well as correlation coefficients (r 2), residue or SSE and RMSE values are shown in Table 3. In addition, data predicted by the isotherm models are shown in Fig. 3.

Comparison between the experimental isotherm data and the calculated isotherm data derived from two-parameter (a), and three- and four-parameter (b) models for Ni(II) biosorption by acetone-pretreated R. glutinis biomass. Conditions: solution pH = 7.5; temperature = 25°C; biosorbent concentration = 1 g l−1

Among the two-parameter isotherm models, those by Langmuir and Freundlich showed the best fit to experimental Ni(II) sorption data. The Langmuir model has been used widely to estimate the maximum biosorption capacity whenever it was not possible to reach it experimentally, and contains the two most important parameters in a biosorption system, q max and b [22]. The first (q max) is attributed to the maximum capacity of sorption to complete saturation of the biosorbent, and the second (b) is a coefficient related to biosorbent-sorbate affinity. Experimental data reasonably fitted the Langmuir isotherm model, with a correlation coefficient (r 2) of 0.959 and acceptable SSE, RMSE and 95% confidence intervals values. The Langmuir model predicted a q max of 48.28 mg g−1, which approximates the experimental value of Ni(II) biosorption capacity at equilibrium (44.45 mg g−1). The Freundlich isotherm model is suitable for describing multilayer adsorption on heterogeneous adsorbents [37]. The value for constant n in the Freundlich model was 2.831, which is within the interval of n values (n = 1–10), which indicate favorable biosorption [22].

The Temkin model did not adequately describe the Ni(II) sorption isotherm because the correlation coefficient value was low (r 2 = 0.934), both SSE and RMSE were higher than those obtained with the Langmuir and Freundlich models and the 95% confidence interval for its parameters are large. Among the two-parameter models tested, the poorest fit to experimental values at equilibrium was obtained with the Dubinin-Radushkevich model, which presented the lowest correlation coefficient, very high SSE and RMSE values, wide 95% confidence intervals and predicted a q max approximately 20% below the experimental value.

Considering the three-parameter isotherm models, with the exception of the Radke-Prausnitz model, all others fitted the experimental data of the Ni(II) sorption isotherm with higher correlation coefficient and lower SSE and RMSE than the two-parameter models. However, the confidence intervals of the three-parameter models were, in general, higher than those of the two-parameter models. Evidently, the Redlich-Peterson model was a good fit to the experimental data (Fig. 3), showing a high value for the correlation coefficient (r 2 = 0.979) and suitable SSE and RMSE values, but the 95% confidence interval for its parameters was very large. Similarly, although the Toth and Sips models rendered a high correlation coefficient value (r 2 = 0.98), low SSE and RMSE values, and described a tendency that was very close to that found within the studied concentration interval (Fig. 3), the predicted q max values were 172.4% and 69% above the experimental result, respectively. Besides, the confidence intervals of the Sips and Toth models parameters were wide. Taking into account the above results, the three-parameter models were not considered adequate to represent the data of Ni(II) biosorption at equilibrium.

The most satisfactory description of Ni(II) biosorption onto R. glutinis was provided by the Fritz-Schluender model. It rendered the highest correlation coefficient (r 2 > 0.99), the lowest SSE and RMSE values of the nine isotherm models tested here, and the confidence intervals of its parameters were very reasonable. The Fritz-Schluender model is empirical in nature and has a large number of constants. The increased number of constants would be able to simulate the model variations more accurately. In the case of biosorptive processes, the factors affecting sorption are many. So, in the absence of a theoretical model that could account for the chemical heterogeneity of the biosorbent surface, an isotherm model having a greater number of model constants would probably be able to predict better the biosorption isotherm [38]. In the present study, this is observed.

To the best of our knowledge, this is the first work to report the Fritz-Schluender model as the most adequate to represent biosorption of a heavy metal by the Rhodotorula species. The Langmuir isotherm has been used recurrently to analyze equilibrium biosorption data by Rhodotorula species, such as lead [13] and uranium biosorption [39] by Rhodotorula glutinis, and cadmium and lead biosorption by Rhodotorula rubra [40].

