Abstract

Escherichia coli is an attractive candidate as a host for polyketide production and has been engineered to produce the erythromycin precursor polyketide 6-deoxyerythronolide B (6dEB). In order to identify and optimize parameters that affect polyketide production in engineered E. coli, we first investigated the supply of the extender unit (2S)-methylmalonyl-CoA via three independent pathways. Expression of the Streptomyces coelicolor malonyl/methylmalonyl-CoA ligase (matB) pathway in E. coli together with methylmalonate feeding resulted in the accumulation of intracellular methylmalonyl-CoA to as much as 90% of the acyl-CoA pool. Surprisingly, the methylmalonyl-CoA generated from the matB pathway was not converted into 6dEB. In strains expressing either the S. coelicolor propionyl-CoA carboxylase (PCC) pathway or the Propionibacteria shermanii methylmalonyl-CoA mutase/epimerase pathway, methylmalonyl-CoA accumulated up to 30% of the total acyl-CoA pools, and 6dEB was produced; titers were fivefold higher when strains contained the PCC pathway rather than the mutase pathway. When the PCC and mutase pathways were expressed simultaneously, the PCC pathway predominated, as indicated by greater flux of 13C-propionate into 6dEB through the PCC pathway. To further optimize the E. coli production strain, we improved 6dEB titers by integrating the PCC and mutase pathways into the E. coli chromosome and by expressing the 6-deoxyerythronolide B synthase (DEBS) genes from a stable plasmid system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyketides are natural products produced by bacteria, fungi and plants. They are a structurally diverse class of compounds, displaying a broad range of activities with applications in human medicine (antibacterials, antifungals, anticancers, immunosuppressants), veterinary medicine (antihelmintics), and agriculture (insecticides) [16]. A potential barrier to production of many therapeutically important polyketides for clinical testing and subsequent large-scale manufacturing is the lack of tractable fermentation hosts. Native polyketide producers can have characteristics that limit their utility for large-scale polyketide production: they sometimes grow slowly and are often difficult to transform with DNA or to manipulate genetically. The genetic tractability and favorable fermentation properties of Escherichia coli make it an attractive candidate host for polyketide production. However, since E. coli does not naturally produce polyketides, it does not contain or express many of the biosynthetic pathway genes necessary for polyketide biosynthesis.

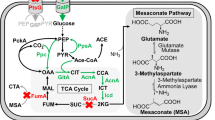

E. coli has been engineered to produce both the fungal polyketide 6-methylsalicylic acid [9] and the complex erythromycin precursor polyketide 6-deoxyerythronolide B (6dEB) [17]. The latter is produced by the successive condensation of one propionyl-CoA and six (2S)-methylmalonyl-CoA molecules by the 6-deoxyerythronolide B (DEBS) polyketide synthase (see Fig. 1). DEBS is composed of a loading module and six extension modules, each of which is responsible for one cycle of polyketide chain elongation. Each module consists of a ketosynthase (KS), acyltransferase (AT) and acyl carrier protein (ACP) domain. Post-translational modification of a serine in the ACP domain with the 4′-phosphopantetheine moiety from coenzyme A is required for enzyme activity. In addition to the KS, AT and ACP domains, each module contains up to three additional processing domains—the ketoreductase (KR), dehydratase (DH), and enoyl reductase (ER) domains—which are responsible for modifying the oxidation state of the β-carbon after each cycle of condensation. Biosynthesis of 6dEB in E. coli required production of propionyl-CoA via expression of the propionyl-CoA ligase prpE, production of (2S)-methylmalonyl-CoA via expression of the propionyl-CoA carboxylase (PCC) genes pccB and accA1, expression of the 4′-phosphopantetheinyl transferase sfp, and expression of the three subunits of the DEBS polyketide synthase, DEBS1–3 [17]. In this system, the genes were expressed from T7 promoters with prpE and sfp integrated into the chromosome, and the remaining five genes expressed from two plasmids. This strain demonstrated the feasibility of producing a complex polyketide in E. coli, with titers reaching a maximum of between 80 and 100 mg/l in high cell density fermentations [18].

In the present study, we sought to rationally improve E. coli 6dEB production by altering strain architecture. First, we evaluated three pathways for the production of (2S)-methylmalonyl-CoA (see Fig. 1): (1) Streptomyces coelicolor PCC [19], (2) Propionibacteria shermanii methylmalonyl-CoA mutase/epimerase [11, 14], and (3) S. coelicolor malonyl/methylmalonyl-CoA ligase (matB) [1] (Andreas Schirmer, unpublished data). Next, we integrated the methylmalonyl-CoA production pathways into the chromosome and examined alternative plasmids with compatible origins of replication for DEBS expression. The genetic tractability of E. coli facilitated rational metabolic engineering to both increase our understanding of the parameters influencing 6dEB production and to produce a strain with improved polyketide titers.

