Abstract

Biogenic production of hydrogen sulphide (H2S) is a problem for the oil industry as it leads to corrosion and reservoir souring. Continuous injection of a low nitrate concentration (0.25–0.33 mM) replaced glutaraldehyde as corrosion and souring control at the Veslefrikk and Gullfaks oil field (North Sea) in 1999. The response to nitrate treatment was a rapid reduction in number and activity of sulphate-reducing bacteria (SRB) in the water injection system biofilm at both fields. The present long-term study shows that SRB activity has remained low at ≤0.3 and ≤0.9 μg H2S/cm2/day at Veslefrikk and Gullfaks respectively, during the 7–8 years with continuous nitrate injection. At Veslefrikk, 16S rRNA gene based community analysis by PCR–DGGE showed that bacteria affiliated to nitrate-reducing sulphide-oxidizing Sulfurimonas (NR–SOB) formed major populations at the injection well head throughout the treatment period. Downstream of deaerator the presence of Sulfurimonas like bacteria was less pronounced, and were no longer observed 40 months into the treatment period. The biofilm community during nitrate treatment was highly diverse and relative stable for long periods of time. At the Gullfaks field, a reduction in corrosion of up to 40% was observed after switch to nitrate treatment. The present study show that nitrate injection may provide a stable long-term inhibition of SRB in sea water injection systems, and that corrosion may be significantly reduced when compared to traditional biocide treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In offshore oil fields, deoxygenated sea water is often injected into the reservoir in order to sustain reservoir pressure and enhance secondary oil recovery. The anoxic conditions combined with the high sulphate content of sea water leads to enrichment of sulphate-reducing bacteria (SRB) in oil installations, pipelines and oil reservoirs [6, 14, 35]. SRB reduce sulphate to the highly toxic and corrosive gas hydrogen sulphide (H2S) during anaerobic respiration. The production of H2S leads to corrosion, reservoir souring and deterioration of oil and gas quality [6, 7, 14, 35]. Microbial influenced corrosion (MIC) may be caused by biogenic production of H2S, but are also caused by other metabolic activities and products involving both aerobic and anaerobic microorganisms [2]. Although the mechanisms involved in MIC are complex, some microbial activity has traditionally been considered more aggressive. One is the action of hydrogen scavenging Desulfovibrio species which may accelerate the corrosion rate by removing hydrogen from the metal surface [4, 5]. Monitoring of microbial activity on offshore installations has been focused on the general activity of SRB and the presence of Desulfovibrio in particular. Recently however, SRB affiliated to the genus Desulfobacterium have been reported to grow directly on metallic iron while reducing sulphate at a much faster rate than observed by Desulfovibrio species [9].

Biocides have traditionally been used to mitigate reservoir souring and reduce MIC, but during the last decade nitrate injection have been introduced as a more efficacious and environmentally safe method. The introduction of nitrate leads to enrichment of nitrate-reducing bacteria (NRB) which inhibit SRB by producing toxic reduction products like nitrite [17, 21] and by increasing the redox potential [16, 26]. Activity of nitrate-reducing sulphide-oxidizing bacteria (NR–SOB) will contribute to the increase in redox potential by biological oxidation of sulphide. NRB may also outcompete SRB in carbon limited systems due to the more favourable energy potential of nitrate reduction compared to sulphate reduction.

Biofilm associated SRB and corrosion rates have been monitored in the sea water injection system at Veslefrikk oil field (North Sea) since the field start up. A shift in the microbial community was observed during biocide treatment in form of an increase in viable counts targeting Desulfovibrio [34]. The shift was followed by an increase in H2S production and corrosion rates. The initial period with nitrate treatment (1999–2001) revealed a 20,000-fold reduction in viable counts of Desulfovibrio, a 50-fold reduction in H2S production (SRB activity) and a reduction in corrosion rate [34]. Reduction in viable counts of Desulfovibrio was evident after only 1 month with nitrate injection, and SRB detected by fluorescent antibody technique (FA) was no longer observed after 4 months. An increase in viable counts of NRB was observed concomitant with the decrease in numbers and activity of SRB. The tendency of increasing corrosion rate with biocide treatment time has also been observed in water injection systems at the Gullfaks field (North Sea) [31]. Implementation of nitrate treatment at Gullfaks lead to a similar response as observed at Veslefrikk [31].

The aim of the current study was to assess the long-term effect of nitrate treatment on SRB activity, corrosion rates and bacterial community composition. Updated monitoring results from Veslefrikk and Gullfaks during the period 2002–2007 are presented, along with results from molecular analysis of the bacterial biofilm community at Veslefrikk during late biocide treatment and nitrate treatment. (Part of the data included in the current study was presented at the NACE International Corrosion Conference in 2002 and 2004 [31, 34]).

Materials and methods

Water injection systems and sampling

The Veslefrikk and Gullfaks oil field is situated in the North Sea (block 30/3 and 34/10 respectively, Norwegian sector). The water injection system at Veslefrikk is partly situated at floater Veslefrikk B and platform Veslefrikk A, connected by a flexible hose [34]. The injection water was treated with glutaraldehyde from the start up in 1989 until January 1999 when biocide treatment was replaced by nitrate treatment. Nitrate [Ca(NO3)2] has since been injected continuously in a quantity corresponding to approximately 0.25 mM NO3 −. The water injection system consists partly of low grade C-steel and partly of higher grade steel.

