Abstract

A closed gas loop bioprocess was developed to improve fungal biotransformation of monoterpenes. By circulating monoterpene-saturated process gas, the evaporative loss of the volatile precursor from the medium during the biotransformation was avoided. Penicillium solitum, isolated from kiwi, turned out to be highly tolerant towards monoterpenes and to convert α-pinene to a range of products including verbenone, a valuable aroma compound. The gas loop was mandatory to reproduce the production of 35 mg L−1 verbenone obtained in shake flasks and also in the bioreactor. Penicillium digitatum DSM 62840 regioselectively converted (+)-limonene to the aroma compound α-terpineol, but shake flask cultures revealed a pronounced growth inhibition when initial concentrations exceeded 1.9 mM. In the bioreactor, toxic effects on P. digitatum during biotransformation were alleviated by starting a sequential feeding of non-toxic limonene portions after a preceding growth phase. Closing the precursor-saturated gas loop during the biotransformation allowed for an additional replenishment of limonene via the gas phase. The gas loop system led to a maximum α-terpineol concentration of 1,009 mg L−1 and an average productivity of 8–9 mg L−1 h−1 which represents a doubling of the respective values previously reported. Furthermore, a molar conversion yield of up to 63% was achieved.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, environmental aspects have become increasingly important to the manufacture of aroma chemicals and to the public perception of the quality of consumable goods [1]. More environmentally friendly processes based on renewable resources are needed by producing companies to meet the requirements for a clean and sustainable chemical industry [1, 2]. This trend complements the consumer’s preference for ‘bio’ or ‘organic’ foods and natural flavorings, which has been steadily growing over the last decades [3, 4]. The fragrance sector, too, faces a shift towards natural substances, e.g., in the personal care market [5]. Biotechnology provides promising synthetic routes to those natural aroma compounds, which cannot be supplied in an economically viable way by classical isolation from natural raw materials. This holds true for many oxyfunctionalized terpenoids, which are important flavor and fragrance compounds but only found in minor quantities in their natural sources [6]. Here, biocatalytic oxyfunctionalization of abundantly available natural precursors represents an attractive alternative. More than 50,000 t year−1 (+)-limonene and over 160,000 t year−1 α-pinene accumulate worldwide as major by-products during citrus oil and wood processing, respectively [6, 7]. These monoterpenes represent an ideal starting material for biocatalysis because of their almost unlimited availability and the fact that they already bear the desired chiral mono- and bicyclic C10 hydrocarbon lead structures ‘pre-synthesized’ by nature. Potential biotechnological natural flavor and fragrance products from α-pinene and (+)-limonene are the valuable verbenone, reminiscent of frankincense, with an average market price of approximately US$3,000 kg−1 [8] and the lilac-like compound (+)-α-terpineol, a bulk fragrance with a world market of 13,000 t year−1 [9], respectively.

Many species from prokaryotes to higher fungi have been shown to be capable of transforming or degrading terpenoids, an observation which may be explained by co-metabolism phenomena (e.g., for detoxification purposes) rather than by catabolic breakdown. Due to their versatile metabolism which partly resembles that of plants, higher fungi are of special interest from the viewpoint of biocatalytic terpene functionalization. However, although some adaptation mechanisms might exist [10], eukaryotic organisms tend to be usually more sensitive towards the toxic effects of terpenes than prokaryotes [11]; in case of the latter, several species, especially pseudomonads, are well known to resist organic solvents by mechanisms such as active solvent efflux and cis–trans isomerization of membrane lipids [12, 13]. Although a vast number of publications illustrating the metabolic versatility of fungi to oxyfunctionalize terpenoids has appeared during the last decades (for reviews, see [4, 14, 15]) only a few research groups have worked on transferring the micro- and molecular biological findings into technical processes. In most cases, the main hurdle has been the low degree of biocompatibility of terpenoids, which becomes manifest in their toxicity towards the microbial cells and often in low activities of the key enzymes (mostly P450 monooxygenases) involved in terpene oxyfunctionalization [16]. The hydrophobic terpenoids dissolve poorly in water—the solubility of α-pinene and limonene is 0.037 and 0.150 mmol L−1 [17], respectively—but very well in the lipophilic membranes of microorganisms leading to high local concentrations even at low aqueous concentrations [17–19]. This causes an increased membrane fluidity which eventually results in the collapse of essential transmembrane gradients and, thus, in the complete loss of cell viability [20]. Additionally, as a separate organic phase may easily form upon dosing terpenes in excess, the complete destruction of the membrane and cell lysis due to ‘phase toxicity’ can occur [20, 21].

Only a few bioprocessing measures have been described to address the toxicity of terpenoids. With an FID detector in the exhaust air stream of a bioreactor to monitor the volatile precursor limonene, toxic overdosing over a longer period was avoided by controlling the precursor feeding [22]. The measurement of the oxygen uptake rate was used for adjusting the limonene feeding to maintain the metabolic viability of the cells, i.e., non-toxic conditions [23]. A bacterial transformation of limonene to perillyl alcohol was performed in an aqueous-organic two-liquid-phase bioprocess using a biocompatible organic carrier solvent for in situ precursor supply and product recovery [24]. A technical issue which has not yet been appropriately addressed is how to efficiently supply the volatile (and toxic) precursor and the oxygen needed for the monoterpene oxyfunctionalization while concomitantly avoiding significant precursor loss via the bioreactor exhaust air. Though approaches of gas enrichment or gas recirculation have already been described for the microbial conversion or degradation of volatile substrates [25, 26], the combination of a precursor-saturated process gas loop with sequential feeding of the precursor in its liquid form and its application to fungal monoterpene transformations has not so far been reported.

