Abstract

Graphitic carbon nitride (g-C3N4) was easily synthesized from melamine and subsequently sonicated to create exfoliated g-C3N4. Samples were characterized with scanning electron and transmission electron microscopy, X-ray diffraction, N2 adsorption–desorption, and Fourier transformed infrared analysis. The un-exfoliated and exfoliated g-C3N4 were both assessed as adsorbents for the removal of Cu2+, Mn2+, Zn2+, Pb2+, Fe3+, and Cd2+ from synthetic solutions and acid mine drainage (AMD) from the Sungun copper mine in Iran. Batch adsorption experiments were conducted to evaluate the adsorption process. The results indicated that the sorption capacities of the g-C3N4 remarkably increased after sonication, apparently indicating that the sorption mechanisms were largely due to chemical interactions between the metal ions and functional groups on the g-C3N4 surface. The kinetic study clarified that the adsorption process followed a pseudo-second-order kinetic model. The sorption isotherms of all of the metal ions on the exfoliated g-C3N4 correlated well with both Langmuir and Freundlich adsorption isotherms. Sorption experiments using both the AMD and the multi-component solutions clarified that exfoliated g-C3N4 has good potential for AMD treatment.

Zusammenfassung

Graphitisches Kohlenstoffnitrid (g-C3N4) wurde einfach aus Melamin synthetisiert und in Folge mittels Ultraschall exfoliiertes g-C3N4 hergestellt. Die Proben wurden mit Rasterelektronenmikroskopie, Transmissionselektronenmikroskopie, Röntgendiffraktometrie, N2-Gasadsorption-Desorption und fouriertransformierter Infrarotanalyse charakterisiert. Das foliierte und das exfoliierte g-C3N4 wurden als Adsorptionsmittel zur Entfernung von Cu2+, Mn2+, Zn2+, Pb2+, Fe3+ and Cd2+ aus synthetischer Lösung und aus sauren Grubenwässern (AMD) aus dem Sungun Kupfererzbergbau eingesetzt. Chargenweise Adsorptionsversuche wurden durchgeführt, um den Adsorptionsprozess zu evaluieren. Die Ergebnisse zeigen, dass das Aufnahmevermögen von g-C3N4 nach der Ultraschallbehandlung signifikant ansteigt. Das ist offenkundig ein Indiz, dass der Sorptionsmechanismus weitgehend auf die chemische Interaktion zwischen den Metallionen und den funktionellen Gruppen an der g-C3N4-Oberfläche beruht. Die kinetische Untersuchung zeigt, dass der Adsorptionsprozess einem pseudo-kinetischem Modell zweiter Ordnung folgt. Die Sorptionsisothermen aller Metallionen auf dem exfoliierten g-C3N4 korrelieren sowohl mit den Langmuir-, als auch mit den Freundlichadsorptionsisothermen. Sorptionsversuche mit AMD aus dem Sungun Kupfererzbergbau und den Mehrkomponentenlösungen zeigen, dass exfoliiertes g-C3N4 gutes Potential für die Behandlung von sauren Grubenwässern hat.

Resumen

El nitruro de carbono grafítico (g-C3N4) se sintetizó fácilmente a partir de melamina y posteriormente se sonicó para crear g-C3N4 exfoliado. Las muestras se caracterizaron con microscopía electrónica de barrido y electrón de transmisión, difracción de rayos X, adsorción-desorción de N2 y análisis infrarrojo transformado de Fourier. El g-C3N4 no exfoliado y exfoliado se evaluaron como adsorbentes para la eliminación de Cu2 +, Mn2 +, Zn2 +, Pb2 +, Fe3 + y Cd2 + de soluciones sintéticas y drenaje ácido de mina (AMD) de la mina de cobre Sungun. Se realizaron experimentos de adsorción en batch para evaluar el proceso de adsorción. Los resultados indicaron que las capacidades de sorción del g-C3N4 aumentaron notablemente después de la sonicación, lo que aparentemente indica que los mecanismos de sorción se debieron en gran medida a las interacciones químicas entre los iones metálicos y los grupos funcionales en la superficie g-C3N4. El estudio cinético mostró que el proceso de adsorción siguió un modelo cinético de pseudo segundo orden. Las isotermas de sorción de todos los iones metálicos sobre el g-C3N4 exfoliado correlacionaron bien con las isotermas de adsorción Langmuir y Freundlich. Los experimentos de sorción usando tanto AMD de Sungun Mine como las soluciones de componentes múltiples mostraron que el g-C3N4 exfoliado tiene un buen potencial para el tratamiento de AMD.