Nitrate replaced biocide treatment at the Gullfaks B platform in October 1999 and at the Gullfaks C platform in November 1999. The nitrate dosage at the start of treatment was equivalent to 0.25 mM NO3 −, but was increased to 0.33 mM NO3 − in October 2001. The water injection systems at the Gullfaks platforms consist of low grade C-steel.

The amount of sea water treated in each system varies between 15,000 and 60,000 m3/day. At both fields oxygen is removed from the injected sea water to a level <20 ppb by vacuum deaeration and bisulphite scavenger (NaHSO3). Additional chemical water treatment include a silicone based antifoam, which was temporarily replaced by a biodegradable organic antifoam (2 mg/l) during the period December 2005 to January 2007 at Veslefrikk and during the period December 2005 to January 2007 at Gullfaks B and July 2005 to January 2007 at Gullfaks C. The biocide treatment regime at both fields during the 5 years prior to nitrate injection was batch treatment with 500 ppm 50% glutaraldehyde 1 h per week.

In order to monitor the microbial community in the water injection systems, biofilm samples were collected by incubating C-steel biocoupons with 0.5 cm2 exposed surface area flush mounted in the anoxic part of the system. At Veslefrikk the biocoupons were situated downstream of the deaeration tower (VFB) and at the injection well head (VFA) where the pressure is ~10 bar and >200 bar respectively. The ambient water temperature is between 20 and 25 °C. The biocoupons used at Veslefrikk (ST52) was delivered by Roxar (Stavanger, Norway). At the Gullfaks platforms the biocoupons were situated downstream of the deaeration tower where the pressure is around 200 bar and the water temperature 25 °C. From 1994 until 2006 the biocoupons were supplied from Oilfield Microbiology Services Ltd (Aberdeen, Scotland) and from 2006 they were supplied from Roxar (Stavanger, Norway). A Roxar biocoupon set constituted of five coupons, while a set from Oilfield Microbiology Services Ltd constituted of six coupons. At Veslefrikk one set was placed at each sampling point. At Gullfaks B and C two parallel sets were placed at one sampling point designated GFB and GFC respectively.

Corrosion measurements were performed on C-steel weight loss coupons (Roxar, Stavanger, Norway) mounted close to the biocoupons. Both biocoupons and corrosion coupons were harvested at irregular time intervals, and corrosion coupons were harvested more frequently than the biocoupons.

For further description of the water injection systems and sampling see Thorstenson et al. and Sunde et al. [31, 34].

Handling of biocoupons

Two out of five or six biocoupons from each set was prepared for quantification of SRB and NRB, and for molecular analysis. Each biocoupon was placed in a N2-flushed 10-ml glass vial with 2 ml 0.2 μm filtered anoxic water from the sampling point and sonicated until the biofilm was dissolved (Bandalin Sonorex Rapid, Berlin, Germany). The coupons were then removed and additional 8 ml of the filtered water was added to each vial. The three or four remaining biocoupons were used for measurements of the sulphate reduction rate as described below (SRB activity).

Quanification of SRB and NRB

Viable counts of SRB was determined by the most-probable-number method (MPN) using a medium targeting lactate oxidizing SRB (Desulfovibrio) as described previously [34]. SRB was also determined by double staining fluorescent antibody technique (FA) [15] modified as described by Nilsen et al. [24] and by using a mixture of polyclonal antibodies specific for SRB previously isolated from water injection systems at the Statfjord and Gullfaks field. The filters used for FA analysis were double stained with DAPI and the number of SRB and total number of bacteria was determined by epifluorescent microscopy. FA analysis was not performed after October 2002. NRB was determined by MPN using a sulphate free mineral medium [22] amended with a mixture of acetate (20 mM), butyrate (5 mM), caproate (5 mM) and lactate (8.2 mM) as carbon and energy source. The medium was prepared in two different redox states, one made anoxic by flushing with N2 targeting facultative anaerobic NRB and one reduced with sulphide targeting obligatory anaerobic NRB [34]. One ml of the biofilm suspension was used to inoculate the MPN series while 0.1 ml was dispersed in 10 ml PBS buffer and filtered for the FA/DAPI counts. The MPN series were incubated at 30 °C for 4 weeks.

SRB activity

The sulphate reduction rate was determined by radiorespiratory measurement of H2S production in intact biofilm on biocoupons. The method is based on that of Maxwell and Hamilton [19] and modified as described below. The experimental set up consisted of a lower incubation glass tube that was connected to an upper H2S-trapping glass tube. The experimental set up was flushed with N2 gas prior to use. The incubation medium consisted of 4 ml of 0.2 μm filtered water from the sampling point added 35S-labelled sulphate to a final activity of 20 μCi (0.74 MBq) (no. SJ162, Amersham, Buckinghamshire, UK). Each biocoupon was placed in a lower tube which was closed and sealed with tape to prevent leakage due to increasing gas pressure during incubation. A volume of 0.45 ml 1 M zinc acetate was then injected onto the filter paper and the upper tube was capped and secured with tape. Three (four) coupons were analysed from each sampling point, two (three) for H2S production and one for background measurement. In the latter case 0.5 ml 6 M HCl was added immediately after the upper tube was sealed. The tubes were incubated at 30 °C for one day and night (~24 h). The biogenic sulphide production was stopped by adding 0.5 ml 6 M HCl. Acid volatile sulphides including H2S was left to be trapped in the zinc acetate saturated filter during a minimum 2 h equilibrium period. The filters were then placed in scintillation vials and covered with liquid scintillation cocktail Ultima Gold (PerkinElmer, Waltham, MA, USA). Total radioactivity was estimated by counting DPM in 0.1 ml incubation medium added 3 ml liquid scintillation cocktail. The sulphate reduction rate per biocoupon was calculated as described by Maxwell and Hamilton [19]. The sulphate reduction rate is given as the amount of H2S produced per biofilm area per day (μg H2S/cm2/day). The sulphate reduction rate is also referred to as SRB activity.

