Abstract

Microbial lipid is a potential alternative feedstock for the biodiesel industry. New culture strategies remain to be developed to improve the economics of microbial lipid technology. This work describes lipid production by the oleaginous yeast Rhodosporidium toruloides Y4 using a 15-l bioreactor with different substrate feeding strategies. Among these strategies, the intermittent feeding mode gave a lipid productivity of 0.36 g l−1 h−1, whereas the constant glucose concentration II (CC-II) mode gave the highest lipid productivity of 0.57 g l−1 h−1. The repeated fed-batch mode according to the CC-II mode was performed with a duration time of 358 h, and the overall lipid productivity was 0.55 g l−1 h−1. Our results suggested that substrate feeding modes had a great impact on lipid productivity and that the repeated fed-batch process was the most appealing method by which to enhance microbial lipid production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Some microorganisms found in bacteria, yeasts, molds and algae can accumulate intracellular lipids over 20% of their dry biomass [17]. When carbohydrates are applied as the feedstock, the majority of these lipids are triacylglycerols containing long-chain fatty acids [19]. These fatty acids normally have linear chains with 14–20 carbon atoms. Since microbial lipid can be produced using inexpensive organic materials as the substrate, it has been considered as a potential feedstock to support a sustainable biodiesel industry [15, 27]. Thus, much attention has been paid to microbial lipid production in recent years.

Production cost is the major limiting factor for a broader use of microbial lipid. Thus, various natural or waste materials such as Jerusalem artichoke [26], biomass hydrolysate [7] and wastewater [23] have been explored as feedstocks to lower production costs. At the same time, costs could also be significantly reduced by productivity improvement. For microbial lipid production, different cultivation modes, including fed-batch and continuous modes, have been demonstrated in the literature. The yeast Candida curvata D growing on glucose and xylose in a continuous culture process obtained a lipid productivity of 0.16 and 0.27 g l−1 h−1, respectively [2]. The growth of Apiotrichum curvatum in a continuous culture system on glucose reached a lipid productivity of 0.42 g l−1 h−1 [5]. A lipid productivity of 0.59 g l−1 h−1 was obtained using fed-batch cultures of Lipomyces starkeyi on ethanol [24]. Yet, a lipid productivity of 0.88 g l−1 h−1 was reported in the fed-batch culture of Rhodotorula glutinis aerated with oxygen-enriched air [13]. However, there are few reports in terms of the influence of glucose feeding strategies on lipid production.

Our previous work showed that the oleaginous yeast Rhodosporidium toruloides Y4 is an excellent lipid producer. A fed-batch cultivation of this yeast in our laboratory gave a cell density higher than 100 g l−1, whereas cellular lipid content was over 60% [10]. The present paper reports our work on lipid production by R. toruloides Y4 under low organic nitrogen conditions with different glucose feeding strategies. Our results indicated that substrate feeding modes had a great impact on lipid productivity, and that a repeated fed-batch culture was the most appealing method by which to enhance microbial lipid production.

Materials and methods

Strain and media

The yeast R. toruloides Y4 was a cornstalk hydrolysate domesticated strain of R. toruloides AS 2.1389, originally from China General Microbiological Culture Collection Center [9]. It was maintained at 4°C on yeast peptone dextrose (YPD) agar slants (glucose 20 g l−1, peptone 10 g l−1, yeast extract 10 g l−1, agar 20 g l−1, pH 6.0) and sub-cultured twice a month. The seed culture medium contained (g l−1): glucose 20, peptone 10, yeast extract 10, pH 6.0. The initial media for fed-batch and repeated fed-batch experiments contained (g l−1): glucose 55, yeast extract 10, KH2PO4 1, MgSO4·7H2O 1, (NH4)2SO4 10, pH 5.6. A solution of 1,000 g l−1 glucose was used as the feeding material in the fed-batch and repeated fed-batch processes.