抽象

石墨碳氮化物(g-C3N4)容易由三聚氰胺合成,并进一步声波降解成剥离态g-C3N4。利用扫描电子显微镜、透射电子显微镜、XRD、N2吸附-解析试验和傅立叶转换红外分析刻画样品的特性。同时评价了剥离态吸附剂和非剥离态吸附剂去除合成溶液和Sungun铜矿酸性排放废水Cu2+、Mn2+、Zn2+、Pb2+、Fe3+和Cd2+的能力和效果。通过批次吸附试验评价吸附过程。结果表明,在声波降解之后, g-C3N4吸附能力显著增强, 表明吸附机理是金属离子与功能团在g-C3N4表面的化学反应。动力学研究表明吸附过程服从伪/假二级动力学模型。所有金属离子的剥离态g-C3N4吸附等温曲线与Langmuir和Freundlich曲线吻合。Sungun矿酸性排放废水和多组分合成液的吸附试验表明:剥离态g-C3N4具有理想的AMD处理前景。

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Removal of metal ions from industrial wastewater has aroused global attention due to their adverse effect on the environment and human health. The pollution of water resources by the indiscriminate disposal of metals has been causing escalating worldwide concerns over three centuries of industrialization (Fu and Wang 2011; Rahimi and Mohaghegh 2016; Ren et al. 2011; Srivastava and Majumder 2008). Acid mine drainage (AMD) and the metal ions from mine waste and tailings leachates must be treated before its release to prevent contamination of the food chain (Akcil and Koldas 2006; Skousen et al. 2017).

Many methods, including chemical precipitation (Fu and Wang 2011; Huisman et al. 2006), sorption (Rahimi and Mohaghegh 2016), reverse osmosis (Ning 2002), and ion exchange (Cheng et al. 2010) have been proposed to eliminate metal ions from water resources. Of these, adsorption is quite interesting because of its low costs, ease of operation, and wide adaptability. So far, several types of adsorbents, including carbon nanotube-based composites (Wang et al. 2013), activated carbon (Alslaibi et al. 2013), metal organic framework (Rahimi and Mohaghegh 2017), zeolites (Motsi et al. 2009), biomaterials (Minamisawa et al. 2004), and graphene (Zhao et al. 2011) have been investigated. However, the difficult procedures to synthesize these materials and modify them have limited their commercial uses. Therefore, easily synthesized, efficient adsorbent materials are still needed.

Carbon nitride is a metal-free material that has various potential applications (Goettmann et al. 2006a, b). Based on theoretical calculations, there are five crystalline structures of carbon nitride, of which “g-C3N4” is the most stable allotrope of carbon nitride at ambient conditions (Hu et al. 2015; Shen et al. 2015). The –NH2/–NH–/=N functional groups of g-C3N4 can adsorb organic and inorganic molecules, including metal ions (Hu et al. 2015; Shen et al. 2015; Yan et al. 2013). However, to the best of our knowledge, its potential use to adsorb metal ions from AMD has not been studied.

The sorption characteristics and uptake efficiency of Cu2+, Fe3+, Mn2+, Zn2+, Cd2+, and Pb2+ ions from aqueous solutions similar to AMD from the Sungun copper mine using un-exfoliated and exfoliated g-C3N4 nano-adsorbents were therefore studied. The g-C3N4 nano-adsorbents were characterized by several techniques and the mechanism of metal ion sorption, sorption kinetics, and isotherms were investigated. Experiments to determine how well the g-C3N4 nano-adsorbents worked were performed using actual AMD from the Sungun mine.

