Abstract

Bacterial populations in fermented grains during fermentation may play important roles in Chinese liquor flavor. PCR-based denaturing gradient gel electrophoresis (DGGE) and 16S rRNA gene library analysis were performed to analyze the bacterial community structure of two styles of liquor. The results of DGGE profiles showed that bacterial diversity decreased with the fermentation process and Lactobacillus acetotolerans became the predominant species at the end of the fermentation. But the obvious differences of bacterial community appeared in the middle stage of two styles of liquor fermentation, in which the different upstream production techniques were used. Moreover, 16S rRNA gene libraries of two styles were constructed. A total of 125 and 107 clones, chosen from two libraries, were grouped into 46 and 49 operational taxonomic units (OTUs) by amplified ribosomal DNA restriction analysis. According to sequencing results of clones, the predominant bacteria in strong aroma style fermented grains were those from the class Bacilli, Bacteroidetes, and Clostridia, whereas the predominant bacteria in fermented grains of roasted sesame aroma style belonged to Bacilli, Flavobacteria, and Gammaproteobacteria. Molecular analysis of the bacterial diversity of the liquor fermentation will benefit the analysis of important microorganisms playing key roles in the formation of liquor flavor components.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As one of the six famous distillates in the world, Chinese liquor has five main categories, which are: strong aroma style, light aroma style, soy sauce aroma style, sweet honey style, and miscellaneous style. The first four styles are the basal styles [5]. Miscellaneous styles also include several types and their production processes are improved on the basis of those of basal styles. For example, roasted sesame aroma style is one of the miscellaneous styles and its production technique is similar to that of strong aroma style except one additional process [5]. Before fermentation in the pits, newly steamed grains are mixed with Daqu, stacked in the ground, and fermented for 24 h at room temperature. The process of stacking is derived from the production technique of soy sauce aroma style and its aim is to increase the quantity of microorganisms.

Chinese liquor is produced from grains with mixed microbial fermentation technique in solid form, and metabolic products of the microorganism are important for liquor quality. Although the principal components of liquor, alcohol and water, account for 97–98% of liquor, other micro-components determine the flavor and quality of liquor. Moreover, the micro-environment in pits changes during the fermentation process, coupled with utilization of nutrimental materials and accumulation of metabolic products, such as pH decrease, increase of alcohol concentration, and so on. These changes will cause the alteration of quantity and species of microorganisms in fermented grains. So, the microorganism community structure of fermented grains not only incarnates the micro-environment in pits, but also affects the formation of flavor components in the latter phase of fermentation in pits. Chinese scientists had researched liquor microorganism from the 1960s and their work was focused on microorganism in Daqu [8, 16], pit mud [15, 18], and fermented grains [9, 20] through traditional culture-dependent methods. However, the majority of microorganism and primordial microorganism community cannot be analyzed through the methods of cultivation, enrichment, and isolation [1, 6, 19]. The predominant key microorganism in fermented grains and the effect of their metabolic products on liquor flavor were difficult to be identified by traditional methods.

In recent years, many DNA fingerprint methods, such as denaturing/temperature gradient gel electrophoresis (DGGE/TGGE) [10, 12], enterobacterial repetitive intergenic consensus (ERIC)-PCR [3], and real-time fluorescent quantitative PCR [2], are widely used to analyze the microorganism community of a complex environment. DGGE overcomes the disadvantages of culture-dependant methods and analyzes microorganism community structure through band migration in gels, directly and reliably. In 2005, the bacterial community in Zaopei of Luzhou-flavor liquor was analyzed by DGGE, which belonged to strong aroma style and was produced in Sichuan province [22]. However, there are obvious differences in liquor flavor of the same style produced in different regions. It is speculated that production techniques and geographic environment will alter liquor flavor by influencing the microorganism community of fermented grains. It is an effective method to identify the actual microorganism diversity of liquor fermentation by analyzing several liquor styles produced in different regions.

In this study, the bacterial community in fermented grains of strong aroma style and roasted sesame aroma style produced in Jiangsu province during the fermentation was analyzed and compared by PCR–DGGE and their microorganism composition was identified through 16S rRNA gene library technique.

