Abstract

Carboxypeptidase produced by Monascus purpureus IFO 4478 was purified to homogeneity. The purified enzyme is a heterodimer with a molecular mass of 132 kDa and consists of two subunits of 64 and 67 kDa. It is an acidic glycoprotein with an isoelectric point of 3.67 and 17.0% carbohydrate content. The optimum pH and temperature were 4.0 and 40 °C, respectively. The enzyme was stable between pH 2.0 and 8.0 at 37 °C for 1 h, and up to 50 °C at pH 5.0 for 15 min. The enzyme was strongly inhibited by piperastatin A, diisopropylfluoride phosphate (DFP), phenylmethylsulfonylfluoride (PMSF), and chymostatin, suggesting that it is a chymotrypsin-like serine carboxypeptidase. Monascus purpureus carboxypeptidase was also strongly inhibited by p-chloromercuribenzoic acid (PCMB) but not by ethylenediaminetetraacetic acid (EDTA) and 1,10-phenanthroline, indicating that it requires cysteine residue but not metal ions for activity. Benzyloxycarbonyl-l-tyrosyl-l-glutamic acid (Z-Tyr-Glu), among the substrates tested, was the best substrate of the enzyme. The K m, V max, K cat, and K cat /K m values of the enzyme for Z-Tyr-Glu at pH 4.0 and 37 °C were 0.86 mM, 0.917 mM min−1, 291 s−1, and 339 mM−1 s−1, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Monascus species have been traditionally used in the fermentation industry in East Asia. In China, they are used to produce not only natural colorants but also red wine and red fermented soybean curd. In Okinawa, Japan, they are used for the production of tofuyo, which is a vegetable protein food made from soybean curd by the action of microorganisms. Tofuyo-making by Monascus has been studied in our laboratory [27, 29]. It was found that a large number of free amino acids (e.g. glutamic acid and aspartic acid) were produced during the maturation of tofuyo. This was considered to be the result of proteolytic enzymes produced by Monascus hydrolyzed soybean protein. However, knowledge of this process is very limited.

In order to elucidate the functions of Monascus enzymes in the maturation of tofuyo, they must be purified and characterized. In a previous study, the production, purification, and properties of an acid proteinase from Monascus were reported [28]. The acid proteinase is an endopeptidase that hydrolyzes proteins from their internal chain to peptides, but only to small amounts of free amino acids [30]. Thus, the action of acid proteinase is not enough to explain the occurrences of a large number of free amino acids during the maturation of tofuyo. By contrast, carboxypeptidase is an exopeptidase that releases free amino acids from the carboxyl termini of peptides or proteins. It is considered to serve as a key enzyme in the production of flavorful amino acids during the maturation of tofuyo. Although a large number of carboxypeptidases have been isolated from various species of fungi such as Aspergillus saitoi [10], A. oryzae [17, 19, 20, 21, 22, 23, 24], A. niger [4, 14], Absidia zychae [16], Mucor racemsus [7], Penicillium janthinellum [6, 9, 31], and Pycnoporus sanguineus [12], the Monascus enzyme has not yet been reported. In this study, we describe the purification and characterization of carboxypeptidase produced by M. purpureus IFO 4478.

Materials and methods

Organism and cultivation

M. purpureus IFO 4478 was used for the production of carboxypeptidase. The fungus was cultured at 28 °C for 6 days with shaking in a medium containing 2% soybean protein isolate (SPI), 1% glucose, 0.5% MgSO4·7H2O, 0.5% KH2PO4 (pH 6.0), with 1% (v/v) mineral solution (per ml: 15 mg CaCl2, 15 mg FeSO4·7H2O, 7.8 µg CuSO4·5H2O, 10 µg H3BO3, 10 µg MnSO4·5H2O, 70 µg ZnSO4, and 10 µg MoO3). The culture broth was filtered through No. 2 filter paper (Advantec, Japan). The filtrate was adjusted to pH 6.0 with 0.1 M citric acid and centrifuged at 10,000 g for 30 min. The supernatant was used as a crude enzyme solution for the purification.