Experimental

Materials

AMD wastewater from the Sungun mine was used to study the sorption activity of the un-exfoliated and exfoliated g-C3N4 adsorbents. All of the materials used for adsorbent fabrication were used without further purification.

Apparatus

The X-ray diffraction (XRD) patterns were produced on a Philips X’pert instrument using Cu Kα irradiation (λ = 0.15406 nm) as the X-ray source. Morphological characteristics were analysed by field emission scanning electron microscopy (FE-SEM, XL30 model) and transmission electron microscopy (TEM). Fourier transformed infrared (FT-IR) spectra were used to investigate the surface functional groups of the g-C3N4 adsorbents. The specific surface area and pore volume distributions of the adsorbents were obtained at 77 K, based on the nitrogen adsorption–desorption isotherms. The metal ion concentrations in each sorption test were determined using a Shimadzu 6300 atomic absorption spectrophotometer (AAS).

Fabrication of Un-exfoliated and Exfoliated g-C3N4

Un-exfoliated g-C3N4 powders were fabricated by calcining melamine, as previously reported (Li et al. 2013). The melamine (6 g) was placed in a semi-closed crucible at 500 °C in a muffle furnace (with a heating rate of 10 °C/min). The crucible was maintained at this temperature for 4 h and then it was heated to 520 °C at the same rate for 2 h. To exfoliate the g-C3N4, the g-C3N4 powder was dispersed in 30 mL of deionized water by sonication for 3 h and then magnetically stirred for 24 h. The resulting light-yellow products were centrifuged to remove the residual un-exfoliated g-C3N4.

Sorption Batch Experiments

For the sorption tests, a circulating water jacket was placed on the batch reactor to maintain a constant temperature. The reactor was first filled with 200 mL of a synthesized solution, that included metal ions (Cu+2, Mn+2, Cd+2, Zn+2, Fe+3, and Pb+2 at concentrations of 228.1, 112.4, 35.9, 91.7, 73.7, and 35.1 mg/L, respectively) and then 0.1 g of one of the adsorbents was fed into the reactor with stirring. At timed intervals, 4 mL of solution was taken out, centrifuged, and submitted for AAS analysis. By performing a proper material balance, the quantity of ions adsorbed was determined at regular time intervals.

For the AMD treatment, 1000 mL of AMD and 0.1 g of the adsorbents were fed into the described reactor. The Cu+2, Mn+2, Cd+2, Zn+2, Fe+3 and Pb+2 concentrations in the Sungun AMD sample were 228.1, 112.4, 35.9, 91.7, 73.7, and 35.1 mg/L, respectively.

Results and Discussion

XRD Analysis

The graphitic stacking structure of both the un-exfoliated and exfoliated g-C3N4 was investigated by XRD (Fig. 1). In the case of the un-exfoliated g-C3N4, sharp and strong diffraction peak at 28.1° corresponding to the (002) plan can be ascribed to the stacking of the conjugated aromatic system with a d-spacing of 0.317 nm. The peak around 13.02° is related to the in-planar repeating motifs of a continuous heptazine network with a d-value of 0.681 nm in g-C3N4 crystal (Hu et al. 2015; Shen et al. 2015). After exfoliation via sonication, the intensity of the (002) peak greatly decreases, obviously showing that un-exfoliated g-C3N4 has been successfully exfoliated.