Materials and methods

Chemicals

Antibiotics were used at the following concentrations: carbenicillin (carb) 100 µg/ml, kanamycin (kan) 50 µg/ml, streptomycin (strep) 20 µg/ml, and tetracycline (tet) 7.5 µg/ml. [3H]β-Alanine (50 Ci/mmol) was purchased from American Radiolabeled Chemicals. [13C3]Propionate was purchased from Aldrich. Sodium propionate, monosodium glutamate, succinic acid, methylmalonic acid, and hydroxocobalamin were purchased from Sigma and prepared as stock solutions, which were adjusted to pH 7.0–7.4. Glass beads (106 µm, acid washed) and acyl-CoA thioesters were purchased from Sigma. The CoA standard mix contained 0.5 mM CoA and 1.6 mM each of malonyl-, methylmalonyl-, succinyl-, acetyl-, propionyl-, and butyryl-CoA.

Strains

The E. coli polyketide production strain BAP1 has been described previously [17]. To facilitate radioactive acyl-CoA analyses, a point mutation in panD, panDS25A, was introduced into BAP1 to produce strain K173–145 (see Table 1; Kennedy et al., in preparation). The genes for the two subunits of S. coelicolor PCC were integrated into the E. coli chromosome to produce the strain K207–3. The PCC genes, accA1 and pccB [19], were cloned into intermediate vectors, each under control of the T7 promoter. The expression cassette containing the PCC genes was then inserted into the region of DNA homologous to the E. coli ygfG gene. The ygfG gene codes for a putative methylmalonyl-CoA decarboxylase[5]; hence, integration into the ygfG locus inactivated ygfG and abolished ygfG-catalyzed methylmalonyl-CoA decarboxylase activity in E. coli. The DNA cassette containing the ygfG homology arms and PCC genes was introduced into the E. coli integration vector pKO3, and the expression cassette was integrated into the ygfG locus in E. coli strain K173–145 as described by Link et al. [12]. The resulting strain, K207–3, contained the PCC cassette (T7prom – accA1- T7prom – pccB – T7term) integrated into the E. coli ygfG locus. To construct an E. coli strain able to produce (2S)-methylmalonyl-CoA from succinyl-CoA, and butryryl-CoA from butyrate, the genes for P. shermanii methylmalonyl-CoA mutase (mutAB), the gene for S. coelicolor methylmalonyl-CoA epimerase (epi) [3] and the gene for E. coli atoC were integrated into the E. coli chromosome to produce strain K214–37. The E. coli atoC gene is a transcriptional activator of the E. coli atoA and atoD genes, the products of which comprise an acyl-CoA transferase that transfers CoA from acetyl-CoA to butyrate [2]. To construct the integration cassette, the genes were first cloned into intermediate vectors, placing each gene under control of a T7 promoter. As described above for the PCC genes, the expression cassette containing mutase, epimerase and atoC from pKOS207–15a (see below) was next inserted into the region of DNA homologous to the E. coli ygfG gene and introduced into the E. coli integration vector pKO3, which was integrated into the ygfG locus in E. coli strain K173–145 as described by Link et al. [12]. The resulting strain, K214–37, contained the mutase/atoC cassette (T7prom–mutAB–T7prom–epi–T7prom–atoC–T7term) integrated into the E. coli ygfG locus.

Plasmids

The DEBS genes expressed from T7 promoters in plasmids pBP130 and pBP144 have been described previously [3, 17] (see Table 2). The T7prom-pccB-rbs-accA1 cassette was deleted from pBP144 by digestion with BglII and NdeI followed by ligation with a 0.1-kb BglII-NdeI fragment from pET26b (Novagen) to make pKOS173-158, which contains the DEBS1 gene under the control of the T7 promoter. The DEBS3 gene was deleted from pBP130 by digestion with EcoRI and religating to make pKOS164-176, while the DEBS2 gene was deleted from pBP130 by digestion with NdeI and religating to make pKOS173-159. The chloramphenicol resistance gene was removed from pACYC184 (p15A origin, New England Biolabs) by digestion with BsmBI and Bsu36I. The linear vector backbone was ligated with a synthetic linker containing PacI, SpeI, HindIII, EcoRI, BglII, SphI, NsiI and AvrII sites to produce tetR, cmS pKOS164-185. The sulphonamide and streptomycin resistance genes (sul and str) were removed from pRSF1010 [20] by digestion with SapI and NotI. They were replaced with a PCR-generated fragment containing both the streptomycin/spectinomycin resistance gene aadA from pAY1105 [13] as well as unique restriction sites for AvrII, NsiI, SphI, BglII, EcoRI, HindIII, and PacI to give pKOS173-171. The T7prom-DEBS2-T7term cassette was subcloned from pKOS164-176 into pKOS164-185 as a BglII-PacI fragment to give pKOS207-4. For construction of pKOS173-176, the T7prom-DEBS3-T7term cassette was isolated as a SphI–PacI fragment from pKOS173-159 and cloned into pKOS173-171. For construction of pKOS207-129, the DEBS3 gene was excised from pKOS173-176 as a NdeI–EcoRI fragment and replaced with the NdeI–EcoRI fragment containing the DEBS1 gene from pKOS173-158. pKOS214-175 is a derivative of pKOS173-158 with the loading domain of DEBS1 deleted (DEBS1ΔATLACPL; Kennedy et al., in preparation).