Table 4 shows the values of Ni(II) biosorption capacity of different microorganisms and the model used to describe biosorption at equilibrium. The Langmuir model is evidently acknowledged as the most adequate for most biosorption data. However, it must be mentioned that, in many cases, it was also the only one assayed, and finding that the correlation coefficient results were acceptable (r 2 > 0.95) no other models were assayed. Besides, it should be noted that several of the values for Ni(II) biosorption capacity shown on Table 4 are theoretical, i.e., they are capacity values predicted by the Langmuir model (data with superscript P), not necessarily reached experimentally.

The values for nickel biosorption capacity obtained in the present work were significantly higher than most results reported in the literature, with the exception of values for Pseudomonas aeruginosa and Microcystis sp. These results indicate that acetone-pretreated R. glutinis biomass is one of the best biosorbents hitherto reported for Ni(II) removal from aqueous solutions and could therefore be used effectively to detoxify wastewaters polluted with Ni(II).

Effect of temperature on Ni(II) biosorption

The present work examined the effect of temperature (25–70°C) on Ni(II) biosorption onto R. glutinis, at two different initial concentration values of the metal (60 and 150 mg l−1). Figure 4 shows that at the two initial Ni(II) concentration values tested, the metal biosorption capacity onto R. glutinis increased as the temperature rose from 25°C to 70°C. This behavior indicates that the biosorption process is endothermic, i.e., it requires energy to be completed. At equilibrium, Ni(II) biosorption onto the R. glutinis biomass increased from 21.14 to 42.2 mg g−1 as the temperature rose from 25°C to 70°C at an initial concentration of 60 mg l−1. At an initial concentration of 150 mg l−1, Ni(II) biosorption capacity increased from 34.48 to 63.53 mg g−1 (Table 5).

Effect of temperature on Ni(II) biosorption by acetone-pretreated R. glutinis biomass. a Initial Ni(II) concentration = 60 mg l−1; b initial Ni(II) concentration = 150 mg l−1. Temperatures: filled circle 25°C; open square 35°C; + symbol 45°C; open diamond 60°C; multiplication symbol 70°C; continuous line pseudo-second-order model prediction. Conditions: solution pH = 7.5; biosorbent concentration = 1 g l−1. When not shown, error bars are smaller than symbol size

Increase in metal biosorption with rising temperature may be due to higher affinity of the metal binding sites, to an increment in the number of available active sites on the biosorbent surface, to the desolvation of the metal species, to the increase of diffusion rate of Ni(II) ions, and to the decrease in thickness of the boundary layer surrounding the biosorbent, such that the mass transfer resistance of metal ions in the boundary layer is reduced. Also, at higher temperatures, the energy of the system facilitates the binding of the metal ion to the biosorbent [6].

Figure 4 shows that the difference in Ni(II) biosorption capacity obtained at 25°C and 35°C is low, particularly at initial concentration of 60 mg l−1. These results are in good agreement with those obtained by several authors, who have reported that the use of metabolically inactive cells as biosorbents shows almost no effect of temperature on metal adsorbance in the range of 25°C to 40°C [13, 30, 35].

Table 5 shows the kinetic parameters of the pseudo-second-order model for the five temperatures and two initial Ni(II) concentration levels tested in this work. Correlation coefficients were high (0.972 < r 2 < 1.0) and SSE and RMSE values low, which indicates the adequacy of the pseudo-second-order model to describe Ni(II) biosorption onto R. glutinis at the assayed temperatures and initial metal concentrations. The applicability of the pseudo-second-order kinetic model was verified by fitting the experimental data (continuous lines in Fig. 4). Results also show that the k 2 values increased as temperatures rose, confirming that the rate of biosorption is faster at higher temperatures, which is probably due to an increase in the interactions between Ni(II) ions and the biosorbent. This behavior is characteristic of endothermic reactions.

Previous studies have reported the endothermic nature of the heavy metal biosorption process, such as those of Cu(II) [53], Cr(III) [34], Cr(VI) [36], V(V) [54], Ni(II) [1, 6, 29, 50], Pb(II) [31], Zn(II) [55], and Cd(II) [56].