Corrosion monitoring

The corrosion measurements were performed according to NACE standard RP 0775; preparation, installation, analysis and interpretation of corrosion coupons in oilfield operations (NACE, Houston, TX, USA).

Molecular analysis

Material for whole-cell PCR was prepared by centrifuging 1 ml of the biofilm suspension at 12,000×g for 20 min. After discharging the supernatant, the pellets were kept frozen at −20 °C until further analysis. Before PCR reaction, the pellet was suspended in 50 μl molecular biology grade water (Eppendorf, Hamburg, Germany). The V3 region of bacterial 16S rRNA genes was amplified by whole-cell PCR using the forward Bacteria primer pA8f with GC clamp [11], and reverse universal primer PRUN518r [20]. The PCR mixture per reaction contained 5 μl biofilm suspension, 0.5 μM of each primer, 25 μl HotStarTaq Master Mix (Qiagen, Hilden, Germany), 5 μg BSA, and molecular biology grade water to a final volume of 50 μl. PCR was performed in GeneAmp2400 thermal cycler (Applied Biosystems, Foster City, CA, USA) by enzyme activation at 95 °C for 15 min; 35 cycles of amplification at 94 °C for 30 s (denaturation), 55 °C for 30 s (annealing), and 72 °C for 1 min (extension); final extension at 72 °C for 10 min. Positive amplification was determined under UV-light after electrophoresis of 5 μl PCR sample in 1.5% agarose gel stained with ethidium brominde.

DGGE analysis of PCR products was performed as described earlier [38] with the following modifications; the gels were prepared with a denaturing gradient ranging from 20% to 60% and was run for 18 h at 70 V. The gels were stained for 45 min with SYBR Gold (Invitrogen, Carlsbad, CA, USA) in 1× TAE, and photographed. The intensity of a DNA band is assumed to represent the relative abundance of a species, so visual estimation of band intensity was used to designate major populations [20].

DNA fragments were excised from the DGGE gel [38] and reamplified using the same PCR procedure as described above, except that no BSA was added, 2 μl DNA eluate was added as template and the reaction was run for 30 cycles. Reamplified DNA was purified using QIAquick PCR purification kit (Qiagen, Hilden, Germany) and sequence PCR was performed using primer PRUN518r and BigDye V.3.1 sequencing kit according to manufacturer (Applied Biosystems, Foster City, CA, USA). Sequence analysis was performed on ABI 3730xl DNA analyzer (Applied Biosystems, Foster City, CA, USA) by Sars Centre DNA sequence facility at University Research of Bergen (Unifob AS, Bergen, Norway). The DNA sequences were analysed using BLAST tool [1] for identification of closest match registered in GenBank (NCBI) [3]. The sequences were also analysed using the Ribosomal Database Project (RDP) classifier [36] for taxonomic classification. The phylogenetic distance between DNA sequences were calculated using ClustalX [33], and trees were constructed using bootstrap neighbour-joining algorithm (1,000 trials) and Tree View version 1.6.6 [25]. Similar sequence types were compared pair wise using BLAST 2 sequences tool (NCBI) [32], and the term “sequence type” refers to a set of sequences with 100% sequence similarity.

The DGGE banding pattern of samples collected during biocide and nitrate treatment was analysed using the gel-analysis program Gel2 k (S. Norland, Department of Biology, University of Bergen, Norway). The program detects the presence or absence of bands on gel pictures and converts the information into binary data. The distance between the samples banding pattern was calculated by simple matching algorithm and presented by a dendogram drawn using the group average.

PCR–DGGE analysis was also performed on the bacterial community in the first dilution step of MPN series after the end of incubation. The same analysis procedures were applied as for the biofilm samples. Representative bands were sequenced.

Nucleotide sequence accession numbers

16S rRNA gene sequences have been deposited in GenBank (NCBI) under accession numbers EU594272–EU594314.

Results from Veslefrikk

SRB numbers and activity

The viable counts targeting Desulfovibrio was generally at a level between 102 and 104 cells/cm2 during the period with nitrate treatment (1999–2006), although a transient increase was observed in October 2002 at both VFB and VFA (Figs. 1, 2). The viable counts constituted at any time ≤1% of the total microbial community at both VFB and VFA, except for the sample from VFB in October 2002 where they constituted 24% of the community. The total bacterial counts were relative stable at 107–108 cells/cm2 during the whole period at both sampling points (Figs. 1, 2). During the 7-year period with nitrate treatment the SRB activity was ≤0.3 μg/H2S/cm2/day at VFB and ≤0.1 μg/H2S/cm2/day at VFA, except for a single high activity measurement in March 2003 at both VFB and VFA (Figs. 1, 2).