The S. coelicolor PCC genes, accA1 and pccB, were initially cloned as PCR products with NdeI sites introduced at the start codons. The sfp gene in pKOS116-172a [3] was removed by NdeI–NsiI digestion and replaced with pccB to give pKOS164-158b. The mutAB genes in pKOS116-95b [3] were removed by digestion with NdeI and HindIII, and replaced with accA1 to give pKOS164-158a. The plasmid for co-expression of accA1 and pccB, pKOS164-159, was constructed by subcloning the T7prom-accA1 fragment from pKOS164-158a into pKOS164-158b as a PacI–NsiI fragment. This plasmid contains two T7 promoters directing the tandem expression of accA1 and pccB with a single T7 terminator. The T7prom-accA1-T7-pccB-T7term cassette was subcloned from pKOS164-159 as a BclI–NheI fragment into BclI–AvrII digested pKOS207-15a (see below) to generate pKOS143-189, allowing expression of these genes from a pACYC backbone.

Construction of a pET-based expression vector for the translationally coupled P. shermanii mutase genes (mutAB) has been described [3]. The S. coelicolor epimerase gene was cloned as a NdeI/NsiI fragment into pKOS116-172a to generate pKOS143-21-13 [3]. The T7prom-epi gene was excised from this plasmid as a PacI/NsiI fragment and cloned into pKOS133-9b, a pET plasmid containing PacI and NsiI sites directly downstream of the mutAB genes [3], generating pKOS143-24-13 with the configuration T7prom-mutAB-T7-epi-T7term. The mutAB/epi cassette from this plasmid was excised as a BclI/NsiI fragment and cloned into pKOS164-185 to generate pKOS207-10a. The atoC gene was PCR amplified from E. coli genomic DNA with a NdeI site introduced at the start codon and cloned as a NdeI/AvrII fragment in pKOS116-172a to generate pKOS149-52-45. The NsiI/AvrII fragment containing T7prom-atoC was excised from pKOS149-52-45 and introduced into NsiI/AvrII-restricted pKOS196-7 (Misty Piagentini, unpublished data) to place this fragment upstream of a T7 terminator, generating pKOS207-9. The T7prom-atoC-T7term fragment from pKOS207-9 was excised as a NsiI/NheI fragment and cloned into NsiI/AvrII-restricted pKOS207-10a to generate pKOS207-15a with the configuration T7prom-mutAB-T7prom-epi-T7prom-atoC-T7term.

The S. coelicolor matB gene was cloned as a glutathione-S-transferase (GST) N-terminal fusion into a pGEX expression vector yielding pKOS132-44 (Andreas Schirmer, unpublished data). The GST tag was amplified by PCR from pKOS132-44 and the PCR product was digested with NdeI and BamHI. MatB was excised with BamHI and NsiI from pKOS 211-142-235 (Sarah Mutka, unpublished data). These two fragments were cloned into NdeI/NsiI-digested pKOS116-172a [3] downstream of the T7 promoter. The T7prom-GST-matB was excised from this vector as a BglII/AvrII fragment and inserted into BclI/SpeI-restricted pKOS207-15a to yield pKOS217-45-2 with the final configuration T7prom-GSTmatB-T7prom-epi-T7prom-atoC-T7term.

Acyl-CoA analysis

Luria/Bertani (LB) medium (1 ml in 16×100 mm culture tubes) containing 10 µCi β-alanine was inoculated with 20 µl overnight culture. The culture was grown and induced as described in the "Polyketide analysis" section. Following growth of the cultures for up to 40 h at 22°C, cells from 1-ml cultures were collected by centrifugation and re-suspended in 300 µl cold 10% trichloroacetic acid (TCA) containing 5 µl CoA standard mix. Glass beads (0.15 ml) were added and the samples were vortexed at 4°C for 2 min. Precipitated protein was removed by centrifugation and 100 µl supernatant was loaded onto an HPLC. HPLC was performed using a 150×4.6-mm 5-µm ODS-3 Inertsil HPLC column (Ansys Technologies). HPLC buffer A contained 100 mM NaH2PO4, 75 mM NaOAc, pH 4.6, and buffer B contained 40% buffer A, 60% methanol. The HPLC column was equilibrated with 90% buffer A/10% buffer B at a flow rate of 1 ml/min. After sample injection, a linear gradient to 30% buffer B was formed over 18 min, followed by a linear gradient to 100% buffer B over 4 min and finishing with a linear gradient back to 10% buffer B over 1 min. The eluant was monitored at 260 nm and by on-line radiometric detection. The intracellular radiolabeled acyl-CoAs were identified by coelution with authentic unlabeled standards.

Polyketide analysis

Fresh transformants of polyketide production strains were grown in LB medium, supplemented with appropriate antibiotics. Except where noted, LB medium (25 ml in 250-ml shake flasks with appropriate antibiotics as necessary) was inoculated with 0.5 ml overnight culture (1:50 dilution). Cultures were grown at 37°C until the OD600 reached 0.4–0.5, then cooled to 25°C. The cultures were induced with IPTG to 0.5 mM final concentration, and appropriate media supplements were added. Media supplements were added to the following final concentrations where indicated: 5 mM propionate, 5 µM hydroxocobalamin (added in the dark), 50 mM succinate, 50 mM glutamate. Following induction, the cultures were grown for an additional 48 h at 22°C. The OD600 was determined at the end of the fermentation and the E. coli cells were collected by centrifugation. Cell-free supernatant (5 ml) was extracted with ethylacetate. The organic fraction (top layer) was removed and dried under vacuum. The residue was re-suspended in 500 µl methanol, and the polyketide product was detected by LC-MS and quantified by ELSD, as previously described [3]. Polyketides were quantified by comparing the peak area from the ELSD with a standard curve of peak areas generated from an authentic sample. Polyketide titers are reported with standard errors as the average of duplicate or triplicate samples, determined from independent colonies of the strain analyzed.