In the present work, we demonstrate that circulating a precursor-saturated process gas in a closed loop together with sequential dosing the precursor in non-inhibitory amounts can considerably improve monoterpene biotransformation performance of Penicillium species on a bioreactor scale, as exemplified by the industrially relevant conversion of α-pinene to verbenone and of (+)-limonene to (+)-α-terpineol (Fig. 1). For the latter biotransformation, our results represent a considerable improvement compared with data obtained in a conventional bioprocess set-up previously reported [27].

Biotransformation of α-pinene to verbenone and limonene to α-terpineol by Penicillium solitum and Penicillium digitatum, respectively [15]

Materials and methods

Microorganisms, media, pre-cultivation

Penicillium solitum was isolated by streaking samples from spoiled kiwi surface on agar plates (20 g L−1 agar in P. solitum medium described below) and incubation at 24°C followed by transfers to new agar plates until separation to pure cultures was achieved. The strain was identified as P. solitum (Westling) by the accredited culture collection DSMZ (Deutsche Sammlung von Mikroorganismen und Zellkulturen, Braunschweig, Germany) whereas Penicillium digitatum DSM 62840 was purchased from DSMZ.

The cultivation medium for P. solitum was composed of 30 g L−1 glucose, 4.5 g L−1 l-asparagine monohydrate, 1.5 g L−1 KH2PO4, 0.5 g L−1 MgSO4 · H2O, 3 g L−1 yeast extract and 1 mL of trace element solution consisting of 80 mg L−1 FeCl3 · 6H2O, 90 mg L−1 ZnSO4 · 7H2O, 30 mg L−1 MnSO4 · H2O, 5 mg L−1 CuSO4 · 5H2O, 0.4 g L−1 C10H14N2Na2O8 · 2H2O (Titriplex IIITM). The cultivation medium for P. digitatum DSM 62840 was composed of 10 g L−1 glucose, 20 g L−1 malt extract, 10 g L−1 peptone and 5 g L−1 yeast extract. Before autoclaving, the pH of the cultivation media were adjusted to 6.0 for P. solitum and to 6.5 for P. digitatum with HCl. The pre-cultures were prepared by washing a 10-day-old cultivation plate with 5 mL sterile medium and transferring the spore containing medium to a 1,000-mL Erlenmeyer flask containing 400 mL medium. The flasks were incubated at 27°C (P. digitatum) or 25°C (P. solitum) for 1–5 days on a rotary shaker at 120g.

Determination of limonene toxicity towards P. digitatum DSM 62840

For determination of limonene toxicity, 300-mL Erlenmeyer flasks containing 95 mL medium were inoculated with 5 mL P. digitatum pre-culture and supplemented with different limonene amounts resulting in the following initial limonene concentrations: 0.6, 0.9, 1.2, 1.9, 3.1, 4.6, 7.7, 15.4, and 30.8 mM. After 3 days of cultivation at 27°C and 120g, the cell dry weight produced was determined gravimetrically.

Biotransformations of limonene and α-pinene in shake flasks

Biotransformation experiments were carried out in 1,000-mL shake flasks containing 400 mL medium at 25°C and 150g inoculated with 18 mL of 24-h-old pre-cultures which had been grown on the same medium and homogenized using an ultraturrax homogeniser (Janke & Kunkel, Germany). After 24 h, the biotransformation was initiated by adding to each flask the respective amount of limonene or α-pinene (see “Results”). The autoxidative conversion of the monoterpenes was verified by medium-only controls (no inoculum) under otherwise identical conditions.