Bacterial numbers and SRB activity in biofilm from VFB during late biocide treatment and nitrate treatment (a); number of SRB quantified by viable counts (MPN, black bars) and by fluorescent antibody technique (FA, white bars) (FA analysis was not performed after October 2002) (b); SRB activity, mean value of two measurements where error bars indicate standard deviation (c); viable counts of NRB targeting facultative anaerobic NRB (black bars) and obligate anaerobic NRB (grey bars) (a, c); total number of bacteria (filled circles)

Bacterial numbers and SRB activity in biofilm from VFA during late biocide treatment and nitrate treatment (a); number of SRB quantified by viable counts (MPN, black bars) and by fluorescent antibody technique (FA, white bars) (FA analysis was not performed after October 2002) (b); SRB activity, mean value of two measurements where error bars indicate standard deviation (c); viable counts of NRB targeting facultative anaerobic NRB (black bars) and obligate anaerobic NRB (grey bars) (a, c); total number of bacteria (filled circles)

NRB numbers

During the 7-year period with nitrate treatment, the viable counts of NRB in the biofilm generally varied between 106–107 cells/cm2, constituting at any time between 0.4–100% and 0.1–48% of the total microbial community at VFB and VFA respectively (Figs. 1, 2).

Corrosion

The mean corrosion rate observed at the well head (VFA) during nitrate treatment was lower than observed during late biocide treatment, but the reduction was not significant within 95% confidence interval (Table 1). There was no significant difference in the mean corrosion rate downstream of deaerator (VFB). The corrosion rate measured in February 2005 at VFB (1.48 mm/year) was much higher than the other measurements and contributed to a significant higher mean corrosion rate at VFB during nitrate treatment. The overall trend at both VFB and VFA was a more stable corrosion rate during nitrate treatment than during biocide treatment (Fig. 3).

PCR–DGGE community profiles

Bacterial 16S rRNA gene sequences was successfully amplified from 11 of 12 biofilm samples from VFB and 12 of 13 biofilm samples from VFA. Samples collected in May 1999 at VFB and October 2002 at VFA during nitrate treatment did not give a PCR product. No samples were harvested for PCR analysis in October 1998.

Cluster analysis of DGGE gel banding pattern showed that samples collected during biocide treatment grouped together with samples collected after 1 and 4 months nitrate injection and the sample collected from VFA in October 2005. The majority of samples collected during nitrate treatment formed two distinct clusters that shared at least 80% similar band pattern. One of the groups consisted of VFA samples collected during the period July 2000 to March 2003 and the sample collected from VFB in September 2001. The other group consisted of VFB samples collected during the period January 2000 to October 2002 and samples collected from VFA in January 2000 and August 2004. The samples collected at VFA in November 2006, VFB in March 2003 and VFB in October 2005 differed significantly in band pattern compared to each other and the other samples. The phylogenetic affiliation of all the sequences retrieved from the DGGE analysis of environmental samples from Veslefrikk is given in Fig. 4.

Phylogenetic tree based on partial 16S rRNA gene sequences retrieved from biofilm are given in bold types and compared to reference sequences from GenBank (NCBI). Reference sequences were cut to the same length as the sample sequences. The scale bar corresponds to 0.1 changes per nucleotide. Bootstrap values were obtained from 1,000 bootstrap trials and are given in percentage. Letters VFA, VFB and VF refers to location of observation; VF means observed at both locations. †Only observed during biocide treatment, *observed during both biocide and nitrate treatment

Major populations during biocide treatment

The distribution of major populations downstream of deaerator (VFB) and at the well head (VFA) is presented in Tables 2, 3 respectively. The overview includes only bacteria observed in more than one sample, in order to focus on populations that have been established in the biofilm for a definite time. The major populations observed during biocide treatment were ε-Proteobacteria (sequence type VF-14) affiliated to the sulphide-oxidizing bacterium ODP B9, α-Proteobacteria (sequence type VF-1) affiliated to the genus Silicibacter, and a member of the order Clostridiales (sequence type VF-463) with 98% sequence similarity to bacterium STA-346E observed in a biocide treated oil reservoir. A δ-Proteobacterium (sequence type VF-87) affiliated to a marine snow associated bacterium (96%) and the SRB Desulfotalea psychrophila (91%) was also observed in the biofilm during biocide treatment.

Major populations during nitrate treatment

Three of the four major populations that were observed during biocide treatment were no longer observed in the biofilm after 1 year with nitrate treatment (Tables 2, 3). The bacterium affiliated to sulphide-oxidizing bacterium ODP B9 (VF-14) still formed major populations after the switch to nitrate, particular at the well head were it was observed throughout the sampling period. New major populations of a ε-Proteobacterium were observed in biofilm at both sites in July 2000, one and a half year after the onset of nitrate injection. The sequence type VF-424 showed 94% sequence similarity to NR–SOB Sulfurimonas denitrificans, and 100% sequence similarity to bacterium strain STB-827E enriched from a Statfjord oil reservoir (North Sea) injected with nitrate. The strain STB-827E was enriched under nitrate-reducing conditions with H2 as electron donor (unpublished results). The Veslefrikk strain VF-424 formed major populations at the well head (VFA) throughout the treatment period, but ceased to dominate downstream of the dearerator (VFB) after September 2001. According to the RDP classifier, the sequence types VF-14 and VF-424 both belong to the genus Sulfurimonas. The following new populations were also affiliated to bacteria previously observed in nitrate-reducing environments; α-Proteobacterium (sequence type VF-25) with 100% sequence similarity to a bacterium observed in a nitrate treated Statfjord oil reservoir and a bacterium (sequence type VF-92) with 97% sequence similarity to bacterium clone: nsmpVI41 observed during nitrification/denitrification process in wastewater. According to RDP classifier sequence type VF-92 belong to the genus Leucothrix. Among the other new populations were sequence type VF-481 which is closely affiliated to a North Sea Bacteroidetes bacterium [29], α-Proteobacteria (sequence types VF-503 and VFA-472) which showed between 98–99% sequence similarity to the marine methyl halide-oxidizing Rhodobacteraceae bacterium 183 [28], and an α-Proteobacterium belonging to the family Phyllobacteriaceae (sequence type VF-31).