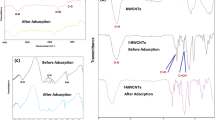

FT-IR Spectroscopy

The FT-IR spectrum of exfoliated g-C3N4 adsorbent is represented in Fig. 2a. The main absorption band at about 1409, 1462, 1573, and 1640 cm−1 are assigned to the stretching vibration modes of heptazine-derived rings (Fig. 2b). Peaks at 1240 and 1320 cm−1 correspond to the secondary and tertiary (C–N) amine fragments, respectively. In addition, the wide band at 3200 cm−1 belongs to the stretching vibration of –NH2– and –NH– (Hong et al. 2016; Li et al. 2017). The residual H atoms bind to the edges of the g-C3N4 sheets as C–NH2 and 2C–NH bonds. The band at 811 cm−1 belongs to the breathing mode of s-triazin (Fig. 2b; Hu et al. 2015). As a reference, the FTIR spectrum of un-exfoliated g-C3N4 was also evaluated, but is not shown here. Obviously, the spectrum of the un-exfoliated g-C3N4 is similar to that of exfoliated g-C3N4, demonstrating that the exfoliated nanosheets keep the same chemical structure as the un-exfoliated one.

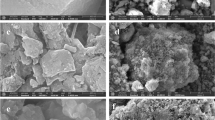

SEM and TEM Analysis

The morphologies of the un-exfoliated g-C3N4 sample were investigated by SEM and overlapping lamellar structures were observed (Supplemental Fig. S-1). However, TEM showed the completely lamellar morphologies of the exfoliated g-C3N4 (Supplemental Fig. S-2), demonstrating that the exfoliation of bulk g-C3N4 was successful. These results are consistent with the XRD results.

BET Surface Area Analysis

Table 1 shows the specific surface area and total pore volume information for un-exfoliated and exfoliated g-C3N4 nano-adsorbents. High specific surface area is generally needed to promote the adsorption of metal ions. As seen in Table 1, exfoliated g-C3N4 has a higher surface area than the un-exfoliated g-C3N4.

Sorption Study

The sorption of metal ions on the un-exfoliated and exfoliated g-C3N4 adsorbents were studied (Fig. 3). The metal ion uptake was higher with the exfoliated g-C3N4 adsorbents than the un-exfoliated ones, indicating that sonication improved the adsorption, presumably by increasing the surface area, although reactive amino groups on the surface of exfoliated g-C3N4 probably also contribute to the high metal ion removals. Additionally, as seen in Fig. 3, sorption efficiency increases quickly at the first contact time. This fast sorption of the metal ions demonstrates that surface complexation or chemical reaction is taking place (Hu et al. 2015; Shen et al. 2015), along with interaction of the metal ions with the nitrogen- and carbon-containing functional groups of the g-C3N4. Thus, inner-sphere surface complexation suitably explains this fast sorption. The total removal processes of metal ions with the exfoliated g-C3N4 are schematically represented in Fig. 4.

Kinetics Studies

To better evaluate the sorption mechanism, the experimental data were fit to a pseudo-second-order rate model (Eq. 1). A pseudo-second-order rate model is consistent with the assumption that the determining rate step may be chemical sorption (valence forces formed by electronic interaction between the adsorbents and adsorbates) (Hu et al. 2015; Rahimi and Mohaghegh 2016; Shen et al. 2015).

Separating the variables in Eq. 1 yields:

where qe is the amount of adsorbed per unit mass at equilibrium, qt is the amount of metal ions adsorbed at time t (mg g−1 adsorbent) and k is the second order rate constant (g mg−1 min−1). A linear form of the typical second-order rate equation is represented by Eq. 3, in which x can be evaluated from Eq. 4:

The pseudo-second-order model constants can be calculated from the linear plots of \(\frac{{\text{t}}}{{{{\text{q}}_{\text{t}}}}}{\text{~}}\) versus time t (Fig. 5).

The aforementioned equations account for the wide range of results and can be used to analyse the isotherm data. The experimental data were simulated using the Langmuir and Freundlich isotherm models. The equations used in the Langmuir and Freundlich adsorption isotherm study are defined in Table 2. The sorption data were fit into both the linearized Langmuir and Freundlich models; the results are illustrated in Table 3.