Isolation of in vivo methylmalonyl-CoA and conversion to succinyl-CoA in vitro

K173-145, expressing the DEBS genes from pKOS173-158 and pBP130, and GST-matB/epi/ atoC from pKOS217-45-2, was fed 10 mM propionate and 5 mM methylmalonate post-induction. The culture was grown for 29 h, and the cell-free extract was analyzed for 6dEB production, as described. A parallel sample was subjected to acyl-CoA analysis, and the putative methylmalonyl-CoA was isolated. The 3H-labeled methylmalonyl-CoA peak (1 ml) was collected and dried under vacuum to 500 µl final volume to remove the organic solvent. An aliquot of the collected sample (1/20) was re-applied to HPLC to confirm that the isolated compound co-eluted with the unlabeled methylmalonyl-CoA standard. The remaining sample was adjusted to pH 7 with potassium phosphate and incubated with (1) purified E. coli methylmalonyl-CoA mutase (Sbm-6His) or (2) Sbm-6His and purified P. shermanii methylmalonyl-CoA epimerase [3]. After 20 min at 30°C, the samples were analyzed by HPLC using the method described for acyl-CoA analysis.

Combined mutase/epimerase/PCC pathways:13C propionate labeling

LB/tet media (7 ml in 25×150-mm culture tubes) was inoculated with 70 µl overnight cultures. The cultures were grown at 37°C until the OD600 reached 0.5, then cooled to 25°C. The cultures were induced and succinate, glutamate, hydroxocobalamin, and [13C3]propionate (to 5 mM) were added as described in the "Polyketide analysis" section. Growth was continued for 48 h at 22°C. Cell-free media (5 ml) was extracted with an equal volume of ethyl acetate, the ethyl acetate was dried under vacuum, and the sample was re-suspended in methanol. The samples were analyzed by LC/MS/MS on a system comprised of an Agilent 1100 HPLC and an Applied Biosystems API3000 triple quadrupole mass spectrometer equipped with a Turboion spray source operated in positive ion mode. For analysis, 10 μl analyte was loaded onto an Inertsil ODS-3 column (2.1×150 mm, 5 μm, Ansys Technologies) and eluted with a linear gradient of 35% MeCN (0.1% acetic acid) to MeCN (0.1% acetic acid) at 0.25 ml/min over 10 min. The eluate was introduced into the mass spectrometer unsplit and subjected to multiple reaction monitoring of the following transitions: m/z 387→239; 390→239; 390→242; 393→239; 393→242; 393→245; 396→242; 396→245; 396→248; 399→245; 399→248; 399→251; 402→248; 402→251; 402→254; 405→254; 408→254. The ratios of the various 13C-labeled 6dEBs were estimated by comparing the areas of the chromatograms generated from each of the reactions.

Results

Production of methylmalonyl-CoA in E. coli

In vivo acyl-CoA analysis is a qualitative assessment of the relative composition of the intracellular acyl-CoA pool. A mutation in the panD gene, which encodes aspartate decarboxylase that catalyzes the conversion of aspartate to β-alanine, allows radioactive labeling of CoA upon feeding with [3H]β-alanine [3, 6]. Since significant levels of polyketide production were observed only in rich medium, the acyl-CoA analyses presented here were derived from cultures grown in LB medium to allow determination of the acyl-CoA profile under polyketide production conditions. Although it is possible to measure relative acyl-CoA levels in LB medium upon feeding with [3H]β-alanine, absolute acyl-CoA levels are difficult to determine due to isotopic dilution. We have previously demonstrated that introduction of the mutase/epimerase pathway provides one route to the production of (2S)-methylmalonyl-CoA in E. coli [3]. A typical acyl-CoA HPLC profile for a strain expressing the PCC pathway is shown in Fig. 2. This strain, K173-145, has an integrated copy of a T7-regulated prpE (propionyl-CoA ligase) gene; hence, propionyl-CoA was detected upon IPTG induction and feeding 5 mM propionate. In addition, methylmalonyl-CoA was produced by T7-regulated accA1 and pccB expressed in this strain from the plasmid pKOS143-189. The methylmalonyl-CoA produced via the mutase pathway and the PCC pathway varied considerably, comprising from <2% to 30% of the in vivo acyl-CoA pool, depending on the strain used and the composition of the media. For the matB pathway, the methylmalonyl-CoA comprised up to 90% of the in vivo CoA pool, depending on the concentration of methylmalonate included in the production medium. Figure 3 shows a typical acyl-CoA profile in the presence of matB, with high levels of methylmalonyl-CoA production due to expression of GST-matB from pKOS132-144 and feeding of 1 mM methylmalonate. Propionyl-CoA was detected due to the addition of 5 mM propionate and the expression of the integrated copy of T7prom-prpE in the background strain, K173-145. Thus, via in vivo acyl-CoA analyses in E. coli, we have demonstrated production of both the starter unit, propionyl-CoA, and the extender unit, methylmalonyl-CoA, both of which are required for 6dEB production. We have shown methylmalonyl-CoA production by three independent pathways in E. coli: the mutase pathway, the PCC pathway and the matB pathway.