Materials and methods

Samples of fermented grains

The sampling was carried in a liquor-production factory in Jiangsu province, China. Samples were taken from the center of the middle layer of three pits of two styles at different time points in 2006. The fermentation process of the pits with the numbers of 2217 and 2216 of strong aroma style started on September 21 and 22, respectively, and lasted 60 days. The fermentation of pit 3 of roasted sesame aroma style commenced in September 22 and its cycle required 30 days. The samples were transferred to sterile bags, sealed, and stored at −70 °C.

DNA extraction

Four grams of sample was suspended in 30 mL of PBS buffer (57.7 mM Na2HPO4, 42.3 mM NaH2PO4) and vortexed for 5 min. The suspension was centrifugated at 200g for 5 min and the pellet was washed thrice by PBS buffer. The cells were collected by centrifugation of the whole supernatant fluid at 9,000g for 5 min and washed thrice by PBS buffer.

The pretreated cells were centrifugated at 9,000g for 5 min. The resulting pellet was resuspended in 1 mL buffer Z [10 mM Tris–HCl (pH 8.0), 150 mM NaCl]. The cells were mixed with 150 μL phenol and 0.3 g glass beads (diameter, 0.1 mm). The cells were lysed using the Mini-BeadBeater (Biospec, USA) for 4 min at 3,200 rpm and the tube was cooled in ice-bath for 1 min, every 80 s. The whole system was mixed with 110 μL of 10% SDS and ice-bathed for 10 min with gentle mixing by inverting the tube every 5 min. A volume of 150 μL chloroform–isoamyl alcohol (v/v, 24:1) was added and the aqueous phase was collected by centrifugation at 15,000g for 10 min. DNA was then purified by sequential extraction with equal volume of Tris–equilibrated phenol, phenol–chloroform (v/v, 25:24), and chloroform–isoamyl alcohol followed by repeated centrifugation at 15,000g for 10 min at 4 °C. Total nucleic acids were subsequently precipitated from the extracted aqueous layer with two volumes of iced ethanol for at least 2 h at −20 °C followed by centrifugation at 15,000g for 15 min at 4 °C. Then, the collected DNA was air-dried and dissolved in 30 μL of sterile water. RNA was digested by adding RNase (0.80 mg/mL) at 37 °C for 30 min. DNA solution was measured by DyNA quant 200 (Pharmacia Biotech, USA) and diluted to a final concentration of 10 ng/μL.

PCR–denaturing gradient gel electrophoresis (DGGE) analysis

A primer pair of P2 (5′-ATTACCGCGGCTGCTGG-3′) and P3-GC (5′-CGCCCG CCGCGCGCGGCGGGCGGGGCGGGGGCACGGGGGGCCTACGGGAGGCAGCAG-3′) was used to amplify variable region three (V3) of 16S rRNA bacterial gene [11].

Each 25 μL PCR reaction contained a final concentration of the following reagents: 10 ng of genomic DNA, 0.5 μM of each of the primers, 200 μM dNTPs, 1× Taq reaction buffer, 2 mM MgCl2, and 1 U Taq polymerase (Takara, Japan). The PCR reaction was performed with the following conditions: 94 °C for 4 min; 30 cycles of denaturation at 94 °C for 45 s, annealing at 55 °C for 45 s, and prolonging at 72 °C for 1 min; final extension at 72 °C for 6 min. Before DGGE analysis, each PCR product was reconditioned for five cycles to reduce single-stranded and heteroduplex DNA [21].

PCR products were then analyzed by DGGE using the Bio-Rad DCode apparatus (USA). The reconditioned samples (approximately 250 ng of DNA) were applied onto 8% (w/v) polyacrylamide gels in 1× TAE buffer with a denaturing gradient ranging from 28 to 52% (100% denaturant corresponded to 7 M urea and 40% deionized formamide). The gels were run at a constant voltage of 200 V and a temperature of 60 °C for 240 min, stained with SYBR green I (Amresco, USA) for 45 min, and documented with the UV I documentation system (UVItec, UK). Cluster analysis of data was analyzed by Quantity One, and principal component analysis (PCA) was performed using the Matlab program.

