Abstract

The paper presents the main characteristics of an innovative platform which has been conceived and designed to extend the operational capabilities of current unmanned surface vehicles in terms of platform stability in waves and of powering requirement at a relatively high speed. The main idea which rules the project is the realization of a small autonomous surface unit (about 6 m in length) capable of undertaking several tasks in the marine environment even with moderate rough sea conditions. The designed vessel has the ability to locate, recover, and launch other members of the autonomous fleet (like AUVs or other underwater devices) and at the same time could carry out a surveillance service of the surrounding areas. To manage these tasks, the vehicle is designed to provide a fairly good autonomy which is needed to face intermediate-range missions (100 nautical miles). The choice of a small waterplane area twin hull (SWATH) form has been motivated by its excellent properties of seakeeping qualities, combined with a non-conventional low resistance underwater hull shape, currently under patenting process, which is able to reduce to a minimum the resistance of the vessel especially at higher speeds. To obtain the most efficient profile of the underwater bodies, a systematic optimization with an automatic procedure based on a parametric definition of the geometry, a state-of-the-art computational fluid dynamics (CFD) flow solver, and a differential evolution global minimization algorithm have been created and used. As expected, all the final CFD computations on the best design have demonstrated the superior efficiency of the developed unconventional SWATH technology with respect to different alternatives of current hull typologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The high cost related to the operational needs of oceanographic vessel and the maturity achieved both by unmanned surface (USV) and underwater (UUV) vehicles suggest the realization of coastal monitoring systems based on a net of autonomous cooperating vehicles (Curtin et al. 1993, 2001, 2005; Bovio et al. 2001). These systems are extremely useful for in situ measurements required for predicting different oceanographic phenomena and, at the same time, are essential to carry out underwater/surface combined patrolling and surveillance aimed, for instance, to the discovery of accidental dangerous events, such as pollutant, but also to the detection of explosive hazards, terrorist attacks, etc.

In this context, NURC, the NATO Undersea Research Center in La Spezia (Italy), started a collaboration with the Marine CFD Group of the University of Genova to develop an innovative design for a multipurpose autonomous surface vehicle that is believed will be the key element to realize an efficient integrated network of autonomous underwater vehicles that can be served, charged, and managed by the new surface vehicle. Figure 1 depicts an aspect of this concept related to the communication. For the USV to be efficient, it should be relatively small (affordable, manageable, and easy to transport and operate) and with a good operational capabilities also in relatively rough seas.

To achieve the desired characteristics, a small waterplane area twin hull (SWATH) type has been chosen because of its excellent properties of seakeeping, which guarantee a good platform stability even in relatively rough seas (sea state 3 in relation to the dimension of the proposed vehicle). Several SWATH vessels for different applications have been designed in the past, but the common characteristic is that the displacement necessary to keep the ship afloat is located well below the free surface, where it is less affected by wave action. The main principle is that a reduction in motion exciting forces is achieved through the very limited variation of buoyancy due to the change of submerged volume of the struts when an incident wave is passing by the hull. This variation of volume, which directly depends on the shape of the hull around the design waterline, is minimized in a SWATH vessel with respect to equivalent monohull or also catamarans and hence also induced forces and moments. Also, other wave exciting components, such as Froude–Krylov forces, are exponentially diminished as depth increases (deeply submerged submarines are not affected by wave action at all). To extremely simplify, in fact, placing the majority of a ship's displacement under the waves is similar in concept to creating a ship that rides atop twin submarines. The consequence is the possibility to deliver a platform steadiness and ride quality typical of a large ship in a much smaller vessel and the consequent ability to operate and sustain a higher cruising speed in rough seas.

On the other hand, the advantage in superior seakeeping of SWATH vessels is normally balanced by a lower efficiency in terms of advance resistance in calm water, their wetted surface being larger than equivalent conventional hull forms. Nevertheless, playing with the geometry of the immersed part of the hull, it is possible to reduce the wave resistance, aiming for a positive interference effect between the generated wave trains, eventually minimizing the requested propulsion power to reach the given design speed (Papanikolaou and Androulakakis 1991; Salvesen et al. 1985; Schellin and Papanikolaou 1991). The optimization of the shape of the underwater hulls for resistance is a quite important point in the design of an efficient USV vessel since the propulsion powering requirement and, consequently, the fuel consumption or the autonomy range are essential features for the operation of these types of vehicles.