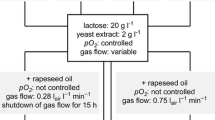

Biotransformations in the bioreactor

The bioreactor had a working volume of 2.7 L and a total volume of 3.7 L (KLF 2000; Bioengineering, Switzerland). It was equipped with a disc stirrer, a dissolved oxygen probe, and a pH electrode. Before inoculation, the pre-culture was homogenized with an Ultra Turrax on highest level for 30 s [28]. Inoculation was carried out by transferring 200 mL of the Ultra Turrax homogenized pre-culture to 2.5 L medium which had been autoclaved in situ prior to use. The agitation speed was limited to 400g during the growth phase and 500g during the biotransformation phase to keep homogeneously dispersed pellets in the bioreactor, because at stronger agitation additional mycelial growth out of the liquid phase into the reactor headspace occured. The aeration rate was 0.05 vvm for P. digitatum and 0.16 vvm for P. solitum, and the temperature was controlled at 27 and 25°C, respectively. In the course of the growth phases of both strains, the pH value steadily decreased, and, whereas it did not fall below approximately pH 4 for P. digitatum, it was controlled at pH 3.7 for P. solitum, once this value had been reached, by 1 M NaOH and 1 M H3PO4 solutions. A metal shell excluded light from the bioreactor. At the end of the growth phase of P. digitatum, when the initial glucose of 30 g L−1 had been depleted to less than 1 g L−1, the stirrer speed was raised to 500g and 1.9 mM limonene was added to the bioreactor at t = 73 h (biotransformation 1) and t = 70 h (biotransformation 2) and the gas loop was started (see below). During the biotransformation period, the same amount of precursor was repeatedly added directly to the bioreactor every 24 h, i.e., altogether a total precursor concentration of 9.5 mM (corresponding to 1,295 mg L−1) was applied. No further glucose was added in biotransformation 1, whereas in biotransformation 2 glucose was supplemented at the starting point and every 24 h of the biotransformation to re-adjust the aqueous glucose concentration periodically to 2 g L−1. In the case of α-pinene biotransformations with the terpene tolerant P. solitum, the precursor was added sequentially at t = 0 h (2.3 mM), t = 25 h (47 mM), t = 54 h (23.5 mM), t = 76 h (23.5 mM), t = 94 h (18.7 mM), t = 124 h (18.7 mM), t = 147 h (28 mM), t = 167 h (23.5 mM), t = 195 (18.7 mM), t = 219 h (23.5 mM), and t = 243 h (23.5 mM). After approximately 48 h cultivation, when the initial glucose (30 g L−1) was almost completely depleted, its concentration was re-adjusted to approximately 2 g L−1 every 24 h by adding a concentrated glucose solution (500 g L−1) in both biotransformations, with gas loop (started at t = 48 h) and without it.

Closed gas loop bioreactor

The gas loop consisted of: 25-L gas holder (Ritter Apparatebau, Germany), gas pump (N 022 A_18, KNF Neuberger, Germany), pressure vessel (Swagelook, USA), a 125-mL stainless steel precursor reservoir tank, manometric switch, compressed air regulator, and rotameter (Krohne, Germany). After establishing the gas loop (start circulating the process gas), the exhaust air from the bioprocess was fed into the gasholder. From there, the gas was transported into the pressure vessel by the gas pump. When reaching 4 bar in the vessel, the pressure pump was stopped by means of the manometric switch. The pressure pump started again when the pressure in the pressure vessel was lower than 1.5 bar. The gas passed through the precursor reservoir tank filled with 12 mL precursor via a sparger to saturate the gas by the volatile precursor before entering the fermenter. Dissolved oxygen was measured by an oxygen probe (Mettler Toledo, Switzerland). Pure oxygen was fed periodically to the gas loop to maintain a dissolved O2 concentration between 5 and 10% air saturation. Accumulation of CO2 in the process gas was avoided by use of a CO2 adsorber (Sofnolime, Molecular Products, UK).

Analytical methods

The products verbenone and α-terpineol were identified by GC–MS analysis (GC17A, QP 5050 software; Shimadzu, Germany) by comparing retention times and mass fragment patterns with those of standard compounds, and they were quantified using camphor as internal standard. Cell lysates were produced by ultrasonic cell disruption (Sonifier W-250D; Branson, USA). These fractions were extracted by n-hexane, dried over anhydrous Na2SO4 and stored at −20°C until GC–MS analysis, which was performed as follows. Column: 30 m VB-30 (ValcoBond, CFS-B03025-025B, VICI Valco Instrument, USA); temperature program: from 60°C, 2°C min−1 to 180°C; carrier gas: helium at 1.1 mL min−1; injector temperature: 220°C; detector temperature: 240°C; sample volume: 3 μL; split 1:10. Samples were injected with an autosampler (AOCi 20; Shimadzu, Germany).

Pooled culture medium (three flasks) was supplemented with an internal standard (camphor, 80 mg L−1 final concentration in the medium) and filtrated. The cell-free medium was extracted continuously using azeotropic pentane/diethyl ether (1:1.12) in a liquid–liquid conti-extractor [29]. The organic layers were dried over Na2SO4 and brought to a final volume of about 1 mL by fractionated distillation. One μL was injected into a Fisons GC 8360 gas chromatograph equipped with a cool on-column injector, a J&W CW 20 M fused silica capillary column (30 m × 0.32 mm i.d. × 0.4 μm film thickness, J&W Scientific Folsom, USA), hydrogen as carrier gas at 3.1 mL min−1, and a flame ionisation detector using a temperature program from 40°C (3 min) to 220°C with a rate of 4°C min−1. Quantification was performed according to the internal standard camphor. The glucose concentration was measured by an immobilized enzyme glucose analyser (YSI 2700 Select; Yellow Springs, USA). The cell wet and dry weights were determined gravimetrically. An appropriate sample volume was filtered through dried, pre-weighed filter paper and weighed directly or after drying at 105°C until constant weight (Sartorius, MA100, Germany).

Results

Initial physiological studies on shake flask scale were performed to characterize the growth behavior of the cultures in the presence of the respective monoterpene and to lay the foundation for the subsequent investigations of the biotransformations in the closed gas loop bioreactor.

