Abstract

Neurotoxic organophosphates (OPs) are widely used as pesticides and for public health purposes, as well as being nerve gases. As a result of the widespread use of these compounds for agriculture, large volumes of wastewater are generated. Additionally, there are large stockpiles of the nerve gases soman, sarin and VX in the United States and elsewhere around the world. Organophosphorus hydrolase (OPH) is an enzyme that catalyzes the hydrolysis of OP nerve agents. To date, however, the use of this enzyme in detoxification processes has been rather limited due to the high cost of its purification and short catalytic half-life. This paper reports the development of a cost-effective method for the production and immobilization of OPH in a pilot application in an enzyme bioreactor column for detoxification of paraoxon and coumaphos in contaminated wastewaters. A fusion between OPH and a cellulose binding domain that binds selectively to cellulose was generated to allow one-step purification and immobilization of OPH on cheap and abundantly available cellulose immobilization matrices. When packed in a column bioreactor, the immobilized fusion enzyme was able to completely degrade coumaphos up to a concentration of 0.2 mM. However, stirring of OPH immobilized on cellulose materials resulted in complete OP degradation of 1.5 mM coumaphos. The bioreactor column degraded the compounds tested at high concentration, rapidly, and without loss of process productivity for about 2 months.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among known pesticide groups, organophosphorus (OP) compounds have grasped attention due to their hazardous nature and their applications as pesticides and chemical weapons. This group of pesticides has a broad spectrum of application for crops and animal protection as well as for public health. Such pesticides are essential for most agriculture-developing programs. However, the extensive use and/or misuse of this group of pesticides in different ways has resulted in many undesirable effects and has caused substantial environmental pollution problems. The World Health Organization reported that exposure to such pesticides results in roughly 3 million cases of severe poisoning and 220,000 deaths annually worldwide. Also, more than 0.7 million cases of poisoning worldwide could be traced to occupational and incidental exposure to OPs [2].

Mulbry et al. [8] illustrated the serious environmental problems in the United States due to use of the OP pesticide coumaphos by the United States Department of Agriculture (USDA) in a tick eradication program. The program was designed to prevent the re-introduction of cattle fever into the United States via ticks (Boophilus microplus and Boophilus annulatus) on cattle imported from Mexico. Treatment of cattle generated a huge volume of coumaphos-contaminated wastewater (460,000 l at a concentration of 2,000 mg/l) requiring disposal. The conventional method approved by the Environmental Protection Agency for disposal of coumaphos wastes is incineration. However, this method has met with serious public opposition because of potentially toxic emissions and economic restrictions. Thus, new methods of environmentally friendly and safe OP detoxification are urgently needed. Genetically engineered microorganisms with increased capability for degradation of this pesticide group could provide a good method for disposing of coumaphos wastes. There are two main approaches in using modified microorganisms, i.e., use of either the whole cell or its enzymes for pesticide detoxification. Chen and Mulchandani [1] reviewed the use of live biocatalysts for pesticide detoxification. They suggested focusing on using genetically engineered microorganisms with extended degradative capabilities in conjugation with searching for microorganisms capable of degrading pesticides rapidly, to establish efficient and cost-effective large-scale processes for pesticide detoxification.

Biodegradation of OP pesticides using the surface-expressed enzyme organophosphorus hydrolase (OPH) has attracted great attention [11, 14]. Also, Qiao et al. [10] studied biodegradation of pesticides using immobilized recombinant Escherichia coli. Recently, Mansee et al. [7] presented an immobilized system using E. coli expressing OPH on the cell surface for biodetoxification of coumaphos. This system achieved biodegradation of coumaphos up to 0.2 mM in contaminated water. Meanwhile, the search for other effective methods of OP biodegradation, e.g., enzymatic methods, is still ongoing.

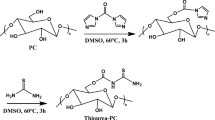

Using enzymatic technology for pesticide, especially OP, biodegradation has become an interesting topic for many authors in the last decade. Richins et al. [12] introduced cellulose-binding domain CBD–OPH fusion enzymes as a promising tool that could be used for OP biodegradation. These authors studied the expression, immobilization, and characterization of such enzyme fusions. The reaction kinetics of the unbound fusion enzymes were similar to those of OPH, with a modest increase in K m . Immobilization of the enzymes on microcrystalline cellulose resulted in a further increase in the K m value. These findings inspired us to investigate the possibility of using such a system for OP biodegradation in the current study.