Phylotypes observed in MPN series

PCR–DGGE analysis of samples from SRB–MPN series after 4 weeks incubation revealed growth of SRB affiliated to the genera Desulfovibrio (4 of 6 phylotypes), Desulfotignum (1 of 6 phylotypes) and Desulfomicrobium (1 of 6 phylotypes). Three of the Desulfovibrio sequence types and the Desulfotignum sequence type were also observed in NRB–MPN series (Fig. 5). In MPN series targeting NRB the predominant taxonomic group observed was γ-Proteobacteria (7 of 23), wherein all sequences was affiliated to the genus Marinobacter. One α-Proteobacterium (sequence type VFA-M203) showed 99% sequence similarity to one of the environmental populations from VFA (sequence type VFA-473 in Fig. 4). Another α-Proteobacterium (sequence type VFA-M201) showed 99% sequence similarity to an NRB that formed major populations in a Statfjord oil reservoir during nitrate injection (unpublished results).

Phylogenetic tree based on partial 16S rRNA gene sequences retrieved from MPN series targeting NRB are given in bold types and compared to reference sequences from GenBank (NCBI). Reference sequences were cut to the same length as the sample sequences, except in case of the sequence with accession nr. AY274450, were only partial sequence was available in GenBank. The scale bar corresponds to 0.1 changes per nucleotide. Bootstrap values were obtained from 1,000 bootstrap trials and are given in percentage. Letters VFA, VFB and VF refers to location of observation; VF means observed at both locations. Asterisk were also observed in MPN series targeting SRB

Results from Gullfaks

SRB activity

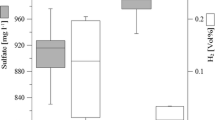

The initial response to nitrate injection at Gullfaks was a rapid reduction in number and activity of SRB and a concomitant increase in number of NRB [31]. The level of SRB activity has remained low during the 8 years with nitrate injection, averaging at 0.86 ± 0.32 μg H2S/cm2/day (±SE, n = 76) at GFB and 0.84 ± 0.28 μg H2S/cm2/day (±SE, n = 59) at GFC. At GFC there was a tendency of decreasing SRB activity with time of nitrate treatment (Fig. 6). The average SRB activity during biocide treatment (1994–1999) was 4.98 ± 0.51 μg H2S/cm2/day (±SE, n = 72) at GFB and 11.73 ± 1.40 μg H2S/cm2/day (±SE, n = 60) at GFC.

Corrosion rates at GFC during biocide treatment (dark grey bars) and nitrate treatment (light grey bars). Upon revision of the data presented previously [31] the corrosion rate from November 2001 have been corrected from 0.03 to 0.29 mm and the corrosion rate from June 2003 have been corrected from 0.33 to 0.19 mm. Corrosion measurement was not performed in September 1999. The average SRB activity was based on measurements from 3–6 biocoupons (filled circles where error bars indicate standard deviation). Upon revision of the data presented previously [31] the SRB activity from October 1998 and August 2001 have been corrected from 3.53 to 1.77 μg H2S/cm2/day and 3.20 to 3.43 μg H2S/cm2/day respectively

Corrosion

A significant reduction in corrosion rate from 0.90 ± 0.08 and 0.61 ± 0.07 mm/year during late biocide treatment to 0.48 ± 0.03 and 0.23 ± 0.01 mm/year during nitrate treatment was observed at GFB and GFC respectively (95% confidence interval) (Table 1). At GFC there was also a 40% significant reduction in corrosion during nitrate treatment when compared to the whole period with biocide treatment. At GFC the trend indicated a decrease in corrosion rate with time of nitrate treatment and decreasing level of SRB activity (Fig. 6).

Discussion

Both SRB activity and corrosion rate increased in the water injection systems at Veslefrikk and Gullfaks during biocide treatment [31, 34]. The increase in H2S production occurred concomitant with the increase in cultivable Desulfovibrio in the biofilm, but at Veslefrikk the viable counts never constituted more than 1% of the total bacterial count [34]. Molecular community analysis confirmed that none of the major populations in the biofilm affiliated to Desulfovibrio. The increase of Desulfovibrio in the biofilm did however seem to accelerate the corrosion rate. Bryant et al. [5] suggests that a combination of low SRB cell numbers and high corrosion rates may be due to a high hydrogenase activity. The species composition in biofilm can also influence the corrosion rate significantly [2]. The molecular community study showed that bacteria affiliated to sulphide-oxidizing Sulfurimonas (VF-14) formed major populations during late biocide treatment. Microaerophilic growth of sulphide-oxidizing bacteria combined with increasing SRB activity may have caused formation of corrosive sulphur species.

