Abstract

Alkaline xylanases from alkaliphilic Bacillus strains NCL (87-6-10) and Sam III were compared with the commercial xylanases Pulpzyme HC and Biopulp for their compatibility with detergents and proteases for laundry applications. Among the four xylanases evaluated, the enzyme from the alkaliphilic Bacillus strain NCL (87-6-10) was the most compatible. The enzyme retained its full activity (40 °C for 1 h) in the presence of detergents, whereas Pulpzyme HC and Sam III showed only 30% and 50% of their initial activity, respectively. Biopulp, though stable to detergents, had only marginal activity (5%)at pH 10. However, all four enzymes retained significant activity (80%) for 60 min in the presence of the proteases Alcalase and Conidiobolus protease. Supplementation of the enzyme enhanced the cleaning ability of the detergents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

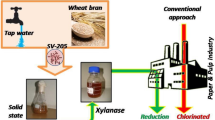

Cellulase-free xylanase finds extensive application in the pulp and paper industry as an effective adjuvant in the bio-bleaching of wood pulps. This pre-treatment lowers the consumption of bleach chemicals, such as molecular chlorine, chlorine dioxide and hydrogen peroxide, with a concomitant increase in brightness [21]. Xylanases are also used in the baking industry [11] and as animal feeds [3, 20]. However, there are no published reports on the use of xylanases in detergents, except for patents by Herbots et al. [6, 7].

For an enzyme to be used as a detergent additive, it should be stable to such detergent components as surfactants, builders, bleaching agents, bleach activators and other formulation chemicals. In general, alkaline proteases are the standard choices for detergent enzymes with formulations ranging from household laundering to solutions for cleaning contact lenses and dentures [14]. Site-directed mutagenesis has made significant contributions in improving catalytic efficiency and stability towards pH, temperature and oxidising agents. Newer enzymes with improved properties, such as Durazym and Maxapem, have been reported [4, 5]. Of late, hydrolytic enzymes, namely alkaline amylase, cellulase and lipase, have been incorporated in detergent formulations to increase the efficiency of the washes [9, 15, 19]. Vegetable- or fruit-derived stains, such as those from mango and grasses, are difficult to remove; and coffee, tea and tobacco stains are even more challenging. Hence, it would be advantageous to incorporate alkaline xylanases along with proteases in detergent formulations to solubilise stubborn stains of plant origin. The present communication details the compatibility and potential application in detergents of the alkaline xylanases from alkaliphilic Bacillus sp. NCL (87-6-10).

Materials and methods

Materials

Media chemicals (HiMedia Laboratories, Mumbai, India), Hammarsten’s casein (Sisco Chemicals, Mumbai, India), xylan (oat spelts) and 3,5-dinitrosalicylic acid (DNS); (Sigma Chemical Co., USA) were used. Alcalase and Pulpzyme HC were from Novo Industries, Denmark. Biopulp is a product of Biocon India. All other chemicals used were of analytical grade.

Wheat bran and soybean meal were obtained locally. Commercial detergents, namely Surf Excel, Surf, 501 bar soap and Rin Shakthi (Hindustan Lever, Mumbai, India), Ariel (Procter & Gamble, Mumbai, India), Nirma soap (Nirma, Ahmedabad, India), Dettol liquid soap (Reckitt Piramal, Mumbai, India), Snow White (Mehta Soap Factory, Pune, India) and Denturite (Bharucha Brothers, Mumbai, India), were purchased from a local market.

Cultures

The two alkaliphilic Bacillus strains, NCL (87-6-10) and Sam III (from the National Collection of Industrial Microorganisms, National Chemical Laboratory, Pune, India, with accession numbers 2128 and 5122 respectively), were maintained on NAX slants (0.2% peptone, 0.2% beef extract, 0.1% NaCl, 1% xylan, 2.5% agar) at 10 °C. Conidiobolus sp. NCL (97-7-11) for protease production was maintained on MGYP slants (0.3% malt extract, 0.5% yeast extract, 0.5% peptone, 1% glucose, 2% agar) at 14 °C.

Xylanase assay

Xylanase activity was determined at pH 10 and 40 °C by measuring the release of reducing sugars from oat spelt xylan by the DNS method [1]. One unit of xylanase activity was defined as the amount of enzyme that produced 1 μmol xylose equivalent min−1 under the assay conditions.

Production of xylanases from alkaliphilic Bacillus strains

Xylanase production from the alkaliphilic Bacillus strains NCL (87-6-10) and Sam III was carried out as described earlier [1, 18]. The cell-free broth was concentrated by ultrafiltration using a YM-3 membrane and precipitated with ammonium sulphate (60% saturation). The precipitate was dissolved in a minimum volume of 20 mM potassium phosphate buffer, pH 7.0, dialysed against the same buffer and used as the source of enzyme for further studies. The specific activity of this enzyme was 250 units mg−1 protein.