Comparison of 6dEB synthesis using three methylmalonyl-CoA production pathways

Production of the complex polyketide 6dEB in E. coli requires propionyl-CoA, (2S)-methylmalonyl-CoA, the expression of the three subunits of the polyketide synthase, DEBS1, DEBS2, and DEBS3, and expression of sfp, a 4′-phosphopantetheinyl transferase [3, 11]. We have shown that the requisite methylmalonyl-CoA can be produced in E. coli by metabolic engineering of one of three independent pathways. In order to identify which pathway supported the highest titers of 6dEB, we assessed 6dEB production in three strains that differed only in the methylmalonyl-CoA production pathway, expressed from a plasmid. Table 3 shows that when the methylmalonyl-CoA precursor was produced via the PCC pathway, around eightfold more 6dEB was produced than when the precursor was supplied via the mutase pathway. In the strain containing the matB pathway, 6dEB was detected but the titer was too low to quantify, even though this strain produced high levels of methylmalonyl-CoA (see Fig. 3). These results show that although we were able to generate methylmalonyl-CoA via three pathways, these pathways supported significantly different levels of 6dEB production in E. coli.

Analysis of the methylmalonyl-CoA synthesized by the matB pathway

Acyl-CoA and 6dEB analyses of strains expressing the matB pathway showed that although high levels of methylmalonyl-CoA were present in vivo (see Fig. 3), only a trace amount of polyketide was produced (Table 3). To further investigate these apparently contradictory results and to determine whether the matB pathway or methylmalonate feeding inhibited polyketide synthesis, we constructed a strain expressing both the matB and mutase/epimerase pathways along with the DEBS genes. When this strain was fed hydroxocobalamin (necessary for mutase activity), methylmalonyl-CoA comprised around 10% of the acyl-CoA pool and 6dEB was produced at 1 mg/l (Table 4). When the same strain was fed both hydroxocobalamin and methylmalonate, methylmalonyl-CoA levels rose to around 47% of the acyl-CoA pool and 6dEB was again produced at 1 mg/l. When hydroxocobalamin was omitted from the culture, i.e. there was no functional mutase activity in the cell, methylmalonyl-CoA levels remained high, at around 52% of the acyl-CoA pool, but virtually no polyketide was produced. These data showed (1) that neither the addition of methylmalonate nor the expression of the matB pathway negatively affected polyketide synthesis, and (2) that despite high levels of production, the methylmalonyl-CoA produced by the matB pathway was not used as a substrate for polyketide biosynthesis.

To establish independently that the peak identified as methylmalonyl-CoA produced via the matB pathway was authentic, we purified the putative methylmalonyl-CoA from extracts of a strain expressing the matB pathway as described in the Materials and methods. Acyl-CoA analysis of this sample showed that 32% of the acyl-CoA pool was comprised of methylmalonyl-CoA. The purified 3H-methylmalonyl-CoA was tested in an in vitro assay with purified 6-His-Sbm (an E. coli methylmalonyl-CoA mutase) [3] to determine whether the methylmalonyl-CoA was a viable substrate for conversion to succinyl-CoA by Sbm. Incubation of the 3H methylmalonyl-CoA with Sbm resulted in approximately 50% of the 3H counts appearing in the succinyl-CoA peak and approximately 50% remaining in the methylmalonyl-CoA peak. Incubation of the 3H methylmalonyl-CoA with Sbm and epimerase converted all of the 3H counts to succinyl-CoA (with some degradation to free CoA). Thus, the (2R,S)-methylmalonyl-CoA produced by matB was indeed a competent substrate for both Sbm and the epimerase. Further analyses will be required to determine why methylmalonyl-CoA produced by matB is unable to support 6dEB production in E. coli.

Integration of the PCC and mutase pathways

The PCC or mutase pathway genes were integrated into the E. coli chromosome, and 6-dEB titers were measured and compared to 6dEB titers in strains expressing these pathway genes from plasmids. The integration of these genes could reduce the metabolic burden on the cells by lowering the intracellular enzyme concentration to more optimal catalytic levels [8]. Furthermore, integration of the metabolic pathway genes allowed greater flexibility in the use of plasmids for DEBS gene expression. For both the PCC and mutase pathways, the integrated strains performed as well (or better) than the plasmid-borne strains. Integration of the PCC genes raised titers from ~6.5 mg/l to ~7.7 mg/l 6dEB, whereas for the mutase pathway integration raised titers from ~0.85 mg/l to ~1.5 mg/l 6dEB. Acyl-CoA analyses of these strains showed comparable levels of methylmalonyl-CoA (data not shown). Thus, we have demonstrated that metabolic pathway genes can be integrated into the chromosome and still support significant levels of complex polyketide production in E. coli.