Sequencing of DGGE fragments

DGGE fragments, marking the main structural characteristics of the pits and fermentation process in the DGGE profile, were cut out with a sterile scalpel. The DNA of each fragment was eluted in 200 μL sterile water overnight at 4 °C. A volume of 1 μL of the eluted DNA of each DGGE band was re-amplified using the same conditions as described above. For further sequencing analysis, every PCR product was ligated into pGEM-T easy vector (Promega, USA) and the corresponding clone library was constructed subsequently. From each library, plasmid DNA was extracted from randomly selected clones and screened for inserts of the expected size and correct DGGE migration properties. For each band, three clones that yielded a single band co-migrating with the original band were sequenced with an automatic sequencer (ABI PRISM 377 DNA Sequencer, PE Biosystems, USA) by Shanghai Generay Biotech Co., Ltd.

To determine the closest known relatives of the partial 16S rRNA sequences obtained, searches were performed in GenBank (http://www.ncbi.nlm.nih.gov/BLAST/) and RDP II (http://rdp.cme.msu.edu/, Release 9.55) with the BLAST and RDP programs. The GenBank accession numbers for the 16S rRNA partial sequences of DGGE bands in this study were EU195444 through EU195448.

16S rRNA gene cloning library

16S rRNA gene libraries were constructed to examine microbial diversity in the initial fermentation (B1 and Z1 samples). PCR was performed to obtain the near-full-length 16S rRNA gene using primers of 27f (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1391r (5′-GACGGGCGGTGWGTRCA-3′) [13]. The PCR reaction was performed with the following conditions: 95 °C for 1.5 min; 25 cycles of denaturation of 95 °C for 30 s, annealing for 30 s at 60 °C (five cycles), 55 °C (five cycles) and 50 °C (15 cycles) orderly and prolonging at 72 °C for 4 min; extension at 72 °C and 60 °C for 10 min, respectively; final cooling to 4 °C. The PCR products were purified with Axyprep PCR clean-up kit (Promega, USA), ligated into a pGEM-T easy vector and transformed into competent E.coli DH5α cells according to the manufacture’s instructions and the laboratory manual [14]. Plasmid DNA was extracted from positive clones and the insert fragments were amplified using a primer pair of T7 and SP6. PCR products were digested with Hinf I and Csp6 I, respectively. According to amplified ribosomal DNA restriction analysis (ARDRA) profiles, all clones in the B1 and Z1 libraries were grouped into operational taxonomic unit (OTUs) [4, 17]. A representative clone from each OTU was sequenced with ABI 377 DNA sequencer by Shanghai Generay Biotech Co., Ltd. The check-chimera command of the RDP facilities was used to detect chimeric sequences. In order to determine whether the constructed libraries were large enough to provide stable phylotype richness, the progressive sampling approach described by Kemp and Aller was utilized [7]. Pseudolibraries of varying sizes were constructed by randomly subsampling clones from the two libraries. Two nonparametric estimators, SChao1 and SACE, were calculated for each subset using an online program (http://www.aslo.org/lomethods/free/2004/0114a.html).

Results

DGGE analysis of fermented grains of strong aroma style

DGGE profiles and clustering analysis of samples collected from two pits of strong aroma style are shown in Fig. 1. The microorganism diversity of samples decreased during the whole fermentation process. There was high diversity in fermented grains at the original stage of fermentation. After about 20 days of fermentation, a special bright band appeared, and the corresponding species became the predominant microbe ultimately. Other bands disappeared slowly during the process. But the samples collected from different pits in the middle of fermentation exhibited little difference in the bacterial community.

a DGGE profiles of 16S rRNA V3 regions of the samples collected at different time from two pits of strong aroma style; b clustering analysis of DGGE profiles. Samples A, B were collected from pits 2217 and 2216, respectively. A1 and B1 6 days of fermentation, A2 and B2 12 days of fermentation, A3 and B3 22 days of fermentation, A4 and B4 42 days of fermentation, A5 and B5 60 days of fermentation