The present investigation was aimed at using an immobilized CBD–OPH fusion enzyme as a fast and effective tool for the bioremediation of water contaminated with the OP pesticide coumaphos. We also attempted to determine the optimum conditions for maximal efficiency of this technique.

Materials and methods

Chemicals

Coumaphos (O,O-diethyl-O-[3-chloro-4methyl-2-oxo-2H-1-benzopyran-7-yl]phosphorothioate) (Fig. 1) and Paraoxon (diethyl-p-nitrophenylphosphate) and the surfactant polyoxyethylene 10 lauryl ether (POLE) were purchased from Sigma (St. Loius, MO).

Production of CBD–OPH fusions

CBD–OPH fusions were produced according to the method of Richins et al. [12]. Expression of CBD–OPH fusions was achieved by growing the E. coli strain BL21 (DE3) pLysE carrying pCOPH-C1 to an OD600 of 2.0 in 40 ml DYT medium at 37°C. Cultures were then transferred to 22°C and induced with 1.0 mM IPTG. Cells were collected by centrifugation and the pellets resuspended in 20 ml PC buffer (50 mM disodium phosphate titrated to pH 8.0 with citric acid; 100 mM CoCl2). Lysozyme was added to the resuspended cells to a final concentration of 10 μg/ml. Following a 15-min incubation at room temperature, cells were cooled to 0°C, and then passed through a French pressure cell (15,000 psi). The solution was centrifuged twice for 10 min at 20,000g and 4°C. The resulting supernatant was used for binding to cellulose materials and enzymatic studies.

Binding of fusion protein to cellulose material

Binding of fusion protein to cellulose material and washing were performed in PCST buffer [phosphate–citrate buffer (50 mM) supplemented with sodium chloride and Triton-X100 to give concentrations of 50 mM and 0.1% (v/v), respectively]. A cellulose matrix, CF11 (2 g), was washed twice with PCST prior to exposure to the crude extract. Binding was performed for 30–60 min at room temperature on an orbital shaker at 60 rpm. Samples were then rinsed extensively with PCST, and finally washed four times with PC buffer.

Construction of bioreactor column

After binding the CBD–OPH protein to CF11, the matrix was packed in a 2.5×20 cm2 column (Kimble, Vineland, NJ, USA) and PC buffer was applied at 15 ml/h for 20 min for system acclimation. The column was then ready for application of solutions containing OP compounds; if the column was to be stored, sodium azide was added to the equilibration solution to a final concentration of 0.02% (w/v) to protect against biological contamination.

Coumaphos biodegradation in the enzyme bioreactor under continuous flow

Coumaphos in PC buffer (pH 8) was applied as a feed solution to the top of the bioreactor column and effluent was withdrawn from the end of the column at the same flow rate, using a precision flow multihead peristaltic pump (EVA Pump, Eppendorf, Milwaukee, WI, USA). Aliquots (2 ml) of the effluent were collected using a fraction collector (Pharmacia LKB, Uppsala, Sweden), and subsequently analyzed for the biodegradation product chlorferon, the hydrolysis product of coumaphos, by measuring the absorbance spectrophotometrically (Cary 1E, Varian, Melbourne, Australia) at 384 nm [7].

Influence of flow rate on coumaphos degradation

The effect of applying different flow rates on the degradation of three different concentrations of coumaphos (0.1, 0.2 and 0.3 mM supplemented with 5% methanol and 1% POLE) was examined to determine the optimum flow rate for this system. The flow rates applied were 16, 32, 96, 150, 200, and 240 ml/h (Figs. 2, 3). For each flow rate, the optimum time required for maximum degradation percent was determined (Fig. 4a, b).

Effect of storage on bioreactor efficiency

To evaluate enzyme bioreactor efficacy over a long period after bioreactor column construction, 1 mM paraoxon was run over the column at a flow rate of 23 ml/h at 0, 15 and 45 days after column construction to assay detoxification potential over time. Efficiency was defined as the biodegradation ratio of paraoxon to para-nitophenol (PNP), as measured spectrophotometrically at a wavelength of 412 nm. After each evaluation, the column was stored at room temperature following addition of sodium azide to prevent microbial contamination.

