Abstract

The production of fungal spores using on-site, non-sterile, portable fermentation equipment is technically constrained. Very little information is available on the production requirements, such as medium concentration, inoculum stabilization, required fermentation times, and maintenance of axenic growth. In this study, we developed a two-part, liquid concentrate of the production medium that remains stable and soluble at room temperature. We also examined inoculum stability and showed that freeze- or air-dried blastospore preparations were stable for 7 days after rehydration when stored at 4 °C. The use of a low-pH (pH 4), relatively rich complex medium provided a growth environment deleterious to bacterial growth yet conducive to rapid sporulation by Paecilomyces fumosoroseus. High concentrations of blastospores (7.9×108/ml) of P. fumosoroseus were produced in a 40-h fermentation with very low levels of bacterial contamination when the fermentor was charged with a blastospore production medium with a starting pH of 4 and inoculated with blastospore concentrations greater than 1×106 spores/ml. These studies demonstrate that the use of disinfected, portable fermentation equipment has potential for on-site production of high concentrations of blastospores of the bioinsecticidal fungus P. fumosoroseus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Insect and plant pathologists have identified literally hundreds of microbial agents, including bacteria, fungi, protozoa and viruses, that show good potential for use as biopesticides. Unfortunately, only a handful of these microbial biocontrol agents have been commercially developed and marketed in the last 20 years. In large part, limited success in commercializing these microbial agents is due to a lack of economical production methods, poor product shelf-life, and inconsistent pest control under field conditions. It has been suggested that on-site or cottage-industry biopesticide production may be one approach to overcoming these constraints [1]. In developing countries with lower labor costs, small-scale, solid fermentation methods are frequently used for the production of certain fungal bioinsecticides [3,6,2]. Even with low wage rates, it has been reported that labor accounts for 30% of the cost of bioinsecticide production using solid-substrate fermentation methods [3]. On-site, small-scale production of bioinsecticides using deep-tank fermentation technology may help lower production costs due to reduced manpower requirements for fermentor operation and product handling. In addition, the use of a freshly produced microbial biopesticide would reduce processing costs and product losses associated with drying, packaging, shipping, and storage.

Beneficial bacteria have been produced commercially using on-site liquid fermentation equipment for use as soil amendments and biocontrol agents in turf [4,16]. By coupling the rapid growth rate of bacteria with high inoculum levels, relatively pure bacterial cultures can be rapidly produced in portable, non-sterile fermentors. The use of these on-site production systems for fungal biopesticide production is considerably more challenging. Fungi typically grow much slower than bacteria and therefore are susceptible to being overrun by bacterial contaminants.

The silverleaf whitefly (Bemisia argentifolii) has been reported to attack over 600 types of plants in warm climates and greenhouses worldwide. The wide host range and virus-vectoring capacity of the silverleaf whitefly continues to make this insect a significant pest of world agriculture [1,15]. The entomopathogenic hyphomycete Paecilomyces fumosoroseus (Wize) Brown and Smith is a pathogen of over 40 insect species and is one of the most common fungi found attacking silverleaf whitefly nymphs and adults [12,18]. The identification of numerous strains of P. fumosoroseus that are capable of rapidly infecting and killing the silverleaf whitefly and the development of B. argentifolii resistance to many commonly used chemical insecticides has heightened commercial interest in using this fungus as bioinsecticide [13,17]. The feasibility of using P. fumosoroseus as a biocontrol agent is dependent on numerous biological and commercial constraints, including the ability to produce high concentrations of stable propagules at a reasonable cost [11,14]. Previous research in our laboratory led to the development of a liquid culture technique for rapidly producing high concentrations of desiccation-tolerant P. fumosoroseus blastospores that were extremely effective in infecting and killing silverleaf whitefly [8,9].