Impact of monoterpene concentration on biotransformation and growth

P. digitatum DSM 62840 had been previously shown to catalyze the conversion of limonene to α-terpineol in a highly regioselective way and at concentrations of up to several hundreds of milligrams in a conventional bioreactor setup [27]. However, limonene, known for its antimicrobial activity, had not been systematically investigated regarding its potential toxicity towards P. digitatum DSM 62840. We therefore determined the maximum limonene concentration applicable without significant growth-inhibiting effects to P. digitatum DSM 62840 in order to further improve the bioprocess performance of this fungus by applying a tailored precursor dosage. For this purpose, a dosage-effect curve was generated correlating the growth of a culture in shake flasks with the initial limonene content present in the medium (Fig. 2) (by reason of a better presentability of the results and a simplification of the discussion, the limonene content is given as ‘concentration’, although its maximum aqueous solubility was usually exceeded). At limonene concentrations of 1.9 and 3.2 mM, about 15 and 35% less biomass formed than in a control culture without limonene dosage (upper horizontal line in Fig. 2), respectively. Further raising the limonene concentration resulted in a steady decrease of cell viability illustrated by the fact that almost no biomass formed after inoculation at >7 mM limonene. Taking into account the threshold concentration where limonene starts to become significantly toxic, shake flasks P. digitatum DSM 62840 cultivation was carried out with an initial limonene concentration of 2 mM, which yielded a maximum α-terpineol concentration of 132 mg L−1 after 4 days. Autooxidative product formation could be ruled out because no α-terpineol was found in the medium-only control experiment (i.e. without inoculum).

Effect of limonene on growth of P. digitatum DSM 62840 in shaking flasks. P. digitatum was inoculated into media initially supplemented with increasing amounts of limonene. By reason of a better presentability, the limonene content is shown as ‘concentration’, although its maximum aqueous solubility was exceeded. The upper horizontal line corresponds to the control value (growth of a culture in a medium without limonene). The lower horizontal line indicates the initial biomass concentration after inoculation

The monoterpene sensitivity described for P. digitatum is typical for higher fungi: during a previous screening for terpene tolerant and transforming microorganisms, a single application of 15 mM of limonene was found to be lethal for the majority (>90 %) of fungi tested [30]. Therefore, the screening was extended to strains growing on plant material rich in essential oils. An isolate (later on identified as P. solitum) from kiwi (Actinidia deliciosa) was found to tolerate elevated millimolar concentrations of limonene and α-pinene and even grow in liquid media containing limonene as sole C-source. With limonene, no marked amounts of biotransformation products formed (<1 mg L−1) but more than 100 mg L−1 total biotransformation products were found after cultivation in shake flasks supplemented with 47 mM α-pinene (Table 1). Among the α-pinene metabolites, verbenone, which accumulated to 35 mg L−1 after 11 days, represents a valuable natural flavor compound.

Design of a closed gas loop bioprocess

Previous experiments revealed that, using a conventional open bioreactor system, a significant amount of the volatile monoterpene used as biotransformation precursor was stripped out through the exhaust air upon aeration of the bioreactor [27]. Furthermore, due to their hydrophobicity, terpenoids, especially the terpene hydrocarbons, tend to being absorbed by all materials made from plastics, such as conventional laboratory-scale bioreactor sealings, fittings, and tubings. During the biotransformation over several days, the terpenoids act as aggressive organic solvents destroying these plastics eventually leading to process leakages. For these reasons, we chose a novel bioprocess design to address the specific issues associated with terpenoids as biotransformation precursors and products and, thus, to better exploit the biocatalytic potential of monoterpene transforming microorganisms: the two main modifications were the use of terpene-resistant Teflon™ for the sealing of the bioreactor instead of conventional rubber gaskets and the establishment of a closed gas loop bioreactor to avoid any precursor loss via the exhaust air during the biotransformation (Fig. 3). The bioprocess was operated following a two-step protocol: initially, the fungi were grown in a conventionally aerated bioreactor with open exhaust gas stream. After approximately 3 days, when the glucose was almost depleted, i.e., the growth curve entered the stationary phase and sufficient biomass had been accumulated, the closed loop containing precursor saturated process gas was established. Additionally, small amounts of the liquid precursor were directly dosed into the liquid culture in intervals during the biotransformation period. By this means, an initial overdose of the toxic precursor via the liquid phase was easily avoided while a constant replenishment via the gas phase was maintained.

Biotransformation of limonene to α-terpineol with P. digitatum in the bioreactor

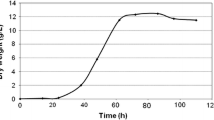

When the growth curve of P. digitatum DSM 62840 entered the stationary phase, the second stage, the actual biotransformation, was started by closing the gas loop once a biomass of approximately 3.5 g L−1 cell dry weight had been accumulated, which occurred after 70–73 h. In contrast to the shake flask experiments, in the bioreactor with closed gas loop the product concentration steadily increased to almost 800 mg L−1 after 150 h and 918 mg L−1 after 176 h (Fig. 4). In a second gas loop biotransformation, where the glucose concentration was periodically re-adjusted to 2 g L−1 during the biotransformation period, as much as 1,009 mg L−1 α-terpineol formed after 193 h with approximately 4 g L−1 cell dry weight. For comparison, previous cultivations of the same strain in a conventional bioreactor setup without gas loop under otherwise identical conditions, i.e., by applying the same bioprocess parameters including the sequential limonene feeding, yielded final biomass concentrations of up to 4.5 g L−1 and a maximum concentration of 506 mg L−1 after 172 h (as indicated by the dotted line in Fig. 4) [27]. The additional glucose feeding performed in biotransformation 2 did not significantly influence productivity and final product concentration, indicating that the C-source which had been depleted during the growth period was not limiting in the subsequent biotransformation period. Although product formation was delayed, the overall result, a roughly doubling of the product concentration in the bioreactor by applying the gas loop concept, was well reproducible as shown by the two separate biotransformation experiments. The molar conversion yields of the gas loop approaches were approximately 57% (biotransformation 1) and 63% (biotransformation 2) based on the limonene consumed by the gas loop and by directly dosing into the biotransformation medium. About 90% of the liquid limonene in the reservoir to saturate the process gas during the biotransformation period was recovered after ending the process and was therefore not included for calculation of the conversion yield.