Culture conditions

All fed-batch and repeated fed-batch cultures were carried out at 30°C in a 15-l stirred-tank bioreactor (FUS-15-l (A), Shanghai Guoqiang Bioengineering Equipment Co. Ltd., Shanghai, China) with an initial volume of 9 l. The inoculum culture was prepared in a shake flask at 30°C, 200 rpm for 36 h, and was inoculated into the bioreactor at a volume ratio of 10%. The pH was held constant at 5.6 by automatic addition of 10 M NaOH or 2 M HCl. The gas flow rate was maintained at 0.8 vvm. The dissolved oxygen was maintained at 40–50% of air saturation by automatically tuning the agitation speed. Samples were withdrawn at different time intervals and stored at −70°C for further analysis.

Culture process setting

All fed-batch cultures were started with an initial glucose concentration of 55 g l−1 and the feeding substrates were fed into the bioreactor using a computer-coupled peristaltic pump. To determine an appropriate substrate feeding strategy, three different modes were examined. The intermittent feeding (IF) mode added concentrated glucose solution into the bioreactor to let the residual glucose concentration increase to 50 g l−1 immediately after the residual glucose concentration was dropped to 0–5 g l−1. In a typical experiment, glucose solution was fed for 5 times in a batch.

The constant concentration I (CC-I) and the constant concentration II (CC-II) mode cultures held the residual glucose concentration at 30 and 5 g l−1, respectively, by continuously pumping concentrated glucose solution into the bioreactor.

The repeated fed-batch culture was performed following the CC-II mode but with multiple cycles. Upon removal of the majority of the mature culture at the end of each cycle, 900 ml of the culture was held in the bioreactor. Fresh initial media were then added and a new cultivation cycle was resumed by the carryover culture.

Analytical methods

Cell biomass, expressed as dry cell weight (DCW), was obtained from cell pellets in 30 ml of culture broth, and dried in an oven at 105°C to a constant weight. Glucose concentration was monitored with an SBA-50B glucose analyzer (Shandong Academy of Sciences, China).

Total lipid was extracted with a mixture of chloroform and methanol [11]. Lipid content was expressed as gram lipid per gram DCW. The fatty acid composition analysis was carried out on a 7890F gas chromatography instrument according to the published procedure [9].

Results and discussion

Effects of different glucose feeding strategies on lipid production

Substrate feeding is one of the most powerful strategies to control microbial cultures in large-scale biochemical processes [16, 19, 21, 25]. To evaluate the effect of glucose feeding strategies on the lipid production course by R. toruloides Y4, we performed different cultivation experiments.

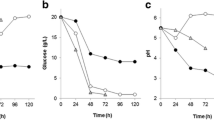

The time courses of DCW, lipid and residual glucose concentration during the IF mode are shown in Fig. 1a. After the initial glucose was exhausted, concentrated glucose solution (1,000 g l−1) was supplemented to hold the media glucose concentration at 50 g l−1. After 146.7 h of cultivation with 5 feedings, the DCW, lipid and lipid productivity were 89.0 g l−1, 52.2 g l−1and 0.36 g l−1 h−1, respectively. Lipid content for the cell biomass sample reached 58.6%. The ammonium-N concentration in the media dropped from 0.194 to 0.009 mol l−1. This observation was in good accord with a nitrogen-deficient associated lipid accumulation mechanism by the yeast R. toruloides [3].

To further improve lipid productivity, we decided to control the glucose concentration. There were examples in the literature indicating that productivity may be improved by controlling the substrate concentration in the production of insecticide [1] and poly (3-hydroxybytyrate) [20]. The CC-I mode experiment maintained the glucose concentration at 30 g l−1 through feeding glucose solution immediately after the media glucose concentration dropped below 30 g l−1. After 143.5 h of cultivation, DCW, lipid and lipid productivity were 92.5 g l−1, 56.2 g l−1 and 0.39 g l−1 h−1, respectively (Fig. 1b). It was clear that the overall lipid productivity was increased by 8.3% compared to that of the IF mode culture, indicating that the CC-I mode culture was more efficient for lipid production. If the residual glucose was maintained during the feeding stage at a lower concentration of 5 g l−1 (the CC-II mode), DCW, lipid production and lipid productivity were 127.5 g l−1, 78.8 g l−1 and 0.57 g l−1 h−1, respectively, after 138.5 h (Fig. 1c). Compared to that of the CC-I mode, the CC-II mode increased lipid productivity, DCW and cellular lipid content by 48, 37.8 and 1.0%, respectively. Thus, the increment in lipid productivity was ascribed to the improvement of DCW. These results suggested that substrate concentration had a major effect on DCW and lipid production. A lower substrate concentration was favorable for DCW and lipid production using the fed-batch process, because higher glucose concentration may exhibit inhibitory effects on cell growth and regulatory effects on cellular metabolism [1, 9, 14]. Similarly, lower residual glucose concentration was also found beneficial for the production of polyhydroxybutyrate with a fed-batch process [22].