Long-term nitrate treatment provided efficient inhibition of SRB activity at both Veslefrikk and Gullfaks. At the Gullfaks field, the reduction in SRB activity was followed by a significant reduction in corrosion of up to 40%. At GFC, the continuous decrease in SRB activity and corrosion rate over a relative long period of time indicates a gradual exclusion of corrosion inducing SRB from the biofilm (Fig. 6). Although there was no statistical significant reduction in corrosion at Veslefrikk, the trend indicated a lower and more stable corrosion rate during nitrate treatment when compared to late biocide treatment.

Some researchers have observed an increase in corrosion rates related to nitrate mediated souring control. Nemati et al. [23] observed increasing corrosion rates after addition of nitrate and NR–SOB Thiomicrospira sp. CVO to a culture of Desulfovibrio sp. strain Lac6, and also after addition of nitrate to a consortium of oil field SRB. Rempel et al. [27] used the same strain CVO and a consortium of oil field SRB and observed a transient increase in corrosion rate associated with the oxidation and removal of sulphide. The authors suggested that the increase in corrosion may be due to formation of aggressive species of sulphur (S0, thiosulphate, polysulphide) during NR–SOB activity. It is reasonable to assume that the rate of chemical and biological oxidation of sulphide was higher during the initial period with nitrate injection at Veslefrikk, than during the long-term treatment when in situ SRB activity was low. The weight loss coupon collected downstream of deaerator (VFB) after 1 month nitrate injection did indeed indicate an increase in corrosion rate (February 1999, Fig. 3), but since the coupon had also been exposed to 3 months biocide treatment it was impossible to connect the increase in corrosion to one of the two treatments. The single high corrosion rate observed at VFB in February 2005 (Fig. 3) deviated significantly from the other corrosion measurements during nitrate treatment, and may have been due to poor O2 control downstream of deaerator around the time of measurement.

There was no evidence that the presence of bacteria affiliated to NR–SOB Sulfurimonas influenced the corrosion rate during long-term nitrate treatment at Veslefrikk, as their difference in dominance at VFB and VFA did not lead to significant difference in corrosion rate at the two sites (Table 1). This would still be true if we were to disregard the high corrosion rate at VFB in February 2005 (which would give a mean weight loss rate of 0.25 ± 0.02 mm/year). The low in situ SRB activity suggest that the sulphide level experienced by NR–SOB was low, and probably became limiting downstream of deaerator (VFB) as the Sulfurimonas like bacteria were no longer observed after 40 months treatment. Stefess et al. [30] showed that sulphide-oxidizing bacteria when grown in steady-state and transient-state continuous cultures tended to produce sulphur rather than sulphate when sulphide load was high. During low sulphide load the predominant oxidation product was sulphate. The tendency to form sulphur as major oxidation product has also been observed in oil field NR–SOB when exposed to increasing sulphide concentrations [12, 13]. Applied to nitrate mediated souring control, the initial period with nitrate injection may lead to a transient accumulation of corrosive S0 and other aggressive sulphur species due to high level of sulphides and their chemical and biological oxidation. However, when a steady-state is achieved with a low in situ SRB activity as observed in the present study, NR–SOB does not influence the corrosion rate significantly.

Although the SRB activity was successfully reduced at both fields and the presence of NR–SOB was found not to pose a corrosion risk when SRB activity was low, the corrosion rate at Veslefrikk and Gullfaks B was higher than at Gullfaks C after nitrate injection. At GFC the trend showed decreasing corrosion rate with time, reaching close to 0.1 mm/year after 8 years treatment. The reason for this difference in response may be due to factors not related to MIC. A better O2 control at Gullfaks C for instance, could have produced such results. This could also explain the higher corrosion rate at GFB compared to GFC during biocide treatment, although SRB activity at GFC was higher than at GFB.

The bacterial community during nitrate treatment at VFB and VFA shared many common populations, but the composition differed between the sampling sites and also changed during the treatment period at each sampling site. The community was highly diverse (Fig. 4) and represented a near complete shift from the community during biocide treatment, without leading to significant changes in the total bacterial counts. The difference in ambient pressure at VFB (10 bar) and VFA (>200 bar) did not lead to a major difference in the bacterial community at the two sites, although biofilm from VFB did hold a larger number of exclusive sequence types (Fig. 4). The community composition was relatively stable during long periods of time at both VFB and VFA, indicating the establishment of a stable biological system. Biofilm composition can be affected by only small perturbations in temperature, nutrient and flow in the environment [18], suggesting that transient changes in, for instance, nitrate dosage or oxygen tension may have contributed to the shifts in community composition that was observed.