The effect of temperature on Ni(II) biosorption was examined in greater detail by applying the Arrhenius equation (Eq. 2). For the two initial Ni(II) concentrations assayed, the biosorption energy of activation (E A) and frequency factor (A 0) were calculated from the slope and intercept of the straight lines obtained in the ln k 2 versus T −1 plots (Arrhenius plots), shown in Fig. 5. The E A and A 0 values for the Ni(II) biosorption onto R. glutinis were 8.746 kJ mol−1 and 10.935 g mg−1 h−1 when the initial Ni(II) concentration was 60 mg l−1, and 13.751 kJ mol−1 and 60.947 g mg−1 h−1 when the initial Ni(II) concentration was 150 mg l−1, respectively (Table 6).

Plot of ln k 2 versus T −1 for the biosorption of Ni(II) by acetone-pretreated R. glutinis biomass: filled circle initial Ni(II) concentration = 60 mg l−1; open square initial Ni(II) concentration = 150 mg l−1. Conditions: solution pH = 7.5; biosorbent concentration = 1 g l−1. When not shown, error bars are smaller than symbol size

The magnitude of the activation energy provides a clue to the type of adsorption, which could be mainly physical or chemical. Activation energy for physical adsorption is usually not higher than 4.184 kJ mol−1, and for chemical adsorption it ranges from 8.4 to 83.7 kJ mol−1 [24, 29]. Activation energy values found in the present work correspond to the chemical adsorption values. In conclusion, Ni(II) biosorption onto R. glutinis is an endothermic chemical adsorption process. In addition, the relatively low E A values found herein indicate that the chemical biosorption process involves weak interactions between Ni(II) ions and the biosorbent, and that this biosorption has a low potential energy barrier [21].

The changes in biosorption entropy (ΔS ‡) and enthalpy (ΔH ‡) were calculated from the slope and the intercept of the straight line in the ln (k 2 T −1) versus T −1 plot (Fig. 6). In addition, the Gibbs free activation energy change (ΔG ‡) was calculated from the ΔS ‡ and ΔH ‡ values. Values for these thermodynamic parameters are shown in Table 6.

Plot of ln (k 2 T −1) versus T −1 for the biosorption of Ni(II) by acetone-pretreated R. glutinis biomass: filled circle initial Ni(II) concentration = 60 mg l−1; open square initial Ni(II) concentration = 150 mg l−1. Conditions: solution pH = 7.5; biosorbent concentration = 1 g l−1. When not shown, error bars are smaller than symbol size

The values for ΔS ‡ and ΔH ‡ were −0.166 kJ mol−1 K−1 and 6.088 kJ mol−1 at initial Ni(II) concentration of 60 mg l−1, and −0.152 kJ mol−1 K−1 and 11.091 kJ mol−1 for the 150 mg l−1 initial Ni(II) concentration. Values for ΔH ‡ were positive, which confirms that the reaction is endothermic and consequently consumes energy. The negative ΔS ‡ values indicate that the adsorption leads to order through the formation of an activated complex, suggesting that Ni(II) biosorption onto the R. glutinis surface is an associated mechanism [25]. Also, a negative ΔS ‡ value normally reflects that no significant change occurs in the internal structure of the biosorbent during the biosorption process [25, 57]. Negative ΔS ‡ values are not uncommon in metal adsorption [57].

The values for ΔG ‡ were positive at all assayed temperatures, suggesting the existence of an energy barrier for Ni(II) biosorption, that the biosorption reaction is endothermic and non-spontaneous, and confirming that an input of energy is required for the reactant molecules to have enough kinetic energy to overcome the energy barrier and the chemical reaction to take place [11, 25].

Conclusions

Acetone-pretreated R. glutinis cells exhibited higher Ni(II) biosorption capacity than untreated cells at pH values ranging from 3 to 7.5. This finding is interesting from a commercial point of view because the acetone-pretreated R. glutinis biomass discarded as waste material from biotechnological processes could be used as a potential biosorbent to remove Ni(II) ions from aqueous solutions.