PCA analysis of Fig. 1 is presented in Fig. 2. The percentage of variance explained by PC1 was 53.91%, while PC2 explained 21.50% of the variance. The samples collected from the same pit migrated to the positive direction along the PC1 axis with the fermentation time and PC1 symbolized the influence of the fermentation process. Moreover, the samples of different pits were distinguished along the PC2 direction and PC2 represented the differences of pits. Since production materials used in the two pits were uniform, the differences of bacterial community were caused by influence of other factors such as micro-environment and pit mud of the pits.

DGGE analysis of fermented grains of two styles

The microorganism diversity of strong aroma style and roasted sesame aroma style is compared in Fig. 3. It was found that the bacterial community of the end of fermentation was similar and only one bright band became the main band. Because of the different upstream production techniques, some relatively preponderant species appeared at the beginning of fermentation of roasted sesame aroma style. In the samples of roasted sesame aroma style, the brightness of the two bands increased suddenly after 5 days of fermentation and decreased slowly.

a DGGE profiles of 16S rRNA V3 regions of the samples collected at different time from two pits of strong aroma style and roasted sesame aroma style; b clustering analysis of DGGE profiles. Samples B, Z were collected from pits 2216 and 3, respectively. B1 6 days of fermentation, B2 12 days of fermentation, B3 22 days of fermentation, B4 42 days of fermentation, B5 60 days of fermentation. Z1 0 day of fermentation, Z2 5 days of fermentation, Z3 11 days of fermentation, Z4 16 days of fermentation, Z5 21 days of fermentation, Z6 30 days of fermentation

PC1 and PC2 explained 47.84 and 28.32% of the variation, respectively (Fig. 4). This result of PCA accorded with that of clustering analysis. The spots of samples of roasted sesame aroma style collected from 5 to 21 days of fermentation were gathered into one group. At the end of fermentation, the bacterial community in fermented grains of roasted sesame aroma style had a similarity with that of strong aroma style. Microorganism fingerprint profiles of fermented grains of the two styles can be distinguished through DGGE and PCA.

Molecular identification of the main bands in DGGE profiles

Five dominant bands (a–e) in the DGGE profile were sequenced and identified. Their closest relatives found in the GenBank database are listed in Table 1. The most dominant bands (bands b and e) in samples of two different styles were related most closely to Lactobacillus acetotolerans (M58801) with a sequence similarity of 99 and 100%, respectively. This result indicated that the majority of microorganisms died because of the decrease of oxygen content and increase of acidity and alcohol concentration during the fermentation, and only L. acetotolerans could endure the extreme environment and became the most predominant species. This result agrees with that of the research of Zaopei of Luzhou-flavor liquor in Sichuan province [22]. From the samples of roasted sesame aroma style, it was determined that both bands c and d were related to L. panis. Band a of the sample in pit 2216 was affiliated with L. manihotivorans (AB289202). The brightness and vanishing process of band a were dissimilar in pits 2216 and 2217, probably due to the influence of the micro-environment in pits.

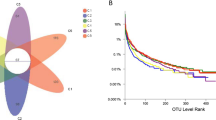

Sequence analysis of 16S rRNA gene cloning library

In order to identify microorganisms contained in fermented grains of the two styles, 16S rRNA gene libraries of B1 and Z1 were constructed. A total of 125 and 107 positive clones selected in B1 and Z1 libraries were grouped into 46 and 49 OTUs by ARDRA, respectively. The numbers of phylotypes were input into the online program and evaluation data files were generated for the B1 and Z1 libraries. For the two libraries, S Chao1 and S ACE, all reached an asymptote (Fig. 5). This indicated that the libraries were large enough to yield stable phylotype richness estimates.