Purification of xylanases

Xylanases A and C were purified according to Balakrishnan et al. (2). The specific activity of the purified enzymes were 370.8 units mg−1 protein and 3045 units mg−1 protein, respectively.

Protease assay

The protease activity was determined at pH 10 and 37 °C by the method of Kunitz [10]. One unit of protease activity was defined as the amount of enzyme resulting in an increase of 1.0 absorbance unit ml−1 reaction mixture min−1 at 37 °C.

Production of protease

Protease production was carried out in a medium containing defatted soybean and MGYP, according to Ingle et al [8]. The broth was concentrated by ultrafiltration using a YM-3 membrane, precipitated with ammonium sulphate (90% saturation), dissolved in 10 mM potassium phosphate buffer, pH 7, dialysed against the same buffer and used as the source of enzyme. The activity of the crude enzyme ranged from 250 Kunitz ml−1 to 300 Kunitz ml−1.

Effect of detergents on enzyme activity

Various commercial detergents, including Surf Excel, Surf, Ariel, Nirma, 501 bar soap, Snow White, Rin Shakthi, Dettol liquid soap and Denturite (7 mg ml−1) were incubated with 15 units of the alkaliphilic Bacillus NCL (87-6-10) xylanase at 40 °C for 5 h. Aliquots were withdrawn at intervals of 60 min and the residual activity was determined under standard assay conditions. Enzyme samples incubated in the absence of detergents served as controls.

Stability of xylanases to Surf Excel

Stability studies were carried out by incubating 0.1 unit of different commercial xylanases, including Pulpzyme HC, Biopulp and the alkaliphilic Bacillus strains NCL (87-6-10) and Sam III, with Surf Excel (7 mg ml−1) at 40 °C for 1 h, followed by determining the residual activity under standard assay conditions.

Effect of proteases on xylanases

The effects of the alkaline proteases Alcalase and Conidiobolus protease on the various xylanase preparations were determined by incubating 0.1 unit of the enzyme with 3 Kunitz of Alcalase and Conidiobolus protease at pH 10.0 at 40 °C for 60 min, followed by determining the residual activity under standard assay conditions. The control consisted of samples incubated in the absence of proteases. Conidiobolus protease at 3 Kunitz corresponded to 0.01% active enzyme by weight of composition, which was calculated from the specific activity (45 kilounits mg−1) of the purified C. coronatus protease [12].

Effect on purified xylanases

Studies at the effects of Surf Exel and alkaline proteases on purified xylanases (A, C) were carried out in a similar manner.

Washing test with xylanase preparations

The application of xylanase as a detergent additive was evaluated on pieces of white cloth (2×2 cm) stained with tea and grass extracts. The stained cloth pieces were dried overnight at 50 °C. The soiled cloth pieces were washed with 50 ml of water containing the detergent solution (0.7 mg ml−1) and crude or purified xylanases (0.1 unit ml−1) for 10 min at 40 °C. Controls consisted of soiled cloth pieces without enzyme treatment. The treated and untreated samples were compared visually, to evaluate the efficacy of the enzyme treatments.

Results and discussion

Activity as a function of pH

The alkaline xylanase from alkaliphilic Bacillus sp. NCL (87-6-10) was active over a broad pH range (pH 6.0–10.0). Since the xylanase was active at alkaline pH, studies on its compatibility and its applications in detergents were undertaken. Activities of the different xylanases at alkaline pH (pH 8.0, pH 10.0) and 40 °C are shown in Table 1. The alkaliphilic xylanase from Bacillus NCL (87-6-10) retained 50% of its initial activity at pH 10.0, while Biopulp exhibited only 10% of its activity. Pulpzyme HC and Sam III showed 30–40% of their initial activities, respectively. Optimal activity at pH 10.0 at 40 °C is ideal for enzyme formulations in detergents, as most washing operations are generally carried out at lower temperatures, due to high energy costs.

Compatibility of alkaliphilic Bacillus xylanase NCL (87-6-10) with commercial detergents

The enzyme showed high stability in the presence of Denturite ( a detergent used for cleaning dentures; Fig. 1). The stability of xylanase in the presence of other detergents ranged from 88% to 60% for 1 h. Dettol liquid soap was most inhibitory; and the enzyme lost more than 60% of its activity within 1 h.

Thus, the alkaline xylanase from alkaliphilic Bacillus was compatible with a wide range of commonly used detergents. Of these, Surf Excel gave the best results. Further experiments were carried out using Surf Excel.