Biosorption of Ni(II) ions onto acetone-pretreated R. glutinis depended strongly on solution pH, initial Ni(II) concentration, shaking contact time and temperature. The Fritz-Schluender four-parameter model was the adsorption model best suited to describe the equilibrium data of Ni(II) biosorption. Results from the present kinetics and thermodynamic studies suggest that chemisorption may be the Ni(II) sorption mechanism. Acetone-pretreated R. glutinis exhibited a very high Ni(II) biosorption capacity (44.45 mg g−1) at 25°C, and its capacity increased approximately 43% when a temperature of 70°C was used (63.53 mg g−1). The high Ni(II) sorption capacity of acetone-pretreated R. glutinis places this biosorbent among the best adsorbents currently available to remove Ni(II) ions from industrial wastewaters.

References

Öztürk A (2007) Removal of nickel from aqueous solution by the bacterium Bacillus thuringiensis. J Hazard Mater 147:518–523

Padmavathy V, Vasudevan P, Dhingra SC (2003) Biosorption of nickel(II) ions on baker’s yeast. Process Biochem 38:1389–1395

Pandey PK, Choubey S, Verma Y, Pandey M, Kalyan-Kamal SS, Chandrashekhar K (2007) Biosorptive removal of Ni(II) from wastewater and industrial effluent. Int J Environ Res Public Health 4:332–339

Subbaiah MV, Vijaya Y, Kumar NS, Reddy AS, Krishnaiah A (2009) Biosorption of nickel from aqueous solutions by Acacia leucocephala bark: kinetics and equilibrium studies. Colloid Surface B 74:260–265

Savolainen H (1996) Biochemical and clinical aspects of nickel toxicity. Rev Environ Health 11:167–173

Malkoc E (2006) Ni(II) removal from aqueous solutions using cone biomass of Thuja orientalis. J Hazard Mater B137:899–908

World Health Organization (WHO) (2005) Nickel in drinking-water. Background document for development of WHO guidelines for drinking-water quality. Geneva, World Health Organization (WHO/SDE/WSH/05.08/55)

Zafar MN, Nadeem R, Hanif MA (2007) Biosorption of nickel from protonated rice bran. J Hazard Mater 145:501–505

Ngwenya BT, Tourney J, Magennis M, Kapetas L, Olive V (2009) A surface complexation framework for predicting water purification through metal biosorption. Desalination 248:344–351

Volesky B (2003) Sorption and biosorption. Sorbex, Montreal

Wang J, Chen C (2009) Biosorbents for heavy metals removal and their future. Biotechnol Adv 27:195–226

Breierová E, Vajcziková I, Sasinková V, Stratilová E, Fišera M, Gregor T, Šajbidor J (2002) Biosorption of cadmium ions by different yeast species. Z Naturforch 57C:634–639

Cho DH, Kim EY (2003) Characterization of Pb2+ biosorption from aqueous solution by Rhodotorula glutinis. Bioprocess Biosyst Eng 25:271–277

Aksu Z, Eren AT (2007) Production of carotenoids by the isolated yeast of Rhodotorula glutinis. Biochem Eng J 35:107–113

Malisorn W, Suntornsuk C (2008) Optimization of β-carotene production by Rhodotorula glutinis DM28 in fermented radish brine. Bioresour Technol 99:2281–2287

Özer A, Özer D (2003) Comparative study of the biosorption of Pb(II), Ni(II) and Cr(VI) ions onto S. cerevisiae: determination of biosorption heats. J Hazard Mater B100:219–229

Kambe-Honjoh H, Sugawara A, Yoda K, Kitamoto K, Yamasaki M (1997) Isolation and characterization of nickel-accumulating yeasts. Appl Microbiol Biotechnol 48:373–378

Mitchell AM, Mellon MG (1945) Colorimetric determination of nickel with dimethylglyoxime. Ind Eng Chem Anal Ed 17:380–382