Purification of the enzyme

All subsequent manipulations, except HPLC, were carried out at 4 °C.

Step 1. The crude enzyme solution was put on a DEAE-cellulose column (5.0×35 cm) equilibrated with 10 mM citrate/20 mM phosphate buffer (pH 6.0). After the column had been washed thoroughly with the same buffer but containing 0.1 M NaCl, the enzyme was eluted with the equilibrating buffer containing 0.2 M NaCl. Active fractions were collected, combined, concentrated by ultrafiltration (UHP-90 K, Advantec), and then dialyzed against 10 mM citrate/20 mM phosphate buffer (pH 6.0).

Step 2. The dialyzed enzyme solution was applied to a DEAE-Toyopearl 650 M column (1.5×20 cm) equilibrated with 10 mM citrate/20 mM phosphate buffer (pH 6.0). After the column had been washed thoroughly with the same buffer, the enzyme was eluted with a NaCl linear gradient from 0 to 0.4 M in the same buffer. Active fractions were collected, combined, concentrated by ultrafiltration (UHP-90 K, Advantec), and then dialyzed against 10 mM citrate/20 mM phosphate buffer (pH 6.0).

Step 3. The dialyzed enzyme solution was placed on a Q-Sepharose Fast Flow column (1.0×10 cm) equilibrated with 10 mM citrate/20 mM phosphate buffer (pH 6.0). After the column had been washed thoroughly with the same buffer, the enzyme was eluted with a NaCl linear gradient from 0 to 0.5 M in the same buffer. Active fractions were collected, combined, concentrated, and the sample buffer exchanged with 10 mM citrate/20 mM phosphate buffer (pH 6.0) containing 0.15 M NaCl by ultrafiltration (Centriprep YM-30, Millipore, USA).

Step 4. The exchanged enzyme solution was injected into a Superdex 200 HR10/30 column equilibrated with 10 mM citrate/20 mM phosphate buffer (pH 6.0) containing 0.15 M NaCl, and eluted with the same buffer at a flow rate of 0.5 ml/min. Active fractions were pooled, concentrated, and the sample buffer exchanged with 25 mM 1-methylpiperazine buffer (pH 5.70) by ultrafiltration (Centriprep YM-30, Millipore, USA).

Step 5. The exchanged enzyme solution was injected into a Mono P HR 5/5 column. Fractions were eluted with a pH gradient from 5.0 to 4.0 generated by 10% Polybuffer 74 (pH 3.97), followed by 20 ml of a NaCl gradient from 0 to 0.4 M in the same buffer at a flow rate of 0.5 ml/min. Active fractions were pooled, dialyzed against 10 mM citrate/20 mM phosphate buffer (pH 6.0), and stored at −20°C before use.

Enzyme and protein assay

Carboxypeptidase activity was determined using a modification of the method of Nakadai [18] with Z-Glu-Tyr as the substrate. The reaction mixture, containing 40 μl of enzyme solution and 160 μl of 5.0×10−4 M Z-Glu-Tyr in 0.05 M acetate buffer (pH 3.5), was incubated at 37 °C for 30 min. One unit of enzyme activity is defined as the amount of enzyme liberating 1 μmol tyrosine from the substrate per min under the applied conditions.

Protein concentrations were determined by the method of Bradford [2] with bovine serum albumin as the standard. Absorbance at 280 nm was used for monitoring protein concentrations in the fractions during the purification.

Carbohydrate content assay

Carbohydrate content was measured by the phenol sulfuric acid method [8] with d-(+)-mannose as standard.

Electrophoresis

PAGE of the enzyme was carried out by the method of Laemmli [15] using an 8.5% polyacrylamide gel in the presence of SDS (SDS-PAGE), or by the method of Davis [5] using a 10% polyacrylamide gel in the absence of SDS (native PAGE). The protein and carbohydrate bands in the gels were stained with Coomassie Brilliant blue R-250 and periodic acid-Schiff (PAS) reagent according to the method of Zacharius [32], respectively. Isoelectric focusing (IEF)-PAGE was carried out with a pH gradient of 3.5–9.5 generated by ampholine pH 3.5–9.5 (Amersham Pharmacia Biotech, USA). The isoelectric point of the purified enzyme was determined using pI marker proteins from a broad pI calibration kit (Amersham Pharmacia Biotech, USA).