The major populations during nitrate treatment belonged to the α, γ, ε-Proteobacteria, Bacteroidetes and Firmicutes. Five of the environmental populations had 100% sequence similarity to bacteria observed near injector in a nitrate treated oil reservoir at the Statfjord field (Fig. 4), suggesting that NRB contributing to SRB inhibition in the two systems have a common origin from the injected sea water. None of the major environmental populations were observed growing in media used for viable counts (Fig. 5). Although the viable counts did not quantify the major in situ NRB populations, they indicated the enrichment and establishment of a viable NRB community in the system. There were no major differences in phylotypes observed in the two NRB–MPN media (data not shown), but the non-reduced medium quantified on average 2–3 orders of magnitude more NRB (Fig. 1, 2). The viable counts targeting Desulfovibrio proved to be a sensitive and simple method to monitor corrosion inducing SRB. An increase in cultivable Desulfovibrio at VFA in October 2002 and March 2003 were associated with increased SRB activity (only March 2003) and increased corrosion rate. Three of the cultivable Desulfovibrio species were observed to grow under nitrate-reducing conditions in NRB–MPN medium (Fig. 5). Some SRB are able to use nitrate as alternative electron acceptor by dissimilatory nitrate reduction to ammonium (DNRA) [8, 10, 37]. According to some studies however, nitrate reduction by SRB is inhibited by high sulphate levels [8, 10] and may thus not occur in situ in sea water injection systems during nitrate treatment.

Continuous injection of nitrate at Veslefrikk oil field lead to establishment of a stable NRB dominated biofilm community in the water injection system. The presence of major NR–SOB populations did not seem to influence the corrosion rate during low in situ SRB activity. The current study shows that continuous nitrate injection may provide a stable long-term inhibition of SRB in sea water injection systems and reduce corrosion by up to 40%.

References

Altschul SF, Madden TL, Schaffer AA, Zhang JH, Zhang Z, Miller W et al (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25(17):3389–3402. doi:10.1093/nar/25.17.3389

Beech IB, Gaylarde CC (1999) Recent advances in the study of biocorrosion—an overview. Rev Microbiol 30(3):177–190. doi:10.1590/S0001-37141999000300001

Benson DA, Karsch-Mizrachi I, Lipman DJ, Ostell J, Wheeler DL (2005) GenBank. Nucleic Acids Res 33:D34–D38. doi:10.1093/nar/gki063

Bryant RD, Jansen W, Boivin J, Laishley EJ, Costerton JW (1991) Effect of hydrogenase and mixed sulfate-reducing bacterial-populations on the corrosion of steel. Appl Environ Microbiol 57(10):2804–2809

Bryant RD, Kloeke FV, Laishley EJ (1993) Regulation of the periplasmic [Fe] hydrogenase by ferrous iron in Desulfovibrio vulgaris (Hildenborough). Appl Environ Microbiol 59(2):491–495

Cord-Ruwisch R, Kleinitz W, Widdel F (1987) Sulfate-reducing bacteria and their activities in oil production. J Pet Technol 39(1):97–106. doi:10.2118/13554-PA

Crolet JL (2005) Microbial corrosion in the oil industry: a corrosionist`s view. In: Ollivier B, Magot M (eds) Petroleum microbiology. American society for microbiology, Washington DC, pp 143–169

Dalsgaard T, Bak F (1994) Nitrate reduction in a sulfate-reducing bacterium, Desulfovibrio desulfuricans, isolated from rice paddy soil-sulfide inhibition, kinetics, and regulation. Appl Environ Microbiol 60(1):291–297

Dinh HT, Kuever J, Mussmann M, Hassel AW, Stratmann M, Widdel F (2004) Iron corrosion by novel anaerobic microorganisms. Nature 427(6977):829–832. doi:10.1038/nature02321

Dunsmore B, Whitfield TB, Lawson PA, Collins MD (2004) Corrosion by sulfate-reducing bacteria that utilize nitrate. Corrosion 2004 paper 04763. NACE International, Houston

Fjellbirkeland A, Torsvik V, Øvreas L (2001) Methanotrophic diversity in an agricultural soil as evaluated by denaturing gradient gel electrophoresis profiles of pmoA, mxaF and 16S rDNA sequences. Anton Leeuw Int J G 79(2):209–217. doi:10.1023/A:1010221409815

Gevertz D, Telang AJ, Voordouw G, Jenneman GE (2000) Isolation and characterization of strains CVO and FWKOB, two novel nitrate-reducing, sulfide-oxidizing bacteria isolated from oil field brine. Appl Environ Microbiol 66(6):2491–2501. doi:10.1128/AEM.66.6.2491-2501.2000

Greene EA, Hubert C, Nemati M, Jenneman GE, Voordouw G (2003) Nitrite reductase activity of sulphate-reducing bacteria prevents their inhibition by nitrate-reducing, sulphide-oxidizing bacteria. Environ Microbiol 5(7):607–617. doi:10.1046/j.1462-2920.2003.00446.x

Herbert BN (1987) Reservoir souring. In: Hill EC, Shennan JL, Watkinson RJ (eds) Microbial problems in the offshore industry. Wiley, London, pp 63–71

Hoff KA (1988) Rapid and simple method for double staining of bacteria with 4′, 6-diamidino-2-phenylindole and fluorescein isothiocyanate-labeled antibodies. Appl Environ Microbiol 54(12):2949–2952

Jenneman GE, McInerney MJ, Knapp RM (1986) Effect of nitrate on biogenic sulfide production. Appl Environ Microbiol 51(6):1205–1211

Jenneman GE, Moffitt PD, Bala GA, Webb RH (1999) Sulfide removal in reservoir brine by indigenous bacteria. Soc Pet Eng Prod Facil 14(3):219–225

Little B, Lee J, Ray R (2007) A review of ‘green’ strategies to prevent or mitigate microbiologically influenced corrosion. Biofouling 23(2):87–97. doi:10.1080/08927010601151782