Ho YS, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124

Febrianto J, Kosasih AN, Sunarso J, Ju YH, Indraswati N, Ismadju S (2009) Equilibrium and kinetic studies in adsorption of heavy metals using biosorbent: a summary of recent studies. J Hazard Mater 162:616–645

Cayllahua JEB, de Carvalho RJ, Torem ML (2009) Evaluation of equilibrium, kinetic and thermodynamic parameters for biosorption of nickel(II) ions onto bacteria strain, Rhodococcus opacus. Miner Eng 22:1318–1325

Basha S, Murthy ZVP (2007) Kinetic and equilibrium models for biosorption of Cr(VI) on chemically modified seaweed, Cystoseira indica. Process Biochem 42:1521–1529

Abdel-Salam M, Burk RC (2010) Thermodynamics and kinetic studies of pentachlorophenol adsorption from aqueous solutions by multi-walled carbon nanotubes. Water Air Soil Pollut 210:101–111

Sağ Y, Kutsal T (2000) Determination of the biosorption activation energies of heavy metal ions on Zoogloea ramigera and Rhizopus arrhizus. Process Biochem 35:801–807

Doğan M, Abak H, Alkan M (2009) Adsorption of methylene blue onto hazelnut shell: kinetics, mechanism and activation parameters. J Hazard Mater 164:172–181

Khambhaty Y, Mody K, Basha S, Jha B (2009) Kinetics, equilibrium and thermodynamic studies on biosorption of hexavalent chromium by dead fungal biomass of marine Aspergillus niger. Chem Eng J 145:489–495

Ewecharoen A, Thiravetyan P, Nakbanpote W (2008) Comparison of nickel adsorption from electroplating rinse water by coir pith and modified coir pith. Chem Eng J 137:181–188

Pümpel T, Macaskie LE, Finlay JA, Diels L, Tsezos M (2003) Nickel removal from nickel plating waste water using a biologically active moving-bed sand filter. Biometals 16:567–581

Aksu Z (2002) Determination of the equilibrium, kinetic and thermodynamic parameters of the batch biosorption of nickel(II) ions onto Chlorella vulgaris. Process Biochem 38:89–99

Ruiz MA (2000) Recuperación de metales pesados de soluciones diluidas por biosorción con bacteria. In: Medrano RH, Galan WL (eds) Biotecnología de Minerales. México, pp 235–262

Bulut Y, Tez Z (2007) Adsorption studies on ground shells of hazelnut and almond. J Hazard Mater 149:35–41

Al-Rub FAA, El-Naas MH, Benyahia F, Ashour I (2004) Biosorption of nickel on blank alginate beads, free and immobilized algal cells. Process Biochem 39:1767–1773

Baig KS, Doan HD, Wu J (2009) Multicomponent isotherms for biosorption of Ni2+ and Zn2+. Desalination 249:429–439

Michalak I, Chojnacka K (2010) The new application of biosorption properties of Enteromorpha prolifera. Appl Biochem Biotechnol 160:1540–1556

Vilar VJP, Botelho CMS, Boaventura RAR (2005) Influence of pH, ionic strength and temperature on lead biosorption by Gelidium and agar extraction algal waste. Process Biochem 40:3267–3275

Tewari N, Vasudevan P, Guha BK (2005) Study on biosorption of Cr(VI) by Mucor hiemalis. Biochem Eng J 23:185–192

Oladoja NA, Asia IO, Aboluwoye CO, Oladimeji YB, Ashogbon AO (2008) Studies on the sorption of basic dye by rubber (Hevea brasiliensis) seed shell. Turkish J Eng Environ Sci 32:143–152

Basha S, Jha B (2008) Estimation of isotherm parameters for biosorption of Cd(II) and Pb(II) onto brown seaweed, Lobophora variegata. J Chem Eng 53:449–455

Bai J, Qin Z, Wang JF, Guo JS, Zhang LN, Fan FL, Lin MS, Ding HJ, Lei FA, Wu XL, Li XF (2009) Study on biosorption of uranium by Rhodotorula glutinis. Guang Pu Xue Yu Guang Pu Fen Xi/Spectrosc Spectral Anal 29:1218–1221