Time courses of α-terpineol formation during two biotransformations of limonene with P. digitatum DSM 62840 in a closed gas loop bioreactor. Both biotransformations were run as a two-stage process: the actual biotransformation was started at t = 70 h (filled circle biotransformation 1) and t = 73 h (open circle biotransformation 2) by adding 1.9 mM limonene when the glucose concentration had been depleted to a value less than 1 g L−1 and about 3.5 and 4 g L−1 cell dry weight had been accumulated, respectively. Dosage of 1.9 mM limonene was repeated every 24 h. In biotransformation 2, glucose was re-adjusted to 2 g L−1 which was repeated every 24 h of biotransformation. The horizontal line indicates the maximum product concentration achievable after 172 h of cultivation of the same strain without gas loop under otherwise identical bioprocess conditions (i.e., inoculum, medium composition and volume, limonene and glucose feeding, bioreactor operation) [27]

GC–MS analysis of the aqueous culture supernatant after gas loop biotransformation revealed no product other than α-terpineol, thereby confirming our results from the shake flask scale. This is an important finding, because monoterpenes may undergo autoxidation [31, 32]. Obviously, even under the intensified oxidative conditions limonene was exposed to in the gas loop system, where the process air is continuously sparged trough limonene before entering the bioreactor, no significant chemical formation of unwanted by-products occured. Thus, the extraordinary regioselectivity of this biotransformation could be fully harnessed on bioreactor scale.

Biotransformation of α-pinene to verbenone with P. solitum in the bioreactor

As α-pinene, in contrast to limonene and P. digitatum, did not show pronounced inhibiting effects on P. solitum, significant higher precursor concentrations were applied in the bioreactor. A small amount of the precursor was already initially added (2.3 mM), followed by concentrations of 18.7–47 mM at intervals of 18–30 h, because we had noticed during shake flask experiments that the growth morphology of the organism changed from initial pellets into free mycelium after dosing α-pinene. This initial monoterpene dosage led to a finely dispersed mycelial biomass and facilitated cultivation of P. solitum in the bioreactor, which otherwise, in contrast to P. digitatum, tended to adhere at the pO2 and pH probes or to grow into the reactor headspace under the operation conditions applied, i.e., a stirrer speed of 400–500g and an aeration rate of 0.16 vvm. At lower agitation or aeration, no product formation could be measured, whereas higher stirrer speeds and aeration rates had no positive impact on growth and product formation in the conventional bioreactor set-up (data not shown). The first bioprocess stage was carried out under conventional conditions, i.e., without circulating the gas stream. The second bioprocess stage, the actual biotransformation, was conducted either with or without the gas loop. Figure 5 illustrates the advantage of the gas loop for two exemplary biotransformations: without gas loop product formation was only about 1.7 mg L−1 after more than 10 days, whereas the aqueous verbenone concentration in the gas loop bioreactor increased to 36 mg L−1 in the same time. GC–MS analysis of the liquid gas loop precursor reservoir after biotransformation revealed no product accumulation and thus excluded a potential absorption of the volatile verbenone from the gas phase to the α-pinene phase. The data illustrate that it was mandatory to apply the gas loop system in order to also realize product concentrations in the same range, which had been obtained on the shake flask scale, in a bioreactor. However, in contrast to the α-terpineol producing fungal system tested, the closed gas loop bioreactor did not lead to an improvement of the verbenone concentration compared to that obtained in shake flask cultures (Table 1), and the open bioreactor experiments even resulted in lower product concentrations. The verbenone formation through autoxidation was negligible on the shake flask scale but significant in the gas loop system where it accounted for 10–30% of the aqueous product concentration measured after the biotransformation experiment, as verified by control experiments without the fungus under otherwise identical conditions (data not shown). Whereas in the case of P. digitatum the extraction of the fungal mycelium harvested at the end of the biotransformation did not significantly increase the total product yield, the extraction of P. solitum mycelium almost doubled the total product concentration to 70 mg L−1.

Comparison of verbenone formation by P. solitum in the bioreactor with and without gas loop. After an initial dosage of 2.3 mM α-pinene, the precursor was sequentially added at intervals of 18–30 h and concentrations of 18.7–47 mM. After almost complete depletion of the initial glucose (30 g L−1) at t = 147 h, its concentration was re-adjusted to approximately 2 g L−1 every 24 h

Table 2 summarizes the biotransformation key results obtained during this work. The data illustrate that the limonene-to-α-terpineol biotransformation is significantly superior to the microbial system producing verbenone from α-pinene. Furthermore, regarding the α-terpineol production with P. digitatum; both maximum product concentration and average productivity were about eightfold improved by the closed gas loop bioreactor concept compared with the shake flask experiments.