Maxwell S, Hamilton WA (1986) Modified radiorespirometric assay for determining the sulfate reduction activity of biofilms on metal-surfaces. J Microbiol Methods 5(2):83–91. doi:10.1016/0167-7012(86)90004-7

Muyzer G, Dewaal EC, Uitterlinden AG (1993) Profiling of complex microbial-populations by denaturing gradient gel-electrophoresis analysis of polymerase chain reaction-amplified genes-coding for 16S ribosomal-RNA. Appl Environ Microbiol 59(3):695–700

Myhr S, Lillebo BLP, Sunde E, Beeder J, Torsvik T (2002) Inhibition of microbial H2S production in an oil reservoir model column by nitrate injection. Appl Microbiol Biotechnol 58(3):400–408. doi:10.1007/s00253-001-0881-8

Myhr S, Torsvik T (2000) Denitrovibrio acetiphilus, a novel genus and species of dissimilatory nitrate-reducing bacterium isolated from an oil reservoir model column. Int J Syst Evol Microbiol 50:1611–1619

Nemati M, Jenneman GE, Voordouw G (2001) Impact of nitrate-mediated microbial control of souring in oil reservoirs on the extent of corrosion. Biotechnol Prog 17(5):852–859. doi:10.1021/bp010084v

Nilsen RK, Beeder J, Thorstenson T, Torsvik T (1996) Distribution of thermophilic marine sulfate reducers in North Sea oil field waters and oil reservoirs. Appl Environ Microbiol 62(5):1793–1798

Page RDM (1996) TreeView: an application to display phylogenetic trees on personal computers. Comput Appl Biosci 12(4):357–358

Poduska RA, Anderson BD (1981) Successful storage lagoon odor control. J Water Pollut Control Fed 53(3):299–310

Rempel CL, Evitts RW, Nemati M (2006) Dynamics of corrosion rates associated with nitrite or nitrate mediated control of souring under biological conditions simulating an oil reservoir. J Ind Microbiol Biotechnol 33(10):878–886. doi:10.1007/s10295-006-0142-z

Schafer H, McDonald IR, Nightingale PD, Murrell JC (2005) Evidence for the presence of a CmuA methyltransferase pathway in novel marine methyl halide-oxidizing bacteria. Environ Microbiol 7(6):839–852. doi:10.1111/j.1462-2920.2005.00757.x

Sekar R, Fuchs BM, Amann R, Pernthaler J (2004) Flow sorting of marine bacterioplankton after fluorescence in situ hybridization. Appl Environ Microbiol 70(10):6210–6219. doi:10.1128/AEM.70.10.6210-6219.2004

Stefess GC, Torremans RAM, de Schrijver R, Robertson LA, Kuenen JG (1996) Quantitative measurement of sulphur formation by steady state and transient state continuous cultures of autotrophic Thiobacillus species. Appl Microbiol Biotechnol 45(1–2):169–175. doi:10.1007/s002530050666

Sunde E, Lillebø BLP, Bødtker G, Torsvik T, Thorstenson T (2004) H2S inhibition by nitrate injection on the Gullfaks field. Corrosion 2004 paper 04760. NACE International, Houston

Tatusova TA, Madden TL (1999) BLAST 2 SEQUENCES, a new tool for comparing protein and nucleotide sequences. FEMS Microbiol Lett 174(2):247–250. doi:10.1111/j.1574-6968.1999.tb13575.x

Thompson JD, Gibson TJ, Plewniak F, Jeanmougin F, Higgins DG (1997) The ClustalX windows interface: flexible strategies for multiple sequence alignment aided by quality analysis tools. Nucleic Acids Res 25(24):4876–4882. doi:10.1093/nar/25.24.4876

Thorstenson T, Bødtker G, Lillebø BLP, Torsvik T, Sunde E, Beeder J (2002) Biocide replacement by nitrate in sea water injection systems. Corrosion 2002 paper 02033. NACE International, Houston

Vance I, Thrasher DR (2005) Reservoir souring: mechanisms and prevention. In: Ollivier B, Magot M (eds) Petroleum microbiology. American society for microbiology, Washington DC, pp 123–142

Wang Q, Garrity GM, Tiedje JM, Cole JR (2007) Naive Bayesian classifier for rapid assignment of rRNA sequences into the new bacterial taxonomy. Appl Environ Microbiol 73(16):5261–5267. doi:10.1128/AEM.00062-07

Widdel F (1988) Microbiology and ecology of sulfate- and sulfur-reducing bacteria. In: Zehnder AJB (ed) Biology of anaerobic microorganisms. Wiley, New York, pp 469–585

Øvreas L, Forney L, Daae FL, Torsvik V (1997) Distribution of bacterioplankton in meromictic Lake Saelenvannet, as determined by denaturing gradient gel electrophoresis of PCR-amplified gene fragments coding for 16S rRNA. Appl Environ Microbiol 63(9):3367–3373

Acknowledgments

The authors would like to thank Kristine Lysnes, Tove Leiknes, Nirmaladevi Sivasambu and Hege Ommedal for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bødtker, G., Thorstenson, T., Lillebø, BL.P. et al. The effect of long-term nitrate treatment on SRB activity, corrosion rate and bacterial community composition in offshore water injection systems. J Ind Microbiol Biotechnol 35, 1625–1636 (2008). https://doi.org/10.1007/s10295-008-0406-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0406-x