In this study, we evaluated techniques for consistently producing viable blastospores of the bioinsecticide P. fumosoroseus using a portable fermentation system. Methods were developed for the concentration of the blastospore production medium as a liquid concentrate. Nutritional and environmental conditions were examined for developing conditions that would support the rapid production of blastospores of P. fumosoroseus and at the same time inhibit the establishment and growth of bacterial contaminants. Environmental conditions known to deter bacterial growth, such as low pH, were evaluated for their affect on blastospore production and fitness using cultures of P. fumosoroseus. The results presented in this study outline a method for the rapid production of high concentrations of blastospores of P. fumosoroseus that are essentially free of bacterial contamination using non-sterile, portable fermentation equipment.

Materials and methods

Culture maintenance and inoculum development

The P. fumosoroseus strain (ARSEF 3581) used in this study was isolated from an infected silverleaf whitefly (Bemisia argentifolii) in Mission, Texas, and was obtained from the USDA- Agricultural Research Service’s Collection of Entomopathogenic Fungi, Ithaca, New York [7]. For blastospore production studies, stock cultures of P. fumosoroseus ARSEF 3581 were grown as single-spore isolates on potato dextrose agar (PDA) plates for 3 weeks at room temperature, cut into 1-mm2 agar plugs, and stored in 10% glycerol at -80 °C. Conidial inocula of Paecilomyces fumosoroseus ARSEF 3581 were obtained from 2-week-old sporulated PDA plates. A conidial inoculum of 5×105 spores/ml was used to inoculate preculture flasks (100 ml in 250-ml baffled flasks) that contained a basal salts medium with 8% glucose and 1.3% casamino acids, as previously described [9]. Blastospores obtained from these 4-day-old precultures were used to inoculate shake-flask cultures for pH studies and fermentors at a final blastospore concentration of 1–5×106 blastospores/ml. Conidia and blastospore concentrations were determined microscopically with a hemocytometer.

Media and culture conditions

The standard medium used for all shake-flask and fermentor blastospore production studies consisted of a basal salts medium supplemented with trace metals, vitamins, and 25 g glucose/l (Difco, Becton Dickinson, Sparks, Md., USA) and 25 g casamino acids/l (vitamin assay, Difco). The basal media contained (per l): KH2PO4, 2.0 g; CaCl2·2H20, 0.4 g; MgS04·7H20, 0.3 g; CoCl2·6H20, 37 mg; FeSO4·7H20, 50 mg; MnSO4·H20, 16 mg; ZnSO4·7H20, 14 mg; thiamin, riboflavin, pantothenate, niacin, pyridoxamine, thioctic acid, 500 μg each; folic acid, biotin, vitamin B12, 50 μg each (Sigmal, St. Louis, Mo., USA).

Experiments were conducted to develop a liquid medium concentrate that could be pumped into the 100-l portable fermentor (Bioject, Hocking International, San Diego, Calif., USA, formerly EcoSoil Systems, San Diego, Calif., USA). To eliminate precipitation of media components in the liquid concentrate, two media solutions were required. Solution A was a 12-fold concentrate of trace metals, vitamins, and acid-hydrolyzed casein. To prepare solution A, the following was added to 700 ml deionized water with agitation and low heat: casamino acids, 300 g; CoCl2·6H20, 444 mg; FeSO4·7H20, 600 mg; MnSO4·H20, 192 mg; ZnSO4·7H20, 168 mg; thiamin, riboflavin, pantothenate, niacin, pyridoxamine, thioctic acid, 6 mg each; and folic acid, biotin, vitamin B12, 600 μg each. After mixing, approximately 20 ml concentrated hydrochloric was added for a final pH of 3.6. The volume of solution A was then adjusted to 1 l and a final pH of 3.6. Solution B was a 30-fold concentrate of glucose and minerals. To prepare solution B, the following was added to 350 ml deionized water with agitation: 750 g glucose; 60 g KH2PO4; 9 g MgS04·7H20, and 12 g CaCl2·2H20. The volume of solution B was then adjusted to 1 l with deionized water. Concentrate sterilization and its use in the fermentor are described below.

Shake-flask blastospore production studies

Shake-flask studies were conducted to evaluate the effect of pH and inoculum stability on the production of blastospores of P. fumosoroseus. For all shake-flask blastospore production studies, 100-ml cultures of P. fumosoroseus were grown in 250-ml baffled, Erlenmeyer flasks (Bellco Glass, Vineland, N.J., USA) at 28 °C and 300 rpm in a rotary shaker incubator (INNOVA 4000, New Brunswick Scientific, Edison, N.J., USA).