Characterization of the enzyme

The molecular mass of the native and denatured enzyme was estimated by gel filtration on a Superdex 200 HR 10/30 column using the method of Andrews [1] and by SDS-PAGE using the method of Weber [26]. Molecular mass marker proteins (Oriental Yeast, Japan) and polypeptide SDS-PAGE standards (Broad Range, Bio-Rad, Japan), respectively were used for calibration.

To estimate the pH and thermal stabilities, the enzyme was pre-incubated at different pHs at 37 °C for 60 min and at different temperatures at pH 5.0 for 15 min, respectively. Residual activities were determined by the above-described method.

To estimate the effects of various compounds on enzyme activity, the enzyme was pre-incubated with 1 mM of these compounds at 37 °C for 15 min (DFP and PMSF for 2 h), and the residual enzyme activity was measured by the above-described method.

The kinetic parameters of the enzyme for Z-Tyr-Glu at pH 4.0 and 37 °C were calculated from a Lineweaver-Burk plot.

Materials

Monascus purpureus IFO 4478 was obtained from the Institute for Fermentation, OSAKA (Osaka, Japan). Synthetic peptides such as Z-Tyr-Glu, Z-Glu-Tyr and Z-Glu-Phe were purchased from the Peptide Institute, Inc. (Osaka, Japan). DEAE-cellulose and DEAE-Toyopearl 650 M were obtained from Whatman Biosystems (Kent, England) and TOSOH (Tokyo, Japan), respectively. Q-Sepharose Fast Flow, Superdex 200 HR 10/30, and Mono P HR 5/5 were from Amersham Pharmacia Biotech (Uppsala, Sweden). All other chemicals used were of analytical grade.

Results

Production of the enzyme

Preliminarily screening, carried out using 28 strains of Monascus, revealed that M. purpureus IFO 4478 exhibited the highest ability to produce carboxypeptidase (data not shown); therefore, this strain was chosen for production of the enzyme. The effect of various nitrogen sources in the medium on enzyme production by strain IFO 4478 was examined (Table 1). The enzyme was induced by most organic nitrogen sources (SPI, 64.2 mU/ml; tryptone, 53.3 mU/ml; polypeptone, 32.6 mU/ml; peptone, 32.2 mU/ml), but not by urea or inorganic nitrogen sources. SPI exhibited the highest ability to induce carboxypeptidase, and the addition of SPI at an initial concentration of 2.0% resulted in maximal activity.

Purification of the enzyme

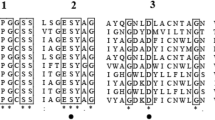

The purification procedures are summarized in Table 2. The enzyme was purified to homogeneity, corresponding to a 213-fold increase compared to the crude enzyme, and a 4% yield. The final enzyme preparation exhibited a single protein band following native-PAGE (Fig. 1B) and IEF-PAGE gel in the absence of urea (native IEF-PAGE, data not shown). However, two protein bands were detected following SDS-PAGE (Fig. 1A) and IEF-PAGE in the presence of urea (denatured IEF-PAGE, data not shown). These results suggested that the enzyme consists of two different polypeptides.

Characterization of the enzyme

The molecular mass of the native enzyme was estimated as 132 kDa by gel filtration. The two protein bands detected on SDS-PAGE gel with (Fig. 1A) or without 2-mercaptoethanol (data not shown) corresponded to molecular mass of 64 and 67 kDa, respectively. These results indicated that the final enzyme preparation is a heterodimer with two subunits linked by a non-disulfide bond.

PAS staining on the native-PAGE gel showed that the purified enzyme is a glycoprotein (Fig. 1C) with 17.0% carbohydrate content. The isoelectric point of the enzyme is estimated to be 3.67 by slab IEF electrophoresis. The optimum pH and temperature of the enzyme for Z-Glu-Tyr were around 4.0 and 40 °C, respectively. The enzyme is stable between pH 2.0 and 8.0 at 37 °C for 1 h, and up to 50 °C at pH 5.0 for 15 min.