Comparison of 6dEB production by PCC and mutase pathways independent of starter unit

The production of 6dEB by DEBS depends on the supply of both the propionyl-CoA starter unit and the (2S)-methylmalonyl-CoA extender unit. As such, polyketide production is influenced by the intracellular concentrations of both propionyl-CoA and methylmalonyl-CoA. For the PCC pathway, the methylmalonyl-CoA is produced from propionyl-CoA, i.e. the starter unit and extender unit pathways are coupled and propionyl-CoA serves both as a precursor to methylmalonyl-CoA and as a substrate for DEBS1. In order to simplify the system to compare the PCC and mutase pathways directly for supply of the extender unit, we used a modified DEBS1 enzyme lacking a loading domain, DEBS1ΔAT L ACP L . This enzyme does not efficiently bind propionyl-CoA, but will accept starter unit analogs as substrates by directly loading them onto the KS domain in module 1 of DEBS (Kennedy et al., in preparation). Strains expressing DEBS1ΔAT L ACP L , DEBS2 and DEBS3 and either the PCC or the mutase pathway from the chromosome were fed the N-acetyl-cysteamine thioester of butyrate (butyryl-SNAc). This thioester, upon loading directly onto KS1, supports production of the 6dEB analog, 15-Me-6dEB (Kennedy et al., in preparation). Using this system, the PCC pathway supported ca. fivefold higher levels of 15-Me-6dEB production compared to the mutase pathway (PCC: 4.5±0.1 mg/l; mutase/epimerase: 0.95±0.1 mg/l). The fact that the ratio of titers produced by the PCC relative to the mutase pathway is the same in strains expressing wild-type DEBS1 (see Table 3) and DEBS1ΔAT L ACP L indicates that the in vivo pool of propionyl-CoA is sufficient to serve both as a precursor to methylmalonyl-CoA and as a substrate for DEBS1.

Direct comparison of the PCC and mutase pathways by 13C propionate labeling

The relative productivities of the PCC and mutase pathways were assessed in strains that expressed the PCC pathway, the mutase pathway, or both pathways. These strains were fed [13C3]propionate, and the incorporation of the 13C into the 6dEB polyketide product was determined by LC/MS/MS (see Materials and methods). Since the PCC pathway converts propionyl-CoA to methylmalonyl-CoA, both starter and extender units will be labeled with 13C. In contrast, for the mutase pathway, only the starter unit propionyl-CoA will be labeled with 13C since the mutase pathway produces methylmalonyl-CoA from succinyl-CoA. In a strain that expressed both the PCC and mutase pathways, an in vivo "competition" was thus established for the methylmalonyl-CoA produced, and it was possible to determine by the number of 13C-labeled two carbon units in the 6dEB product whether the methylmalonyl-CoA originated from the PCC or the mutase pathway. For the strain expressing only the PCC pathway, greater than 90% of the 6dEB produced was uniformly labeled with 13C, as would be expected for the incorporation of seven labeled propionate units into 6dEB via the PCC pathway (Fig. 4). For the strain expressing only the mutase pathway, greater than 90% of the 6dEB produced was labeled at only 3 carbons, as would be expected for the incorporation of a single labeled propionate unit and 6 unlabeled methylmalonate units via succinyl-CoA into 6dEB. For the strain expressing both pathways, greater than 90% of the 6dEB produced was again uniformly labeled with 13C. Thus, in the strain expressing both the PCC and mutase pathways, the flux of precursors incorporated into 6dEB proceeds exclusively through the PCC pathway. Curiously, the strain expressing both the PCC and mutase pathways supported lower titers of 6dEB than the PCC pathway alone (2.5 mg/l vs 9.5 mg/l; see Fig. 4). One possible explanation for this result is that the presence of the mutase and epimerase enzymes in the strain with the mixed pathways creates a sink for the methylmalonyl-CoA since the equilibrium constant for the reaction catalyzed by the mutase enzyme favors the production of succinyl-CoA by a factor of about 20. Taken together, our results show that of the three pathways analyzed for methylmalonyl-CoA production in E. coli, the PCC pathway supports the highest levels of 6dEB production.

Production of 13C-6dEB from [13C3]propionate by PCC vs mutase pathways. In all the strains, the three DEBS genes were expressed from two plasmids, pKOS207-129 and pBP130. The strain labeled PCC is K207-3, with the PCC genes expressed from the chromosome, and pKOS164-185, the pACYC vector backbone. The strain labeled mutase is K173-145 with pKOS207-15a expressing the mutase genes from a pACYC backbone. The strain labeled mutase/PCC is K207-3 with pKOS207-15a. All strains were fed 5 mM [13C3]propionate/50 mM succinate/50 mM glutamate/5 µM hydroxocobalamin. The observed incorporation number was determined by LC/MS/MS analyses of the 13C-6dEB (see Materials and methods). Compound A is 6dEB with 13C-labeled carbons from the starter unit only, as would be predicted if the extender methylmalonyl-CoA units came from the mutase pathway. Compound B is 6dEB uniformly labeled with 13C, as would be predicted if the methylmalonyl-CoA came from the PCC pathway