For pH studies, cultures were grown in our standard blastospore production media in which the starting pH had been adjusted to 6.5, 4.5, 4.0, or 3.5 by the addition of 2 N HCl or 2 N NaOH. Blastospore concentrations were measured microscopically using a hemocytometer 2 and 3 days post inoculation. The final pH of the cultures was measured 3 days post-inoculation.

Inoculum stability studies were conducted using freeze-dried and air-dried blastospore preparations that were rehydrated with deionized water and stored at 4 °C for various times prior to use as inoculum. Shake-flask cultures were inoculated with the rehydrated blastospores of P. fumosoroseus to deliver a final concentration of 5×106 blastospores/ml based on the blastospore concentration and viability immediately after rehydration. After rehydration, the blastospore concentration of the resultant suspensions was measured microscopically with a hemocytometer. The viability of blastospores after rehydration and after storage for various times at 4 °C was determined using a previously described blastospore germination assay [9]. Briefly, blastospores were incubated in 250-ml baffled Erlenmeyer flasks containing 50 ml potato dextrose broth (Difco) in a rotary shaker incubator at 28 °C and 300 rpm. One hundred spores were observed microscopically to determine the presence or absence of a germ tube.

Blastospore inocula for air- and freeze-drying experiments was prepared from 4-day-old cultures grown in our standard blastospore production medium as described above. For freeze-drying, blastospore-containing whole cultures were suspended in 2% lactose, 1% bovine serum albumin and freeze-dried as previously described [9]. Air-dried blastospore preparations were produced by adding diatomaceous earth (Hyflo, Celite Corporation, Lompoc, Calif., USA) to cultures of P. fumosoroseus containing blastospores at a concentration of 1 g diatomaceous earth/2×1010 blastospores. Spent medium was removed from the blastospores: diatomaceous earth mixture by vacuum filtration in a Buchner funnel (Whatman #1 filter paper). The filter cake (~ 65% moisture) was crumbled and air-dried in a shallow aluminum pan at room temperature. The drying air was maintained at >65% relative humidity for improved blastospore stability [8].

Blastospores produced fermentor

Fermentor studies were conducted in a 60-l working volume in the 100-l portable fermentation system. The fermentor system was not a sterile environment. The system was surface disinfected by rinsing the fermentor vessel, media, inoculum- and water-addition lines with either ethanol (70% w/v) or peracetic acid (18% w/v) for 2 min before and after use. Deionized process water was passed through an ultraviolet water treatment unit (DW-8, Aquafine Corporation, Valencia, Calif., USA) prior to entering the fermentor vessel.

Five liters of solution A and 2 l of solution B media concentrates were used to supply nutrients for the 60-l P. fumosoroseus fermentations in the 100-l portable fermentor. Media concentrates were placed in 10-l Nalgene carboys with tubing connectors and autoclaved for 1 h. Sterile tubing was connected to the carboys and to the media-addition valves on the fermentor. Filter-sterilized deionized water was added to the fermentor to a volume of ~53 l. The water was recirculated through the system. After the media concentrates were pumped into the fermentation vessel, the final blastospore production medium had a pH of ~4. Foaming was controlled by the addition of 650 ml of a 5% solution of silicon-based antifoam (#289, Sigma) through a medium-addition valve on the fermentor.

Blastospore inoculum of P. fumosoroseus was provided as various volumes of whole cultures that delivered a total of 3×1011 blastospores or 5×106 blastospores/ml, final spore concentration. Blastospore inocula were produced in shake-flask cultures. Inoculum was pumped into the fermentor through an addition port in the refrigerated compartment present on the portable fermentor unit.

The portable fermentor was controlled utilizing an on-board Intel 386 computer panel. A C-plus computer program monitored the volume and temperature of the fermentation. This program also controlled the time of incubation of the fermentation.