The effects of various metal salts and reagents on the enzyme activity were examined at pH 4.0 as shown in Table 3. The enzyme was completely inhibited by Sn2+ and SDS, strongly inhibited by Pb2, Fe3+, DFP, PMSF, piperastatin A, chymostatin, and PCMB, partially inhibited by Hg2+ and TPCK, but not inhibited by EDTA and 1,10-phenanthroline. In addition, the enzyme was not activated by metal ions, indicating that it is a chymotrypsin-like serine carboxypeptidase, and that there may be cysteine and histidine residues but no metal ion in or near its active site.

The substrate specificity of the enzyme is shown in Table 4. The enzyme has a broad substrate specificity catalyzing the hydrolysis of various peptides. Among the substrates tested, Z-Tyr-Glu was the best substrate of the enzyme, followed by Z-Glu-Phe and Z-Glu-Tyr. The enzyme prefers peptides containing an aromatic or glutamic acid in the C-terminal position (P1′) or penultimate position (P1) of the C-terminus, suggesting that it possesses chymotrypsin-like activity. The enzyme did not nearly hydrolyze peptides containing an amide group in the C-terminal position (P1′) or proline or glycine in the penultimate position (P1).

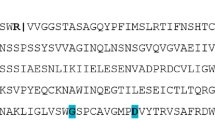

The kinetic parameters of the enzyme for Z-Tyr-Glu at pH 4.0 and 37 °C were calculated from a Lineweaver-Burk plot (Fig. 2). The K m, V max, k cat, and k cat/K m of the enzyme were 0.86 mM, 0.917 mM min−1, 291 s−1, and 339 mM−1 s−1, respectively.

Discussion

In preliminary experiments, we found that M. purpureus IFO 4478 exhibited the highest ability to produce carboxypeptidase among 28 strains of the genus Monascus. Further experiments on induction of the enzyme by various nitrogen compounds suggested that SPI was the most potent inducer of carboxypeptidase from M. purpureus IFO 4478. It has also been reported that carboxypeptidases from Aspergillus saitoi and Penicillium janthinellum are induced by defatted soybean [11, 31].

The M. purpureus IFO 4478 enzyme was purified to homogeneity and characterized. Inhibitory and specificity studies on the purified enzyme suggested that it is a chymotrypsin-like serine carboxypeptidase. Serine carboxypeptidases are widely distributed in fungi as well as in higher plants and animal tissues, but they are particularly abundant in filamentous fungi [3]. Carboxypeptidase from M. purpureus IFO 4478, like most other fungal serine carboxypeptidases, has an acidic optimal pH and requires a serine residue, but not metal ions for its catalytic activity [3]. Serine carboxypeptidase from M. purpureus IFO 4478 was strongly inhibited by PCMB, partially by TPCK, indicating that cysteine and histidine residues are located in or near its active site, similar to the serine carboxypeptidase from yeast [13].

SDS-PAGE and molecular mass analysis of the purified enzyme revealed that it is a heterodimer with a native molecular mass of 132 kDa. The enzyme comprises two different subunits, of 64 and 67 kDa, linked by a non-disulfide bond. Although carboxypeptidases from other fungi, such as those from A. saitoi [10] and A. niger [14], carboxypeptidase Ib, I, II, and O from A. oryzae [17, 19, 20, 24], and carboxypeptidase S2 from P. janthinellum [9] have similar molecular masses, they are not heterodimers, but either homodimers or homotrimers [10] whose subunits are made up of a single polypeptide chain linked by disulfide bridge. The serine carboxypeptidase from M. racemosus is also a heterodimer [7], but with a lower native molecular mass of 52 kDa. That enzyme comprises two different subunits, of 31and 18 kDa, linked by a disulfide bridge.