A representative clone from each OTU was sequenced and the nearest neighbor taxonomy was determined in RDP II. The class distribution of clones in B1 and Z1 libraries is shown in Fig. 6. The main bacteria in fermented grains of strong aroma style belonged to Bacilli, Bacteroidetes, and Clostridia and the clones of Bacteroidetes, Clostridia, and Deferribacteres were tested only in the B1 library. However, the main bacteria in fermented grains of roasted sesame aroma style included the class Bacilli, Flavobacteria, and Gammaproteobacteria, and the clones of Flavobacteria, Sphingobacteria, Betaproteobacteria, Actinobacteria, and Gammaproteobacteria were detected only in the Z1 library. Although B1 and Z1 libraries contained the clones of Bacilli, the composition of Bacilli was different. In B1 library, the percentage of clones of Lactobacillus was 32.8% and that of clones of Bacillus was only 2.4%. Nevertheless, in Z1 library, the clones of Bacillus occupied 24.3% and the clones of Lactobacillus accounted for just 2.4%. The first sample of strong aroma style was collected after 6 days of fermentation and that of roasted sesame aroma style was sampled just at the beginning of fermentation. At the initial stage, Lactobacillus sp. propagated quickly and became the main bacteria.

Discussion

The liquor quality is correlated not only with production techniques, but also with grains and the local geographic environment around liquor-production factories, such as climate, air, water, and soil. Although the same style liquor contains uniform key flavor components, production techniques and geographic environment will result in the different evolvement of microorganism community in fermented grains. After solid-form distillation, the different types and concentration of micro-components in the distillate influence liquor quality.

The structure and diversification course of microorganism community in fermented grains of strong aroma style and roasted sesame aroma style during the fermentation process produced in Jiangsu were analyzed through two methods of PCR–DGGE and 16S rRNA gene library analysis. At the beginning of fermentation, there was high diversity of microorganisms in fermented grains. With the fermentation time, many microorganisms could not endure the changes of micro-environment in pits and were led to death. At the end of fermentation, L. acetotolerans became the major predominant species. However, the results of DGGE profile of Zaopei sampled from Sichuan province showed that microorganism diversity decreased quickly and only one band could be detected in the gel during 1–10 weeks of fermentation [22]. This phenomenon appeared in fermented grains of strong aroma style in Jiangsu after about 1 month of fermentation and this difference may be induced by fermentation temperature in pits. In Sichan, the original temperature of fermentation is about 18 °C and that of fermentation in Jiangsu is only 12 °C. The higher temperature accelerates oxygen utilization, propagation, and death of microorganisms. Moreover, the results of library identification revealed that great genera differences existed in fermented grains of the different styles produced in different regions and the clones of only three genuses including Acetobacter, Bacillus and Lactobacillus were all detected in two libraries (data of sequencing and identification not shown). Some microorganism genuses detected were not reported in the previous researches and their functions in the fermentation need further investigation.

The combined analysis of microorganism community structure in Daqu and fermented grains obtained by DNA fingerprint methods with interrelated results using other experiment means, such as traditional microbial identification based on culture and separation, detection of liquor solid-form fermentation and analysis of aroma components in liquor, will help to isolate and identify important microbes corresponding to the formation of characteristic key flavor components, and direct improvement of production techniques.

References

Amann R, Ludwig W, Schleifer KH (1995) Phylogenetic identification and situ detection of individual microbial cells without cultivation. Microbiol Rev 58:143–169

Bowers HA, Tengs T, Glasgow HB, Burkholder JJM, Rublee PA, Oldach DW (2000) Development of real-time PCR assays for rapid detection of Pfiesteria piscicida and related dinoflagellates. Appl Environ Microbiol 66(11):4641–4648

di Giovanni GD, Watrud LS, Seidler RJ, Widmer F (1999) Fingerprinting of mixed bacterial strains and BIOLOG gram-negative (GN) substrate communities by enterobacterial repetitive intergenic consensus sequence-PCR (ERIC-PCR). Curr Microbiol 38:217–223

Dunbar J, White S, Forney L (1997) Genetic diversity through the looking glass: effect of enrichment bias. Appl Environ Microbiol 63:1326–1331