Repeated fed-batch culture

The repeated fed-batch process is known to enhance the productivity of microbial cultures, because it extends the production phase by replacing a large portion of the mature culture with fresh media. It saves time due to its reduced need for cleaning, sterilization and inoculation processes. For example, a repeated fed-batch process has been applied in the biochemical production of amino acids [6] and erythritol [8].

Results of a repeated fed-batch culture of R. toruloides Y4 based on the CC-II mode are shown in Fig. 2. After the first cycle was completed at 133.8 h with a DCW of 127.5 g l−1, the bioreactor was discharged and 900 ml of cell culture was left over to serve as the inoculum. The second cycle started by supplementing 8.1l of fresh lipid production media. Similarly, the third cycle was initiated at 239 h. Overall, the repeated fed-batch experiment lasted for 358 h. Lipid concentrations for the first, the second and the third cycles were 78.7, 55.3 and 54.7 g l−1, respectively. Although lipid concentrations for the second and the third cycle were clearly lower than that of the first one, it was interesting to note that these two cycles gave very close results. On the other hand, the lipid productivity decreased progressively after each cycle. The lipid productivity in the three cycles was 0.57, 0.55 and 0.51 g l−1 h−1, respectively, whereas the overall lipid productivity for this process was 0.55 g l−1 h−1. Therefore, it was inferred that the cell activity decreased slowly in the repeated fed-batch process.

It should be noted that no nitrogen or additional nutrients, except a concentrated glucose solution, was supplemented for fed-batch cultures with the IF mode, the CC-I mode and the CC-II mode. During the late stage of the fed-batch process, i.e., after 80 h of cultivation in most cases, cell biomass production was reduced. This was mainly due to the fact that nitrogen sources were exhausted, and the carbon flux was channeled into lipid biosynthesis. However, for the repeated fed-batch culture process, fresh medium with nitrogen sources can be applied to restart an exponential cell propagation process.

Comparison

Cultivation of oleaginous microorganisms on glucose with different feeding strategies has been done to obtain a higher lipid productivity (Table 1). In those continuous culture process, product titer, productivity and cellular lipid content were relatively low (Table 1, entries 1 and 2). In contrast, fed-batch modes gave significantly higher product titer and cellular lipid content was also higher. An early work with R. glutinis obtained a lipid productivity of 0.88 g l−1 h−1 (Table 1, entry 3); however, it was aerated with oxygen-enriched air, which could be expensive for a large-scale operation. Our previous work achieved a lipid productivity of 0.54 g l−1 h−1 when R. toruloides Y4 was cultured according to the fed-batch mode (Table 1, entry 4), but the initial concentration of organic nitrogen sources was 31.4 g l−1. Because yeast extract and peptone were relatively expensive, the present study applied yeast extract at 10 g l−1, and the remaining nitrogen sources were supplemented with ammonia sulfate. In this way, the costs for nitrogen sources were substantially reduced. In the CC-II mode culture, a high lipid content of 61.8% and a higher lipid titer of 78.8 g l−1 were reached (Table 1, entry 7). The lipid productivity of 0.57 g l−1 h−1 in the CC-II mode culture was higher than that of our previous study, indicating that the lipid production could be improved by optimizing control of the substrate feeding process. Thus, further study should focus on carefully managing glucose concentration in the bioreactor using advanced techniques.