In the present study, a numerical, fully automatic, computer-based parametric optimization procedure devised on the basis of an original scheme already applied with success in the past (Brizzolara 2004) is enhanced and actualized for the case with modern parametric geometry generation modules and optimization algorithms, similar to those recently developed and succesfully applied in the case of other hull form optimization problems (Brizzolara et al. 2010; Biliotti et al., 2010). The result is the unconventional hull for the ASV presented in Fig. 2, with its main features described in the next section.

This optimization procedure is described in Section 3, while the last chapter gives the assessment of the hydrodynamic performance of the vessel obtained with a state-of-the-art computational fluid dynamics (CFD) code, able to solve the viscous-free surface full-scale flow around the hull.

2 Layout and general arrangement

The limited main dimensions of the vessel are influenced by some key requirements:

-

The ability to cover the assigned range at design speed with onboard fuel and power generation and conversion devices

-

The ability of storing, recharging, and releasing autonomous underwater vehicles (AUVs) of lengths up to 2.2 m and maximum weights of about 100 kg

-

Transportability inside a standard container (ISO lwh 12.2 × 2.44 × 2.59)

Consequently, since the very beginning of the project, a dismountable aluminum alloy structure, represented in Fig. 4, has been designed to satisfy the imposed constraints.

The optimized vessel configuration, currently under patenting process (Brizzolara 2011a, b), is basically composed of a main central body with its keel line suspended almost 1 m above sea level and by two couples of vertical struts that connect to the underwater hulls. The coupling is obtained by junctions between the top of the struts and the side of the main body which can be opened for the packing process; in addition, a system of rods, which link the bottom of the main body with the side of the struts, avoids the relative rotation of the structure around the joints.

An iterative approach has been followed to converge to the definitive version of the designed vessel. This iterative design procedure is typical in naval architecture where the design, despite a few parameters fixed as constraints, changes constantly under the influence of boundary conditions that step by step will lead to a more accurate configuration. The process is definitely nonlinear and can be then imagined as a spiral in which all the steps have to be repeated in order to narrow down the domain of the input variables and to converge to the best compromise solution that is able to respect hydrostatic equilibrium and stability, strength, and payload capacity while optimizing hull form and propulsion system shape for resistance and seakeeping.

So with the few given data known for the preliminary configuration, performance prediction and weight estimation, followed by a stability check, have been performed to better understand the power required for the propulsion system of the vessel and its seakeeping qualities. Then, after an evaluation of the obtained results, some changes were introduced to improve the vessel’s characteristics, which means that the analysis has to be repeated again several times. The iterative process finally brought a more stable and efficient configuration with the layout optimized for resistance and stability, depicted in Fig. 2.

Having set the main dimensions and components, it was possible to identify the general arrangement of the components inside the structure (Fig. 3) in order to better define static moments and the qualitative position of the center of gravity. Moreover, with the estimated required propulsion power of 39 kW at the design speed, it has been decided to install two diesel generators each of 22 kW, which provide the energy to the whole vessel, and to fit them into the central part of the upper body.

Two diesel fuel tanks, placed inside the underwater hulls in the middle and one per side (see Fig. 3), guarantee a range of more than 100 miles at full speed required for medium/short-range missions.

Because of the typical high sensitivity to load changes of the SWATH configuration, inside the underwater hulls, in the same position as the fuel tanks, two mirrored ballast tanks have been fitted for compensation of the loss of weight and trim moment change due to fuel consumption. On the other hand, the possibility to recover an AUV has to be considered as a weight increase that can be balanced with a reserve of buoyancy. This has been achieved with two other seawater tanks of adequate capacity, normally full of ballast water, from which the fluid can be pumped out to gain volume when an increase of weight occurs. This system is important to keep the design draft and trim of the vessel in different loading conditions; otherwise, static attitude changes, in particular a draft reduction and trim variation, will determine an increase of the advance resistance, related to the generation of free surface waves, and a reduction of transverse and longitudinal hydrostatic stability due to the raising of the center of gravity. The vertical position of the center of gravity has indeed a strong influence on the metacentric height which has to be high enough for the survivability of the vehicle and to control its reactivity to wave’s exciting forces and moments.

The hydrostatics calculations indicate that the initial metacentric heights of the vessel in the transverse and longitudinal planes are not so distant from one another, differently from a conventional monohull where the longitudinal metacentric height is in the order of the vessel length while the transversal metacentric height is in the order of its draft. This fact implies the non-existence of a preferable direction of heeling for the vessel (which, for a conventional monohull, is normally the roll motion) that will heel almost the same angle in the longitudinal and transverse axis, with a final resulting axis markedly eccentric.