Effect of Surf Excel on xylanase preparations

In order to compare the properties of the xylanase from alkaliphilic Bacillus NCL (87-6-10) with other xylanases, two commercially available xylanases, namely Pulpzyme HC and Biopulp, were also evaluated for their compatibility with Surf Excel. The xylanase from an isolate of alkaliphilic Bacillus Sam III was also included. Enzymes are generally incorporated at low concentrations (from 0.0005% to 0.5% active pure protein by weight) in detergent formulations [6, 7]. The enzymes were evaluated at a concentration of 0.1 unit ml−1 for 1 h. Alkaliphilic Bacillus NCL (87-6-10) xylanase retained approximately 75% of the initial activity after 60 min, whereas Pulpzyme HC exhibited only 10% of its activity. However, Biopulp and Sam III showed 60% and 40% of their initial activities respectively (Fig. 2). These studies indicate that the xylanase from the NCL strain retained a significant amount of its activity at concentrations as low as 0.1 unit. An enzyme concentration of 0.1 unit corresponded to 0.0005% of the composition by weight of active enzyme, based on a specific activity of 3045 units mg−1 protein [2], which lies within the desired range of 0.0005% to 0.5% by weight of active enzyme in Surf Exel.

Xylanase activity in the presence of Surf Excel

The xylanase was assayed in the presence of xylan at two different concentrations of Surf Excel (7.0 mg ml−1, 0.7 mg ml−1). Suitable controls were included and the results are shown in Table 2. The enzyme is not only stable but is active in the presence of detergents, even at concentrations as low as 0.03 unit in 7 mg Surf Excel ml−1.

Compatibility of xylanases with proteases in detergents

To increase the efficiency of detergents, a combination of proteases, amylases, cellulases and lipases are incorporated in the detergents. Among these, proteases form an important component of most detergent formulations. It is therefore desirable to have an enzyme that is active in the presence of proteases. Hence, the action of Alcalase and Conidiobolus protease on the different xylanases was studied. Conidiobolus protease has been reported from this laboratory to be compatible with detergents [13]. All four alkaline xylanases evaluated showed high stability (80%) towards protease action (data not shown ). Proteases are generally added at levels from 0.0001% to 2.0% active enzyme by weight of the composition. The concentration of the Conidiobolus protease used in the present work, namely 3 Kunitz (equivalent to 0.01% active enzyme) falls well within the range [6, 7]. Similar observations were made by Shikata et al. [16] and Singh et al. [17] for alkaline cellulases from alkaliphilic Bacillus species.

Effect on purified xylanases

Figure 3 shows the stability of the crude and purified xylanases A and C to detergents. Xylanase A was 100% active when incubated for 60 min with Surf Excel, while Xylanase C was inactivated markedly within 60 min. Fifty percent of Xylanase C was lost in 15 min when it was incubated with Surf Excel. Xylanase A was also more stable to Alcalase than xylanase C (Table 3).

Action of xylanases on soiled cloth

Figure 4 shows the effect of enzyme supplementation to Surf Excel in the cleaning efficiency of certain stains. In order to substantiate the results obtained with the crude culture broth, a homogenous preparation of xylanase A was also used to carry out the application trials. From Fig. 4, it is evident that the component of the culture filtrate which gave a boost to the cleaning performance was the xylanase enzyme.

Washing performance of alkaline xylanases from alkaliphilic Bacillus NCL (87-6-10) in the presence of detergents on tea stains (a) and grass stains (b). Sample 1 Untreated (control), sample 2 washed with detergents, sample 3 washed with detergents and crude xylanases, sample 4 washed with detergents and pure xylanase A. Xylanase was added at 0.1 units ml−1 in all cases

In conclusion, our studies show that the xylanases from alkaliphilic Bacillus sp. NCL (87-6-10) are not only compatible with a wide variety of commercial detergents of different formulations, but can also be used as a detergent additive.