Optimization of DEBS gene expression from plasmids

The original plasmid system used by Pfeifer et al. [17] for DEBS gene expression contains two plasmids with different antibiotic resistances but the same origin of replication (pBP130 and pBP144). This system is very unstable, with greater than 90% of the cells losing at least one of the plasmids by the end of a high cell density fermentation, even in the presence of antibiotics (Janice Lau, unpublished data). A three plasmid system for expression of the three DEBS genes from compatible plasmids was designed and compared to the original two plasmid system. These plasmids were examined for their ability to support 6dEB production in K207-3, the strain with the PCC pathway genes integrated into the chromosome. The system with three compatible plasmids produced significantly higher titers than the original unstable two plasmid system after 48 h in shake flask fermentations (Table 5). All three plasmids were found to be equally stable even after 120 h in shake flasks, in contrast to results observed with the original two plasmid system. The three-plasmid system is a useful tool since it allows the maximum flexibility in switching genes or promoters. However, in preliminary work at high cell density in fermenters, the p15A-origin plasmid was found to be unstable even in the presence of antibiotics (Janice Lau, unpublished data). The other two plasmids (pET-origin and colD-origin) were quite stable even in the absence of antibiotic selection. Therefore, a new plasmid system was designed that expressed the three DEBS genes from two plasmids, pBP130 and pKOS207-129. This combination of plasmids supported high levels of 6dEB production even in the absence of antibiotic selection in both shake flask (Table 5) and high cell density fermentations (Janice Lau, unpublished data). Thus, by a process of rational engineering, we developed a strain that produces significantly higher titers of 6dEB than the original E. coli production strain [17] and has superior stability at high cell density in fermenters.

Discussion

In order to gain insight into parameters influencing polyketide production in engineered E. coli [3,17], we investigated the effect of precursor supply and plasmid stability on 6dEB production. We first compared acyl-CoA pools and 6dEB production resulting from expression of three pathways for production of the extender unit (2S)-methylmalonyl-CoA: the PCC pathway, the mutase pathway, and the matB pathway (see Fig. 1). Expression of matB and feeding of methylmalonate led to the accumulation of high levels of methylmalonyl-CoA (see Fig. 3). However, the matB-synthesized methylmalonyl-CoA, which we demonstrated serves as a substrate for two other enzymes in vitro, was not efficiently converted to 6dEB by DEBS in vivo. The reasons for this are unclear and will need to be studied further. In contrast, the PCC and mutase pathways both supported production of methylmalonyl-CoA (up to 30% of the total acyl-CoA pools) and 6dEB biosynthesis, with strains expressing the PCC pathway yielding approximately fivefold higher titers of 6dEB than strains expressing the mutase pathway. In a strain expressing both the PCC and mutase pathways, [13C]propionate-labeling experiments showed that the PCC pathway was the dominant pathway for supply of methylmalonyl-CoA for 6dEB biosynthesis (see Fig. 4). Thus, our results reproducibly showed that the PCC pathway supported the highest levels of 6dEB production in E. coli.

To increase flexibility in manipulating plasmids in the E. coli production strain, we examined how integration of the PCC and mutase pathway genes would affect 6dEB titers. In addition to greater flexibility in plasmid manipulation, decreasing the gene dosage and expression levels of these enzymes could positively influence 6dEB titers by reducing the metabolic burden on the cells [8]. We found that strains with integrated PCC or mutase pathways functioned as well as or better than strains expressing these genes from high or medium copy plasmids. Identification of the PCC pathway as the most productive for 6dEB synthesis, and integration of this pathway into the chromosome, facilitated the use of different plasmids for expression of the DEBS genes. The instability of the system developed by Pfeifer et al. [17] led us to explore the effect on 6dEB titers of increasing plasmid stability through use of plasmids with compatible origins of replication. We designed two new systems for DEBS gene expression that demonstrated improved stability and improved polyketide titers (see Table 5). One system, which expressed the DEBS genes from three compatible plasmids, was stable in shake flasks and allowed maximum flexibility for switching promoters and genes between plasmids. A similar three-plasmid system has been successfully used in S. coelicolor to make many novel polyketides [23]. In addition, a second two-plasmid system proved to be stable in both shake flasks and high cell density fermentations (Janice Lau, unpublished data) without the need for antibiotic selection to maintain the plasmids. Preliminary results in high cell density fermentations of the strain expressing the integrated PCC genes and the most stable two-plasmid system for DEBS1–3 gene expression showed a several-fold improvement over the titers seen with the original system designed by Pfeifer et al. [18]. Current titers for 6dEB analog production from high density fermentation of our optimized E. coli strain match those of our actinomycete (S. coelicolor) production strain (around 1 g polyketide/l of culture) [4]. The S. coelicolor strain has been engineered for the heterologous production of 6dEB analogs altered at the starter unit [7], and has been optimized for polyketide production through several iterations of classical strain improvement. Hence, by a series of "rational" strain improvements, we have quickly constructed an E. coli strain that rivals our best S. coelicolor production strain for 6dEB analog production.

By this series of experiments, we engineered an E. coli production strain with increased titers of the complex polyketide 6dEB and with significantly improved stability in high cell density fermentation, key achievements in the development of an industrial production host. Many avenues remain to be explored for further improvement of the E. coli production strain, including (1) examining alternative promoters for regulating gene expression, such as the tightly regulated, arabinose-inducible PBAD promoter [10,15], (2) regulating mRNA transcript levels by using mRNA secondary structure elements to affect stability [21,22], and (3) determining the effect of integration of the DEBS genes on 6dEB titers. In parallel, further development of media and conditions for high cell density fermentations could result in additional gains in 6dEB titers. The rapid improvements in 6dEB titers achieved in E. coli as compared to S. coelicolor validate efforts to further develop E. coli as a polyketide production host. Future work will be required to determine whether E. coli will serve as a useful host for the production of other polyketides.