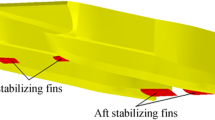

With the same intent of managing the dynamic trim and sinkage of the vessel (at high speed), as well as the dynamic stability of the vessel in waves, four active stabilizer fins have been installed which will guarantee the correct optimal attitude when the vehicle is advancing and a good damping also in stationary condition (with a zero speed control and actuator mode). These two pairs of lifting surfaces are placed on the inner side and at the far ends of the hulls in order to obtain the maximum trimming moment. The space left in the aft end of each hull has been dedicated to the housing of electric motor, gear box, and shaft line, whereas the space in the fore side is available for many underwater instruments useful for measurements and detection of obstacles or hazards. Finally, the central body has been divided into three separate compartments by two transversal watertight bulkheads. Inside the fore and aft parts, there are the diesel generators, the frequency converters, and equipment for autonomy; in the mid-compartment, a docking space large enough to host an AUV have been reserved, suitable for recharging and collecting data processes.

For the structures of such a small vessel, a light metal shell with transversal main girders has been adopted, presented in Fig. 4. The material chosen is a light aluminum alloy, such as 5083 H321, having a specific weight of about 2.7 kg/dm3. A special cradle composed of articulated transversal main structural elements, connected to the two main longitudinal girders by means of resilient supports, has been designed for the foundation of the two diesel generators. By this special arrangement, the vibration induced by the diesel engines will experience high damping in their propagation to surrounding structures, enhancing the silence of the vessel for the best air and water noise measurements. Watertight dismountable openings have been designed to guarantee the access of the electric motors in the underwater hull and other components in the struts. The weight of the vessel’s outer shell and that of the reinforcing structures was estimated on the basis of the actual metal volume of the structures as designed in the 3D model, as shown in the arrangement in Fig. 4.

As anticipated, stability resulted to be a very crucial item of the whole project. Although the SWATH configuration offers superior seakeeping qualities, the hydrostatic stability index has to be evaluated very carefully because of the high sensitivity of this vessel to weight variations in terms of its magnitude and change in position. Particular attention has been paid to match the longitudinal position of the center of buoyancy and the center of gravity (LCB–LCG), with some reserve given by additional ballast water tanks since a very little gap of the relative position between this two centers determines an important change of the longitudinal trim angle. This happens as a consequence of the slender geometry of the struts in the horizontal plane, which is characterized by a very little waterplane area, that do not offer a large amount of buoyancy reserve which can counterbalance weight changes. The solution adopted to avoid the problem has been to taper the struts just above the waterplane, increasing width and length, in order to gain volume in case a pitching moment occurs. The same solution have been adopted for forces and moments which can act in the transversal plane, and a detailed analysis of the transversal stability was performed with regard to the side area exposed out of the water, being larger than the frontal one.

Moreover, one of the tasks that have to be satisfied is the continuous operability up to in sea state 3, corresponding to a significant wave height between 0.5 and 1.25 m and a wind speed up to about 30 kn. For this reason, several transverse quasi-static (large angles) stability tests have been executed to verify the response of the vessel to the combined effect of wind and waves. An example of extreme wind stiffness test is given in Fig. 5; it consists in evaluating the transversal static angle of equilibrium between the righting moment of the vessel and the heeling moment due to a constant wind blowing on the side area. Instead of a wind typical of sea state 3, for reasons of safety factor, a speed of 25 m/s, which is almost equal to 50 kn, has been imposed. In addition, all the calculations have been performed including the free surface correction of all the tanks considered as half filled in order to evaluate the stability of the vessel in the worst possible conditions (in the intact mode).

In Fig. 6, three different static righting arm curves are plotted, corresponding to different design alternatives having different shapes of the struts above the water, in particular: The lowest curve is for the straight vertical struts while the highest one is for the final strut configuration, as shown in Fig. 2, with flared sides above the waterline and a longitudinal-inclined stem profile.

3 Hull form design and optimization

In order to optimize the shape of the SWAT hull, a fully parametric model of its geometry has been created using the method of Abt et al. (2003). The optimization chains derived from the method were first devised and applied with success for SWATH hulls by Brizzolara (2004) with a different mathematical representation of the underwater bodies. The main concept behind the parametric optimization is to define a limited set of free variable parameters by which it is possible to change, and hence control, the geometry which has been modeled. In this new study, two separate models have been constructed: one for the submerged hull and one for the struts.