The fermentation broth was agitated by pumping the broth from the bottom to the top of the fermentor through a 2.5-cm PVC line at a rate of ~100 l per minute. Aeration was accomplished using two air compressors (Gast, model DOA -P101-AA) each delivering 30l air min−1. Air from one compressor entered the fermentor at the bottom of the fermentor vessel. The other compressor delivered filtered air to the 22.5-cm PVC broth recirculation line at a point immediately before the 46-cm-long static in-line mixer (35385K34, McMaster-Carr, Chicago, Ill., USA). The static mixer vigorously combined air and culture broth to increase oxygen transfer. All compressed air was filtered by passage through a 10 μm and then a 1-μm hydrophobic filter (Pall, RIF400 and RIF100, respectively) prior to entry in the fermentation system. All exhaust air was filtered through a 0.2 μm hydrophobic filter (Pall, SCF92 HP01S). Paecilomyces fumosoroseus cultures were grown in the fermentor for 48 h at 28 °C with pH uncontrolled.

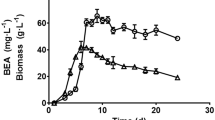

Samples were taken from the fermentor 0, 18, 24, 40, and 48 h after inoculation. Blastospore concentrations were measured microscopically, after appropriate dilution, with a hemocytometer. Bacterial contamination was evaluated 0, 18, and 40 h post-inoculation by spread-plating appropriate dilutions of culture broth on nutrient agar plates and incubating them at 37 °C. Colony-forming units (CFU) provided a measure of bacterial contamination. Fungal contamination was qualitatively measured by spread-plating the fermentation broth samples on PDA, incubating the plates at 28 °C, and visually evaluating the plates for colonies that were not typical of P. fumosoroseus. Fungal contamination was not observed.

Statistical analysis

In shake-flask experiments, all treatments were run in triplicate and all experiments were repeated at least twice. Mean values for data from fermentor trials were obtained from eight separate fermentor runs. For statistical analysis, mean values for blastospore yield and pH were subjected to analysis of variance (ANOVA) using Fisher’s protected least significant difference at P<0.05 (JMP Version 3, SAS Institute, Cary, N.C., USA). For data not suitable for ANOVA, standard error values were calculated and provided as a measure of variance.

Results and discussion

On-site production of a bioinsecticidal propagule using portable fermentors would not only provide an optimally effective, freshly produced propagule, but also would eliminate the costs and product losses associated with the stabilization, storage, and transportation of these living microbial agents. P. fumosoroseus has shown excellent potential as a bioinsecticide for various soft-bodied insects including whiteflies, thrips, and aphids. In this study, methodologies were evaluated and optimized for the liquid-culture production of blastospores using portable, sanitized, non-sterile fermentation equipment.

Since the portable fermentation system was equipped with multiple media-addition ports, experiments were conducted to evaluate the separation of the media components into two precipitate-free concentrates. When blastospore production media derived from these concentrates were compared to blastospore production media prepared using our standard protocol, both media yielded blastospore concentrations of 1.1×109 blastospores/ml after 2 days growth [10]. Media concentrates stored at room temperature for 1 month showed no loss in blastospore production capability (data not shown).

Another critical process issue for use of a portable fermentor for on-site production of blastospores is the development of an effective method for delivering a suitable inoculum to the fermentor. Our previous experiments demonstrated that the use of blastospore inocula >1×106 blastospores/ml shortened fermentation times to approximately 48 h while supporting high blastospore yields [10]. Stabilization of blastospores of P. fumosoroseus as dry powders has been accomplished with freeze- and air-drying [9]. Since the portable fermentation equipment is equipped with a refrigerated compartment for storing inocula suspensions and allows repeated injections of inocula for multiple fermentations, freeze-dried or air-dried blastospore suspensions were evaluated for stability and blastospore production after being rehydrated and then stored at 4 °C. Blastospore suspensions were calculated to deliver 5×106 blastospores/ml in the fermentation medium when freshly produced. After storage at 4 °C for 7 days, rehydrated air- or freeze-dried blastospore suspensions maintained over 50% viability and, when these suspensions were used as inocula, there was no significant difference in blastospore yields after 2 days growth (Table 1). After 17 days storage at 4 °C, ~15% of the rehydrated blastospores were still viable. Based on 2-day fermentation times for blastospore production, inocula from rehydrated freeze-dried or air-dried blastospore preparations are suitable for use with the portable fermentation system. Moreover, these rehydrated blastospore suspensions can be used to inoculate up to three fermentation runs.