Discussion

(+)-Limonene and α-pinene represent the most prominent ‘waste’ monoterpenes because they accumulate in large amounts of up to several hundred thousand tons per year as by-products of the wood and citrus processing industries, making them attractive natural raw materials for the chemical industry [15]. However, due to the similar chemical reactivity of the carbon atoms, organic chemistry encounters difficulties if a selective attack of one position in these C10 terpene hydrocarbons is aimed at [33]. Here, microbial transformation based on regio- and stereoselective enzymatic reactions represents an interesting alternative, especially for oxyfunctionalizations toward high-value natural flavor and fragrance compounds [14].

In contrast to the known biocatalytic activity of P. digitatum against limonene, the biotransformation activity of P. solitum against α-pinene was a new finding as a result of our screening efforts to identify terpene tolerant fungi from appropriate habitats for natural flavor production, especially from the essential oil components, limonene and α-pinene. Interestingly, this strain totally catabolized limonene without significant formation of biotransformation products whereas with α-pinene as precursor several biotransformation products were found in notable concentrations. The products are well-known metabolites from α-pinene transformation by ascomycetes, some Pseudomonas species, and the black yeast Hormonema UOFS Y-0067 [14, 34], with the exception of fenchol which has not so far been described as a transformation product of α-pinene. In contrast to P. digitatum, scale-up from shake flask to bioreactor turned out to be difficult for submerged cultures of P. solitum, which showed a pronounced sensitivity to agitation in a stirred tank reactor. The low product concentration in the open bioreactor system most probably resulted from the high volatility of the product which was lost via the exhaust air upon active aeration at 0.16 vvm, which was the lowest aeration rate with this bioreactor operation where product formation was measurable at all (about 1.7 mg L−1; cf. Fig. 5). The water solubility of both α-terpineol (670 mg L−1) and verbenone (943 mg L−1) is within the same order of magnitude, but the vapour pressure of verbenone (0.136 mmHg, 25°C) is 4.4 times higher compared to α-terpineol (0.031 mmHg, 25°C) This also explains the fact that the verbenone production in the open bioreactor system was even lower than in the shake flask. Despite the 20-fold increase in product concentration by closing the gas loop, the overall product formation of the α-pinene biotransformation with P. solitum still remained relatively low. Additionally, α-pinene was prone to autoxidation [31, 32]. Thus, working conditions would have to be changed to totally suppress chemical verbenone production in order to meet the legal requirements for labeling the product a ‘natural flavor’ [4, 15]. Interestingly, total verbenone concentration was almost doubled to 70 mg L−1 by disrupting the cells before extractive product recovery because a significant part of the lipophilic verbenone was obviously retained by the fungal cell membranes. Although superior to other higher fungi, such as Aspergillus and Penicillium species, for which verbenone concentrations of 15–33 mg L−1 have been reported [8, 35], the biotransformation capacity of P. solitum is still too low for a technical application. A low inherent activity of the enzyme(s) involved or a restricted precursor access to the enzyme(s)—probably intracellular and cofactor-dependent redox enzyme(s)—may be the limiting factor because, unlike the P. digitatum biotransformation system, the precursor α-pinene was present in great excess in the stirred bioreactor with P. solitum. In contrast to the α-pinene-to-verbenone oxidation, the α-terpineol synthesis from limonene appears to follow a simple double bond hydration reaction, which would demand neither cofactor-dependent enzymes nor oxygen and which might explain the superior product formation kinetics and the fact that no intracellular biotransformation product was found in P. digitatum. However, the α-terpineol synthesis is postulated to proceed via an initial epoxidation of the 8, 9 double bond followed by a reductive cleavage of the epoxide [27, 33, 36], although a respective enzyme has not yet been identified.

The scale-up from shake flask to bioreactor usually increases process efficiency because the chemical and physical environment is more readily controllable. In the case of monoterpene biotransformations, however, additional dispositions have to be made accounting for the volatility and toxicity of the precursor. This becomes especially evident in the present work for the α-terpineol formation with P. digitatum. Not only the conventional variables, such as pH and pO2, were controlled but, using the modified process setup, i.e., the closed precursor-saturated gas loop, it was also possible to prevent both the evaporative loss of the volatile precursor from the biotransformation medium to the gas phase—thereby guaranteeing its constant availability to the fungus—and its irrecoverable loss via the exhaust stream. By keeping the process gas always precursor-saturated, an elegant feeding method to continuously replenish the biotransformation medium with precursor from the gas phase was established. This gas phase dosage complemented the sequential direct feeding of aliquots of the liquid precursor, which had been identified by our preceding toxicity studies as being only slightly inhibiting to P. digitatum DSM 62840. By this concept, product concentration and productivity were considerably improved and a molar conversion yield of up to 63% was achieved. In contrast, the open bioreactor system used in previous studies most probably suffered from periods of precursor limitation as only the sequential direct feeding of the liquid monoterpene was applied and an online measurement of limonene in the liquid phase was impractical [27]. The maximum specific product concentrations were in the range of 250–290 mg g−1 dry cells. Other studies with Penicillium on analytical or shake flask scale reported comparable yields from 172 to 373 mg α-terpineol g−1 dry cells [9, 37, 38]. A possible explanation for the fact that these values are in the same range may be that, during biotransformation, the rising aqueous concentration of the less volatile and comparably well soluble α-terpineol became increasingly inhibiting towards Penicillium species. Product inhibition effects of α-terpineol on P. digitatum cells during limonene biotransformation have already been described by Tan and Day [38]. Therefore, even higher product concentrations might be possible by combining the gas loop system with appropriate in situ product recovery techniques. Whereas all previously published quantitative data on α-terpineol formation with P. digitatum have been derived from assay or shake flask scales [22, 36, 37, 39], the novel process design enabled us to also report an α-terpineol production in the g L−1 range on a bioreactor scale for the first time. Very recently, a newly isolated fungus, Fusarium oxysporum 152b, was shown to produce up to 2.4 g L−1 α-terpineol from (+)-limonene after medium optimization in shake flasks [40]. Despite the obviously pronounced product tolerance of this fungus, the high toxicity and high volatility of the precursor were claimed to strongly impede further increased product concentrations. Consequently, the closed gas loop bioreactor concept may also be beneficial to the aforementioned biotransformation and could lead to even higher α-terpineol concentrations than reported to date. The combination of high-performing strains with a tailored bioprocess design may thus serve as a sound basis for further developments towards the biotechnological production of valuable natural flavor and fragrance compounds from cheap and abundantly available natural terpenoids in the future.