Effect of stirring on coumaphos detoxification

Application of coumaphos solution to the column is restricted by its solubility. Hence, if the concentration exceeds the range 0.1–0.3 mM, insoluble coumaphos blocked the tube, consequently limiting the capacity of the bioreactor for OP biodegradation. For this reason, the technique of stirring high concentrations of coumaphos was employed to assess its efficacy in biodegradation of high levels of coumaphos using immobilized enzyme. In this context, coumaphos at 1.0 and 1.5 mM was stirred with 0.25 g CBD–OPH-CF11, and coumaphos biodegradation was followed over time. The experiment was performed at 25 and 45°C.

Results and discussion

The primary goals of the current investigation were to achieve degradation of the OP pesticide coumaphos and to determine optimum conditions for such biodegradation using an immobilized CBD–OPH fusion enzyme system. Moreover, raising coumaphos concentration to levels higher than can be biodegraded by current bioreactors was another main objective of this study.

Influence of flow rate on coumaphos degradation

The results revealed the relationship between coumaphos degradation and its flow rate as a feed solution through a bioreactor column. Three coumaphos concentration levels (0.1, 0.2 and 0.3 mM) were tested. For all experiments, the feed solution was prepared in citrate–phosphate buffer pH 8, 5% methanol, with 1% surfactant POLE (POLE was added to ensure complete solubility of OP in the feed solution [5, 6]).

Degradation of coumaphos (at 0.1 and 0.2 mM) by the CBD–OPH fusion enzyme bioreactor reached almost 99% for all flow rates tested except 200–240 ml/h (Figs. 2, 3). The optimum flow rate for 0.1 and 0.2 mM coumaphos was found to be 120 and 150 ml/h, respectively. The time required to reach the maximum degradation percent was found to be inversely proportional to the flow rate at each coumaphos concentration (Fig. 3). From these figures, it is obvious that maximal degradation of coumaphos can be achieved by increasing the flow rate, with only a minor decrease in degradation percent. However, increasing the flow rate beyond 200 ml/h, significantly decreases the coumaphos degradation percent. For 0.3 mM coumaphos, the degradation percentages were ~62 and 32% for 150 and 200 ml/h, respectively (Fig. 5). These results show a significant decrease in the degradation percent compared to the other two concentration levels tested. These results are in agreement with the results of Mansee et al. [7] for coumaphos degradation through a cell bioreactor column where the degradation percent was inversely correlated with concentration over the range tested.

Effect of storage on column efficiency

The stability of the CBD–OPH fusion enzyme over the 45 days following immobilization on the cellulose material was examined by measuring its capacity for degradation of 1 mM paraoxon. The degradation rate of paraoxon at 0, 15 and 45 days after immobilization was almost the same (Fig. 6); slight differences were recorded in the steady state in each case, which was reached earlier in the first run than in the other two treatments. In the first day run, maximum degradation was reached after ~2 h, while ~3 h were required in the other two treatments. However, the results showed that the CBD–OPH was still active in biodegradation 45 days from column construction. These results are supported by the results of Kim et al. [4] and Wang et al. [15], who reported that immobilized cells of genetically engineered E. coli expressing both OPH and CBD on the cell surface degraded paraoxon rapidly, and retained almost 100% efficiency over a period of 45 days. Moreover, Richins et al. [12] stated that CBD–OPH fusion proteins could be immobilized onto a variety of cellulose matrices, retaining up to 85% of their original activity for 30 days.

Influence of stirring on the coumaphos degradation

Although good biodegradation efficiency was achieved using continuous flow of OP through the bioreactor column, the concentration of OP is limited to the capacity of the system to degrade no more than 0.2 mM. Stirring the OP solution with CBD–OPH immobilized to cellulose materials enabled the system to degrade 1 mM coumaphos. Figure 7 shows that 1 mM coumaphos is completely degraded in 90 min after stirring with 0.25 g CBD–OPH immobilized on CF11 at 25°C. Increasing the coumaphos concentration to 1.5 mM decreased the degradation percent to 82% after 24 h of stirring (Fig. 7). By raising the ambient temperature from 25 to 45°C, complete biodegradation of 1.5 mM coumaphos was recorded after 24 h of stirring (Fig. 7).

This experiment showed that stirring coumaphos with CBD–OPH has an intrinsic effect on its biodegradation greater than that of passing a solution through the bioreactor column. Moreover, increasing the ambient temperature to 45°C allowed degradation of 1.5 mM coumaphos, which could not be achieved using the bioreactor column. The relationship between OP degradation percent and ambient temperature found in the present investigation is supported by the results of Kaneva et al. [3] and Mulchandani et al. [9], who found that the initial specific paraoxon hydrolysis rate increased from 0.056 μM min−1 (grams cell dry weight)−1 at 25°C to 0.16 mM min−1 (grams cell dry weight)−1 at 45°C for soluble OPH. Although increasing the temperature initially led to enhanced paraoxon degradation rates, it is important to recognize that OPH is labile and undergoes temperature-dependent inactivation [13].