The major technical hurdle in producing fungal cultures in a non-sterile fermentation environment is the reduction of bacterial contamination. In general, fungi grow more slowly than bacteria and therefore tend to be poor competitors. Of utmost importance in the production of microbial biocontrol agents is product quality and purity. Unwanted microbial growth can reduce the vigor of the biocontrol agent and potentially introduce an unwanted or deleterious microbe into the biocontrol product. In addition to the requirement for adequate cleaning procedures to reduce the initial bacterial levels in the fermentation environment, two growth factors that favor the competitiveness of P. fumosoroseus cultures are the use of a nutritionally rich blastospore production medium and the relatively short fermentation times required for the production of yeast-like blastospores of this fungus. It has also been shown that P. fumosoroseus cultures naturally lower the pH of the medium during blastospore production (unpublished data). A low-pH growth environment can effectively reduce the growth of many potential bacterial contaminants [5].

No significant differences were observed in blastospore yield after 2–3 days growth using blastospore production media with a starting pH ranging of 6.5–3.5 (Table 2). While cultures grown in media with a starting pH of 6.5 ended with a pH of 4.3 after 3 days growth, no significant reduction in medium pH was noted for cultures grown in media with a starting pH of 4.5 or lower. Based on these results, media concentrates for fermentor studies were adjusted to provide a production medium with a starting pH of ~4.0.

To evaluate the potential for high-quality P. fumosoroseus blastospore production in a non-sterile fermentation environment, numerous 60-l cultures were grown for 48 h in the portable fermentor. Fermentations were conducted using media concentrates that produced a blastospore production medium with a starting pH of ~4.0; blastospore inocula were added to provide 5×106 blastospores/ml. Eleven fermentations were attempted, with eight being successfully completed. Two of the aborted fermentor runs had foaming problems due to the lack of antifoam addition and the other aborted fermentation had a high initial bacterial contamination due to inadequate cleaning. Data from the eight successful fermentor runs showed that blastospore production peaked at 7.9×108 blastospores/ml after 40 h fermentation with very low levels (<103 CFU/ml) of bacterial contamination (Table 3). Bacterial concentrations at the start of the fermentation runs were ~1.4×105 CFU/ml peaking at almost 106 CFU/ml after 18 h growth. The reduction in bacterial concentrations over time suggests that the low pH or the production of antibacterial compounds by the P. fumosoroseus cultures may be bactericidal.

In conclusion, these studies have shown that the potential exists to use non-sterile, on-site fermentation systems for the production of blastospores of P. fumosoroseus. Yeast-like rapid growth coupled with the capacity to grow and produce high blastospore concentrations under low pH conditions appear to favor the competitiveness of P. fumosoroseus over normal bacterial contaminants. Maintaining low initial levels of bacterial contamination in the fermentation environment through proper cleaning and sanitation is imperative. It is likely that biocontrol fungi that grow more slowly or that must grow vegetatively and then differentiate to form conidia would not have the same competitive advantage in this non-sterile fermentation environment. While these results suggest that on-site fermentation can be a suitable method for producing blastospores of the bioinsecticidal fungus P. fumosoroseus, validation of this process will require the production of blastospores in the portable fermentation equipment at various remote locations using local utilities and prevailing conditions. Technicians trained in detecting the presence of unwanted microorganisms and in understanding the physical and biological parameters that regulate the fermentation process will be an essential requirement to ensure that quality biocontrol products are produced and distributed to end-users.