The parametric definition of the submerged hull is based on the definition of a B-spline curve with seven control points: two of them are used for the forward and stern extremes of the hull and the adjacent two for the variation of the curvature radius at leading and trailing edge; the internal points govern the unconventional shape with an intermediate contraction of a transverse section. The underwater body can have an ellipsoidal shape with a given ration of the principal radii, equal to 1.15 in this case.

The model used for the creation of the two struts is based on their-wing like shape; hence, the basic curve is a wing profile that, as presented in Fig. 6, is defined by a length, a value of the maximum thickness, its longitudinal position along the chord, and the half entrance and trailing angles (at the leading and trailing edges).

The surfaces of the two struts per underwater hull are then cut with the hull itself, and the result is the half (symmetric) fully parametric model of a SWATH. An example of shape variation obtained with an overall number of 20 parameters is presented in Fig. 7. This is then used in the optimization process with the aim of finding the set of free parameters which provide the lowest wave resistance of the vessel.

The optimization environment uses the software based on the method of Spicer et al. (1998). The high-level workflow, presented in Fig. 8, of the devised optimization procedure can be summarized in five main sections:

-

The definition of the set of free variables which have to be used by the genetic algorithm

-

A first tentative geometry of the SWATH is created.

-

A check on volume constraint is performed and, in order to speed up the process, no CFD calculation is done for any geometry that does not respect this constraint, which is referred to as an unfeasible design case.

-

Then, for all feasible designs (i.e., those that respect the imposed constraints), the calculation of wave resistance values is carried out by means of the boundary element method, as first introduced in Brizzolara (2004).

-

The last step is the section for processing the results obtained in the output of the CFD calculations, mainly aimed at the evaluation of the objective function (wave resistance in this case).

Figure 9 shows a comparison of the free wave patterns for a conventional (drop-shaped) and optimized hull forms as predicted by the same solver (panel method) used in the optimization procedure. The panel meshes of the two hull form are given in Fig. 10.

At this relatively high speed, the wave formation is mainly concentrated in the divergent through and crests components; the difference between the two hulls is mainly visible in the divergent crests and troughs of the struts in the external and internal free surface domains.

The design of experiment, which is the exploration of the design space created by the combination of the range of variation of all free variables, is obtained by means of a Sobol algorithm, composed of 100 starting designs. Compared with a completely random algorithm, the Sobol maintains the random distribution of points but improves the exploration of extreme regions of the design space, which means that it spreads the evaluation points over a wider space and not just around the solution.

The selected optimization algorithm is the NSGA-II (non-dominated sorting genetic algorithm) first introduced by Deb et al. (2000), which allows both continuous (real-coded) and discrete (binary-coded) variables, constraints are not imposed through penalty factors, elitism for multi-objective search is used, diversity and spread of candidate individuals are guaranteed without the use of shared parameters, and the concurrent evaluation of n independent individuals is possible (for parallelization purposes). A maximum number of 200 generations have been used, together with a crossover probability of 0.7 and mutation probability of 0.8.

The ratio between feasible and non-feasible (not respecting volume constraint) individuals is about 1:3. The history of the wave resistance coefficients calculated during the optimization procedure for each feasible individual is given in the plot of Fig. 11. As is noticeable, there are some feasible points that are well below the average trend line of wave resistance reduction (C W, <2.0 × 10−3). These cases, which we name fake design, do correspond to valid 3D geometries respecting the volume constraint (feasible designs), but their panel meshes are incorrectly generated, normally corresponding to a faulty irregular shape of the struts. The result of the calculation of these points is an unrealistically low wave resistance that, unfortunately, the automatic procedure is not able to recognize and discard. The presence of these points, though, does not compromise the convergence, and they can be hence checked and discarded a posteriori.

A rather good and fast convergence of the genetic algorithm is reached after about 4,000 evaluations, as clearly visible from the average trend line in Fig. 11, interpolating the history of the objective function evaluated for the different feasible design alternatives.

Due to the large separation of the two underwater hulls (s/L = 0.75), no particular interference effects are expected between the wave trains generated by each demi-hull. This is confirmed by the results of Fig. 12 which presents the predicted wave resistance coefficients for the basic, the conventional (drop-shaped), and the optimized hull forms as a function of the transversal separation of the two demi-hulls non-dimensionalized on the hull length (s/L). The twin hull interference factor calculated for the optimum hull shape, in fact, is even slightly higher than the reference hulls forms, at the design s/L = 0.775.