References

Guentert M (2007) The flavour and fragrance industry—past, present, and future. In: Berger RG (ed) Flavours and fragrances chemistry, bioprocessing and sustainability. Springer, Berlin, pp 1–14

Soetaert W, Vandamme E (2006) The impact of industrial biotechnology. Biotechnol J 1:756–769. doi:10.1002/biot.200600066

Cheetham PSJ (1991) The flavour and fragrance industry. In: Moses V, Cape RE (eds) Biotechnology, the science and the business. Harwood, NJ, pp 481–506

Demyttenaere JCR (2001) Biotransformation of terpenoids by microorganisms. In: Atta ur R (ed) Bioactive natural products (Part F). Elsevier, Oxford, pp 125–178

Feygin H (2007) Topics in perfumery: creating effective natural fragrances. Perfum Flavor 5:26–29

Ohloff G (1994) Scent and fragrances. The fascination of odors and their chemical perspectives. Springer, Berlin

Braddock RJ (1998) Handbook of citrus by-products and processing technology. Wiley, New York

Agrawal R, Joseph R (2000) Bioconversion of α-pinene to verbenone by resting cells of Aspergillus niger. Appl Microbiol Biotechnol 53:335–337. doi:10.1007/s002530050030

Tan Q, Day DF (1998) Organic co-solvent effects on the bioconversion of (R)-(+)-limonene to (R)-(+)-α-terpineol. Process Biochem 33:755–761. doi:10.1016/S0032-9592(98)00046-6

Onken J, Berger RG (1999) Effects of R-(+)-limonene on submerged cultures of the terpene transforming basidiomycete Pleurotus sapidus. J Biotechnol 69:163–168. doi:10.1016/S0168-1656(99)00040-1

Berger RG (1995) Aroma biotechnology. Springer, Berlin

von Wallbrunn A, Richnow HH, Neumann G, Meinhardt F, Heipieper HJ (2003) Mechanism of cis–trans isomerization of unsaturated fatty acids in Pseudomonas putida. J Bacteriol 185:1730–1733. doi:10.1128/JB.185.5.1730-1733.2003

Kieboom J, Dennis JJ, Zylstra GJ, de Bont JA (1998) Active efflux of organic solvents by Pseudomonas putida S12 is induced by solvents. J Bacteriol 180:6769–6772

Schrader J (2007) Microbial flavour production. In: Berger RG (ed) Flavours and fragrances chemistry, bioprocessing and sustainability. Springer, Berlin, pp 509–573

Schrader J, Berger RG (2001) Biotechnological production of terpenoid flavor and fragrance compounds. In: Rehm HJ, Reed G (eds) Biotechnology. Wiley, Weinheim, pp 373–422

van der Werf MJ, de Bont JAM, Leak DJ (1997) Opportunities in microbial biotransformation of monoterpenes. In: Scheper T (ed) Advances in biochemical engineering, biotechnology. Springer, Berlin, pp 147–177

Fichan I, Larroche C, Gros JB (1999) Water solubility, vapor pressure, and activity coefficients of terpenes and terpenoids. J Chem Eng Data 44:56–62. doi:10.1021/je980070+

McIntosh TJ, Simon SA, MacDonald RC (1980) The organization of n-alkanes in lipid bilayers. Biochim Biophys Acta 597:445–463. doi:10.1016/0005-2736(80)90219-9

Knobloch K, Weigand H, Weis N, Schwarm H-M, Vigenschow H (1986) Action of terpenoids on energy metabolism. In: Brunke E-J (ed) Progress in essential oil research. Walter de Gruyter, Berlin, pp 429–445

Bruce LJ, Daugulis AJ (1991) Solvent selection strategies for extractive biocatalysis. Biotechnol Prog 7:116–124. doi:10.1021/bp00008a006

Sikkema J, de Bont JA, Poolman B (1995) Mechanisms of membrane toxicity of hydrocarbons. Microbiol Rev 59:201–222