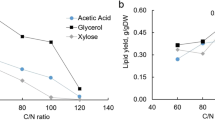

Compared to the fed-batch strategies, the repeated fed-batch had some advantages. The repeated mode differed from the traditional fed-batch process as a small portion of the culture containing lipid-rich cells were directly carried over from the previous batch to seed the new one. Our culture experiment for 358 h gave an average lipid productivity of 0.55 g l−1 h−1, which was very close to that obtained in the CC-II mode culture. Process optimization on parameters such as media composition (low-cost substrate), medium replacement ratio and time of replacement should further lead to advancement in lipid productivity. Nitrogen feeding should be taken into consideration, because the molecular ratio of carbon-to-nitrogen (C/N) was important for lipid accumulation [9, 18]. Usually, a C/N ratio of 70 was sufficient to ensure the lipid production process, and a higher C/N ratio gave a higher lipid content. However, lipid productivity could be reduced when nitrogen sources were extremely scarce. In the repeated fed-batch culture, the C/N ratio should have a little difference for each cycle. In the future, nitrogen sources should be optimized and controlled more carefully.

Lipid coefficient, i.e., gram lipid per gram substrate, is one of the most important parameters for microbial lipid technology. The theoretical lipid coefficient was estimated as 0.32 g lipid g−1 glucose [18]. We should point out that our experiments gave a very high lipid coefficient of over 0.20 g lipid g−1 glucose (Table 1, entries 5–8). In the case of the repeated fed-batch culture, the lipid coefficient was 0.24 g lipid g−1 glucose. These results suggest that improvement of lipid productivity using different substrate feeding strategies did not compromise the lipid yield.

Fatty acid compositional analysis

Lipid samples produced by different processes were transmethylated and analyzed by gas chromatography. The fatty acid composition showed little change regardless of culture conditions (Table 2). Overall, four major constituent fatty acids were oleic acid (18:1), palmitic acid (16:0), stearic acid (18:0) and linoleic acid (18:2). The sum of palmitic acid and oleic acid contents was over 80%. We also determined the contents of neutral lipids, glycolipids, sphingolipids, phospholipids and other polar lipids in the lipid samples [4]. The majority were the neutral lipids, which took over 85% (w/w) in all samples (data not shown). The fatty acid compositional profile and the content of neutral lipids were quite similar to those of soybean oil and rapeseed oil, indicating that lipid produced by R. toruloides Y4 has great potential as a feedstock for biodiesel production [12].

Conclusions

This paper presented comparative experimental results of lipid production by R. toruloides Y4 under different substrate feeding strategies. It demonstrated that the repeated fed-batch process was of great potential for a large-scale lipid production. Our results also indicated that the yeast R. toruloides Y4 was a robust strain suitable for further development in terms of biotechnological production of lipid.

References

Cayuela C, Kai K, Park YS, Iijima S, Kobayashi T (1993) Insecticide production by recombinant Bacillus subtilis 1A96 in fed-batch culture with control of glucose concentration. J Ferment Bioeng 75:383–386

Evans CT, Ratledge C (1983) A comparison of the oleaginous yeast Candida curvata, grown on different carbon sources in continuous and batch culture. Lipid 18:623–629

Evans CT, Ratledge C (1984) Influence of nitrogen metabolism on lipid accumulation by Rhodosporidium toruloides CBS 14. J Gen Microbiol 130:1705–1710

Fakas S, Papanikolaou S, Galiotou-Panayotou M, Komaitis M, Aggelis G (2006) Lipids of Cunninghamella echinulata with emphasis to c-linolenic acid distribution among lipid classes. Appl Microbiol Biotechnol 73:676–683

Hassan M, Blanc PJ, Granger LM (1993) Lipid production by an unsaturated fatty acid auxotroph of the oleaginous yeast Apiotrichum curvatum grown in a single stage continuous culture. Appl Microbiol Biotechnol 40:483–488

Hermann T (2003) Industrial production of amino acids by coryneform bacteria. J Biotechnol 104:155–172

Hu CM, Zhao X, Zhao J, Wu SG, Zhao ZB (2009) Effects of biomass hydrolysis by-products on oleaginous yeast Rhodosporidium toruloides. Bioresour Technol 100:4843–4847

Koh ES, Lee TH, Lee DY, Kim HJ, Ryu YW, Seo JH (2003) Scale-up of erythritol production by an osmophilic mutant of Candida magnoliae. Biotechnol Lett 25:2103–2105