The reduction of wave resistance achieved by the optimum hull, in fact, comes exclusively from the positive interference between the wave trains generated by the components of each demi-hull even in isolation. In this design case, the proper calibration of the longitudinal positions of the intermediate contracted section and of the other two maximum area sections plays a major role in the wave interference (cancelation) effects.

4 Estimation of hull resistance and propulsion power

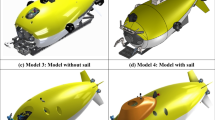

To confirm the utility of the automatic optimization process, five hull form shapes have been devised by a traditional trial-and-error procedure on the basis of the results of the simulations made with a state-of-the-art RANSE solver: STAR-CCM+, extensively validated and tuned in the last years on different kind of hulls with very good results, also in case of unconventional SWATHs (Brizzolara and Villa 2009).

The test conditions were a top speed of 12 kn and a fixed even keel draft of 0.9 m. The geometries designed and tested are represented in Fig. 13 in terms of the generatrix curve of the ellipsoidal underwater body contained in the longitudinal plane. The fifth curve corresponds to the best geometry obtained with the automatic procedure.

The designed models are characterized as follows:

-

1.

Initial solution on the experience of previous SWATH optimizations (∇ = 4.02 m3; WS = 31.1 m2; Brizzolara 2004)

-

2.

Same shape of design 1, modified to enhance the interference effect [∇ = 4.26 m3; WS = 32.3 m2]

-

3.

Same hull of design 1, but with the two aft struts placed vertically instead of being leaned as the fore ones (∇ = 3.98 m3; WS = 30.7 m2)

-

4.

Other designed by experience (∇ = 4.05 m3; WS = 31.5 m2)

-

5.

Optimum solution obtained with the automatic optimization process based on panel method (∇ = 4.148 m3; WS = 31.999 m2)

Where ∇ is the displaced volume and WS is the wetted surface in static condition.

As is clear from Fig. 14, where the total resistance predicted by the RANSE solver is presented, excluding case 3 that has different canting angles between the forward and aft pairs of struts, model 5, obtained from the optimization procedure, has been confirmed to be the best solution in terms of lower resistance. This result confirms two facts: The automatic parametric optimization procedure is more effective than a traditional trial-and-error procedure (that moreover took about 1 week instead of 1.5 days); secondly, the optimization with regard to wave resistance only can be in any case valid (with a limitation on the leading and trailing edge radii) to diminishing of the total resistance, as verified a posteriori with a fully viscous RANSE code.

Subsequently, more computations have been done to define the resistance–speed curve of the vessel and to identify the hump speed, a characteristic relative maximum of the towing resistance typical of high-speed SWATH vessels. The corresponding wave patterns are represented in the plots of Fig. 15: The rather steep and high waves generated at the hump speed of 6 knots explain this characteristic point. It is important to avoid long time navigation of the vessel around this inefficient rate.

On the basis of the effective power estimated with the RANSE solver, a selection of the optimum propeller of the Wageningen B-series has been performed. From systematic calculations, imposing the known load coefficient K T/J 2, the final optimum propeller results have a diameter of 700 mm, a max rotational speed of revolutions per minute at 12 knots, with an open water efficiency of about 0.65.

For these calculations, a propeller expanded area ratio of 0.45 has been assumed based on standard cavitation criteria. An empirically derived thrust deduction factor of 0.95 and a wake fraction of 0.7 have also been assumed. More accurate studies, aimed to the CFD quantification of these propulsion factors with ad hoc RANSE calculations and propeller optimization, in a similar way as that already done in the case of the OEX AUV propeller redesign (Brizzolara and Gaggero 2010), are programmed for the definitive stage of the project. The final brake power estimated on the basis of the predicted optimum propeller efficiency is presented in Fig. 16 and has been used to select the characteristics of the two electric motors and the final power of the two diesel generators.

Powering requirement predicted for advancing at 12 knots is rather satisfactory if compared with vessels of the same size and displacement.

5 Conclusions

The basic design and optimization of the resistance/powering characteristics of an innovative small (7 m long) unmanned surface vehicle, which could be the first step towards a new generation of autonomous vessels, has been detailed in the paper. The vessel was conceived and designed to be a fundamental element of a more efficient cooperative UUV/USV network: The propulsion is diesel electric and the electric power can be used to recover, recharge, and autonomously launch UUV.

The advantages of the unconventional (Brizzolara 2011a, b) optimized hull form are the excellent seakeeping property, typical of SWATH vessels, together with the improved resistance (and powering) characteristics with respect to conventional shapes.