Abraham WR, Hoffmann HMR, Kieslich K, Reng G, Stumpf B (1985) Microbial transformations of some monoterpenoids and sesquiterpenoids. In: Porter R, Clark S (eds) Enzymes in organic synthesis Ciba Foundation Symposium 111. Pitman, London, pp 146–159

Schäfer S, Schrader J, Sell D (2004) Oxygen uptake rate measurements to monitor the activity of terpene transforming fungi. Process Biochem 39:2221–2228. doi:10.1016/j.procbio.2003.11.023

van Beilen JB, Holtackers R, Luscher D, Bauer U, Witholt B, Duetz WA (2005) Biocatalytic production of perillyl alcohol from limonene by using a novel Mycobacterium sp. cytochrome P450 alkane hydroxylase expressed in Pseudomonas putida. Appl Environ Microbiol 71:1737–1744. doi:10.1128/AEM.71.4.1737-1744.2005

Steinig GH, Livingston AG, Stuckey DC (2000) Bioconversion of hydrophobic compounds in a continuous closed-gas-loop bioreactor: feasibility assessment and epoxide production. Biotechnol Bioeng 70:553–563. doi:10.1002/1097-0290(20001205)70:5<553::AID-BIT10>3.0.CO;2-2

Freitas dos Santos LM, Livingston AG (1993) A novel bioreactor system for the destruction of volatile organic compounds. Appl Microbiol Biotechnol 40:151–157. doi:10.1007/BF00170444

Kaspera R, Krings U, Pescheck M, Sell D, Schrader J, Berger RG (2005) Regio- and stereoselective fungal oxyfunctionalisation of limonenes. Z Naturforsch 60(C):459–466

Taubert J, Krings U, Berger RG (2000) A comparative study on the disintegration of filamentous fungi. J Microbiol Methods 42:225–232. doi:10.1016/S0167-7012(00)00194-9

Wu S, Krings U, Zorn H, Berger RG (2005) Volatile compounds from the fruiting bodies of beefsteak fungus Fistulina hepatica (Schaeffer: Fr.). Fr Food Chem 92:221–226. doi:10.1016/j.foodchem.2004.07.013

Bauer B (2004) Biotechnologische Veredelung vonterpenhaltigen Reststofffraktionen der citrusverarbeitenden Industrie zu hochwertigen natürlichen Duft- und Aromastoffen. PhD thesis, Leipzig University Hannover, Germany

Arctander S (1969) Perfume and flavor chemicals: (aroma chemicals). Monclair, NJ

Moore RN, Golumbic C, Fisher GS (1956) Autoxidation of α-pinene. J Am Chem Soc 78:1173–1176. doi:10.1021/ja01587a022

Duetz WA, Bouwmeester H, van Beilen JB, Witholt B (2003) Biotransformation of limonene by bacteria, fungi, yeasts, and plants. Appl Microbiol Biotechnol 61:269–277

van Dyk MS, van Rensburg E, Moleleki N (1998) Hydroxylation of (+)-limonene, (−)-α-pinene and (−)-β-pinene by a Hormonema sp. Biotechnol Lett 20:431–436. doi:10.1023/A:1005399918647

Agrawal R, Deepika NU, Joseph R (1999) Strain improvement of Aspergillus sp. and Penicillium sp. by induced mutation for biotransformation of α-pinene to verbenol. Biotechnol Bioeng 63:249–252. doi:10.1002/(SICI)1097-0290(19990420)63:2<249::AID-BIT14>3.0.CO;2-D

Kieslich K, Abraham WR, Stumpf B, Thede B, Washausen P (1986) Transformations of terpenoids. In: Brunke E-H (ed) Progress in essential oil research. Walter de Gruyter, Berlin, pp 367–394

Stumpf B, Abraham W-R, Kieslich K (1983) Verfahren zur Herstellung von (+)-α-Terpineol durch mikrobiologische Umwandlung von Limonen. Germany patent P 3 243 090

Tan Q, Day DF (1998) Bioconversion of limonene to α-terpineol by immobilized Penicillium digitatum. Appl Microbiol Biotechnol 49:96–101. doi:10.1007/s002530051143

Adams A, Demyttenaere JCR, De Kimpe N (2003) Biotransformation of (R)-(+)- and (S)-(−)-limonene to [α]-terpineol by Penicillium digitatum—investigation of the culture conditions. Food Chem 80:525–534. doi:10.1016/S0308-8146(02)00322-9

Bicas JL, Barros FF, Wagner R, Godoy HT, Pastore GM (2008) Optimization of R-(+)-α-terpineol production by the biotransformation of R-(+)-limonene. J Ind Microbiol Biotechnol 35:1061–1070. doi:10.1007/s10295-008-0383-0

Acknowledgment

This work was financially supported by Deutsche Bundesstiftung Umwelt, DBU (project no. AZ 13053/17).

Author information

Authors and Affiliations

Corresponding author

Additional information

M. Pescheck and M. A. Mirata have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Pescheck, M., Mirata, M.A., Brauer, B. et al. Improved monoterpene biotransformation with Penicillium sp. by use of a closed gas loop bioreactor. J Ind Microbiol Biotechnol 36, 827–836 (2009). https://doi.org/10.1007/s10295-009-0558-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-009-0558-3