Removal of Toxic Metal Ions from Natural AMD Wastewater

To further investigate how the exfoliated g-C3N4 works as an adsorbent, actual AMD wastewater was gathered from the low-grade sulphur deposit at the Sungun copper mine. As seen in Fig. 6, the exfoliated g-C3N4 nano-adsorbents efficiently removed the metals.

Reusability and Cost Assessment

Reusability through adsorption/desorption cycles for metal ions is an important factor for long-term sorbent applications. So, the recycling times of g-C3N4 for metal ion removals were studied (6–12 cycles). After sorption, desorption was performed via washing the g-C3N4 with HCl or HNO3 solution, it was thoroughly rinsed with water, then dried, and reused. The sorption capacity of the exfoliated g-C3N4 decreased slightly for all metal ions after six cycles of regeneration/reuse tests, with increasing reuse. These results indicate that g-C3N4 is chemically stable and reusable, and is a promising candidate for cyclic removal of metal ions from aqueous solutions.

The estimated investment and operational costs (including both fixed and variable costs) ranged from 0.04 $/m3 of water treated, if the g-C3N4 is used 12 times, to 0.08 $/m3 if the g-C3N4 is used six times. The highest component of the variable costs is raw materials; fixed costs include lab supplies and packaging. These cost estimates are compared with those of other advanced wastewater treatment technologies in Supplemental Table 1.

Conclusions

Un-exfoliated graphitic carbon nitride (g-C3N4) was prepared using a simple thermal decomposition approach and subsequently exfoliated by sonication. Both the un-exfoliated and exfoliated g-C3N4 was characterized. The sorption behavior of the as-synthesized g-C3N4 was investigated for the uptake of metal ions from a prepared aqueous solution and actual samples of mine-related AMD (from the Sungun copper mine). The results indicated that the sorption capacities of the g-C3N4 remarkably increased after exfoliation. Additionally, the findings revealed that the sorbent properties such as high surface area, morphology, and specific functional groups (binding sites) strongly influence removal efficiency. The sorption processes for all of the metal ions followed second-order kinetics, and the sorption isotherms could be simulated well by both the Langmuir and Freundlich adsorption isotherms based on the correlation coefficients (R2). However, the Langmuir model fits the metal ion sorption isotherms much better than the Freundlich model. Interestingly, the ion removal results from the actual AMD showed that the g-C3N4 has great potential as an adsorbent for the pre-concentration of metal ions. Additionally, the sorption mechanisms appear to be mainly attributable to chemical interactions between the metal ions and the g-C3N4 surface. Therefore, the inner-sphere surface complexation mechanism satisfactorily explained this fast sorption.

References

Akcil A, Koldas S (2006) Acid mine drainage (AMD): causes, treatment and case studies. J Clean Prod 14:1139–1145

Alslaibi TM, Abustan I, Ahmad MA, Foul AA (2013) Application of response surface methodology (RSM) for optimization of Cu2+, Cd2+, Ni2+, Pb2+, Fe2+, and Zn2+removal from aqueous solution using microwaved olive stone activated carbon. J Chem Technol Biotechnol 88:2141–2151

Cheng Z, Wu Y, Wang N, Yang W, Xu T (2010) Development of a novel hollow fiber cation-exchange membrane from bromomethylated poly (2,6-dimethyl-1,4-phenylene oxide) for removal of heavy-metal ions. Ind Eng Chem Res 49:3079–3087

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manage 92:407–418

Goettmann F, Fischer A, Antonietti M, Thomas A (2006a) Chemical synthesis of mesoporous carbon nitrides using hard templates and their use as a metal-free catalyst for Friedel-Crafts reaction of benzene. Angew Chem Int Ed 45:4467–4471

Goettmann F, Fischer A, Antonietti M, Thomas A (2006b) Metal-free catalysis of sustainable Friedel-Crafts reactions: direct activation of benzene by carbon nitrides to avoid the use of metal chlorides and halogenated compounds. Chem Commun 43:4530–4532