Li YH, Liu B, Zhao ZB, Bai FW (2006) Optimized culture medium and fermentation conditions for lipid production by Rhodosporidium toruloides. Chin J Biotechnol 22(4):650–656

Li YH, Zhao ZB, Bai FW (2007) High-density cultivation of oleaginous yeast Rhodosporidium toruloides Y4 in fed-batch culture. Enzyme Microb Technol 41:312–317

Li ZF, Zhang L, Shen XJ, Lai BS, Sun SQ (2001) A comparative study on four method of fungi lipid extraction. Microbiology 28:72–75

Liu B, Zhao ZB (2007) Biodiesel production by direct methanolysis of oleaginous microbial biomass. J Chem Technol Biotechnol 82:775–780

Pan JG, Kwak MY, Rhee JS (1986) High density cell culture of Rhodotorula glutinis using oxygen-enriched air. Biotechnol Lett 8:715–718

Papagianni M, Boonpooh Y, Mattey M, Kristiansen B (2007) Substrate inhibition kinetics of Saccharomyces cerevisiae in fed-batch cultures operated at constant glucose and maltose concentration levels. J Ind Microbiol Biotechnol 34:301–309

Meng X, Yang JM, Xu X, Zhang L, Nie QJ, Xian M (2009) Biodiesel production from oleaginous microorganisms. Renew Energy 34:1–5

Nurmianto L, Greenfield PF, Lee PL (1994) Optimal feeding policy for recombinant protein production via the yeast Saccharomyces cerevisiae in fed-batch culture. Process Biochem 29:55–68

Ratledge C (1987) Lipid biotechnology, a wonderland for the microbial physiologist. J Am Oil Chem Soc 64:1647–1656

Ratledge C, Wynn JP (2002) The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms. Adv Appl Microbiol 51:1–51

Rau U, Manzk C, Wagner F (1986) Influence of substrate supply on the production of sophorose lipids by Candida bombicola ATCC 22214. Biotechnol Lett 18:149–154

Shang L, Jiang M, Chang HN (2003) Poly(3-hydroxybutyrate) synthesis in fed-batch culture of Ralstonia eutropha with phosphate limitation under different glucose concentrations. Biotechnol Lett 25:1415–1419

Suzuki T, Yamane T, Shimizu S (1986) Mass production of PHB by fed-batch culture with controlled carbon/nitrogen feeding. Appl Microbiol Biotechnol 24:370–374

Tsuge T, Tanaka K, Shimoda M, Ishizaki A (1999) Optimization of l-lactic acid feeding for the production of poly-d-3-hydroxybutyric acid by Alcaligenes eutrophus in fed-batch culture. J Biosci Bioeng 88:404–409

Xue FY, Miao JX, Zhang X, Luo H, Tan TW (2008) Studies on lipid production by Rhodotorula glutinis fermentation using monosodium glutamate wastewater as culture medium. Bioresour Technol 99:5923–5927

Yamauchi H, Mori H, Kobayashi T, Shimizu S (1983) Mass production of lipids by Lipomyces starkeyi in microcomputer-aided fed-batch culture. J Ferment Technol 61:275–280

Yano T, Kurokawa M, Nishizawa Y (1991) Optimum substrate feed rate in fed-batch culture with the DO-stat method. J Ferment Bioeng 71:345–349

Zhao X, Wu SG, Hu CM, Wang Q, Hua YY, Zhao ZB (2010) Lipid production from Jerusalem artichoke by Rhodosporidium toruloides Y4. J Ind Microbiol Biotechnol 37:581–585

Zhao ZB, Hua YY, Liu B (2005) Strategies to secure feedstock supply for Chinese biodiesel industry. Chin Biotechnol 25(11):1–6

Acknowledgments

Financial support provided by the National High Technology Research and Development Program of China (2007AA05Z403) and the Knowledge Innovation Program of CAS (KGCX2-YW-336) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, X., Hu, C., Wu, S. et al. Lipid production by Rhodosporidium toruloides Y4 using different substrate feeding strategies. J Ind Microbiol Biotechnol 38, 627–632 (2011). https://doi.org/10.1007/s10295-010-0808-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0808-4