Fan WL, Qian MC (2006) Characterization of aroma compounds of Chinese “Wuliangye” and “Jiannanchun” liquors by aroma extract dilution analysis. J Agric Food Chem 54:2695–2704

Giovannoni SJ, Britschgi TB, Moyer CL, Field KG (1990) Genetic diversity in sargasso sea bacterioplankton. Nature 345:60–62

Kemp PF, Aller JY (2004) Estimating prokaryotic diversity: when are 16S rDNA libraries large enough? Limnol Oceanogr Methods 2:114–125

Liao JM, Yao WC, Tang YM, Ren DQ (2001) Preliminary identification of microbes in liquor Qu of strong aroma style. Liquor Mak 28(5):42–43

Luo ZT (1986) Preliminary research on microbes in Zaopei. Microbiology (2):59–60

Muyzer G (1999) DGGE/TGGE a method for identifying genes from natural ecosystems. Curr Opin Microbiol 2:317–322

Muyzer G, de Waal EC, Uitterlinden AG (1993) Profiling of complex microbial populations by denaturing gradient gel electrophoresis analysis of polymerase chain reaction-amplified genes coding for 16S rRNA. Appl Environ Microbiol 59(3):695–700

Muyzer G, Smalla K (1998) Application of denaturing gradient gel electrophoresis (DGGE) and temperature gradient gel electrophoresis (TGGE) in microbial ecology. Antonie van Leeuwenhoek 73:127–141

Reysenbach AL, Pace NR (1995) Reliable amplification of hyperthermophilic archaeal 16S rRNA genes by the polymerase chain reaction. In: Robb FT, Place AR, Sowers KR, Schreier HJ, DasSarma S, Fleischmann EM (eds) Archaea––a laboratory manual: thermophiles. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, pp 101–106

Sambrook J, Fritsch EF, Maniatis T (1999) Molecular cloning: a laboratory manual. Science Press, Beijing

Shi AH (1986) Analysis on microorganisms in liquor pit of strong aroma style during fermentation. Liquor Mak (4):24–29

Shi AH, Guan JK, Zhang WP, Xu ER, Xu CX (2001) Analysis of microbial species in Xufang Daqu and determination of the dominant microbes. Liquor Mak Sci Technol 108(6):26–28

Vaneechoutte M, Rossau R, Vos PD, Gillis M, Janssens D, Paepe N, Rouck AD, Fiers T, Claeys G, Kersters K (1992) Rapid identification of bacteria of the comamonadaceae with amplified ribosomal DNA-restriction analysis (ARDRA). FEMS Microbiol Lett 93:227–234

Wang RM, Guan FM, Lu FY (2001) Research on functional microbial product of activity pit clay. Liquor Mak 28(1):33–35

Ward DM, Weller R, Bateson MM (1990) 16S rRNA sequences reveal numerous uncultured microorganisms in a natural community. Nature 345:63–65

Xiong CX (1994) Research on changes of microbes and materials in Zaopei during fermentation of strong aroma style liquor. Liquor Mak Sci Technol (2):25

Zhang XL, Yan X, Gao PP, Wang LH, Zhou ZH, Zhao LP (2005) Optimized sequence retrieval from single bands of TGGE (temperature gradient gel electrophoresis) profiles of the amplified 16S rDNA fragments from an activated sludge system. J Microbiol Methods 60(1):1–11

Zhang WX, Qiao ZW, Shigematsu T, Tang YQ, Hu C, Morimura S, Kida K (2005) Analysis of the bacterial community in Zaopei during production of Chinese Luzhou-flavor liquor. J Inst Brew 111(2):215–222

Acknowledgments

This research was financially supported by the program for Changjiang Scholars and Innovative Research Team in University (IRT0532) and National Key Technology R&D Program (2007BAK36B02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, HY., Zhang, XJ., Zhao, LP. et al. Analysis and comparison of the bacterial community in fermented grains during the fermentation for two different styles of Chinese liquor. J Ind Microbiol Biotechnol 35, 603–609 (2008). https://doi.org/10.1007/s10295-008-0323-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0323-z