Hong J, Chen C, Bedoya FE, Kelsall GH, O’Hare D, Petit C (2016) Carbon nitride nanosheet/metal–organic framework nanocomposites with synergistic photocatalytic activities. Catal Sci Technol 6:5042–5051

Hu R, Wang X, Dai S, Shao D, Hayat T, Alsaedi A (2015) Application of graphitic carbon nitride for the removal of Pb(II) and aniline from aqueous solutions. Chem Eng J 260:469–477

Huisman JL, Schouten G, Schultz C (2006) Biologically produced sulphide for purification of process streams, effluent treatment and recovery of metals in the metal and mining industry. Hydrometallurgy 83:106–113

Li T, Zhao L, He Y, Cai J, Luo M, Lin J (2013) Synthesis of g-C3N4/SmVO4 composite photocatalyst with improved visible light photocatalytic activities in RhB degradation. App Catal B Environ 129:255–263

Li X, Pi Y, Wu L, Xia Q, Wu J, Li Z, Xiao J (2017) Facilitation of the visible light-induced Fenton-like excitation of H2O2 via heterojunction of g-C3N4/NH2-Iron terephthalate metal-organic framework for MB degradation. Appl Catal B Environ 202:653–666

Minamisawa M, Minamisawa H, Yoshida S, Takai N (2004) Adsorption behavior of heavy metals on biomaterials. J Agric Food Chem 52:5606–5611

Motsi T, Rowson NA, Simmons MJH (2009) Adsorption of heavy metals from acid mine drainage by natural zeolite. Int J Miner Process 92:42–48

Ning RY (2002) Arsenic removal by reverse osmosis. Desalination 143:237–241

Rahimi E, Mohaghegh N (2016) Removal of toxic metal ions from Sungun acid rock drainage using mordenite zeolite, graphene nanosheets, and a novel metal–organic framework. Mine Water Environ 35:18–28

Rahimi E, Mohaghegh N (2017) New hybrid nanocomposite of copper terephthalate MOF-graphene oxide: synthesis, characterization and application as adsorbents for toxic metal ion removal from Sungun acid mine drainage. Environ Sci Pollut Res 24:22353–22360

Ren XM, Chen CL, Nagatsu M, Wang XK (2011) Carbon nanotubes as adsorbents in environmental pollution management: a review. Chem Eng J 170:395–410

Shen C, Chen C, Wen T, Zhao Z, Wang X, Xu A (2015) Superior adsorption capacity of g-C3N4 for heavy metal ions from solutions. J Colloid Interf Sci 456:7–14

Skousen J, Zipper CE, Rose A, Ziemkiewicz PF, Nairn R, McDonald LM, Kleinmann RL (2017) Review of passive systems for acid mine drainage treatment. Mine Water Environ 36:133–153

Srivastava NK, Majumder CB (2008) Novel biofiltration methods for the treatment of heavy metals from industrial wastewater. J Hazard Mater 151:1–8

Wang Q, Wang XK, Chai ZF, Hu WP (2013) Low-temperature plasma synthesis of carbon nanotubes and graphene based materials and their fuel cell applications. Chem Soc Rev 42:8821–8834

Yan TT, Chen H, Wang X, Jiang F (2013) Adsorption of perfluorooctane sulfonate (PFOS) on mesoporous carbon nitride. RSC Adv 3:22480–22489

Zhao GX, Li JX, Ren XM, Chen CL, Wang XK (2011) Few-layered graphene oxide nanosheets as superior sorbents for heavy metal ion pollution management. Environ Sci Technol 45:10454–10462

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akbari Dehkharghani, A. Exfoliated Graphitic Carbon Nitride for the Fast Adsorption of Metal Ions from Acid Mine Drainage: A Case Study from the Sungun Copper Mine. Mine Water Environ 38, 335–341 (2019). https://doi.org/10.1007/s10230-018-0561-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-018-0561-x