References

An JH, Kim YS (1998) A gene cluster encoding malonyl-CoA decarboxylase (MatA), malonyl-CoA synthetase (MatB) and a putative dicarboxylate carrier protein (MatC) in Rhizobium trifolii--cloning, sequencing, and expression of the enzymes in Escherichia coli. Eur J Biochem 257:395–402

Cronan JEJ, LaPorte DC (1996)Tricarboxylic acid cycle and glyoxylate bypass. In: Neidhardt FC (ed) Escherichia coli and Salmonella typhimurium: cellular and molecular biology, 2nd edn. American Society for Microbiology, Washington, D.C., pp 206–216

Dayem LC, et al (2002) Metabolic engineering of a methylmalonyl-CoA mutase-epimerase pathway for complex polyketide biosynthesis in Escherichia coli. Biochemistry 41:5193–5201

Desai RP, et al (2002) Enhanced production of heterologous macrolide aglycones by fed-batch cultivation of Streptomyces coelicolor. J Ind Microbiol Biotechnol 28:297–301

Haller T, et al (2000) Discovering new enzymes and metabolic pathways: conversion of succinate to propionate by Escherichia coli. Biochemistry 39:4622–4629

Jackowski S, Rock CO (1981) Regulation of coenzyme A biosynthesis. J Bacteriol 148:926–932

Jacobsen JR, et al (1997) Precursor-directed biosynthesis of erythromycin analogs by an engineered polyketide synthase. Science 277:367–369

Jones KL, Kim SW, Keasling JD (2000) Low-copy plasmids can perform as well as or better than high-copy plasmids for metabolic engineering of bacteria. Metab Eng 2:328–338

Kealey JT, et al (1998) Production of a polyketide natural product in nonpolyketide-producing prokaryotic and eukaryotic hosts. Proc Natl Acad Sci USA 95:505–509

Khlebnikov A, et al (2001) Homogeneous expression of the P(BAD) promoter in Escherichia coli by constitutive expression of the low-affinity high-capacity AraE transporter. Microbiology 147:3241–3247

Leadlay PF (1981) Purification and characterization of methylmalonyl-CoA epimerase from Propionibacterium shermanii. Biochem J 197:413–419

Link AJ, Phillips D, Church GM (1997) Methods for generating precise deletions and insertions in the genome of wild-type Escherichia coli: application to open reading frame characterization. J Bacteriol 179:6228–6237

Magrini V, et al (1998) The aadA gene of plasmid R100 confers resistance to spectinomycin and streptomycin in Myxococcus xanthus. J Bacteriol 180:6757–6760

McKie N, et al (1990). Adenosylcobalamin-dependent methylmalonyl-CoA mutase from Propionibacterium shermanii. Active holoenzyme produced from Escherichia coli. Biochem J 269:293–298

Morgan-Kiss RM, Wadler C, Cronan JE Jr (2002) Long-term and homogeneous regulation of the Escherichia coli araBAD promoter by use of a lactose transporter of relaxed specificity. Proc Natl Acad Sci USA 99:7373–7377

O'Hagan D (1991) The polyketide metabolites. Ellis Horwood, Chichester

Pfeifer BA, et al (2001) Biosynthesis of complex polyketides in a metabolically engineered strain of E. coli. Science 291:1790–1792

Pfeifer B, et al (2002) Process and metabolic strategies for improved production of Escherichia coli-derived 6-deoxyerythronolide B. Appl Environ Microbiol 68:3287–3292

Rodriguez E, Gramajo H (1999) Genetic and biochemical characterization of the alpha and beta components of a propionyl-CoA carboxylase complex of Streptomyces coelicolor A3(2). Microbiology 145:3109–3119

Scholz P, et al (1989) Complete nucleotide sequence and gene organization of the broad-host-range plasmid RSF1010. Gene 75:271–288

Smolke CD, Keasling JD (2002) Effect of copy number and mRNA processing and stabilization on transcript and protein levels from an engineered dual-gene operon. Biotechnol Bioeng 78:412–424

Smolke CD, Martin VJ, Keasling JD (2001) Controlling the metabolic flux through the carotenoid pathway using directed mRNA processing and stabilization. Metab Eng 3:313–321

Xue Q, et al (1999) A multiplasmid approach to preparing large libraries of polyketides. Proc Natl Acad Sci USA 96:11740–11745

Acknowledgements

We thank Sarah Mutka, Janice Lau, Misty Piagentini and Andreas Schirmer of Kosan Biosciences for providing plasmids and results prior to publication, and Richard Hutchinson and Leonard Katz of Kosan Biosciences for critically reading the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

S. Murli and J. Kennedy contributed equally to this work

Rights and permissions

About this article

Cite this article

Murli, S., Kennedy, J., Dayem, L.C. et al. Metabolic engineering of Escherichia coli for improved 6-deoxyerythronolide B production. J IND MICROBIOL BIOTECHNOL 30, 500–509 (2003). https://doi.org/10.1007/s10295-003-0073-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-003-0073-x