Serine carboxypeptidase from M. purpureus, like most other fungal carboxypeptidases, is an acidic glycoprotein with an isoelectric point of 3.67 and 17.0% carbohydrate content. The isoelectric point is similar to that of carboxypeptidase I from A. niger [4] and carboxypeptidase S1 from P. janthinellum [9]; however, the carbohydrate content is lower than that of carboxypeptidase I from A. niger [4] and higher than that of carboxypeptidase S1 from P. janthinellum [9].

The relative hydrolysis rates of N-acylpeptides indicated that the enzyme, like acid carboxypeptidase from A. saitoi [10], prefers substrates with bulky amino acids, such as glutamic acid, tyrosine, and phenylalanine, in the penultimate position (P1) from the C-terminus, but it also prefers substrates with bulky amino acids in the C-terminal position (P1′), in contrast to the enzyme from A. saitoi [10], which prefers substrates with neutral and basic amino acids, even proline, in the C-terminal position (P1′). The M. purpureus enzyme, like acid carboxypeptidases from A. oryzae var. viride [17], does not hydrolyze peptides with glycine or proline in the penultimate position (P1). Z-Tyr-Glu was the best substrate of carboxypeptidase from M. purpureus, also similar to carboxypeptidase Ib from A. oryzae var. viride [17]. This is consistent with the findings that glutamic acid is the one of the most abundant free amino acids found in matured tofuyo [27, 29]. Z-Glu-Tyr was also reported to be the best substrate of acid carboxypeptidases III, IV, O-1, and O-2 from A. oryzae [21, 22, 23], carboxypeptidases Z-1 and Z-2 from A. zychae [16], and carboxypeptidase S1 from P. janthinellum [9], while Z-Glu-Phe was the best substrate of serine carboxypeptidase from P. carneus [25]. In the present study, both Z-Glu-Tyr and Z-Glu-Phe were good substrates of carboxypeptidase from M. purpureus. Thus, carboxypeptidase from M. purpureus appears to play an important role in removing the bitter compounds from soybean proteins and peptides during the maturation of tofuyo.

This is the first report on the purification and characterization of a serine carboxypeptidase from the genus Monascus. Although it is similar to other fungal serine carboxypeptidases in its molecular mass, glycoprotein, pI, optimum pH, and substrate specificity, it differs in its protein structure (heterodimer, the two subunits of which are not linked by a disulfide bond). Therefore, it seems to be a new type of fungal serine carboxypeptidase. Cloning and sequencing of the gene encoding the M. purpureus serine carboxypeptidase will elucidate the molecular features of the enzyme. In addition, the large-scale synthesis of this enzyme and its application in the food industry will be the subjects of further studies.

References

Andrews P (1965) The gel-filtration behavior of proteins related to their molecular weights over a wide range. Biochem J 96:595–606

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Breddam K (1986) Serine carboxypeptidase: a review. Carlsberg Res Commun 51:83–128

Dal Degan F, Ribadeau-Dumas B, Breden K (1992) Purification and characterization of two serine carboxypeptidases from Aspergillus niger and their use in C-terminal sequencing of proteins and peptide synthesis. Appl Environ Microbiol 58:2144–2152

Davis BJ (1964) Disc electrophoresis. II. Method and application to human serum proteins. Ann NY Acad Sci 121:404–427

Dey ES, Aasmul-Olsen S (1993) Novel serine penicillocarboxypeptidase CPD-S3 from Penicillium janthinellum IBT 3991: purification characterization, and uses in peptide synthesis and modification. Enzyme Microb Technol 15:1042–1050

Disanto ME, Li QH, Logan DA (1992) Purification and characterization of a developmentally regulated carboxypeptidase from Mucor racemosus. J Bacteriol 174:447–455

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugar and related substances. Anal Chem 38:350–356

Hofmann T (1976) Penicillocarboxypeptidase S-1 and S-2. Methods Enzymol 45:587–599

Ichishima E (1972) Purification and characterization of a new type of acid carboxypeptidase from Aspergillus. Biochem Biophys Acta 258:274–288

Ichishima E, Yamane A, Nitta T, Kinoshita M, Nikkuni S, Oka T, Yokoyama S (1973) Production of a new type of acid carboxypeptidase of molds of the Aspergillus niger group. Appl Microbiol 26:327–331