References

Balakrishnan H, Dutta Choudhury M, Srinivasan MC, Rele MV (1992) Cellulase-free xylanase production from an alkalophilic Bacillus species. World J Microbiol Biotechnol 8:627–631

Balakrishnan H, Kamal Kumar B, Dutta-Choudhury M, Rele MV (2002) Characterization of alkaline thermoactive cellulase-free xylanases from alkalophilic Bacillus (NCL 87-6-10). J Biochem Mol Biol Biophys 6:325–334

Bedford MR, Classen HL (1992) The influence of dietary xylanase on intestinal viscosity and molecular weight distribution of carbohydrates in rye-fed broiler chicks. In: Visser J, Beldman G, Kusters–van Somerman MA, Voragen AGJ (eds) Xylans and xylanases. Elsevier Science, Amsterdam, pp 361–370

Estell DA, Wells JA (1988) Modified enzymes and methods for making same. US patent 4,760,025

Gupta R, Beg QK, Lorenz P (2002) Bacterial alkaline proteases: molecular approaches and industrial applications. Appl Microbiol Biotechnol 59:15–32

Herbots IMAJ, Moese RL, Baeck AC, Busch A (1998) Cleaning compositions comprising xylan degrading alkaline enzyme and bleaching agent. Patent WO 983943A1

Herbots IMAJ, Moese RL, Baeck AC, Busch A (1998) Cleaning compositions comprising xylan degrading alkaline enzyme and non-plant cell walls degrading enzyme. Patent WO 9839403A1

Ingale SS, Rele MV, Srinivasan MC (2002) Alkaline protease production by Basidiobolus (NCL 97.1.1): effect of ‘darmform’ morphogenesis and cultural conditions on enzyme production and preliminary enzyme characterization. World J Microbiol Biotechnol 18:403–408

Ito S, Shikata S, Ozaki K, Kawai S, Okamoto K, Inoue S, Takei A, Ohta Y, Satoh T (1989) Alkaline cellulase for laundry detergents: production by Bacillus sp. KSM 635 and enzymatic properties. Agric Biol Chem 53:1275–1281

Laskowski M (1955) Trypsinogen and trypsin. Methods Enzymol 2:26–36

Maat JM, Verbakel RJ, Stam H, Santos da Silva MJ, Bosse M, Egmond MR, Hagemans MLD, Gorcom RFM van, Hessing JGM, Hondel JJ van den, Rotterdam C van (1992) Xylanases and their application in bakery. In: Visser J, Beldman G, Kusters–van Somerman MA, Voragen AGJ (eds) Xylans and xylanases. . Elsevier Science, Amsterdam, pp 349–360

Phadatare SU (1991) Studies on alkaline proteases from Conidiobolus. PhD thesis, University of Poona, Pune, Maharashtva, India

Phadatare SU, Deshpande VV, Srinivasan MC (1993) High activity alkaline protease from Conidiobolus coronatus (NCL 86.8.20): enzyme production and compatibility with commercial detergents. Enzyme Microb Technol 15:72–76

Rao MB, Tanksale AM, Ghatge MS, Deshpande VV (1998) Molecular and biotechnological aspects of microbial proteases. Microbiol Mol Biol Rev 62:597–635

Schulein M, Oxenboll KM, Andersen LN, Lassen SF, Kauppinen MS, Nielsen JB (1996) An enzyme and enzyme preparation with endoglucanase activity. WO 96:11262

Shikata S, Saeki S, Okoshi H, Yoshimatsu T, Ozaki K, Kawai S, Ito S (1990) Alkaline cellulases for laundry detergents: production by alkalophilic strains of Bacillus and some properties of the crude enzymes. Agric Biol Chem 54:91–96

Singh J, Batra N, Sobti RC (2001) A highly thermostable, alkaline CMCase produced by a newly isolated Bacillus sp. VG1. World J Microbiol Biotechnol 17:761–765

Shah AK, Sidid SS, Ahmad A, Rele MV (1999) Treatment of bagasse pulp with cellulase-free xylanases from an alkalophilic Bacillus sp. Sam 3. Bioresource Technol 68:133–140

Srinivasan MC, Rele MV, Ingle S (1999) Production and application of enzymes stable to and active under extreme environments: An overview. Proceedings of the Indian National Science Academy (PINSA) B. 65:143–162

Paridon Pa van, Boonman JCP, Selten GCM, Geerse C, Barug D, Bot PHM de, Hemke G (1992) The application of fungal endoxylanase in poultry diets. Visser J, Beldman G, Kuster-van Somerman MA, Voragen AGJ (eds): Xylans and Xylanases. Elsevier Science. Amsterdam, pp 371–378

Viikari L, Kantelinen A, Sundquist J, Linko M (1994) Xylanases in bleaching: From an idea to the industry. FEMS Microbiol Rev 13:335–350

Acknowledgements

The authors thank Dr. V. Shankar and Dr. M.C. Srinivasan for their valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamal Kumar, B., Balakrishnan, H. & Rele, M.V. Compatibility of alkaline xylanases from an alkaliphilic Bacillus NCL (87-6-10) with commercial detergents and proteases. J IND MICROBIOL BIOTECHNOL 31, 83–87 (2004). https://doi.org/10.1007/s10295-004-0119-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-004-0119-8