References

Auld BA, Morin L (1995) Constraints in the development of bioherbicides. Weed Technol 9:638–652

Bartlett MC, Jaronski ST (1988) Mass production of entomogenous fungi for biological control of insects. In: Burge MN (ed) Fungi in biological control systems. Manchester University Press, Manchester, New York, pp 61–85

Cherry AJ, Jenkins NE, Heviefo G, Bateman R, Lomer CJ (1999) Operational and economic analysis of a West African pilot-scale production plant for aerial conidia of Metarhizium spp. for use as a mycoinsecticide against locusts and grasshoppers. Biocontrol Sci Technol 9:35–51

Environmental Protection Agency (1997) Growth of Pseudomonas aureofaciens strain Tx-1 using the bioject automated microbial fermentation and injection system, vol 2. Registration File Symbol 70688-R

Gerhardt P (1993) Methods for general and molecular bacteriology. Chap. 2 Enrichment and isolation. ASM Press, Washington DC

Goettel MS, Roberts DW (1992) Mass production, formulation and field application of entomopathogenic fungi. In: Lomer CJ, Prior C (eds) Biological control of locusts and grasshoppers. C. A. B. International, UK, pp 230–238

Humber RA (1992) Collection of entomopathogenic fungal cultures: catalog of strains, ARS-110, U.S. Department of Agriculture, Agricultural Research Service

Jackson MA (1999) Method for producing desiccation tolerant Paecilomyces fumosoroseus spores. U.S. patent no. 5,968,808, October 19, 1999

Jackson MA, McGuire MR, Lacey LA, Wraight SP (1997) Liquid culture production of desiccation tolerant blastospores of the bioinsecticidal fungus Paecilomyces fumosoroseus. Mycol Res 101:35–41

Jackson MA, Cliquet S, Iten LB (2003) Media and fermentation processes for the rapid production of high concentrations of stable blastospores of the bioinsecticidal fungus Paecilomyces fumosoroseus. Biocontrol Sci Technol 13:23–33

Jaronski ST (1986) Commercial development of deuteromycetous fungi of arthropods: a critical appraisal. In: Samson RA, Vlak JM, Peters D (eds) Fundamental and Applied aspects of invertebrate pathology. Fourth International Colloquium of Invertebrate Pathology, Wageningen, The Netherlands, pp. 653–656

Lacey LA, Kirk AA, Hennessey RD (1993) Foreign exploration for natural enemies of Bemisia tabaci and implementation in integrated control programs in the United States. International Conference on Pests in Agriculture, Montpellier, France, pp. 351–361

Lacey LA, Fransen JJ, Carruthers R (1995) Global distribution of naturally occurring fungi of Bemisia, their biologists and use as biological control agents. Taxonomy, biology, damage control and management. Intercept, Andover, UK, pp 401–433

Latge, J-P, Hall RA, Cabrera-Cabrera RI, Kerwin JC (1986) Liquid fermentation of entomopathogenic fungi. In: Samson RA, Vlak JM, Peters D (eds) Fundamental and applied aspects of invertebrate pathology. Fourth International Colloquium of Invertebrate Pathology, Wageningen, The Netherlands, pp. 603–606

Nene YL (1973) Note on a fungus parasite of Bemisia tabaci Genn., a vector of several plant viruses. Ind J Agric Sci 43:514–516

Odelson DA, Doyle J (1998) On site fermentation for biological applications. Alternative paradigms for commercializing biological control workshop. New Burnswick, NJ,[http://www.rci.Rutgers.edu/~insects/biopesticides.htm

Puterka GJ, Humber RA, Poprawski TJ (1994) Virulence of fungal pathogens (imperfect fungi: hyphomycetes) to pear psylla (homoptera: psyllidae). Environ Entomol 23:2

Smith P (1993) Control of Bemisia tabaci and the potential of Paecilomyces fumosoroseus as a biopesticide. Biocontrol News and Information. 14:71N–78 N

Acknowledgement

The authors wish to express their appreciation and gratitude to Loren Iten for his insight on utilization of the in-line static mixer for increased aeration in the fermentor recirculation lines, and to Kevin Mitchell for his technical expertise and assistance throughout the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jackson, M.A., Payne, A.R. & Odelson, D.A. Liquid-culture production of blastospores of the bioinsecticidal fungus Paecilomyces fumosoroseus using portable fermentation equipment. J IND MICROBIOL BIOTECHNOL 31, 149–154 (2004). https://doi.org/10.1007/s10295-004-0127-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-004-0127-8