Ichishima E, Yoshimura K, Tomoda K (1983) Acid carboxypeptidase from a wood-deteriorating basidiomycete, Pycnoporus sanguineus. Phytochemistry 22:825–829

Kuhn RW, Walsh KA, Neurath H (1974) Isolation and partial characterization of an acid carboxypeptidase from yeast. Biochemistry 13:3871–3877

Kumagai I, Yamasaki M, Ui N (1981) Isolation, purification and some chemical properties of an acid carboxypeptidase from Aspergillus niger var. Macrosporus. Biochim Biophys Acta 659:334–343

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Lee BR, Takeuchi M, Kobayashi Y (1993) Purification and characterization of serine carboxypeptidase from Absidia Zychae. Biosci Biotechnol Biochem 57:618–622

Mikami S, Miura O, Watanabe T, Iwano K, Shinoki S, Shimada T, Nunokawa Y (1987) Purification and some properties of acid carboxypeptidase from Sake koji. Hakkokogaku (in Japanese) 65:37–43

Nakadai T, Nasuno S, Iguchi N (1971) Quantitative estimation of activities of peptidases in Koji. Tyoumikagaku (in Japanese) 18:435–441

Nakadai T, Nasuno S, Iguchi N (1972) Purification and properties of acid carboxypeptidase I from Aspergillus oryzae. Agric Biol Chem 36:1343–1352

Nakadai T, Nasuno S, Iguchi N (1972) Purification and properties of acid carboxypeptidase II from Aspergillus oryzae. Agric Biol Chem 36:1473–1480

Nakadai T, Nasuno S, Iguchi N (1972) Purification and properties of acid carboxypeptidase III from Aspergillus oryzae. Agric Biol Chem 36:1481–1488

Nakadai T, Nasuno S, Iguchi N (1973) Purification and properties of acid carboxypeptidase IV from Aspergillus oryzae. Agric Biol Chem 37:1237–1251

Takeuchi M, Ushijima T, Ichishima E (1982) A new acid carboxypeptidase, O-1, from Aspergillus oryzae. Curr Microbiol 7:19–23

Takeuchi M, Ichishima E (1986) A 155 K acid carboxypeptidase O from Aspergillus oryzae. Agric Biol Chem 50:633–638

Umetsu H, Hishinuma K, Wake E, Ichishima E (1996) Production, purification, and properties of serine carboxypeptidase from Paecilomyces carneus. Curr Microbiol 33:44–48

Weber K, Pringle JR, Osborn M (1972) Measurement of molecular weights by electrophoresis on SDS-acrylamide gel. Methods Enzymol 26:3-27

Yasuda M (1990) Studies on manufacturing of tofuyo. Nippon Shokuhin Kogyo Gakkaishi (in Japanese) 37:403–409

Yasuda M, Shimabukuro M, Kikuchi S (1991) Production, purification and properties of acid proteinase from genus Monascus. Nippon shokuhin kogyo Gakkaishi 38:954–961

Yasuda M, Matsumoto T, Sakaguchi M, Kobamoto N (1993) Changes in chemical components of tofuyo prepared by Monascus fungus during fermentation. Nippon Shokuhin Kogyo Gakkaishi (in Japanese) 40:331–338

Yasuda M, Sakaguchi M (1998) Degradation of soybean protein by an acid proteinase from Monascus anka. Food Sci Technol Int Tokyo 4:6–8

Yokoyama S, Oobayashi A, Tanabe O, Ichishima E (1974) Submerged production, purification, and crystallization of acid carboxypeptidase from Penicillium janthinellum IFO-8070. Appl Microbiol 28:742–747

Zacharius RM, Zell TE, Morrison JH, Woodlock JJ (1969) Glycoprotein staining following electrophoresis on acrylamide gels. Anal Biochem 30:148–152

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, F., Tachibana, S., Taira, T. et al. Purification and characterization of a new type of serine carboxypeptidase from Monascus purpureus . J IND MICROBIOL BIOTECHNOL 31, 23–28 (2004). https://doi.org/10.1007/s10295-004-0107-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-004-0107-z