Salinas E, Elorza de Orellano M, Rezza I, Martinez L, Marchesvky E, Sanz de Tosetti M (2000) Removal of cadmium and lead from dilute aqueous solutions by Rhodotorula rubra. Bioresour Technol 72:107–112

Sar P, Kazy SK, Asthana RK, Singh SP (1999) Metal adsorption and desorption by lyophilized Pseudomonas aeruginosa. Int Biodeter Biodegrad 44:101–110

Kao WC, Huang CC, Chang JS (2008) Biosorption of nickel, chromium and zinc by MerP-expressing recombinant Escherichia coli. J Hazard Mater 158:100–106

Pradhan S, Singh S, Rai LC (2007) Characterization of various functional groups present in the capsule of Microcystis and study of their role in biosorption of Fe, Ni and Cr. Bioresour Technol 98:595–601

Çentikaya-Dönmez GC, Aksu Z, Öztürk A, Kutsal T (1999) A comparative study on heavy metal biosorption characteristics of some algae. Process Biochem 34:885–892

Klimmek S, Stan HJ, Wilke A, Bunke G, Buchholz R (2001) Comparative analysis of the biosorption of cadmium, lead, nickel, and zinc by algae. Environ Sci Technol 35:4283–4288

Deng S, Ting YP (2005) Characterization of PEI-modified biomass and biosorption of Cu(II), Pb(II) and Ni(II). Water Res 39:2167–2177

Filipović-Kovačević Ž, Sipos L, Briški F (2000) Biosorption of chromium, copper, nickel and zinc ions onto fungal pellets of Aspergillus niger 405 from aqueous solutions. Food Technol Biotechnol 38:211–216

Fourest E, Roux JC (1992) Heavy metal biosorption by fungal mycelial by-products: mechanisms and influence of pH. Appl Microbiol Biotechnol 37:399–403

Saiano F, Ciofalo M, Cacciola SO, Ramirez S (2005) Metal ion adsorption by Phomopsis sp. biomaterial in laboratory experiments and real wastewater treatments. Water Res 39:2273–2280

Dilek FB, Erbay A, Yetis U (2002) Ni(II) biosorption by Polyporous versicolor. Process Biochem 37:723–726

Romera E, Fraguela P, Ballester A, Blázquez ML, Muñoz JA, González F (2003) Biosorption equilibria with Spirogyra insignis. 15th international biohydrometallurgy symposium. IBS 2003. pp 783–792

Wong JPK, Wong YS, Tam NFY (2000) Nickel biosorption by two chlorella species, C. vulgaris (a commercial species) and C. miniata (a local isolate). Bioresour Technol 73:133–137

Pamukoglu MY, Kargi F (2007) Effects of operating parameters on kinetics of copper(II) ion biosorption onto pre-treated powdered waste sludge (PWS). Enzyme Microb Technol 42:76–82

Namasivayam C, Sangeetha D (2006) Removal and recovery of vanadium(V) by adsorption onto ZnCl2 activated carbon: kinetics and isotherms. Adsorption 12:103–117

Babarinde NAA, Babalola JO, Adebisi OB (2008) Kinetic, isotherm and thermodynamic studies of the biosorption of zinc(II) from solution by maize wrapper. Int J Phys Sci 3:50–55

Kim T, Park S, Cho S, Kim H, Kang Y, Kim S, Kim S (2005) Adsorption of heavy metals by brewery biomass. Korean J Chem Eng 22:91–98

Mohan D, Singh KP, Singh VK (2005) Removal of hexavalent chromium from aqueous solution using low-cost activated carbons derived from agricultural waste materials and activated carbon fabric cloth. Ind Eng Chem Res 44:1027–1042

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the BioMicroWorld 2009 Special Issue.

Rights and permissions

About this article

Cite this article

Suazo-Madrid, A., Morales-Barrera, L., Aranda-García, E. et al. Nickel(II) biosorption by Rhodotorula glutinis . J Ind Microbiol Biotechnol 38, 51–64 (2011). https://doi.org/10.1007/s10295-010-0828-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0828-0