The present investigation found a relationship between coumaphos degradation and its flow rate as feeding solution through a bioreactor column. Optimum conditions for biodegradation by a CBD–OPH fusion enzyme immobilized system were determined. Moreover, the biodegradation efficiency of CBD–OPH was maintained even after more than 45 days from column construction. Stirring coumaphos with immobilized CBD–OPH had a greater intrinsic effect on its biodegradation than passing the solution through the bioreactor column. The relationship between OP degradation percent and ambient temperature was also explained.

References

Chen W, Mulchandani A (1998) The use of live biocatalysts for pesticide detoxification. Trends Biotechnol 16:71–76

Gill I, Ballesteros A (2000) Degradation of organophosphorus nerve agents by enzyme–polymer nanocomposites: efficient biocatalytic materials for personal protection and large-scale detoxification. Biotechnol Bioeng 70:400–410

Kaneva I, Mulchandani A, Chen W (1998) Factors influencing parathion degradation by recombinant Escherichia coli with surface-expressed organophosphorus hydrolase. Biotechnol Prog 14:275–278

Kim JW, Rainina EI, Mulbry WW, Engler CR, Wild JR (2003) Enhanced-rate biodegradation of organophosphate neurotoxins by immobilized nongrowing bacteria. Biotechnol Prog 18:429–436

Layton AC, Muccini M, Gosh MM, Sayler GS (1998) Construction of a bioluminescent reporter strain to detect polychlorinated biphenyls. Appl Environ Microbiol 64:5023–5026

Liu Z, Jacobson AM, Luthy RG (1995) Biodegradation of naphthalene in aqueous nonionic surfactant systems. Appl Environ Microbiol 61:145–151

Mansee AH, Chen W, Mulchandai A (2000) Biodetoxification of coumaphos insecticide using immobilized Escherichia coli expressing organophosphorus hydrolase enzyme on cell surface. Biotechnol Bioprocess Eng 5:436–440

Mulbry WW, Del Valle PL, Karns JS (1996) Biodegradation of organophosphate insecticide coumaphos in highly contaminated soil and in liquid wastes. Pestic Sci 48:149–155

Mulchandani A, Kaneva I, Chen W (1999) Detoxification of organophosphate nerve agents by immobilized Escherichia coli with surface-expressed organophosphorus hydrolase. Biotechnol Bioeng 63:216–223

Qiao ChL, Yan YCh, Shang HY, Zhou XT, Zhang Y (2003) Biodegradation of pesticides by immobilized recombinant Escherichia coli. Bull Environ Contam Toxicol 71:370–374

Richins R, Kaneva I, Mulchandani A, Chen W (1997) Biodegradation of organophosphorus pesticides by surface-expressed organophosphorus hydrolase. Nat Biotechnol 15:984–987

Richins R, Mulchandani A, Chen W (2000) Expression, immobilization, and enzymatic characterization of cellulose binding domain–organophosphorus hydrolase fusion enzymes. Biotechnol Bioeng 69:591–596

Rowland SS, Speedie MK, Pogell BM (1991): Purification and characterization of a secreted recombinant phosphotriesterase (parathion hydrolase) from Streptomyces lividans. Appl Environ Microbiol 57:440–444

Shimazu M, Mulchandani A, Chen W (2001) Simultaneous degradation of organophosphorus pesticides and p-nitrophenol by a genetically engineered Moraxella sp. with surface-expressed organophosphorus hydrolase. Biotechnol Bioeng 76:318–324

Wang AA, Mulchandani A, Chen W (2002) Specific adhesion to cellulose and hydrolysis of organophosphate nerve agents by a genetically engineered Escherichia coli strain with a surface-expressed cellulose-binding domain and organophosphorus hydrolase. Appl Environ Microbiol 68:1684–1689

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mansee, A.H., Chen, W. & Mulchandani, A. Detoxification of the organophosphate nerve agent coumaphos using organophosphorus hydrolase immobilized on cellulose materials. J IND MICROBIOL BIOTECHNOL 32, 554–560 (2005). https://doi.org/10.1007/s10295-005-0059-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-005-0059-y