The automatic, parametric geometry and CFD-based optimization procedure has been introduced and verified in the case of the presented vessel. It was demonstrated, as also verified by RANSE simulations of the viscous flow around the hull, that a reduction in powering requirement of more than 30% at the highest speeds can be achieved by the optimized shape with respect to a conventional (drop-shaped) solution.

The resistance and, consequently, the powering curve of this unconventional hull form are characterized by a hump in a small range of lower speeds. Users should be well aware of this hump speed range in order to avoid it in long-term navigation.

Further studies are being programmed in order to enhance the vessel’s characteristics and operational capabilities, among others, to verify and to assess the maximum sea state conditions tolerated by the vessel and the definition and optimization of active stabilizer fins integrated motion control system.

References

Abt C, Birk L, Harries S (2003) parametric hull design: the FRIENDSHIP-Modeler. International Conference on Ship and Shipping Research—NAV 2003, Palermo, June 2003

Bovio E, Tyce R, Schmidt H (eds) (2001) Autonomous Underwater Vehicle and Ocean Modelling Networks: GOATS 2000 Conference Proceedings. Number CP-46. NATO Undersea Research Centre, La Spezia, Italy

Brizzolara S (2011) Dispositivo Natante. Italian Patent Request no. GE2011A000011

Brizzolara S (2004) Parametric optimization of SWAT-hull forms by a viscous-inviscid free surface method driven by a differential evolution algorithm. 25th Symposium on Naval Hydrodynamics, St. John’s, Newfoundland and Labrador, Canada, 8–13 August 2004, vol V, pp 47–64

Brizzolara S, Villa D (2009) Numerical and experimental hydrodynamic performance of SLICE hull forms, NAV 2009—16th Conference on Ship and Shipping Research, Messina, 26th–27th November 2009

Brizzolara S, Vernengo G, Biliotti I et al. (2010) Automatic parametric hull form optimization of fast naval vessels. 7th International Conference on High Performance Marine Vessel, HIPER 2010, Melbourne, Florida

Brizzolara S, Gaggero S (2010) OEX PROPELLER—Phase II new propeller design and CFD analysis for the OEX autonomous unmanned vehicle. Report NRC-03-10, University of Genoa, Marine CFD Group

Brizzolara (2011) Dispositivo Natante. Italian patent pending, presentation no. GE2011A000011

Biliotti I, Vernengo G, Brizzolara S (2010) Parametrization and optimization of round bilge and deep-V frigate hull types for resistance and seakeeping. 1st Friendship European User Meeting and Conference 2010, Potsdam, Germany

Curtin TB, Bellingham JG, Catipovic J, Webb D (1993) Autonomous oceanographic sampling networks. Oceanography 6(3):86–94

Curtin TB, Bellingham JG (2001) Autonomous ocean sampling networks. IEEE J Ocean Engineering 26(4):421–423

Curtin TB, Crimmins DM, Curcio J, Benjamin M, Roper C (2005) Autonomous underwater vehicles: trends and transformations. Mar Tech Soc Journal 39(3):65–76

Deb K, Agrawal S, Pratap A, Meyarivan T (2000) A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In: Schoenauer M et al (eds) Parallel problem solving from nature. Springer, Paris, pp 849–858

Papanikolaou Α, Androulakakis Μ (1991) Hydrodynamic optimization of high-speed SWATH. Proceedings of 1st FAST '91 Conference, Trondheim, Norway

Salvesen N, von Kerczek CH, Scragg CA, Cressy CP, Meinhold MJ (1985) Hydro-numeric design of SWATH ships. SNAME Transactions 93(1985):325–346

Schellin ΤΕ, Papanikolaou Α (1991) Prediction of seakeeping performance of a SWATH-ship and comparison with measurements. Proceedings of the 1st FAST ‘91 Conference, Trondheim, Norway

Spicer D, Cook J, Poloni C, Sen P (1998) EP 20082 FRONTIER: industrial multiobjective design optimisation. ECCOMAS 98. Wiley, Chichester

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Michel Rixen

This article is part of the Topical Collection on Maritime Rapid Environmental Assessment

Rights and permissions

About this article

Cite this article

Brizzolara, S., Curtin, T., Bovio, M. et al. Concept design and hydrodynamic optimization of an innovative SWATH USV by CFD methods. Ocean Dynamics 62, 227–237 (2012). https://doi.org/10.1007/s10236-011-0471-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10236-011-0471-y